Xray XB4 thread

#9241

Tech Regular

iTrader: (6)

Please also read the answers to these posts.

You have hundreds of people trashing on their XB4's month after month with no issues at all.

Here in Europe we run on high grip astro and carpet all the time……..with no issues at all during an entire season of racing at the highest level with boosted 4.5T motor.

People need to:

Just one of these things will affect gear life…….then add up several of them and you WILL have problems !

Material have been added by Xray to where the bearings sit in the bulkhead and to the bevel gear to prevent the gear mesh to be affected by the above points, BUT there is a limit to what you can do before the responsibility has to be on the end user to actually make sure everything is done correctly.

These cars are race vehicles and DO require some knowledge from the end user to perform at their best.

Follow these tips and you will have zero problems with gears wearing out prematurely

Enjoy your upgrade from the B44.3

Bent

You have hundreds of people trashing on their XB4's month after month with no issues at all.

Here in Europe we run on high grip astro and carpet all the time……..with no issues at all during an entire season of racing at the highest level with boosted 4.5T motor.

People need to:

- Stop over-tightening screws for the diff housing (allows the diff housing/bevel gear to expand and affect gear mesh).

- Stop overfilling their diffs (allows the diff housing/bevel gear to expand and affect gear mesh).

- Stop over-tightening screws for the bulkhead cover using electric screw drivers (allows the diff bulkhead cover to expand and affect gear mesh).

- Replace worn out bulkhead.

- Replace both pinion and bevel gear if already stripped one of the gears.

- Replace shot bearings.

- Stop cranking their slipper down way too hard and instead set their slipper according to grip level (we run 0mm on the spring/loosest setting).

- Stop using the 1/8th buggy method of cranking the throttle to get the car back on its wheels.

Just one of these things will affect gear life…….then add up several of them and you WILL have problems !

Material have been added by Xray to where the bearings sit in the bulkhead and to the bevel gear to prevent the gear mesh to be affected by the above points, BUT there is a limit to what you can do before the responsibility has to be on the end user to actually make sure everything is done correctly.

These cars are race vehicles and DO require some knowledge from the end user to perform at their best.

Follow these tips and you will have zero problems with gears wearing out prematurely

Enjoy your upgrade from the B44.3

Bent

#9242

Hi everyone,

I've just purchased my first X-Ray, XB4 16 (long time associated user) and wanted to get some build advice in respect to the extending the life of the bevel gears.

At my local track (indoor carpet) historically the XRay users chew through bevel gears all too frequently, most recently someone went through 2 in one night with their new XB4 16. This has also been the achilles heel for the 15 models as well.

Given the cost associated with replacing these gears (and the DNFing)

1. Is there a mod to avoid or eliminate this issue?

2. Is this a common problem globally?

2. Why has X-Ray not addressed this issue in the 16 model?

Thanks for your assistance

I've just purchased my first X-Ray, XB4 16 (long time associated user) and wanted to get some build advice in respect to the extending the life of the bevel gears.

At my local track (indoor carpet) historically the XRay users chew through bevel gears all too frequently, most recently someone went through 2 in one night with their new XB4 16. This has also been the achilles heel for the 15 models as well.

Given the cost associated with replacing these gears (and the DNFing)

1. Is there a mod to avoid or eliminate this issue?

2. Is this a common problem globally?

2. Why has X-Ray not addressed this issue in the 16 model?

Thanks for your assistance

The only thing I'd add, is be sure you don't forget to put the bottom two screws in the bulkhead. They're easy to forget but you will definitely have issues if you forgot to put them in.

#9243

I too my xb4 apart to clean it up and replace bearings and change diff fluid and when I put the rear end back together the suspension on the right side won't compress all the way. The shock compression stops about a 1/4" away from the full compressed position (see pic). The only thing I can think of is that I installed a new upright and idk if maybe it's not the right one? But idk if that upright is even the new one. I can't tell now.they both look the same ideas?

I've only had the buggy for a short time so idk if it was like this before I disassembled it or not. I don't think it was but can't say for sure.

I've only had the buggy for a short time so idk if it was like this before I disassembled it or not. I don't think it was but can't say for sure.

#9245

Do you know what they are supposed to be? But why would one side compress properly and not the other if they are incorrect? They do go really far into the cup though.

#9246

Since they are both so far in the outdrive, it could just be the camber is slightly different so that's causing one side to sit slightly farther in and hit. I run up travel spacers so the shock bottoms out before the driveshaft does, preventing them from binding up.

68 is the correct size for the rear driveshafts.

68 is the correct size for the rear driveshafts.

#9247

I don't know if they are the right ones or not. Like I said I bought this roller from someone. I raced it a couple times and I am just now going through it. I am not home right now but if I remember right I think they said Hudy Spring Steel 68mm. Because originally that is what I thought is that it was bottoming out on the outdrive cup because I could feel it on the other side pushing when I compressed that one side.

