TLR 22SCT Thread (Check First Page for FAQ & INFO)

Tech Initiate

Update on my son, aka The Spindle Destroyer.

As mentioned in an earlier post, he broke 3 spindles his first time on a track. Folks recommended the threaded king pin, and I picked up a set (TLR1043).

Our second trip to the track was much better. Not saying he's ready to race, but he is keeping it off the walls/pipes much better.

Better, but not perfect...

He managed to break the solid pin and the spindle. I couldn't watch him all the time because I was marshaling, but I didn't hear any big crash, nothing obvious. Is breaking the pin something that does happen sometimes, or is this unusual? I'm seriously considering buying a die and some rod stock and making these pins. They won't be TiNi-coated, but it's better than paying $6-9 for a new set every week.

Something else I noticed about the spindle breakage. Every single one has split in half, right through the mold mark where it is filled (I think the term is gate.) Not sure if it's relevant, or that spot just happens to be where the stress is focused when the spindle is torqued apart.

As mentioned in an earlier post, he broke 3 spindles his first time on a track. Folks recommended the threaded king pin, and I picked up a set (TLR1043).

Our second trip to the track was much better. Not saying he's ready to race, but he is keeping it off the walls/pipes much better.

Better, but not perfect...

He managed to break the solid pin and the spindle. I couldn't watch him all the time because I was marshaling, but I didn't hear any big crash, nothing obvious. Is breaking the pin something that does happen sometimes, or is this unusual? I'm seriously considering buying a die and some rod stock and making these pins. They won't be TiNi-coated, but it's better than paying $6-9 for a new set every week.

Something else I noticed about the spindle breakage. Every single one has split in half, right through the mold mark where it is filled (I think the term is gate.) Not sure if it's relevant, or that spot just happens to be where the stress is focused when the spindle is torqued apart.

Tech Master

iTrader: (93)

Update on my son, aka The Spindle Destroyer.

As mentioned in an earlier post, he broke 3 spindles his first time on a track. Folks recommended the threaded king pin, and I picked up a set (TLR1043).

Our second trip to the track was much better. Not saying he's ready to race, but he is keeping it off the walls/pipes much better.

Better, but not perfect...

He managed to break the solid pin and the spindle. I couldn't watch him all the time because I was marshaling, but I didn't hear any big crash, nothing obvious. Is breaking the pin something that does happen sometimes, or is this unusual? I'm seriously considering buying a die and some rod stock and making these pins. They won't be TiNi-coated, but it's better than paying $6-9 for a new set every week.

Something else I noticed about the spindle breakage. Every single one has split in half, right through the mold mark where it is filled (I think the term is gate.) Not sure if it's relevant, or that spot just happens to be where the stress is focused when the spindle is torqued apart.

As mentioned in an earlier post, he broke 3 spindles his first time on a track. Folks recommended the threaded king pin, and I picked up a set (TLR1043).

Our second trip to the track was much better. Not saying he's ready to race, but he is keeping it off the walls/pipes much better.

Better, but not perfect...

He managed to break the solid pin and the spindle. I couldn't watch him all the time because I was marshaling, but I didn't hear any big crash, nothing obvious. Is breaking the pin something that does happen sometimes, or is this unusual? I'm seriously considering buying a die and some rod stock and making these pins. They won't be TiNi-coated, but it's better than paying $6-9 for a new set every week.

Something else I noticed about the spindle breakage. Every single one has split in half, right through the mold mark where it is filled (I think the term is gate.) Not sure if it's relevant, or that spot just happens to be where the stress is focused when the spindle is torqued apart.

Last edited by DriveItLikeYSIT; 01-19-2015 at 05:49 AM.

Tech Initiate

iTrader: (1)

The pin is snug through the spindle but swings freely on the castor.

I wonder if temperature is a contributing factor. Reading back in the thread, a lot of the California/Florida folks have few issues while the midwest/northeast guys had problems.

I wonder if temperature is a contributing factor. Reading back in the thread, a lot of the California/Florida folks have few issues while the midwest/northeast guys had problems.

Update on my son, aka The Spindle Destroyer.

As mentioned in an earlier post, he broke 3 spindles his first time on a track. Folks recommended the threaded king pin, and I picked up a set (TLR1043).

Our second trip to the track was much better. Not saying he's ready to race, but he is keeping it off the walls/pipes much better.

Better, but not perfect...

He managed to break the solid pin and the spindle. I couldn't watch him all the time because I was marshaling, but I didn't hear any big crash, nothing obvious. Is breaking the pin something that does happen sometimes, or is this unusual? I'm seriously considering buying a die and some rod stock and making these pins. They won't be TiNi-coated, but it's better than paying $6-9 for a new set every week.

Something else I noticed about the spindle breakage. Every single one has split in half, right through the mold mark where it is filled (I think the term is gate.) Not sure if it's relevant, or that spot just happens to be where the stress is focused when the spindle is torqued apart.

As mentioned in an earlier post, he broke 3 spindles his first time on a track. Folks recommended the threaded king pin, and I picked up a set (TLR1043).

Our second trip to the track was much better. Not saying he's ready to race, but he is keeping it off the walls/pipes much better.

Better, but not perfect...

