Team Associated TC6 Thread

Tech Master

iTrader: (62)

Generally you can get binding in your drive train from a number of source. You should check that as you build the car. I would start by removing the tires, drive hex, pins and shims. Then spin the drive train to see if it feels looser. That would give you a good starting point.

Tech Addict

iTrader: (5)

Anybody know the fix for the TC6.1 servo saver popping loose/off? I'm sure it's been covered however I could not find it in a search.

That's 2 weeks in a row now. The first week it popped loose after 3 rounds, the car was newly assembled. The second time, today. I had locktite'd the thread and cap, but no use. It popped off first round...

What's the solution? Is there a West/South conversion, kit?

That's 2 weeks in a row now. The first week it popped loose after 3 rounds, the car was newly assembled. The second time, today. I had locktite'd the thread and cap, but no use. It popped off first round...

What's the solution? Is there a West/South conversion, kit?

Anybody know the fix for the TC6.1 servo saver popping loose/off? I'm sure it's been covered however I could not find it in a search.

That's 2 weeks in a row now. The first week it popped loose after 3 rounds, the car was newly assembled. The second time, today. I had locktite'd the thread and cap, but no use. It popped off first round...

What's the solution? Is there a West/South conversion, kit?

That's 2 weeks in a row now. The first week it popped loose after 3 rounds, the car was newly assembled. The second time, today. I had locktite'd the thread and cap, but no use. It popped off first round...

What's the solution? Is there a West/South conversion, kit?

Tech Addict

iTrader: (5)

Are you talking about the spring tension nut? If so, thread locker should work but you have to let it setup for 24 hours or so. I'm not sure what you mean by "popped off" as it sounds like something should first be popped on before it can pop off. I used to make a 90* saver cam to go along with my floating servo mount but it's a bit expensive to make at this time so I stopped.

) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.

) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.I actually purchased your Floating servo mount, but don't know what else is required with the kit to convert he 6.1 over.

Hi Rick, yes the spring tension nut spun off (popped  ) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.

) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.

I actually purchased your Floating servo mount, but don't know what else is required with the kit to convert he 6.1 over.

) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.

) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.I actually purchased your Floating servo mount, but don't know what else is required with the kit to convert he 6.1 over.

Now for the servo mount... You will need 1 short AE ball stud (the black one I believe) with 8mm length threads. This will replace the button head screw used on the Ackerman adjustment. You will need 1 AE long ball cup like the ones used on their off road kits. I use these from time to time so they are good to have on hand. With these 2 parts, you will be able to connect the servo to the steering directly. Everything else is either being used already or at least came with your kit like 1 of the factory servo mounts and spacers to get your servo into the right position. I can send some pics if that will help.

Tech Addict

iTrader: (1)

Hi Rick, yes the spring tension nut spun off (popped  ) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.

) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.

I actually purchased your Floating servo mount, but don't know what else is required with the kit to convert he 6.1 over.

) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.

) I did use thread locker and let it set up over a week. Maybe I need to use lots more, or even Red.I actually purchased your Floating servo mount, but don't know what else is required with the kit to convert he 6.1 over.

I cannot send my 6.1 into retirement

It now is the base for a (maybe strange) conversion. The idea is to have an ultraflat 4-wheel-drive chassis with a 235mm pan car body

Nearly two years ago I showed how to fit flat bodies (GT and/or Pan) on the TC6 chassis. I will use this idea and combine it with ridiculous wide foam tires to get this:

Still a lot to do. Body and servo mount (need one more) are ordered. Then I have to adapt to the body width with spacers under the suspension mounts and hexes. The front has 215mm already, the rear can be 227mm

I just hope the front is low enough to fit under the body...

In the end this thing shall break track records and be fun!

It now is the base for a (maybe strange) conversion. The idea is to have an ultraflat 4-wheel-drive chassis with a 235mm pan car body

Nearly two years ago I showed how to fit flat bodies (GT and/or Pan) on the TC6 chassis. I will use this idea and combine it with ridiculous wide foam tires to get this:

Still a lot to do. Body and servo mount (need one more) are ordered. Then I have to adapt to the body width with spacers under the suspension mounts and hexes. The front has 215mm already, the rear can be 227mm

I just hope the front is low enough to fit under the body...

In the end this thing shall break track records and be fun!

Tech Fanatic

iTrader: (1)

Front tires too wide.

Use max 30mm from regular 1/10 nitro car

Use max 30mm from regular 1/10 nitro car

I cannot send my 6.1 into retirement

It now is the base for a (maybe strange) conversion. The idea is to have an ultraflat 4-wheel-drive chassis with a 235mm pan car body

Nearly two years ago I showed how to fit flat bodies (GT and/or Pan) on the TC6 chassis. I will use this idea and combine it with ridiculous wide foam tires to get this:

Still a lot to do. Body and servo mount (need one more) are ordered. Then I have to adapt to the body width with spacers under the suspension mounts and hexes. The front has 215mm already, the rear can be 227mm

I just hope the front is low enough to fit under the body...

