Xray NT1

#4352

[QUOTE=musti72;6119438]Hi, I recently broke one more Universal Shaft of my NT1. It was broken where the axle and shaft meets. It had happened one more time before, since then I was running dogbone on that side and no problem with that... The other CVD on the other side is finally broken from the same place!!

Did that happen to you before? I was running 90-100% Dualrate, and it was 25degree on %100. I know that most of the racers run full Dualrate, so it shouldnt be the problem.

I ordered my dogbones so I will be running dogbones at all four corners from now on!

Anyone experienced?

When I put my car on set up guages I set maximum turn at 17 degrees at full dual rate. I try to get the steering I need with full turn between 15 an17 degree max. Worked on other parts of geometry to get the steer and have no problems with not having enough steering, At times I do need to reduce the dual rate on given days. This works for me. I was told that the less the front wheels are turned in a corner the more corner speed you can carry but of course you first must get around the corner. Not sure if this is right or wrong and as I said this works for me.

Did that happen to you before? I was running 90-100% Dualrate, and it was 25degree on %100. I know that most of the racers run full Dualrate, so it shouldnt be the problem.

I ordered my dogbones so I will be running dogbones at all four corners from now on!

Anyone experienced?

When I put my car on set up guages I set maximum turn at 17 degrees at full dual rate. I try to get the steering I need with full turn between 15 an17 degree max. Worked on other parts of geometry to get the steer and have no problems with not having enough steering, At times I do need to reduce the dual rate on given days. This works for me. I was told that the less the front wheels are turned in a corner the more corner speed you can carry but of course you first must get around the corner. Not sure if this is right or wrong and as I said this works for me.

#4353

100% dualrate on your transmitter/receiver/servo combination isn't the same as another car. So giving the degree like you did is a better option to compare. I don't know my degree, i'll probably measure it tonight.

What about maintenance, do you clean them often and replace pins?

What about maintenance, do you clean them often and replace pins?

I cleaned them but there wasnt any reason to change the pins, they seemed quite new.

#4354

When I put my car on set up guages I set maximum turn at 17 degrees at full dual rate. I try to get the steering I need with full turn between 15 an17 degree max. Worked on other parts of geometry to get the steer and have no problems with not having enough steering, At times I do need to reduce the dual rate on given days. This works for me. I was told that the less the front wheels are turned in a corner the more corner speed you can carry but of course you first must get around the corner. Not sure if this is right or wrong and as I said this works for me.

About corner speed, I use just needed steering on the large corners so it doesnt lose speed, but full turn helps on slow and tight corners.

Another note: When the first one broke, I also tried mugen universal shaft with xrays wheel axle. It worked some time, but I couldnt test it for a longer time for durability.

#4355

If I can make a serious attempt at the nationals with Twiggys old car (getting on to 2 years now) and a couple of 1.5 yrold donks,Im sure that you will get by with all the equipment that you have in your kit wether it be the upside down , inverted or just plain the right way up.

Thomas If you can just listen ,learn, put all the things that are available to all of us together on the track and just Bloody drive fast then you should be able to reach the a mains.

Remember there are no secrets to going fast , you just have to go fast!

