SC10 4x4 Thread

nice find!

tomorrow will be my first attempt at a real race. i haven't had my sc10 4x4 for long but what i have done so far is diffs (front 20,000/ rear 5,000), chassis brace, front and rear sway bars, jconcept subculture tires and that's about it. then again if you can't keep it right side up and on the track all the hop ups in the world won't help you win. the track is clay and pretty slick. any suggestions on a good set up for a beginner?

Tech Regular

Don't be afraid to set your endpoints "low". There's tons of steering in the car, once i dialed mine back the steering was nice, smooth and a lot more controllable

.

Last edited by rcuser67898578; 12-09-2023 at 08:59 PM.

tomorrow will be my first attempt at a real race. i haven't had my sc10 4x4 for long but what i have done so far is diffs (front 20,000/ rear 5,000), chassis brace, front and rear sway bars, jconcept subculture tires and that's about it. then again if you can't keep it right side up and on the track all the hop ups in the world won't help you win. the track is clay and pretty slick. any suggestions on a good set up for a beginner?

I am assuming you won't have tons of time to change a bunch of stuff around, and its probably a good idea first to start with what you got unless your setup is really off.

what I can recommend is:

- Grab some setups off of AEs site that appear to match your conditions

- When you have issues, compare to those setups to get any idea of what could be useful to change

- Download and take with the Xray Hudy Offroad setup guide as well as the Mark Pavadis guide. These can be had for free.

Tech Master

iTrader: (24)

Wow this thread has been kind of quiet lately. Well here is something I have been working on. I have been running my X-Factory SCX SC truck and Durango DEX210 buggy in mid motor configuration and both use a 4 gear tranny. The advantage of a 4 vs 3 gear tranny is the motor rotation is in the same direction as the wheels. This should enhance traction on power and allow better altitude control. One of the big problems I have with my SC10 4x4 is I am not happy with the altitude control. It is much better since I have added a cDiff but no where near my Tekno. So I started researching a 4 gear setup on an SC10 4x4. Well no one makes an aftermarket 4 gear tranny case, but Marcus (RCShox) did experiment with a modded SC10 4x4 4 gear setup and he gave me a place to start. I pretty much copied a lot of his ideas, but went with a steel idler instead of plastic for durability. I also went with a "C" support for the idler rather than a spindle for more support. There were a lot of things that need to be worked out, motor mounting (the top mount is where the idler now sits), finding a 32p idler gear, make the "C" support, etc. I was able to get a prototype built and bench tested it. I still have a couple of issues to work out and a lot of fine tuning. Then I need to see how it holds up under full power. Here are some pictures.

Modded motor mount uses an extended slot and two screws on the bottom to hold the motor.

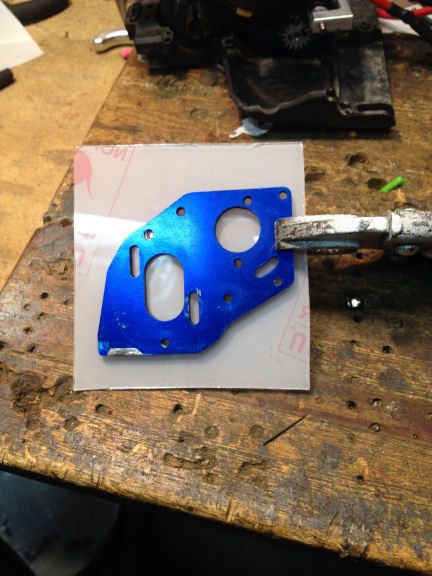

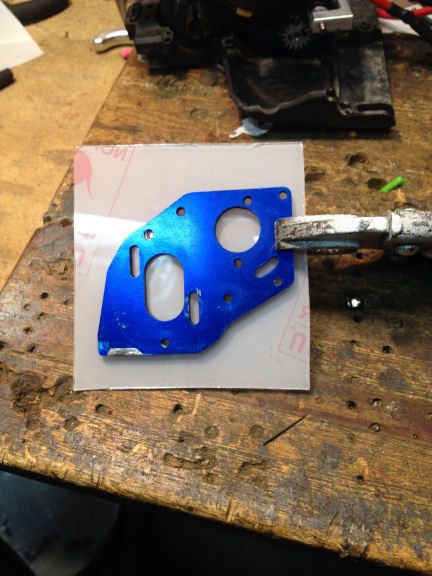

"C" support to hold the idler gear to the motor plate. Idler is a 32p pinion drilled out to accept two 5x10mm bearings.

"C" support bolted to the motor plate.

Front view, showing belt clearance.

Bench testing at 1/2 throttle.

Modded motor mount uses an extended slot and two screws on the bottom to hold the motor.

"C" support to hold the idler gear to the motor plate. Idler is a 32p pinion drilled out to accept two 5x10mm bearings.

"C" support bolted to the motor plate.

Front view, showing belt clearance.

Bench testing at 1/2 throttle.

Sweet!

Love the ingenuity!

Love the ingenuity!

Tech Adept

I will pay whatever you want to charge plus an arm and a leg, but really only a leg. I need two arms too drive like a pro. I could stand on one leg with no problem.

Tech Master

iTrader: (24)

After testing my first attempt at a 4 gear modded tranny I decided to make a few improvements and also try another design I considered. I originally went with the "C" support for the idler because it is stronger. I also considered a spindle to hold the idler, which would be easier to make and be more compact.

[

To help me line things up and locate where new holes need to go I decided to make a clear copy of the motor plate. I clamped the stock motor plate to a piece of lexan.

Used a thin sharpie to trace the holes.

[

To help me line things up and locate where new holes need to go I decided to make a clear copy of the motor plate. I clamped the stock motor plate to a piece of lexan.

Used a thin sharpie to trace the holes.

Tech Master

iTrader: (24)

Dup

Last edited by Shark413; 12-29-2013 at 04:02 PM.

Tech Master

iTrader: (24)

Tech Master

iTrader: (24)

Tech Master

iTrader: (24)

The clear motor plate allowed me to check alignment of everything. Once everything looks good, I will use the clear plate as a template to transfer the mods to the aluminum plate.

lining up the idler gear and spindle. I found a 18T idler allowed me to use the upper motor mount hole for mounting.

Spindle allows plenty of room for the belt.

Everything installed, once I verify the alignment I will use the clear plate to transfer mods to the actual aluminum motor plate. I need to add another slot for the 2nd motor screw.

lining up the idler gear and spindle. I found a 18T idler allowed me to use the upper motor mount hole for mounting.

Spindle allows plenty of room for the belt.

Everything installed, once I verify the alignment I will use the clear plate to transfer mods to the actual aluminum motor plate. I need to add another slot for the 2nd motor screw.

Tech Master

iTrader: (24)

Tech Master

iTrader: (24)

I wouldn't want that on my conscience, but let me do some actual track testing to see how it holds up and performs before you start cutting anything, lol.

5Likes

5Likes