Tekin RX8 1/8 Scale Brushless ESC Thread

#7126

Randy,

What do you think of the above posted advice? For some reason my RX8-2050 in my Losi 8ight buggy with 15/45 is coming off the track after a long main (12 minutes) on a warm but not hot day (80F) at around 175F using my Exergen gun. That is after coming down off the drivers stand and carrying the car a very short distance back to the pits.

I had no performance issues, neither did I see any drop off at the end of the main, but I'm a little concerned about the motor heat. I just got my RX8 back from you guys and the only thing I changed was to add Lipo cutoff for 4S. Everything else is set to defaults.

Should I gear down? Or would limiting the throttle end point be better? What else can I do for heat? During the qualifiers, this doesn't happen. It comes off at around 130F, but the longer mains it seems to heat up.

What do you think of the above posted advice? For some reason my RX8-2050 in my Losi 8ight buggy with 15/45 is coming off the track after a long main (12 minutes) on a warm but not hot day (80F) at around 175F using my Exergen gun. That is after coming down off the drivers stand and carrying the car a very short distance back to the pits.

I had no performance issues, neither did I see any drop off at the end of the main, but I'm a little concerned about the motor heat. I just got my RX8 back from you guys and the only thing I changed was to add Lipo cutoff for 4S. Everything else is set to defaults.

Should I gear down? Or would limiting the throttle end point be better? What else can I do for heat? During the qualifiers, this doesn't happen. It comes off at around 130F, but the longer mains it seems to heat up.

#7127

What do you guys recommend for mounting. I have tried many ,ethods. Right now I have an RC-monster XT8 chassis and the esc is bolted right to the chassis. I have mounted them with servo tape, dual lock, shoegoo, zipties. Nothing seems to make a difference it seems. Thats why I hard mounted it. I figured all the extra cushion is actually causing more vibrations rather than helping?

I have tried everything too and still had failures.

I think someone from Tekin (might have been Randy)

stated a few pages back that sans user abuse,it's not

a mounting issue.

I am very surprised to hear that it's a red top that popped..

I have tried everything too and still had failures.

I think someone from Tekin (might have been Randy)

stated a few pages back that sans user abuse,it's not

a mounting issue.

I am very surprised to hear that it's a red top that popped..

#7128

Sorry Randy, you misread my question. It's in my buggy. Should I still go down? If I remember once you said you thought 16/45 was appropriate in the buggy, so I'm wondering if instead of going below 15 teeth, I should play with punch or endpoints to get the heat down.

#7130

Tech Adept

iTrader: (1)

Give that a try. There is a little tab at the top of the page to choose RX8 or RS

For what it is worth,

Spironi

#7131

Sorry,

If you're running a 2050 in a buggy I'd run a 15/45 in a Losi. However if it's a Hotbodies V8, RC8b or other buggy with a 4.3 internal setup I'd suggest running more like an 18-19 pinion.

If you're running a 2050 in a buggy I'd run a 15/45 in a Losi. However if it's a Hotbodies V8, RC8b or other buggy with a 4.3 internal setup I'd suggest running more like an 18-19 pinion.

#7132

Randy....How are you and ty mounting your ESCs on your Losi's ? directly to the tray correct ? anything in between ?

#7133

quick question for everyone else who has experianced multiable failures?

I have had multiable failures and have tried all the different mounting methods, velcro with a zip tie, screws with orings, thick double sided tape, the gell double sided tape with multiable stacks.

What i am wondering now is how is everyone soldering their wires? I had been soldering them where the wire came out at a 90* to the solder post. All of my failure had to do with the esc cutting in and out after a few runs.

Now with my new esc's that i have recieved back I soldered the wires inline with the soldering post. So far i have had no issues after about 9 battery packs. (this is more than i have gotten out of all my other esc's before failure) I am thinking that maybe if you are soldering the wires at a 90* to the post you are creating torque on the board when the wires flex from impacts and over time you wind up shorting out the board internally. However, with the wires mounted inline with the post the viberations seem to happen more in the wire than directly on the post/board?

Just wondering, and trying to help out tekin figure what is causeing the issues with certain units having mult. failures. would like to hear what others have to say/think?

I have had multiable failures and have tried all the different mounting methods, velcro with a zip tie, screws with orings, thick double sided tape, the gell double sided tape with multiable stacks.

What i am wondering now is how is everyone soldering their wires? I had been soldering them where the wire came out at a 90* to the solder post. All of my failure had to do with the esc cutting in and out after a few runs.