In the end this thing shall break track records and be fun!

It now is the base for a (maybe strange) conversion. The idea is to have an ultraflat 4-wheel-drive chassis with a 235mm pan car body

Nearly two years ago I showed how to fit flat bodies (GT and/or Pan) on the TC6 chassis. I will use this idea and combine it with ridiculous wide foam tires to get this:

Still a lot to do. Body and servo mount (need one more) are ordered. Then I have to adapt to the body width with spacers under the suspension mounts and hexes. The front has 215mm already, the rear can be 227mm

I just hope the front is low enough to fit under the body...

In the end this thing shall break track records and be fun!

Trust me I am not an engineer

Tech Addict

iTrader: (5)

Does it seem like the nut is stripped or maybe just loose? once you have it set (pretty tight) you are not likely going to reset it. Tighten the nut and apply a little CA glue.

Now for the servo mount... You will need 1 short AE ball stud (the black one I believe) with 8mm length threads. This will replace the button head screw used on the Ackerman adjustment. You will need 1 AE long ball cup like the ones used on their off road kits. I use these from time to time so they are good to have on hand. With these 2 parts, you will be able to connect the servo to the steering directly. Everything else is either being used already or at least came with your kit like 1 of the factory servo mounts and spacers to get your servo into the right position. I can send some pics if that will help.

Now for the servo mount... You will need 1 short AE ball stud (the black one I believe) with 8mm length threads. This will replace the button head screw used on the Ackerman adjustment. You will need 1 AE long ball cup like the ones used on their off road kits. I use these from time to time so they are good to have on hand. With these 2 parts, you will be able to connect the servo to the steering directly. Everything else is either being used already or at least came with your kit like 1 of the factory servo mounts and spacers to get your servo into the right position. I can send some pics if that will help.

Okay, I have applied a load of Loctite, it has sat for a week now. I'll try it this weekend. The threads look fine, it's just coming loose.

The servo saver cleared the top tray?

I cannot send my 6.1 into retirement

It now is the base for a (maybe strange) conversion. The idea is to have an ultraflat 4-wheel-drive chassis with a 235mm pan car body

Nearly two years ago I showed how to fit flat bodies (GT and/or Pan) on the TC6 chassis. I will use this idea and combine it with ridiculous wide foam tires to get this:

Still a lot to do. Body and servo mount (need one more) are ordered. Then I have to adapt to the body width with spacers under the suspension mounts and hexes. The front has 215mm already, the rear can be 227mm

I just hope the front is low enough to fit under the body...

In the end this thing shall break track records and be fun!

It now is the base for a (maybe strange) conversion. The idea is to have an ultraflat 4-wheel-drive chassis with a 235mm pan car body

Nearly two years ago I showed how to fit flat bodies (GT and/or Pan) on the TC6 chassis. I will use this idea and combine it with ridiculous wide foam tires to get this:

Still a lot to do. Body and servo mount (need one more) are ordered. Then I have to adapt to the body width with spacers under the suspension mounts and hexes. The front has 215mm already, the rear can be 227mm

I just hope the front is low enough to fit under the body...

In the end this thing shall break track records and be fun!

Need some info please...searched google and this forum and see it talked about but not how to do it. I have a 6.1 and as of yesterday my large belt falls off after a couple laps. I dont see how to tighten the belt? I am fairly new to RC so any help will be appreciated..Even a link on how to..thanks in advance

Need some info please...searched google and this forum and see it talked about but not how to do it. I have a 6.1 and as of yesterday my large belt falls off after a couple laps. I dont see how to tighten the belt? I am fairly new to RC so any help will be appreciated..Even a link on how to..thanks in advance

