TLR 22 5.0

#2536

Tech Apprentice

So I am getting can into racing after a 20 year layoff. I picked up a used 5.0 Elite to get started with. What are the common wear item i should go through the car and replace to get me through the race season? The car has been run exclusively on packed clay tracks, and my local track is also packed clay.

#2537

So I am getting can into racing after a 20 year layoff. I picked up a used 5.0 Elite to get started with. What are the common wear item i should go through the car and replace to get me through the race season? The car has been run exclusively on packed clay tracks, and my local track is also packed clay.

#2538

Tech Fanatic

I ordered the parts that were listed to covert to the 22x-4 rear arms. Any recommendations for C and D block pill setup?

#2539

I'd start with 1 down / in on the D Block and 1 Down / out on the C Block.

#2541

Tech Apprentice

iTrader: (2)

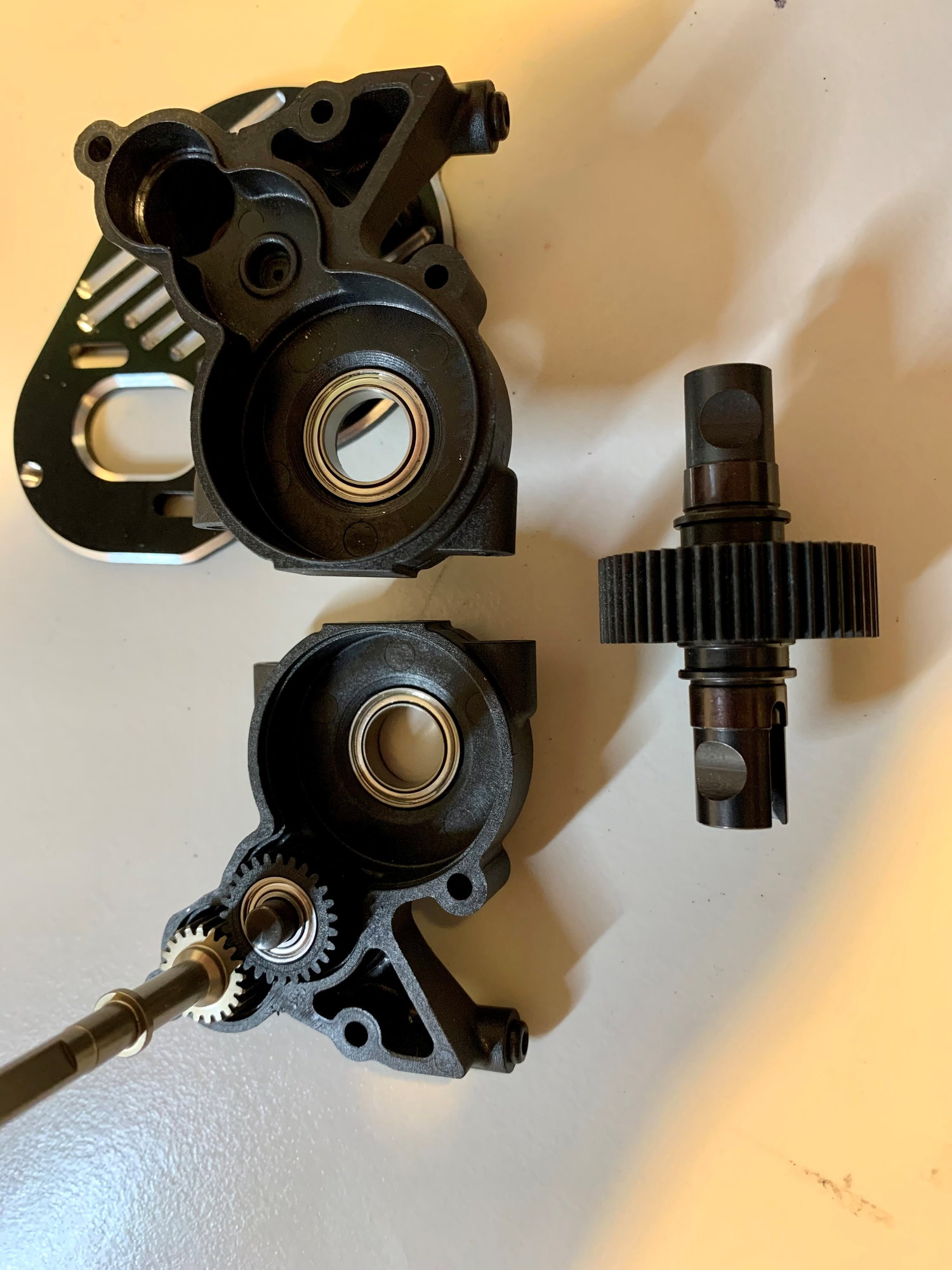

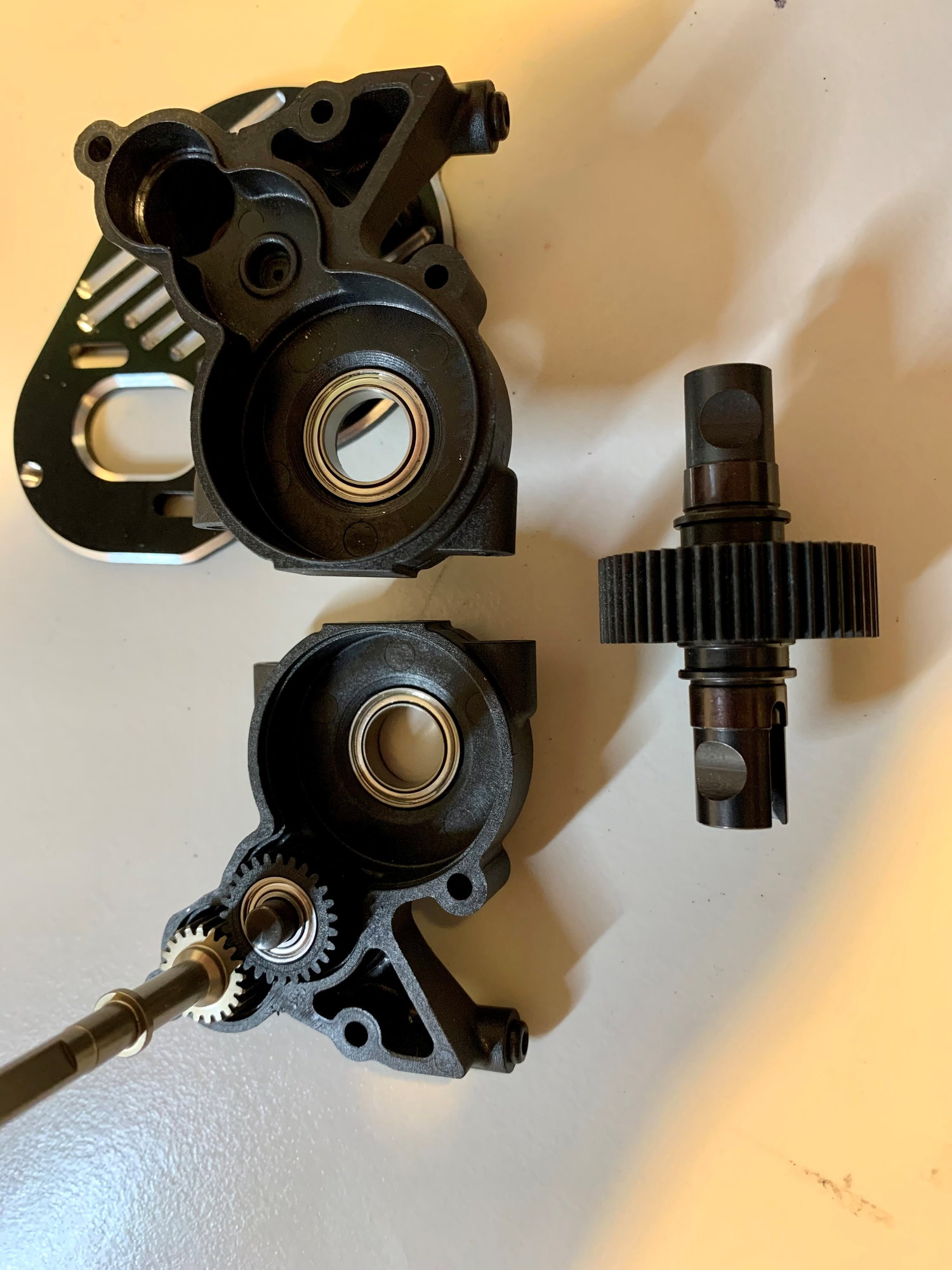

Building a standup trans for my son's 5.0. His laydown transmission was performing properly. Assembled the standup trans per the 3.0 instructions, but there is a clicking noise when the input shaft is spun at a fast speed by hand. Slow and medium speeds don't produce the noise. It sounds like something is loose inside the trans. All of the gears and bearings are the same from his laydown trans. The only new gear is the center idler gear. I thought that may be the issue, so I got another standup kit and put that new idler gear in, but it does the same thing. I also swapped everything over to the other standup transmission case, but still the clicking sound.