Now with my new esc's that i have recieved back I soldered the wires inline with the soldering post. So far i have had no issues after about 9 battery packs. (this is more than i have gotten out of all my other esc's before failure) I am thinking that maybe if you are soldering the wires at a 90* to the post you are creating torque on the board when the wires flex from impacts and over time you wind up shorting out the board internally. However, with the wires mounted inline with the post the viberations seem to happen more in the wire than directly on the post/board?

Just wondering, and trying to help out tekin figure what is causeing the issues with certain units having mult. failures. would like to hear what others have to say/think?

#7134

What changes should I make? Turn down the EPA? Turn down the punch? Change the gearing? Just F-it and run it hot???

Again, I know you're busy, but I gave all the details in my first post above and I don't want to have to send back another unit for repair.

#7135

quick question for everyone else who has experianced multiable failures?

I have had multiable failures and have tried all the different mounting methods, velcro with a zip tie, screws with orings, thick double sided tape, the gell double sided tape with multiable stacks.

What i am wondering now is how is everyone soldering their wires? I had been soldering them where the wire came out at a 90* to the solder post. All of my failure had to do with the esc cutting in and out after a few runs.

Now with my new esc's that i have recieved back I soldered the wires inline with the soldering post. So far i have had no issues after about 9 battery packs. (this is more than i have gotten out of all my other esc's before failure) I am thinking that maybe if you are soldering the wires at a 90* to the post you are creating torque on the board when the wires flex from impacts and over time you wind up shorting out the board internally. However, with the wires mounted inline with the post the viberations seem to happen more in the wire than directly on the post/board?

Just wondering, and trying to help out tekin figure what is causeing the issues with certain units having mult. failures. would like to hear what others have to say/think?

I have had multiable failures and have tried all the different mounting methods, velcro with a zip tie, screws with orings, thick double sided tape, the gell double sided tape with multiable stacks.

What i am wondering now is how is everyone soldering their wires? I had been soldering them where the wire came out at a 90* to the solder post. All of my failure had to do with the esc cutting in and out after a few runs.

Now with my new esc's that i have recieved back I soldered the wires inline with the soldering post. So far i have had no issues after about 9 battery packs. (this is more than i have gotten out of all my other esc's before failure) I am thinking that maybe if you are soldering the wires at a 90* to the post you are creating torque on the board when the wires flex from impacts and over time you wind up shorting out the board internally. However, with the wires mounted inline with the post the viberations seem to happen more in the wire than directly on the post/board?

Just wondering, and trying to help out tekin figure what is causeing the issues with certain units having mult. failures. would like to hear what others have to say/think?