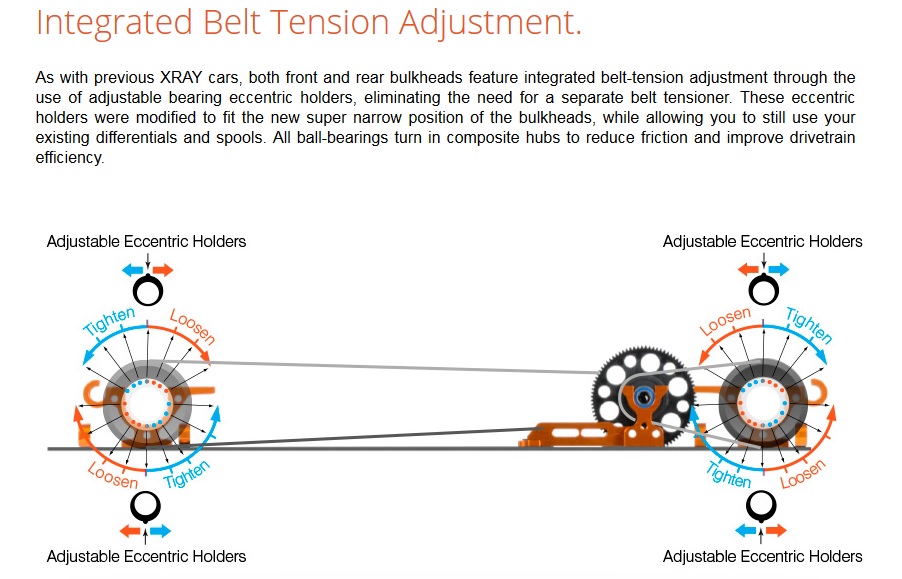

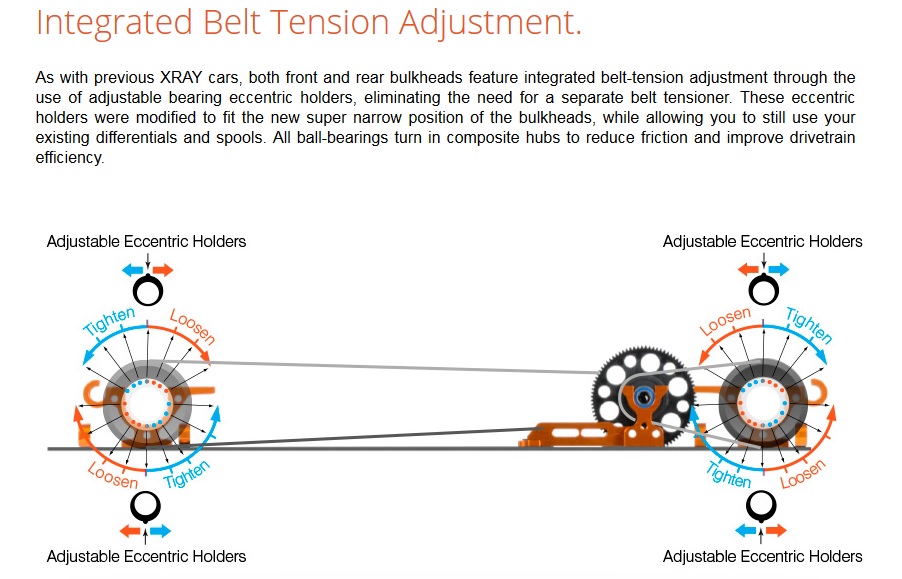

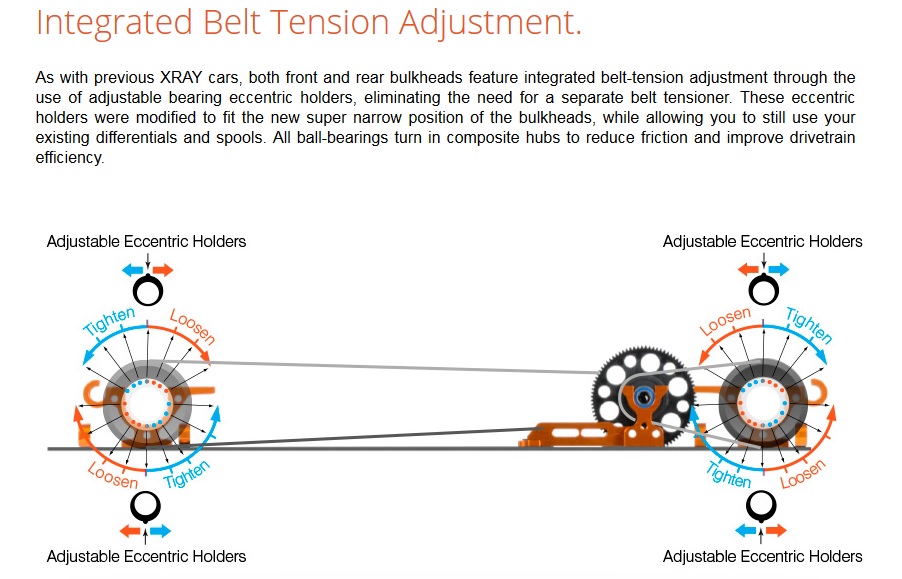

Here is an example illustration from Xray which uses the same design, simply remove the upper bulk head and rotate the bearing holder in the respective direction in order to tighten it... if you max out the adjustment and the belt is still loose, then it's time to replace the belt as it has stretched out too far:

thanks for the info...the bearing holder looks like it is 2 piece? do i rotate like a ratchet (like with a little force)..or simply rotate it and reinstall the bulk head? I took it apart yesterday and it just seems like it wants to lift out of the bearing holder and only fits in there one oblong way...lol sorry i told you i was a newb..

yes, lift it out of the bulkhead, rotate it, then re-insert the bearing holder so that each notch is in the same slot on both sides of the bulk head. Keep increasing one slot at a time until you reach the desired tension. With the TC6... I think the grooves are inside the plastic bearing holder itself... same concept with XRay.

20Likes

20Likes