He managed to break the solid pin and the spindle. I couldn't watch him all the time because I was marshaling, but I didn't hear any big crash, nothing obvious. Is breaking the pin something that does happen sometimes, or is this unusual? I'm seriously considering buying a die and some rod stock and making these pins. They won't be TiNi-coated, but it's better than paying $6-9 for a new set every week.

Something else I noticed about the spindle breakage. Every single one has split in half, right through the mold mark where it is filled (I think the term is gate.) Not sure if it's relevant, or that spot just happens to be where the stress is focused when the spindle is torqued apart.

Colder weather definitely makes the plastic harder and more brittle. I'd recommend that you keep the car warm before heading to the track (in the house and not the garage), which should help some.

Update on my son, aka The Spindle Destroyer.

As mentioned in an earlier post, he broke 3 spindles his first time on a track. Folks recommended the threaded king pin, and I picked up a set (TLR1043).

Our second trip to the track was much better. Not saying he's ready to race, but he is keeping it off the walls/pipes much better.

Better, but not perfect...

He managed to break the solid pin and the spindle. I couldn't watch him all the time because I was marshaling, but I didn't hear any big crash, nothing obvious. Is breaking the pin something that does happen sometimes, or is this unusual? I'm seriously considering buying a die and some rod stock and making these pins. They won't be TiNi-coated, but it's better than paying $6-9 for a new set every week.

Something else I noticed about the spindle breakage. Every single one has split in half, right through the mold mark where it is filled (I think the term is gate.) Not sure if it's relevant, or that spot just happens to be where the stress is focused when the spindle is torqued apart.

As mentioned in an earlier post, he broke 3 spindles his first time on a track. Folks recommended the threaded king pin, and I picked up a set (TLR1043).

Our second trip to the track was much better. Not saying he's ready to race, but he is keeping it off the walls/pipes much better.

Better, but not perfect...

He managed to break the solid pin and the spindle. I couldn't watch him all the time because I was marshaling, but I didn't hear any big crash, nothing obvious. Is breaking the pin something that does happen sometimes, or is this unusual? I'm seriously considering buying a die and some rod stock and making these pins. They won't be TiNi-coated, but it's better than paying $6-9 for a new set every week.

Something else I noticed about the spindle breakage. Every single one has split in half, right through the mold mark where it is filled (I think the term is gate.) Not sure if it's relevant, or that spot just happens to be where the stress is focused when the spindle is torqued apart.

The 2.0 spindles and caster blocks are stronger. The geometry is better as well. I would recommend updating to the 2.0 spindle and caster blocks for the better performance as well as they should be stronger. I have yet to break a 2.0 spindle. I did break a few (well deserved) spindles on my 1.0 and then went alum as well.

I broke one pin once. Not unusual if the truck has a pipe addiction. They are tough...not completely immune to breakage though. It does sound like he is getting better though. I have a lot of fun watching my son drive too...I finally put him in a turned-down Ebuggy (3.0e) and I've had a lot more fun watching him and a lot less repairs.

Anyway, I was very surprised at how much more fun I had watching him drive that 1/8 than I was when I drove it....and, besides....I don't want him trashing my 22's...buggy OR truck!!! But he can hack on the pipes with that ebuggy all day and that's fine with me!! Long live 1/10 2wd classes!!

Anyway, I was very surprised at how much more fun I had watching him drive that 1/8 than I was when I drove it....and, besides....I don't want him trashing my 22's...buggy OR truck!!! But he can hack on the pipes with that ebuggy all day and that's fine with me!! Long live 1/10 2wd classes!!

Tech Regular

iTrader: (4)