#7138

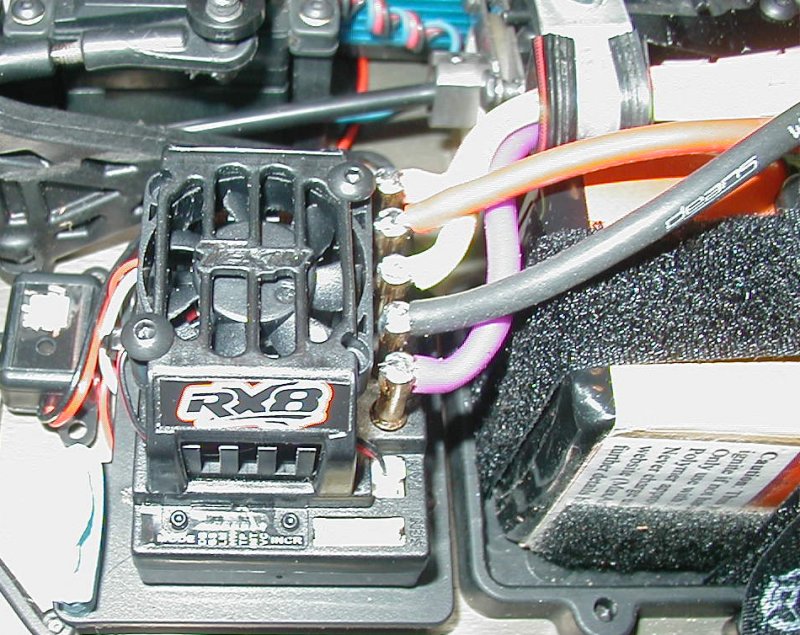

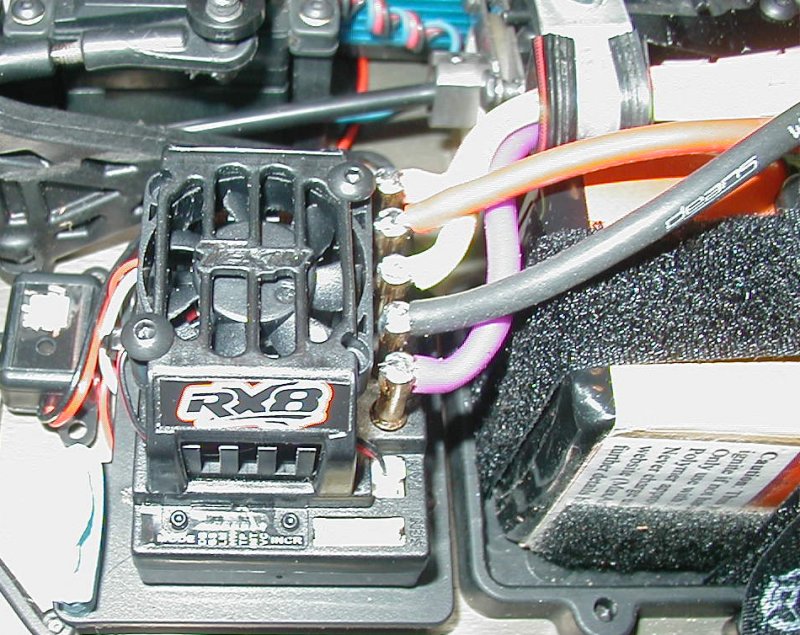

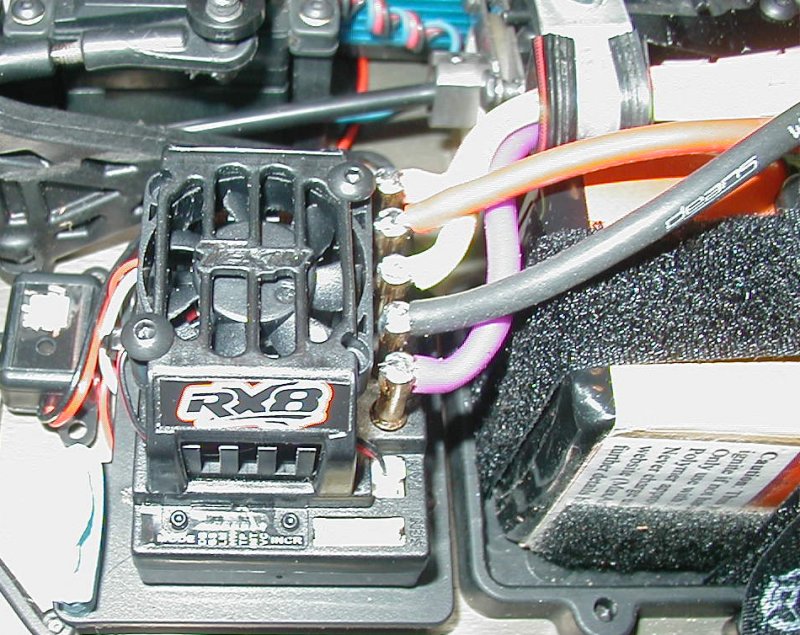

It may not be so much the direction you solder the wires but whether or not they put stress on the board. The following pic is a buggy setup with a early release RX8 that has run for a whole season and plus about an hour practice every week during race season with no failure. The clamp you can see to the top right of the pic eliminates any stress the wires may put on the ESC even on hard landings.

I really think the failures have to do with being mounted in the rear of buggies on the chassis. There is very little cushioning to protect the ESC from the jarring.

I am actually considering going back to using my RCPD center diff mount to put the ESC back over the middle of the center diff instead of having it down on the chassis in my buggy.

#7139

What I have dealt with is wires breaking internally. I have as good of an install as you can without something picking up the slack. I could run 12" wires all the way down to the chassis on my car and that would work but 12" would just add more resistance to my system. So, I'm thinking of a wire clip that bolts to the center diff housing. I have ran a Losi and an Xray and there is nothing between the motor and the ESC to pick up the slack. I have broken wires on my battery plug and my wires going to my motor. 1/8 buggy just needs some wire management. Something simple to pick up the slack of the wires.

#7140

Yeah the wire router on the Ve8 is awesome help for that. I have been trying to come up with somewhere else to mount my esc. I want 1 of the RCPD esc mounts and could use 1 because I dont run the mech brakes, but he dont make 1 that fits the center diffmount. Its not the same as the d8.

3Likes

3Likes