Team Associated B6 & B6D thread

|

|||

#5206

What changes can be made to get rid of an on power push

#5207

Just reference the post #. Many of us alter our settings so we see a lot more posts per page.

#5209

Tech Apprentice

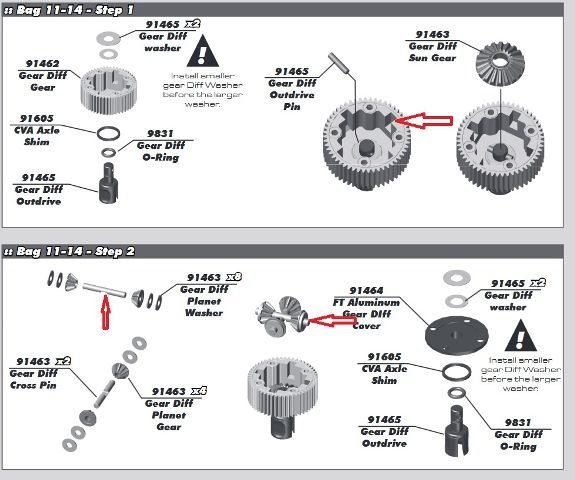

Having removed 2 gears I can now see it's not possible to use a second shaft.it would just float around hitting the bevel gear. The shafts rely on the spiders to locate them.

I've gone with 7k oil. It feels tighter than I was expecting.

Looking forward to testing it out.

I've gone with 7k oil. It feels tighter than I was expecting.

Looking forward to testing it out.

#5210

Tech Apprentice

#5211

Tech Apprentice

What's the general consensus on ackerman settings for a B6 on medium grip carpet.

#5212

It's just a thought I can see the part wearing out.

#5213

What an awesome idea! rx inside a servo! I'm pre-ordering one for my B6

https://www.amainhobbies.com/spektru...6240rx/p585268

https://www.amainhobbies.com/spektru...6240rx/p585268

i notice it has only 2 plug in slots, throt and bind, i have no knowledge of specktrum stuff, will a transponder work if plugged in the bind slot on any of their recievers?

#5215

Tech Addict

iTrader: (13)

shows in stock at http://www.horizonhobby.com/product/...-p-spmss6240rx

i notice it has only 2 plug in slots, throt and bind, i have no knowledge of specktrum stuff, will a transponder work if plugged in the bind slot on any of their recievers?

i notice it has only 2 plug in slots, throt and bind, i have no knowledge of specktrum stuff, will a transponder work if plugged in the bind slot on any of their recievers?

Thanks for the heads up. Ordered one to try out. I will report back. I plan to put my transponder in the Bind spot.

#5216

Tech Apprentice

The shafts are located by the slots in the gear diff and then the slots in each shaft allow them to cross each other on the same plane. But those slots on each shaft keep shafts from rotating if the bevel gears were to grab the shaft. So by removing one of the shafts, the shaft left over has the ability to rotate, and that might cause wear on the gear diff slot that locates the shafts. Now, if that wear is none existent or no one really cares about it, then you can certainly run just one shaft.

It's just a thought I can see the part wearing out.

It's just a thought I can see the part wearing out.

#5219

Tech Regular

I havent torn my diff down yet but i would think that you would be ok to put in both shafts as long as the one without gears is on the bottom. If my memory is correct on one side the notch doesnt go all the way down. If u put the one without gears in first then the one with gears on top it would hold everything together. I could be wrong though.

649Likes

649Likes