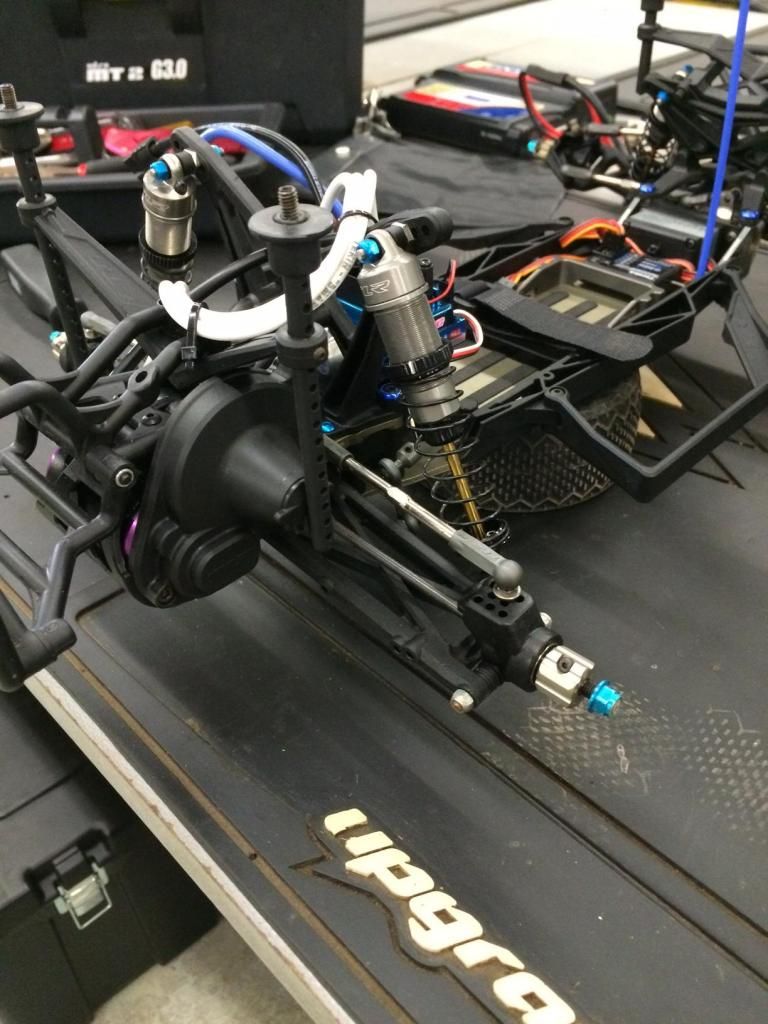

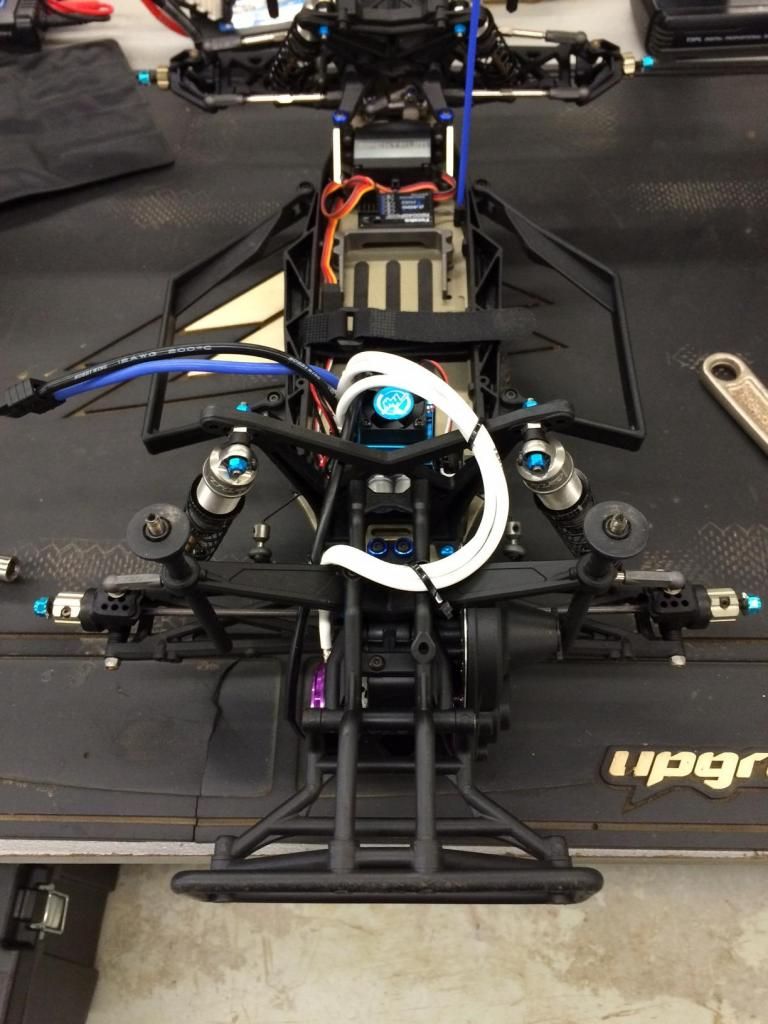

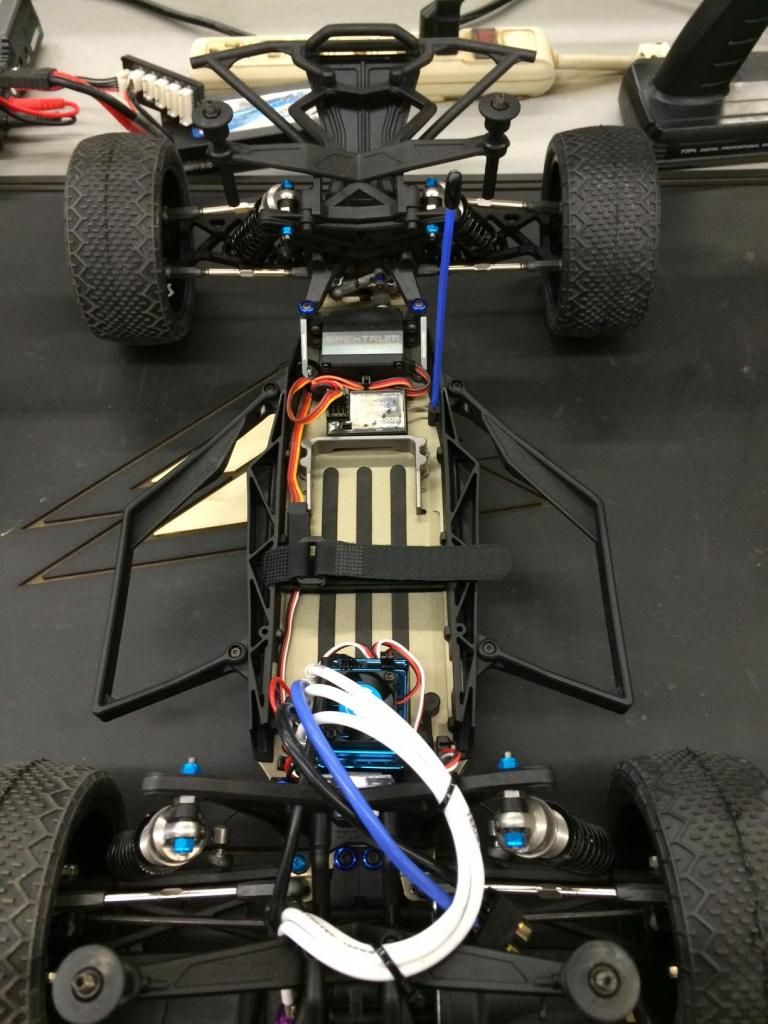

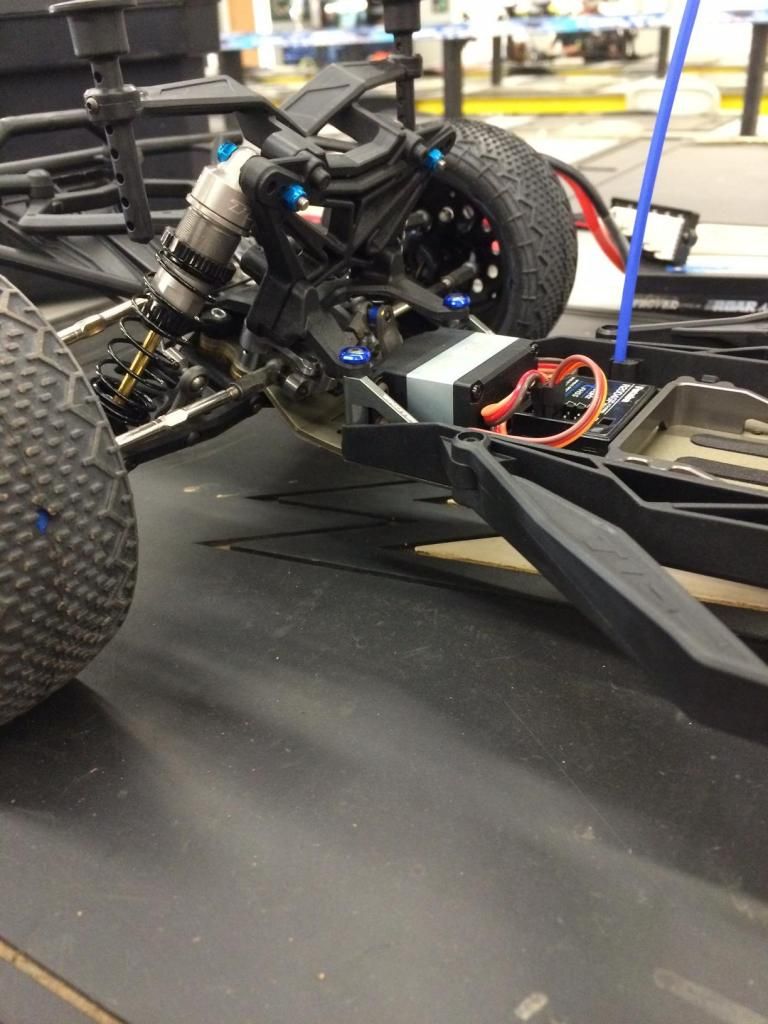

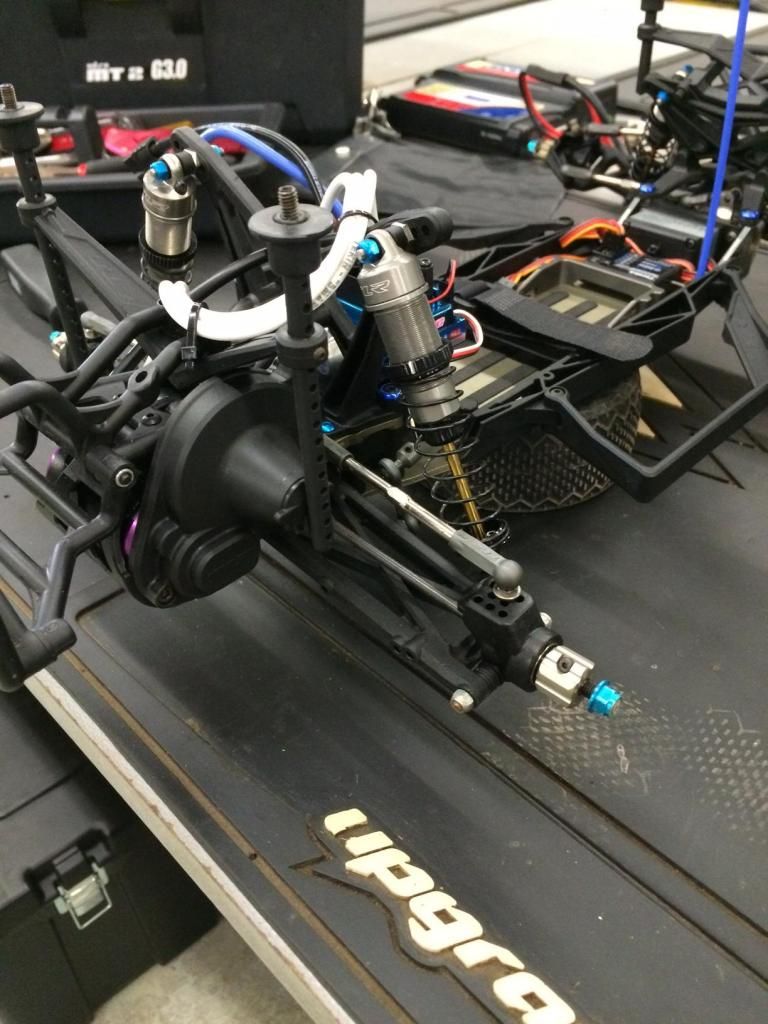

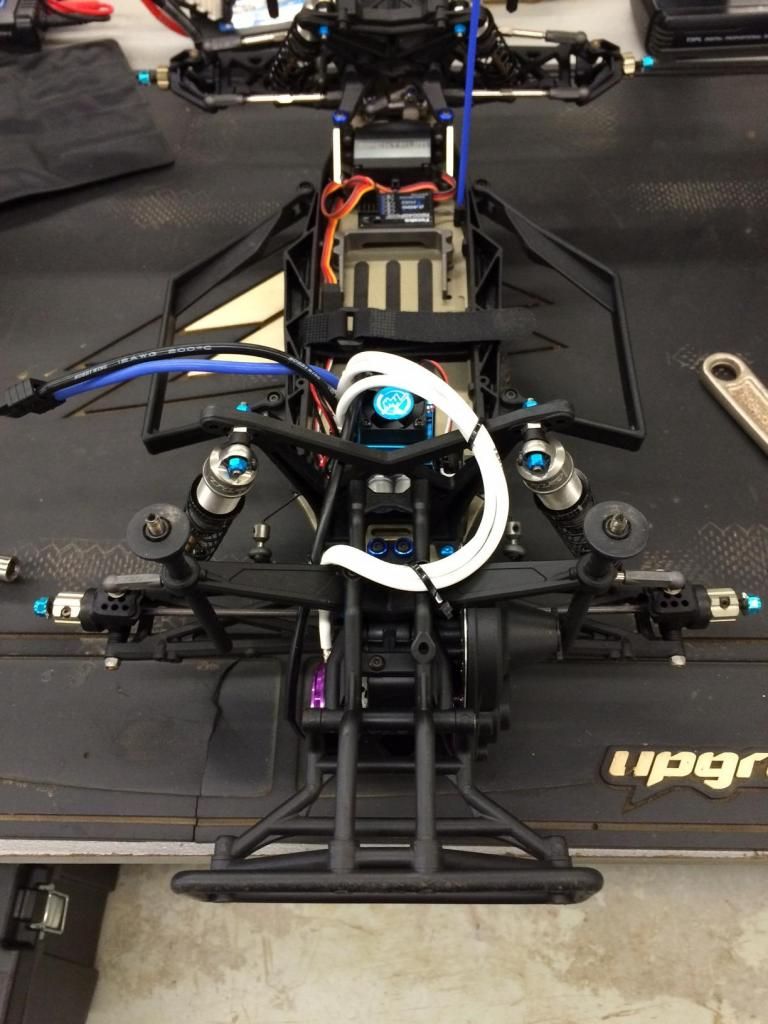

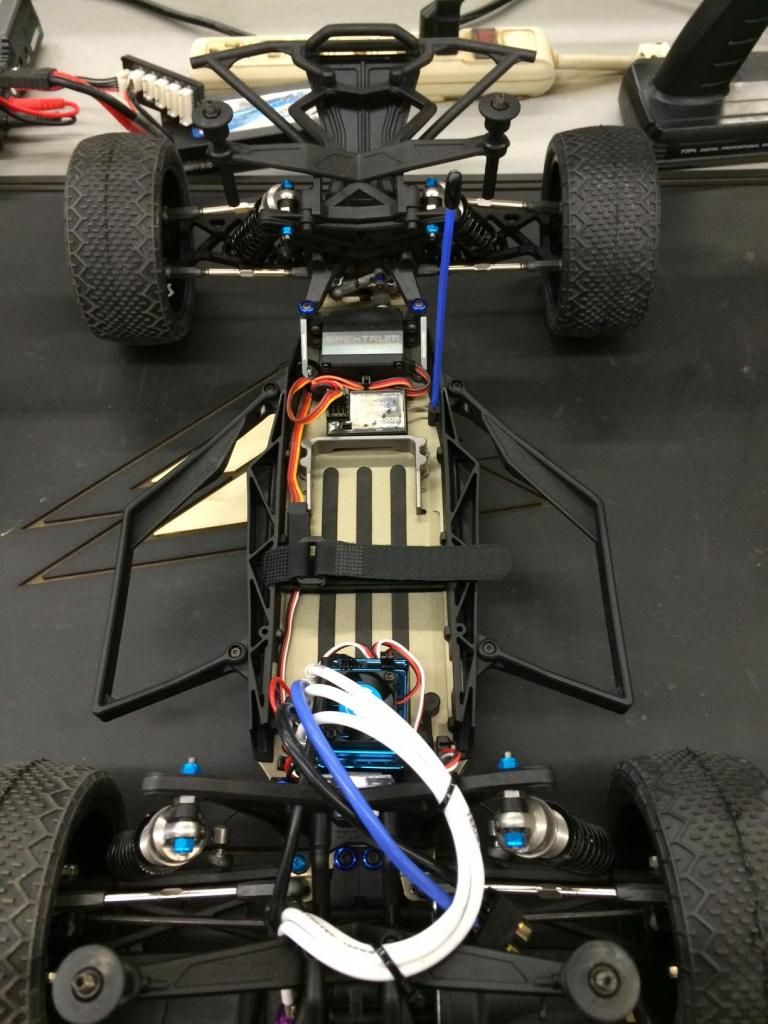

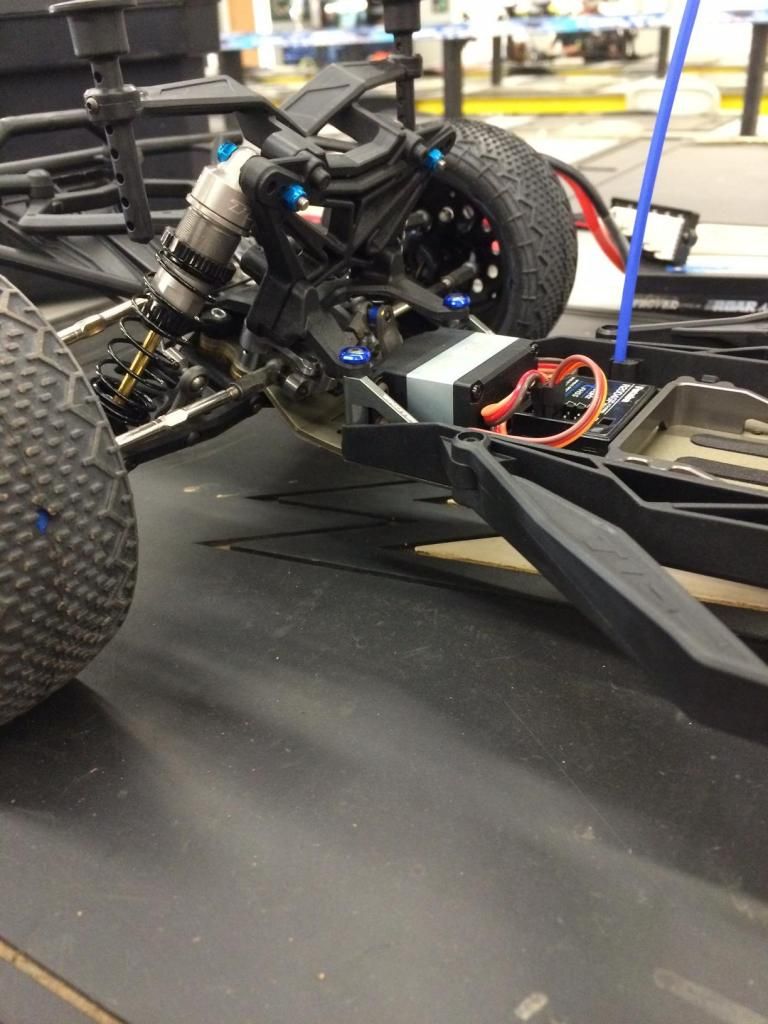

Hopefully Casper or Frank can help me out. I run at OCRC with my 1.0 and have been having some rear traction problems. I am running the Casper/Dunford setup on the first page, but with small personal tweaks like the rear shocks being at location 1-outside (for more rear side traction).