I have tried spinning the gears with one side of the trans case off, but I can't get it to make the sound like that.

I noticed that the differential is slightly loose side-to-side. It has 0.7mm of play in the L-R direction, but fits snug in the bearings and the bearings fit tightly in the case. It doesn't feel like that is causing the noise.. it feels like it is coming from the center idler gear, but not sure, and don't know what to do about it. I doubt I got two bad kits, but not sure what else to check. Please help!

I have tried spinning the gears with one side of the trans case off, but I can't get it to make the sound like that.

I noticed that the differential is slightly loose side-to-side. It has 0.7mm of play in the L-R direction, but fits snug in the bearings and the bearings fit tightly in the case. It doesn't feel like that is causing the noise.. it feels like it is coming from the center idler gear, but not sure, and don't know what to do about it. I doubt I got two bad kits, but not sure what else to check. Please help!

Last edited by ThisIsRDG; 12-15-2022 at 05:07 PM. Reason: Added photo

#2542

Tech Apprentice

iTrader: (2)

Building a standup trans for my son's 5.0. His laydown transmission was performing properly. Assembled the standup trans per the 3.0 instructions, but there is a clicking noise when the input shaft is spun at a fast speed by hand. Slow and medium speeds don't produce the noise. It sounds like something is loose inside the trans. All of the gears and bearings are the same from his laydown trans. The only new gear is the center idler gear. I thought that may be the issue, so I got another standup kit and put that new idler gear in, but it does the same thing. I also swapped everything over to the other standup transmission case, but still the clicking sound.

I have tried spinning the gears with one side of the trans case off, but I can't get it to make the sound like that.

I noticed that the differential is slightly loose side-to-side. It has 0.7mm of play in the L-R direction, but fits snug in the bearings and the bearings fit tightly in the case. It doesn't feel like that is causing the noise.. it feels like it is coming from the center idler gear, but not sure, and don't know what to do about it. I doubt I got two bad kits, but not sure what else to check. Please help!

I have tried spinning the gears with one side of the trans case off, but I can't get it to make the sound like that.

I noticed that the differential is slightly loose side-to-side. It has 0.7mm of play in the L-R direction, but fits snug in the bearings and the bearings fit tightly in the case. It doesn't feel like that is causing the noise.. it feels like it is coming from the center idler gear, but not sure, and don't know what to do about it. I doubt I got two bad kits, but not sure what else to check. Please help!

I've done some more experiementing... If I remove the dif and spin the input shaft, there is no clicking heard from the input shaft or idler. If I remove the input shaft and spin the dif, the clicking is there, so this is either coming from the dif or the idler. However, the same gears and bearings (with the laydown idler) did not make any noise or vibration in the laydown transmission.

And now I've tried a second dif... no difference, still clicking. And I also pulled the ceramic bearings and put in the factory bearings. Doesn't spin as freely but clicks when in the correct position or tilted toward the motor mounting plate. If I tilt it away from the motor mounting plate, the clicking greatly decreases... almost fully gone.

Hopefully this info is helping someone come up with some ideas, becuase I've tried everything I can think of.

#2543

Tech Apprentice

So I ran my second race with my 5.0 on Friday. I’m still running in novice, but I finished second in the class. I think a few more races and I will be moving up to sportsman stock.

One thing that has bugged me is the fact I have gone through 4 front spindle carriers. They keep breaking where the nut passes through them to attach the different length arms. I particularly attribute this to the fact I’ve been tapping the wall a bit much, and my car has aluminum steering blocks, and titanium turn buckles. So the plastic spindle block arms are the weakest part in my steering setup. I just wish there was a cheaper way to get the replacements blocks than the $11 bag with the entire front caster assembly in it.

One thing that has bugged me is the fact I have gone through 4 front spindle carriers. They keep breaking where the nut passes through them to attach the different length arms. I particularly attribute this to the fact I’ve been tapping the wall a bit much, and my car has aluminum steering blocks, and titanium turn buckles. So the plastic spindle block arms are the weakest part in my steering setup. I just wish there was a cheaper way to get the replacements blocks than the $11 bag with the entire front caster assembly in it.

#2544

Tech Apprentice

iTrader: (2)

Extra note - This does have ceraming bearings with the grease stripped out and just a bit of light oil, so it will easily free spin. The clicking does not seem to impact/slow the momentum, but it is heard and felt.

