MUGEN SEIKI MRX5

#1876

grind it down from the front......from the front does nothing.... The problem is the amount of cone htat was sticking out of the rear.

With a NR flash it comes with 2 cones the 5.5 cone i used and did the following

Here is the difference a 5.5 cone has the same Dia as a 7 at the rear, and the same at the front the problem is always at the rear in this case.

I took the 5.5 cone down to 5.0, works fine its just a PITA to do.

Thanks for the info, tips and help.

I used the following Fly wheels and got the following gap between motor and flywheel on a stock 5.5 cone

Mugen 1.17

Arrow max 1.20

Prior to sanding thats the best I could get.

With the cone at 5.0 I can shim the clutch anyway I like

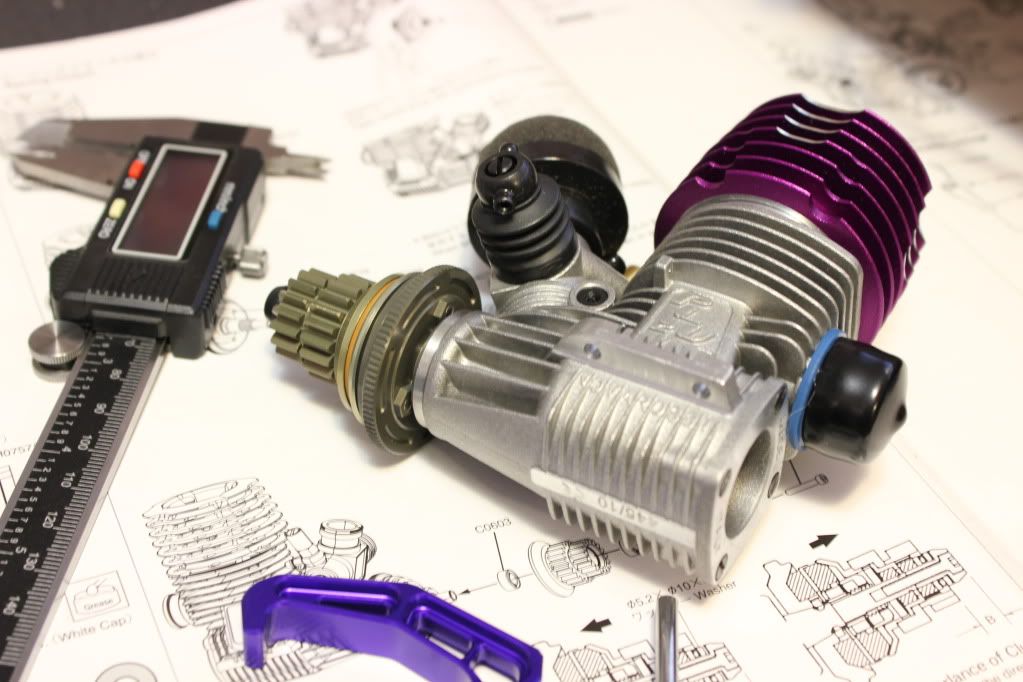

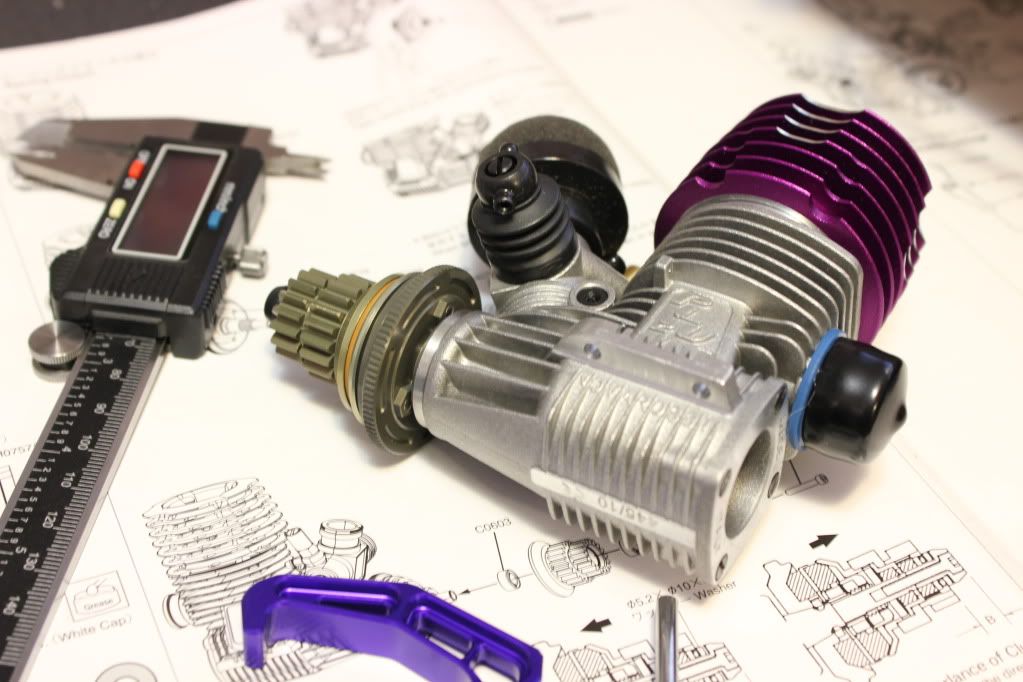

Here is some pics, The pics are messy but I am working away at things so, I like it busy

With a NR flash it comes with 2 cones the 5.5 cone i used and did the following

Here is the difference a 5.5 cone has the same Dia as a 7 at the rear, and the same at the front the problem is always at the rear in this case.

I took the 5.5 cone down to 5.0, works fine its just a PITA to do.

Thanks for the info, tips and help.

I used the following Fly wheels and got the following gap between motor and flywheel on a stock 5.5 cone

Mugen 1.17

Arrow max 1.20

Prior to sanding thats the best I could get.

With the cone at 5.0 I can shim the clutch anyway I like

Here is some pics, The pics are messy but I am working away at things so, I like it busy

what flywheel r u using it dont look right?

#1879

Its says in the post you quoted. right in the middle of the post.

I also gave a measurement of all the stock parts used vs a arrowmax part.

The measurement I posted was the distance from the motor to the back edge of the flywheel.

With a 5.5 cone and all stock mugen parts....from the post you qouted

"""I used the following Fly wheels and got the following gap between motor and flywheel on a stock 5.5 cone

Mugen 1.17

Arrow max 1.20"""

