Understanding F1 Tuning: Letís break it down

#257

#259

Tech Addict

I did something like that on an old ae tc3 diff. Took all the balls/plates and thrust bearing out and just drilled a couple of holes through the diff halfs. The bolt goes through the diff halfs and spur gear. Pretty sure i tapped one half so no nut required.

#260

If you take the balls out and lock the diff it will loosen unless its pinned. The biggest advantage to a spool diff would be weight loss. With 2.5 million in my gear diff it's for all practical purposes locked but its heavy. 25.5 motors lack balls they make good rpm but power is minimal so lightening the axle assembly plus the ability to hook up immediately could prove very beneficial. I just would like to try it if it's easy to use existing parts or I will just make my own to try but would prefer the later.

#262

thrust bearings slip, the cone rides on the inside ring of bearing, the outside of bearing supports the hub. To truly lock it down and tight enough so it does not loosen, it has to be cranked very tight, the load is applied to ALL components.

#266

To lock my xray differential, I removed my balls and replaced the thrust bearing with shims. No problem tightening it down. Certain spurs need modification, if they have increased width around the center hole. To save some weight, you could find some bushings to replace the two bearings between the diff halves.

Most racers at my local track are locking them in similar fashion. Haven't seen any issues with it so far.

Most racers at my local track are locking them in similar fashion. Haven't seen any issues with it so far.

#267

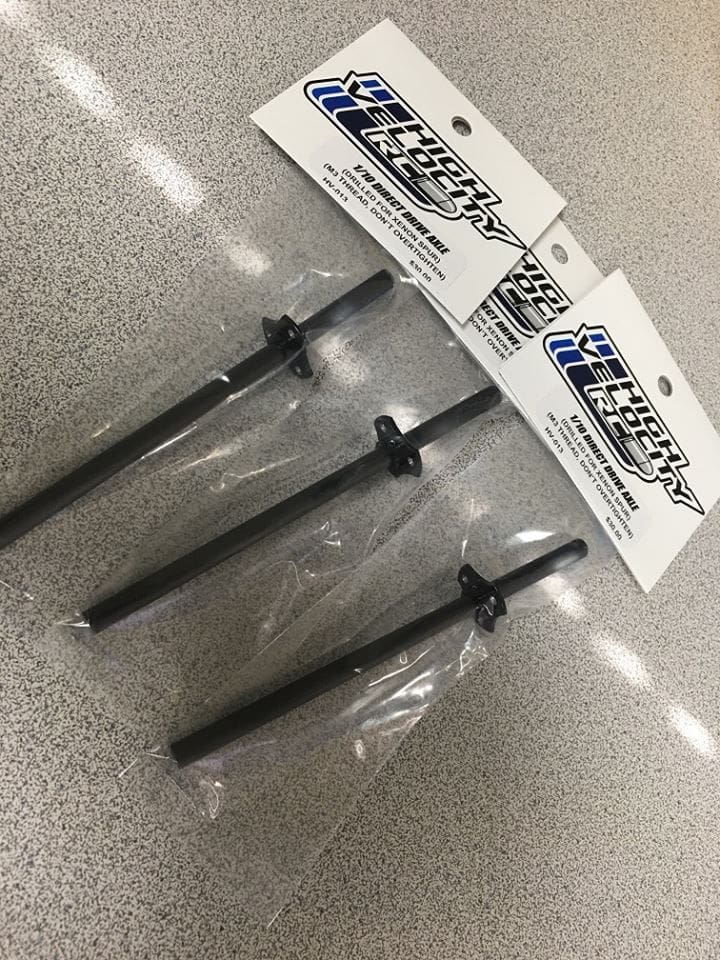

Here is a spool option.

#268

#270

430Likes

430Likes