Team Associated B6 & B6D thread

|

|||

#2762

Tech Fanatic

iTrader: (35)

Took my b6d out to the track for the first time today and almost finished my day without breaking anything.  Technically didn't break and actually just lost a rear inner hinge pin. Easy fix.

Technically didn't break and actually just lost a rear inner hinge pin. Easy fix.

Anyway, being my first experience with 2wd buggys (17.5), I had no real issues learning how to drive the b6d with the box setup with the exception of jumps. I feel as if I just don't get enough acceleration on jumps and it keeps me from moving around the track quickly. I have a Reedy Sonic 17.5 with 72/31 gearing.

I was having the most trouble with the rhythm section at my track which most were taking as a "double double" and the final set of jumps before the straight (single double). Here's a video of the current layout:

https://youtu.be/n9g0LsxYXq4

Should I be able to take the jumps the way I described with a 17.5 setup, or am I really limited to taking single jumps? My first instinct was to tighten my slipper a bit, as I did have a little bit of slipping happening on full throttle. Other than that though I didn't know what else to tweak.

Technically didn't break and actually just lost a rear inner hinge pin. Easy fix.

Technically didn't break and actually just lost a rear inner hinge pin. Easy fix. Anyway, being my first experience with 2wd buggys (17.5), I had no real issues learning how to drive the b6d with the box setup with the exception of jumps. I feel as if I just don't get enough acceleration on jumps and it keeps me from moving around the track quickly. I have a Reedy Sonic 17.5 with 72/31 gearing.

I was having the most trouble with the rhythm section at my track which most were taking as a "double double" and the final set of jumps before the straight (single double). Here's a video of the current layout:

https://youtu.be/n9g0LsxYXq4

Should I be able to take the jumps the way I described with a 17.5 setup, or am I really limited to taking single jumps? My first instinct was to tighten my slipper a bit, as I did have a little bit of slipping happening on full throttle. Other than that though I didn't know what else to tweak.

#2763

i also run at norcal. on that back section, it's double/double all day. shouldn't be a problem even for 17.5, although i've seen some buggies struggle with it in the intermediate classes. some of that is driving, some of it is setup, maybe some of it is not great electronics (battery/motor).

limeaway, which reedy motor are you using? if you're using the short stack mach 3, i'd go down to 30/72 and play with endbell timing. also are you running a fan on your motor?

limeaway, which reedy motor are you using? if you're using the short stack mach 3, i'd go down to 30/72 and play with endbell timing. also are you running a fan on your motor?

#2764

Tech Initiate

I originally had the lock nut flush with the top of the slipper shaft as instructed by the manual, but after tightening it I have about 2 threads visible on the shaft. It didn't make too much of a difference. How tight do you have your slippers?

I only checked my motor temp once this afternoon, but I think it was around 100-110 no fan. Super low.

@rcphreak, I'm using a Reedy Sonic M3 motor (ASC254) with no fan and zero timing.

I appreciate the help y'all!

I only checked my motor temp once this afternoon, but I think it was around 100-110 no fan. Super low.

@rcphreak, I'm using a Reedy Sonic M3 motor (ASC254) with no fan and zero timing.

I appreciate the help y'all!

#2765

ok. that's the regular stack height stator, so your gearing probably isn't too far off. if anything, you could go up a tooth.

as far as the timing, you've got to turn that up. i'm not familiar with that motor and where it likes timing, but i would think you could start with 25 degrees and check temps. ideally, you should run a fan. that'll lower your temps by 20 degrees and allow you to run more timing. when you start to turn up the timing, the motor will come alive.

i run a slipper eliminator. the equivalent for you would be to just lock down the slipper.

as far as the timing, you've got to turn that up. i'm not familiar with that motor and where it likes timing, but i would think you could start with 25 degrees and check temps. ideally, you should run a fan. that'll lower your temps by 20 degrees and allow you to run more timing. when you start to turn up the timing, the motor will come alive.

i run a slipper eliminator. the equivalent for you would be to just lock down the slipper.

#2766

I originally had the lock nut flush with the top of the slipper shaft as instructed by the manual, but after tightening it I have about 2 threads visible on the shaft. It didn't make too much of a difference. How tight do you have your slippers?

I only checked my motor temp once this afternoon, but I think it was around 100-110 no fan. Super low.

@rcphreak, I'm using a Reedy Sonic M3 motor (ASC254) with no fan and zero timing.

I appreciate the help y'all!

I only checked my motor temp once this afternoon, but I think it was around 100-110 no fan. Super low.

@rcphreak, I'm using a Reedy Sonic M3 motor (ASC254) with no fan and zero timing.

I appreciate the help y'all!

Slipper eliminator and MIP bi-metal drives will also do wonders for acceleration.

Last edited by tsair; 08-21-2016 at 11:20 PM.