I've done some more experiementing... If I remove the dif and spin the input shaft, there is no clicking heard from the input shaft or idler. If I remove the input shaft and spin the dif, the clicking is there, so this is either coming from the dif or the idler. However, the same gears and bearings (with the laydown idler) did not make any noise or vibration in the laydown transmission.

And now I've tried a second dif... no difference, still clicking. And I also pulled the ceramic bearings and put in the factory bearings. Doesn't spin as freely but clicks when in the correct position or tilted toward the motor mounting plate. If I tilt it away from the motor mounting plate, the clicking greatly decreases... almost fully gone.

Hopefully this info is helping someone come up with some ideas, becuase I've tried everything I can think of.

I've done some more experiementing... If I remove the dif and spin the input shaft, there is no clicking heard from the input shaft or idler. If I remove the input shaft and spin the dif, the clicking is there, so this is either coming from the dif or the idler. However, the same gears and bearings (with the laydown idler) did not make any noise or vibration in the laydown transmission.

And now I've tried a second dif... no difference, still clicking. And I also pulled the ceramic bearings and put in the factory bearings. Doesn't spin as freely but clicks when in the correct position or tilted toward the motor mounting plate. If I tilt it away from the motor mounting plate, the clicking greatly decreases... almost fully gone.

Hopefully this info is helping someone come up with some ideas, becuase I've tried everything I can think of.

While I was disassembling and reassmebling for the 20th time, I noticed something about the center idler shaft/pin. It snugly fits into the trans housing on the motor plate side, but on the opposite side it is very slightly loose. I put a small dab of black grease in the loose side and reassembled. That made the noise stop. So the noise was coming from the idler shaft/pin slightly bouncing, and tapping the trans housing. Glad to have this issue behind me.... I thought I was doing something wrong in my assmebly.

#2545

Maybe time to change the idler shaft.

It happens to me, to much play(even if it was light) then it s start to destroy idler pulley, and even the spur.

It happens to me, to much play(even if it was light) then it s start to destroy idler pulley, and even the spur.

#2547

#2548

Tech Fanatic

The arms are longer. Helps keep the car more planted in higher grip levels. You get a little more grip mid corner, and less tendency to traction roll, as well as allowing for getting on the throttle earlier. It does change the way the car feels though. It took me a couple of weeks to wrap my head around how much more mid corner speed I could safely use with the X-4 arms.

Like Frank said, its not a "need" hopup, but on a glued track, you are getting closer toward need than want. Either way, its a fun option to play with, and in higher grip levels inspires more confidence. I find i prefer the car overall with them on now. I think the stock arms are still easier to drive, but the car is more consistent with the X-4 arms. But keep in mind, i suck, and am slow, and could probably lap the track faster in a Jazzy Power Scooter.

Parts needed to make the conversion are, obviously, the 22X-4 arms. I run 17.5, and prefer the standard 22X-4 arms. The stiffazel made the car a little twitchy on dirt. YMMV, try both.

The Vision Racing 22X-4 C Block allows you to run the X-4 arms without modifying them, which is great.

And you will need the 22X-4 hinge pin set for the inner arm, and the outer hub.

You will also need the 68mm TLR bones, or some people prefer the AE 69mm bones for more plunge.

Then set your pills, and your turnbuckles, and enjoy the learning curve.

Like Frank said, its not a "need" hopup, but on a glued track, you are getting closer toward need than want. Either way, its a fun option to play with, and in higher grip levels inspires more confidence. I find i prefer the car overall with them on now. I think the stock arms are still easier to drive, but the car is more consistent with the X-4 arms. But keep in mind, i suck, and am slow, and could probably lap the track faster in a Jazzy Power Scooter.

Parts needed to make the conversion are, obviously, the 22X-4 arms. I run 17.5, and prefer the standard 22X-4 arms. The stiffazel made the car a little twitchy on dirt. YMMV, try both.

The Vision Racing 22X-4 C Block allows you to run the X-4 arms without modifying them, which is great.

And you will need the 22X-4 hinge pin set for the inner arm, and the outer hub.

You will also need the 68mm TLR bones, or some people prefer the AE 69mm bones for more plunge.

Then set your pills, and your turnbuckles, and enjoy the learning curve.

#2549

#2550

Tech Addict

Which has the same function as the Vision Racing C Block, but it doesnt have the center screw in the chassis mid plate, so you can still run weights, or the TLR transmission case brace.

886Likes

886Likes