My issue is that if I run the green front spring, the truck over-steers and the rear gets loose. If I run blue, i feel like it pushes too much and I loose time.

Maybe the blue spring with a stiffer front sway bar? Remove the rear so it can roll a little more and bite harder on the tire sidewall? I switched to 32.5 weight oil all around and like the additional pack (was running 27.5). I am running j-concepts bar codes in gold (I made the switch from pro-line suburb pinks and will never go back). I have attached a few images below so get an idea of my setup. Any thoughts? The pictures are a little order. I am now running almost 0 degrees toe, and i beleive -2 camber. -2 camber on the rear as well and the rear shock mount position is 1-outside.

My issue is that if I run the green front spring, the truck over-steers and the rear gets loose. If I run blue, i feel like it pushes too much and I loose time.

Maybe the blue spring with a stiffer front sway bar? Remove the rear so it can roll a little more and bite harder on the tire sidewall? I switched to 32.5 weight oil all around and like the additional pack (was running 27.5). I am running j-concepts bar codes in gold (I made the switch from pro-line suburb pinks and will never go back). I have attached a few images below so get an idea of my setup. Any thoughts? The pictures are a little order. I am now running almost 0 degrees toe, and i beleive -2 camber. -2 camber on the rear as well and the rear shock mount position is 1-outside.

For rear traction are we looking for forward bite or side bite?

I almost always run a less aggressive front tire on my SCT. So a JC pressure point tire up front with barcodes in the rear for the tires.

I almost always run a less aggressive front tire on my SCT. So a JC pressure point tire up front with barcodes in the rear for the tires.