Do you know what they are supposed to be? But why would one side compress properly and not the other if they are incorrect? They do go really far into the cup though.

Do you know what they are supposed to be? But why would one side compress properly and not the other if they are incorrect? They do go really far into the cup though.

Bent

#9249

Since they are both so far in the outdrive, it could just be the camber is slightly different so that's causing one side to sit slightly farther in and hit. I run up travel spacers so the shock bottoms out before the driveshaft does, preventing them from binding up.

68 is the correct size for the rear driveshafts.

68 is the correct size for the rear driveshafts.

I don't right now. But I can post it around 6 tonight when I get home from work.

#9251

I was also wondering is it the norm to shim the diffs on the XB4? I didn't get this as a kit so I don't know if shims came in the kit or not but there are none in my gear boxes from when the previous owner built it. All my teknos had shims supplied to shim the diffs. My pinion and diff gear seem fine I am just wondering for future reference.

#9252

I was also wondering is it the norm to shim the diffs on the XB4? I didn't get this as a kit so I don't know if shims came in the kit or not but there are none in my gear boxes from when the previous owner built it. All my teknos had shims supplied to shim the diffs. My pinion and diff gear seem fine I am just wondering for future reference.

The only shims used go inside the diff for the planetary and sattelite gears.

Bent

#9253

Where would those spacers go? Do you have a pic or a page# from the manual? Or do you mean up travel spacers in the shock body itself? Do you have a link to what you are using for these? or a part number?

I don't right now. But I can post it around 6 tonight when I get home from work.

I don't right now. But I can post it around 6 tonight when I get home from work.

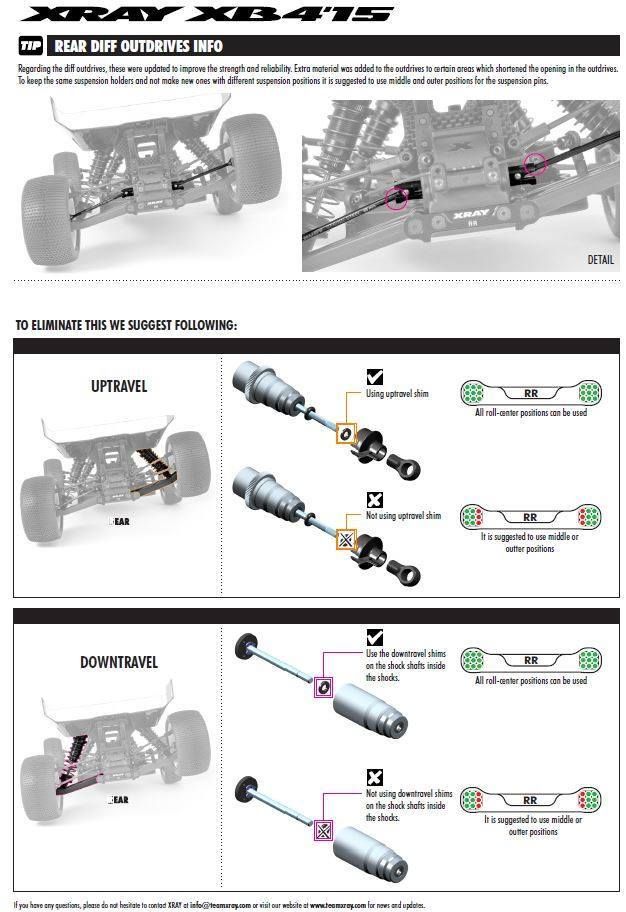

Included in the kit is plastic shims of 1mm, 2mm and 3mm (part #306219).

Depending on the position of the shocks, hinge pin inserts and camber links the number of shims required will vary.

Us the number of shims that keep the drive shaft from hitting the outdrive on full up and down travel.

This applies to both the front and rear shocks of course.

Bent

#9254

#9255

Bentka,

I am thinking about purchasing the brass rear hanger set for my 16 XB4. Just wanted to get your input on how much they will benefit the buggy on loose bite track conditions.

Would you happen to know how many extra grams of weight they will add.

With your early advice to run my 16 XB4 with the motor in its spec kit position first over the rear position has me wondering about just adding the brass hangers for the extra weight.

As always Bentka I appreciate your help and thus sharing set up advise.

Best,

Norse

I am thinking about purchasing the brass rear hanger set for my 16 XB4. Just wanted to get your input on how much they will benefit the buggy on loose bite track conditions.

Would you happen to know how many extra grams of weight they will add.

With your early advice to run my 16 XB4 with the motor in its spec kit position first over the rear position has me wondering about just adding the brass hangers for the extra weight.

As always Bentka I appreciate your help and thus sharing set up advise.

Best,

Norse

248Likes

248Likes