Team Associated B6 & B6D thread

|

|||

#1906

Tech Apprentice

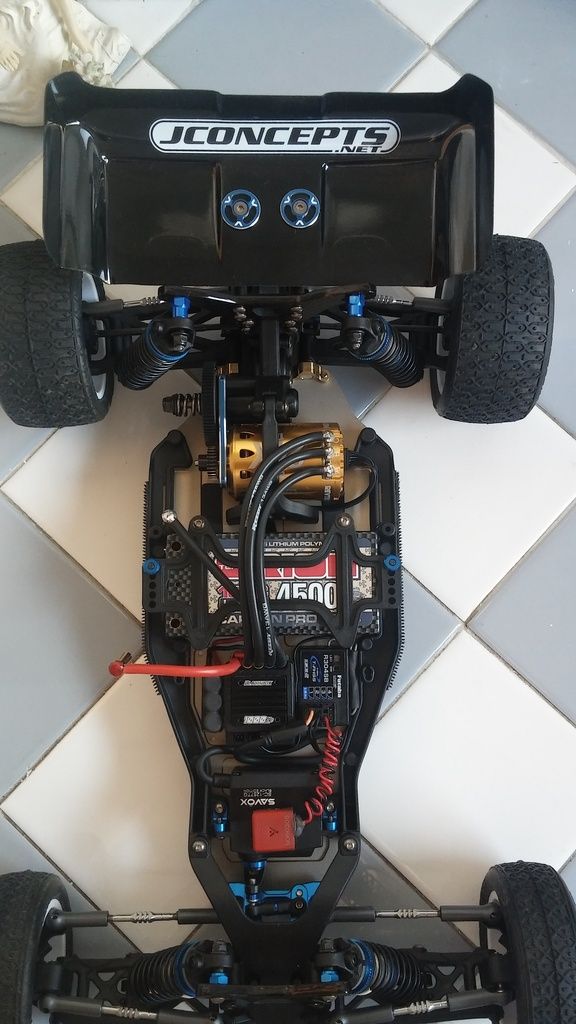

Just finished building my B6. Has anyone gone from box to high grip carpet to test out the stock setup? Any observations?

Only upgrade I've done so far is the front bronze bulkhead and a PL Trifecta wing. Waiting on the body to be finished. Planning on doing aluminum steering links and servo horn, rear aluminum D mount, the steel plate under the electronics, sway bars if I find that I need them and aluminum wing buttons.

Running a Track Star 8.5 setup, Savox 1258TG, SMC 60C 4400mah Shorty, Airtronics MX-V radio. Front tires are low profile PL Wedges, cut rim, no insert and rear are PL Pin Points stock insert.

Only upgrade I've done so far is the front bronze bulkhead and a PL Trifecta wing. Waiting on the body to be finished. Planning on doing aluminum steering links and servo horn, rear aluminum D mount, the steel plate under the electronics, sway bars if I find that I need them and aluminum wing buttons.

Running a Track Star 8.5 setup, Savox 1258TG, SMC 60C 4400mah Shorty, Airtronics MX-V radio. Front tires are low profile PL Wedges, cut rim, no insert and rear are PL Pin Points stock insert.

#1908

Looks really nice. I'm new to this c,d mount & pill toe in system. Is 5 degree max toe and 1 degree min toe using pills in c and d mount? Thanks

#1909

The latest setups seem to have mored toward narrower inner pivots.(if i my decoder ring is working correct) This would help calm down the rear end a bit correct? I am running the laydown on a mid bite track. My skill level probably should have me using the standup but the corner exit speed makes it really hard to do. Most of the issues i was having was with fresh tires but it was a handful

#1910

Tech Addict

Finished and ready to roll!

Designed all stickers myself so I wont mix up another color into the design scheme

Designed all stickers myself so I wont mix up another color into the design scheme

#1911

I think your (man1ac) chassis cover is super cool !!

#1912

Tech Addict

#1913

So you have the B6 and not B6D? What track surface type and traction level you were racing on? What tires and inserts you running? Thanks in advance.

#1914

#1916

elex300, that is one sweet wring clean up! Talk about perfection!

#1917

#1919

Tech Apprentice

I really liked that I was able to fit my huge receiver in there and not need to upgrade to a radio that uses smaller receivers. Between the servo/esc wiring, on/off switch and esc cap I used up pretty much all the space and only have a small nook to fit the transponder when I rent one at the track.

649Likes

649Likes