Hey all,

I have a 22SCT 1.0 and I purchased the TLR231027 bell crank system. I installed the system and noticed a huge difference however I popped the tow turnbuckle ball cup twice barely grazing a pipe both times, Stinks as I held fast lap in both heats and the A-main. My question is this.... I did not install the spindles that came with the new bell crank system, after looking at the new spindles with the bell crank kit it seemed they are the same as the spindles I already had on the truck, 1.0. Do I need to install the new spindles? Are they different? I also used the 1.0 turnbuckles I had on the truck instead of the ones that were shorter with the bell crank system.

I have always had ball cup issues with the truck and switched to captured ends to solve the problem years ago. However the bell crank system uses those new off set turnbuckle ends so I removed the captured ends and went back to the ball cups.

If the answer to 'Do I need to install the new spindles?' is yes do the new spindles work with the 1.0 caster blocks? Do I need to order the 2.0 caster blocks as well? (Part numbers please)

Before the A-main I installed new ball cup ends(HD) on the truck as well as replaced the ball studs with new....still popped off.

Any ideas? This isn't new territory for me I have always had bad luck with the ball cups when the 1.0 first came out and even after moving to the HD ball cup ends.

I noticed some guys were placing spacers under the ball studs. Does this rectify ball cups popping off for the tow linkage? I have never had a camber link pop off just the tow links that are attached to the steering system whether it be the old slide system or the new bell crank system. Please help!

Thanks Gentlemen!

I have a 22SCT 1.0 and I purchased the TLR231027 bell crank system. I installed the system and noticed a huge difference however I popped the tow turnbuckle ball cup twice barely grazing a pipe both times, Stinks as I held fast lap in both heats and the A-main. My question is this.... I did not install the spindles that came with the new bell crank system, after looking at the new spindles with the bell crank kit it seemed they are the same as the spindles I already had on the truck, 1.0. Do I need to install the new spindles? Are they different? I also used the 1.0 turnbuckles I had on the truck instead of the ones that were shorter with the bell crank system.

I have always had ball cup issues with the truck and switched to captured ends to solve the problem years ago. However the bell crank system uses those new off set turnbuckle ends so I removed the captured ends and went back to the ball cups.

If the answer to 'Do I need to install the new spindles?' is yes do the new spindles work with the 1.0 caster blocks? Do I need to order the 2.0 caster blocks as well? (Part numbers please)

Before the A-main I installed new ball cup ends(HD) on the truck as well as replaced the ball studs with new....still popped off.

Any ideas? This isn't new territory for me I have always had bad luck with the ball cups when the 1.0 first came out and even after moving to the HD ball cup ends.

I noticed some guys were placing spacers under the ball studs. Does this rectify ball cups popping off for the tow linkage? I have never had a camber link pop off just the tow links that are attached to the steering system whether it be the old slide system or the new bell crank system. Please help!

Thanks Gentlemen!

Tech Regular

iTrader: (4)

A little bit of both. Basically, at the end of the straight in the back of the track, there is that sharp 90 degree turn then the double. I always have to tip-toe around that 90. The truck seems to oversteer becuase the back slides around on the front. Any ideas?

Tech Regular

iTrader: (4)

Hey all,

I have a 22SCT 1.0 and I purchased the TLR231027 bell crank system. I installed the system and noticed a huge difference however I popped the tow turnbuckle ball cup twice barely grazing a pipe both times, Stinks as I held fast lap in both heats and the A-main. My question is this.... I did not install the spindles that came with the new bell crank system, after looking at the new spindles with the bell crank kit it seemed they are the same as the spindles I already had on the truck, 1.0. Do I need to install the new spindles? Are they different? I also used the 1.0 turnbuckles I had on the truck instead of the ones that were shorter with the bell crank system.

I have always had ball cup issues with the truck and switched to captured ends to solve the problem years ago. However the bell crank system uses those new off set turnbuckle ends so I removed the captured ends and went back to the ball cups.

If the answer to 'Do I need to install the new spindles?' is yes do the new spindles work with the 1.0 caster blocks? Do I need to order the 2.0 caster blocks as well? (Part numbers please)

Before the A-main I installed new ball cup ends(HD) on the truck as well as replaced the ball studs with new....still popped off.

Any ideas? This isn't new territory for me I have always had bad luck with the ball cups when the 1.0 first came out and even after moving to the HD ball cup ends.

I noticed some guys were placing spacers under the ball studs. Does this rectify ball cups popping off for the tow linkage? I have never had a camber link pop off just the tow links that are attached to the steering system whether it be the old slide system or the new bell crank system. Please help!

Thanks Gentlemen!

I have a 22SCT 1.0 and I purchased the TLR231027 bell crank system. I installed the system and noticed a huge difference however I popped the tow turnbuckle ball cup twice barely grazing a pipe both times, Stinks as I held fast lap in both heats and the A-main. My question is this.... I did not install the spindles that came with the new bell crank system, after looking at the new spindles with the bell crank kit it seemed they are the same as the spindles I already had on the truck, 1.0. Do I need to install the new spindles? Are they different? I also used the 1.0 turnbuckles I had on the truck instead of the ones that were shorter with the bell crank system.

I have always had ball cup issues with the truck and switched to captured ends to solve the problem years ago. However the bell crank system uses those new off set turnbuckle ends so I removed the captured ends and went back to the ball cups.