#2767

Tech Initiate

I assumed out of the box the motor was set at 0 timing, but as I was about to add timing I saw that it was already set at 20 deg.  I'll probably go up to 25 or 30.

I'll probably go up to 25 or 30.

I'm headed back to the track tomorrow so I'll have another chance to toy around with my set up.

I'll probably go up to 25 or 30.

I'll probably go up to 25 or 30. I'm headed back to the track tomorrow so I'll have another chance to toy around with my set up.

#2768

How do you guy run your B6 gear diff. on high grip carpet track; with 2 or 4 gears ?

#2769

Tech Adept

We run med - high grip carpet, on my B6 all 4 diff gears, 3k oil. Ran 4 gears 2k oil on b5m same surface.

#2771

Still got to get the cars out to the track.

But if I had to guess which one to get it is the Diggity Designs ones. Quasi-Isotropic weave carbon fiber.

#2772

I picked up the Schelle ones last weekend but won't get to the track until next week.

#2774

Tech Initiate

Just received my B6D and electronics. Getting into 2wd buggy for the fall/winter season. I've read through pages and pages of this forum and found some recommended upgrades on page 175. Those being titanium turnbuckles, ceramic bearings, and a Schelle slipper.

I've also seen, here & there, some other recommendations but would like to ask about some specific items. I will be running mod on an indoor, high traction, clay surface. http://track.speedrc.com/

Before I begin the build, I'd like to know if the following is worth the investment.

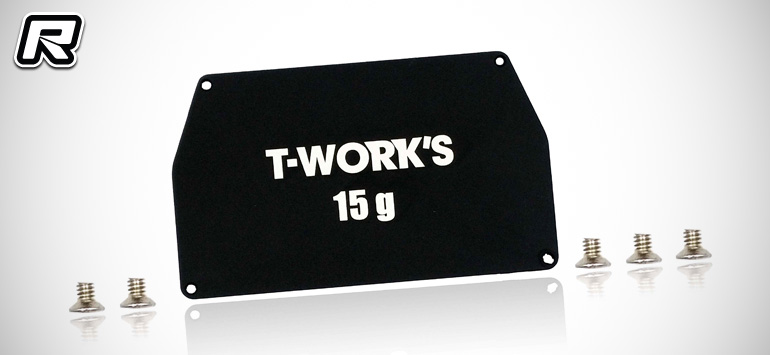

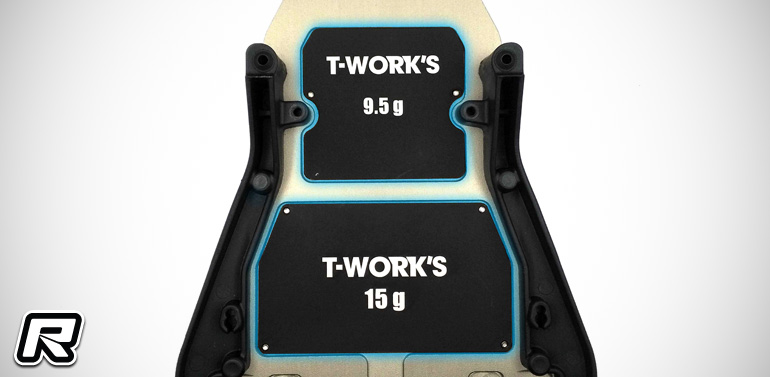

Steel Chassis Weights, 24g & 36g - ASC91747, ASC91748

Aluminum Rear Ballstud Mount - ASC91693

Brass Bulkhead - ASC91659

Brass C Mount 25g - ASC91690

Aluminum Bellcrank - ASC91668

Any advice is appreciated.

I've also seen, here & there, some other recommendations but would like to ask about some specific items. I will be running mod on an indoor, high traction, clay surface. http://track.speedrc.com/

Before I begin the build, I'd like to know if the following is worth the investment.

Steel Chassis Weights, 24g & 36g - ASC91747, ASC91748

Aluminum Rear Ballstud Mount - ASC91693

Brass Bulkhead - ASC91659

Brass C Mount 25g - ASC91690

Aluminum Bellcrank - ASC91668

Any advice is appreciated.

#2775

Steel Chassis Weights, 24g & 36g - ASC91747, ASC91748 Not needed for clay imo, more for carpet

Aluminum Rear Ballstud Mount - ASC91693 Comes standard

Brass Bulkhead - ASC91659 Not needed, maybe aluminum though #91658

Brass C Mount 25g - ASC91690 intended for use with the B6, wont fit without dremeling on the D, the 12g brass, #91687 may be a good tuning option though. Car comes with aluminum C mount

Aluminum Bellcrank - ASC91668 Not needed imo

Any advice is appreciated.

649Likes

649Likes