I took off .5 off the back of the cone and was able to assembly everything with the mugen parts. After I did that, I took it all back apart and assemblyed it with a Arrowmax fly wheel and a CSO aluminum Bell, no change same settings.

As far as I can tell most of you must use a different cone. I tried 3 different cones the only ones i have. a 5.5 a 7 and one that was 5.5 but looked a little different.

None of them got be down to .75 or lesson the gap between the flywheel and motor.

I also tried 2 mugen fly wheels and 2 arrowmax, no change.

Problem solved I will just turn down the the cone's from now to 5.0 in the future if i have problems.

I also gave a measurement of all the stock parts used vs a arrowmax part.

The measurement I posted was the distance from the motor to the back edge of the flywheel.

With a 5.5 cone and all stock mugen parts....from the post you qouted

"""I used the following Fly wheels and got the following gap between motor and flywheel on a stock 5.5 cone

Mugen 1.17

Arrow max 1.20"""

I took off .5 off the back of the cone and was able to assembly everything with the mugen parts. After I did that, I took it all back apart and assemblyed it with a Arrowmax fly wheel and a CSO aluminum Bell, no change same settings.

As far as I can tell most of you must use a different cone. I tried 3 different cones the only ones i have. a 5.5 a 7 and one that was 5.5 but looked a little different.

None of them got be down to .75 or lesson the gap between the flywheel and motor.

I also tried 2 mugen fly wheels and 2 arrowmax, no change.

Problem solved I will just turn down the the cone's from now to 5.0 in the future if i have problems.

#1881

Tech Adept

Hello guys,

car is awesome i love to drive 1/8th scale again,

i have one major question:

What trackwide (with weels) are u useing (frond and rear) most of the time, i think mine is very wrong.

greetings

car is awesome i love to drive 1/8th scale again,

i have one major question:

What trackwide (with weels) are u useing (frond and rear) most of the time, i think mine is very wrong.

greetings

#1882

Yes, and that end never seens to make a difference.