If the answer to 'Do I need to install the new spindles?' is yes do the new spindles work with the 1.0 caster blocks? Do I need to order the 2.0 caster blocks as well? (Part numbers please)

Before the A-main I installed new ball cup ends(HD) on the truck as well as replaced the ball studs with new....still popped off.

Any ideas? This isn't new territory for me I have always had bad luck with the ball cups when the 1.0 first came out and even after moving to the HD ball cup ends.

I noticed some guys were placing spacers under the ball studs. Does this rectify ball cups popping off for the tow linkage? I have never had a camber link pop off just the tow links that are attached to the steering system whether it be the old slide system or the new bell crank system. Please help!

Thanks Gentlemen!

A little bit of both. Basically, at the end of the straight in the back of the track, there is that sharp 90 degree turn then the double. I always have to tip-toe around that 90. The truck seems to oversteer becuase the back slides around on the front. Any ideas?

Stiffer front spring or leave the greens on and go to a stiffer front swaybar should help this some.

Again less agressive front tire helps as well take some twitchiness out of the truck. I would try the 2.0 rear hubs. I can't remember if those are a direct bolt on to the 1.0. This significantly raises the rear camber link and guys really like the rear stability that brings.

Tech Regular

iTrader: (6)

Hey all,

I have a 22SCT 1.0 and I purchased the TLR231027 bell crank system. I installed the system and noticed a huge difference however I popped the tow turnbuckle ball cup twice barely grazing a pipe both times, Stinks as I held fast lap in both heats and the A-main. My question is this.... I did not install the spindles that came with the new bell crank system, after looking at the new spindles with the bell crank kit it seemed they are the same as the spindles I already had on the truck, 1.0. Do I need to install the new spindles? Are they different? I also used the 1.0 turnbuckles I had on the truck instead of the ones that were shorter with the bell crank system.

I have always had ball cup issues with the truck and switched to captured ends to solve the problem years ago. However the bell crank system uses those new off set turnbuckle ends so I removed the captured ends and went back to the ball cups.

If the answer to 'Do I need to install the new spindles?' is yes do the new spindles work with the 1.0 caster blocks? Do I need to order the 2.0 caster blocks as well? (Part numbers please)

Before the A-main I installed new ball cup ends(HD) on the truck as well as replaced the ball studs with new....still popped off.

Any ideas? This isn't new territory for me I have always had bad luck with the ball cups when the 1.0 first came out and even after moving to the HD ball cup ends.

I noticed some guys were placing spacers under the ball studs. Does this rectify ball cups popping off for the tow linkage? I have never had a camber link pop off just the tow links that are attached to the steering system whether it be the old slide system or the new bell crank system. Please help!

Thanks Gentlemen!

I have a 22SCT 1.0 and I purchased the TLR231027 bell crank system. I installed the system and noticed a huge difference however I popped the tow turnbuckle ball cup twice barely grazing a pipe both times, Stinks as I held fast lap in both heats and the A-main. My question is this.... I did not install the spindles that came with the new bell crank system, after looking at the new spindles with the bell crank kit it seemed they are the same as the spindles I already had on the truck, 1.0. Do I need to install the new spindles? Are they different? I also used the 1.0 turnbuckles I had on the truck instead of the ones that were shorter with the bell crank system.

I have always had ball cup issues with the truck and switched to captured ends to solve the problem years ago. However the bell crank system uses those new off set turnbuckle ends so I removed the captured ends and went back to the ball cups.

If the answer to 'Do I need to install the new spindles?' is yes do the new spindles work with the 1.0 caster blocks? Do I need to order the 2.0 caster blocks as well? (Part numbers please)

Before the A-main I installed new ball cup ends(HD) on the truck as well as replaced the ball studs with new....still popped off.

Any ideas? This isn't new territory for me I have always had bad luck with the ball cups when the 1.0 first came out and even after moving to the HD ball cup ends.

I noticed some guys were placing spacers under the ball studs. Does this rectify ball cups popping off for the tow linkage? I have never had a camber link pop off just the tow links that are attached to the steering system whether it be the old slide system or the new bell crank system. Please help!

Thanks Gentlemen!

I used captured links before the bell crank install, so never really had popping issues prior to the bell crank install

Tech Regular

iTrader: (4)

ok thanks casper. Ill try that. I just bought a 1 race old 22 2.0 so im stoked for that. In all honestly, I am an AE guy through-and-through, but since I sold my sc10.2 for this truck, I really like it.

What do you think of the fact that I am running a rear motor truck at OCRC, but have a full stick pack pretty much pushed all the way forward. I have the TLR metal battery brace, as seen in the pics, and I run the battery all the way forward. I really like it so far but am really tempted to go to MM. I can’t image it would be too much different of a weight distribution from what Im running now.

What do you think of the fact that I am running a rear motor truck at OCRC, but have a full stick pack pretty much pushed all the way forward. I have the TLR metal battery brace, as seen in the pics, and I run the battery all the way forward. I really like it so far but am really tempted to go to MM. I can’t image it would be too much different of a weight distribution from what Im running now.

Tech Master

iTrader: (17)

I am no expert but it sure looks like you have a lot of pre-load on the rear shocks...what ride height is that at? Mine for comparison, the adjusters are up alot higher and set at 28MM.

1Likes

1Likes