#4356

Tech Initiate

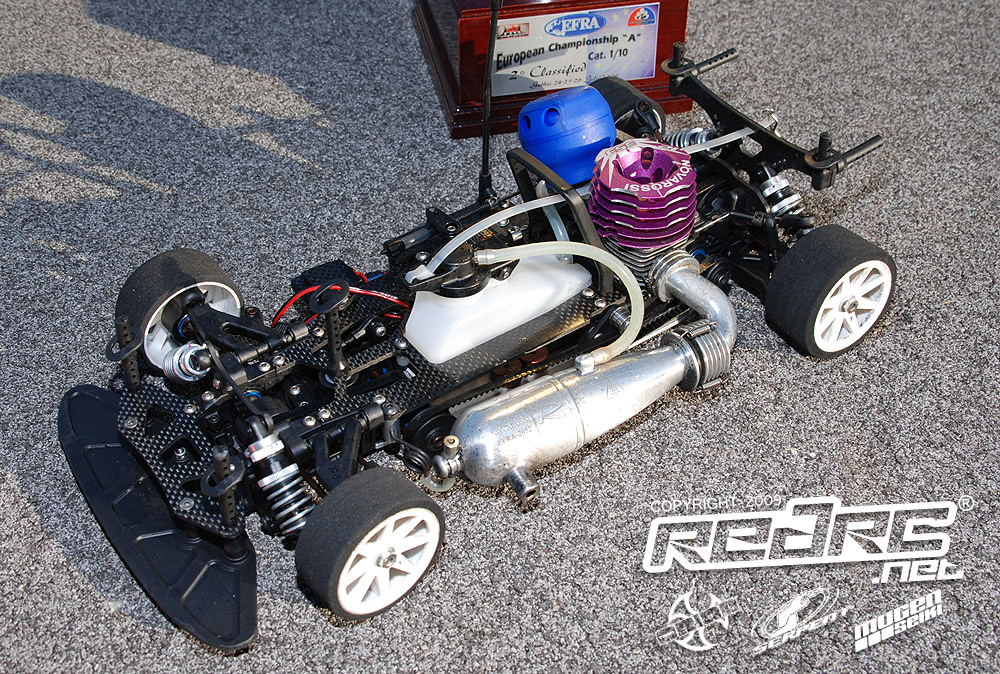

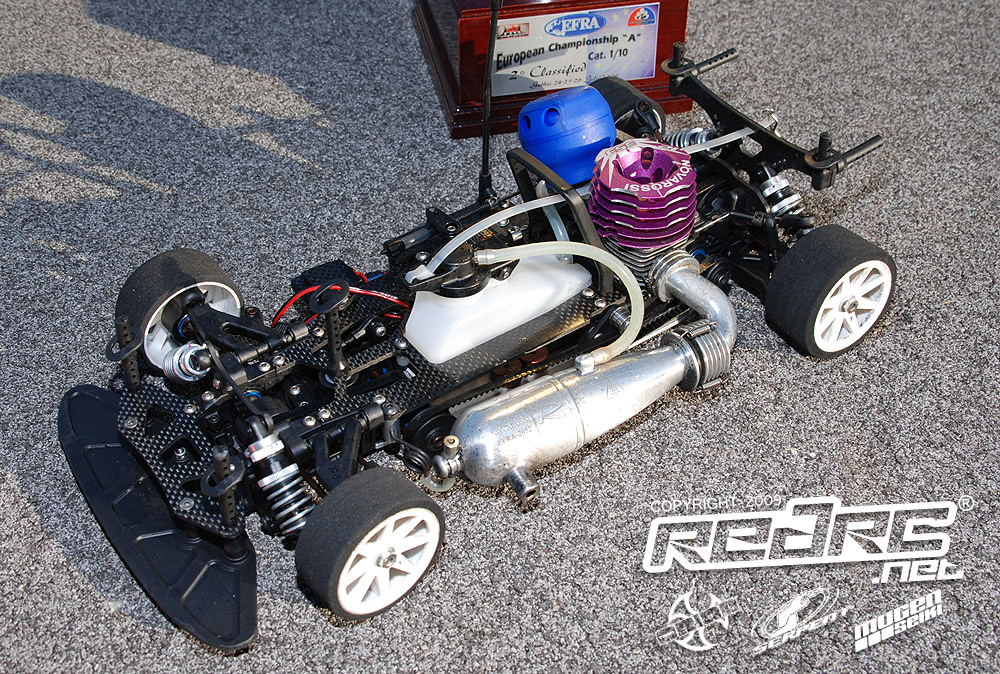

Did anyone notice that Dirk was running his Xray without a foam bumper?

And what's with the horizontal body posts at the back?

And what's with the horizontal body posts at the back?

#4357

The horizontal body posts are there to keep the body from tucking and catching on to the rear tires in case of impact. You can use front body posts or the Xray "Back stoppers."

#4358

Tech Apprentice

#4361

Hi guys I have a small issue and just wandered if anyone has come accross it, did a rebuild on my shocks tonight just the standard 08 shocks and 3 came up fine nice and smooth with good rebound but the 4th was nearly impossible to push in the shaft in I checked that the holes are all clear in the ring cap and the two fluid holes on the shaft all good but tested again and still no good?I changed over from one of the other shocks the top with membrane etc but still no good could it be a bent shaft or twisted housing?

cheers

cheers

#4362

Hi guys I have a small issue and just wandered if anyone has come accross it, did a rebuild on my shocks tonight just the standard 08 shocks and 3 came up fine nice and smooth with good rebound but the 4th was nearly impossible to push in the shaft in I checked that the holes are all clear in the ring cap and the two fluid holes on the shaft all good but tested again and still no good?I changed over from one of the other shocks the top with membrane etc but still no good could it be a bent shaft or twisted housing?

cheers

cheers

#4364

Tech Apprentice

18Likes

18Likes