Team Associated B6 & B6D thread

|

|||

#4876

I'm not either... lol

Looks like I'll be picking up some plastic servo horns... unless there's other options some of y'all have used...

Looks like I'll be picking up some plastic servo horns... unless there's other options some of y'all have used...

#4877

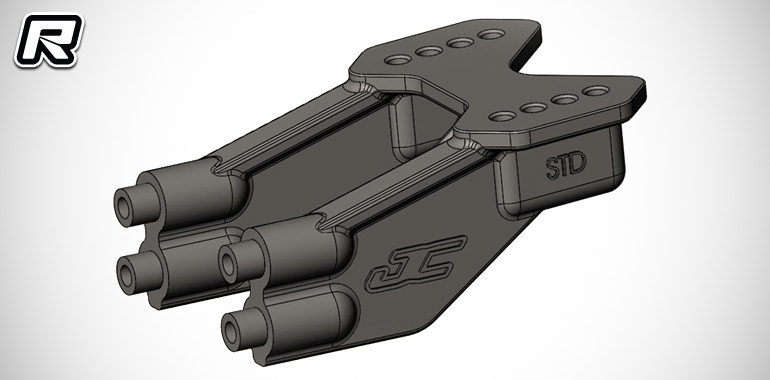

http://www.redrc.net/2016/12/jconcep...yle-waterfall/

http://www.redrc.net/2016/12/rdrp-b6...ounting-plate/

http://www.redrc.net/2016/12/jconcep...g-mount-wedge/

http://www.redrc.net/2016/12/rdrp-b6...ront-bulkhead/

http://www.redrc.net/2016/12/avid-b6...ock-standoffs/

http://www.redrc.net/2016/12/rdrp-te...ss-c-d-mounts/

http://www.redrc.net/2016/12/rdrp-b6...ounting-plate/

http://www.redrc.net/2016/12/jconcep...g-mount-wedge/

http://www.redrc.net/2016/12/rdrp-b6...ront-bulkhead/

http://www.redrc.net/2016/12/avid-b6...ock-standoffs/

http://www.redrc.net/2016/12/rdrp-te...ss-c-d-mounts/

#4878

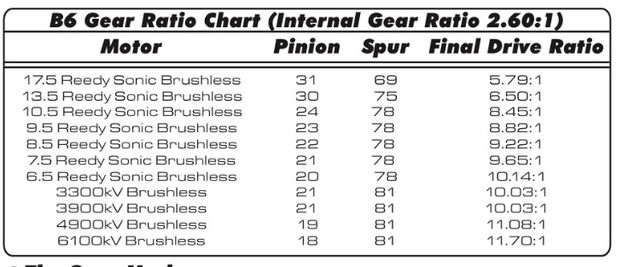

If I'm running stock on a medium size indoor track 17.5. What spur and pinion do I need to be fast

#4879

#4881

it depends on the motor.

#4885

Tech Regular

I'm running 18/84 with a 4600kv. 84 is as big as a spur you can put on the B6D.

I tried 87 its too large.

Too large meaning it rubs on the chassis and you cant use the gear cover with a 87.

I think 87 is for Stadium Trucks and Short course trucks anyway.

I tried 87 its too large.

Too large meaning it rubs on the chassis and you cant use the gear cover with a 87.

I think 87 is for Stadium Trucks and Short course trucks anyway.

#4886

Tech Apprentice

As for having a true wonder ESC for mod and stock, etc. It may be your best served spending alittle more and getting something that fits your needs. Or, if you are not too concerned with having the latest, if they still have some of those hobbywing V2.1s floating around those are pretty powerful escs for a cheap price new these days.

Again to clarify i want to run my B6D stock and mod.

#4887

I have no problem with an older model. Especially since i can get one for $80. Although, I have been having trouble finding a good comparison. between the 2.1 and 3.1. i just want to do my research to determine if it is worth getting the newer version.

Again to clarify i want to run my B6D stock and mod.

Again to clarify i want to run my B6D stock and mod.

#4888

Tech Master

iTrader: (49)

I have no problem with an older model. Especially since i can get one for $80. Although, I have been having trouble finding a good comparison. between the 2.1 and 3.1. i just want to do my research to determine if it is worth getting the newer version.

Again to clarify i want to run my B6D stock and mod.

Again to clarify i want to run my B6D stock and mod.

#4889

I have no problem with an older model. Especially since i can get one for $80. Although, I have been having trouble finding a good comparison. between the 2.1 and 3.1. i just want to do my research to determine if it is worth getting the newer version.

Again to clarify i want to run my B6D stock and mod.

Again to clarify i want to run my B6D stock and mod.

#4890

Tech Adept

iTrader: (1)

The nylon steering gear is plenty strong to strip a small buggy servo.

The solution would be add a saver like a 1/8 buggy but there is no package space and the low wheel loads from a light 1/10 buggy don't warrant it. If u smack it enough times your servo will be toast.. aluminum just a bit faster.

The solution would be add a saver like a 1/8 buggy but there is no package space and the low wheel loads from a light 1/10 buggy don't warrant it. If u smack it enough times your servo will be toast.. aluminum just a bit faster.

649Likes

649Likes