I have 3 stock clutch setups and i have 2 setups that use aftermarket parts.

The clutch itself and the parts dont seem to be the problem.

its the cone

Also mugen does not give you a cone with the kit, not in the 2 kits I have.

Some people said they use teh mugen cone, well thats nice and all but its not in the kit.

The assembly of the clutch using stock parts with a stock 5.5 Novarossi cone akk ended up the same way, With the Incert that goes into the end of the bell the part with the trust bearing on it never bottoming out, when it does nto bottom out it locks up the thrust bearing and it also was putting the bell right into the clutch disk

As soon as i removed .5 from the back side of the cone it all went together

I would like to note a friend ran into the same problem.

CanyonCarverR1 What cone did you use?? Brand, Size, ect any info?

#1884

Tech Rookie

I bought this car toy earlier. Its really a gud toy for kids. U can see this on above picture was look awesome i really like this type of toys. You can over there...guys

#1885

Tech Rookie

Nice talk

#1886

Tech Master

iTrader: (13)

Yes, and that end never seens to make a difference.

I have 3 stock clutch setups and i have 2 setups that use aftermarket parts.

The clutch itself and the parts dont seem to be the problem.

its the cone

Also mugen does not give you a cone with the kit, not in the 2 kits I have.

Some people said they use teh mugen cone, well thats nice and all but its not in the kit.

The assembly of the clutch using stock parts with a stock 5.5 Novarossi cone akk ended up the same way, With the Incert that goes into the end of the bell the part with the trust bearing on it never bottoming out, when it does nto bottom out it locks up the thrust bearing and it also was putting the bell right into the clutch disk

As soon as i removed .5 from the back side of the cone it all went together

I would like to note a friend ran into the same problem.

CanyonCarverR1 What cone did you use?? Brand, Size, ect any info?

I have 3 stock clutch setups and i have 2 setups that use aftermarket parts.

The clutch itself and the parts dont seem to be the problem.

its the cone

Also mugen does not give you a cone with the kit, not in the 2 kits I have.

Some people said they use teh mugen cone, well thats nice and all but its not in the kit.

The assembly of the clutch using stock parts with a stock 5.5 Novarossi cone akk ended up the same way, With the Incert that goes into the end of the bell the part with the trust bearing on it never bottoming out, when it does nto bottom out it locks up the thrust bearing and it also was putting the bell right into the clutch disk

As soon as i removed .5 from the back side of the cone it all went together

I would like to note a friend ran into the same problem.

CanyonCarverR1 What cone did you use?? Brand, Size, ect any info?

#1887

Different then the ones that came with the motor.

#1888

i have always used the cones that come with the motor, i have never never ran into that kind of problem trust me there something u are doing wrong its hard to see from the pics unless u take a step by step pic, and i never heard of this prob from anyone i race with. i have seen some cones only give u a .8 gap with no shims behind the thrust bearing but never no gap. the best cone that will bring the flywheel closest to the motor is the kyosho. are u putting the spacer that comes with the motors behind the cone?

#1889

#1890

i have always used the cones that come with the motor, i have never never ran into that kind of problem trust me there something u are doing wrong its hard to see from the pics unless u take a step by step pic, and i never heard of this prob from anyone i race with. i have seen some cones only give u a .8 gap with no shims behind the thrust bearing but never no gap. the best cone that will bring the flywheel closest to the motor is the kyosho. are u putting the spacer that comes with the motors behind the cone?

I will check into the kyosha cone see what it is.

Really no mystery to putting it together. I place the cone on the crank Slide it all the way to the back flush with the bearing.place the fly wheel on. and then put on the fly wheel nut.

Then i tighten down the nut, and I now check the gap between flywheel and motor. A fellow form member posted that he was around .6-.65 or something like that, so if its over 1.0 there is no need to go any farther, but if you do as you put it together you would run into the part the bearings and thrust bearing ride on, this part will not come into contact with the tip of the crank.

And if it does not come into contact it will bind the thrust bearing and also because everything is pushed out the bell comes into contact with the disk.

The best info i have got on this so far is knowing the measurement of some other racers gap between the motor and the clutch flywheel.

And also finding out there are some other cones out there that people have used.

With a proper size cone the setup of the clutch is simple

3Likes

3Likes