LC Racing EMB-1H Official Thread

#1096

In the Truggy, after trying 300cst and 400cst on the truggy, Rear to Front with the kit pistons and springs ended up going 500cst rear and 650cst front, remaining still stock.

Will see how it goes, I may see about getting another piston set to modify as I think stock its a 4 hole piston now, and a 3 hole would work better from a pack perspective I am thinking for carpet.

Will see how it goes, I may see about getting another piston set to modify as I think stock its a 4 hole piston now, and a 3 hole would work better from a pack perspective I am thinking for carpet.

#1097

had a good day of running the truggies to test them out.

Few things to run by the group:

- Daughter was able to detach the front spindle on a hit from the carrier intact. I bolted it up again, I am assuming this is an area to go with the cnc parts, should it be the carrier or the spindle, or both?

- Buddy had a rear dogbone pop out, cvd time?

- noticed some "chatter" in the wheels upon turning, thinking this is due to the stock servo saver setting. We are running the metal gear servos, what do you recommend to tigthen the saver up to? (stock i think is like 1mm)

- should get the alloy steering components?

- who makes an alloy servo horn that could be minimally modified?

Few things to run by the group:

- Daughter was able to detach the front spindle on a hit from the carrier intact. I bolted it up again, I am assuming this is an area to go with the cnc parts, should it be the carrier or the spindle, or both?

- Buddy had a rear dogbone pop out, cvd time?

- noticed some "chatter" in the wheels upon turning, thinking this is due to the stock servo saver setting. We are running the metal gear servos, what do you recommend to tigthen the saver up to? (stock i think is like 1mm)

- should get the alloy steering components?

- who makes an alloy servo horn that could be minimally modified?

#1098

had a good day of running the truggies to test them out.

Few things to run by the group:

- Daughter was able to detach the front spindle on a hit from the carrier intact. I bolted it up again, I am assuming this is an area to go with the cnc parts, should it be the carrier or the spindle, or both?

- Buddy had a rear dogbone pop out, cvd time?

- noticed some "chatter" in the wheels upon turning, thinking this is due to the stock servo saver setting. We are running the metal gear servos, what do you recommend to tigthen the saver up to? (stock i think is like 1mm)

- should get the alloy steering components?

- who makes an alloy servo horn that could be minimally modified?

Few things to run by the group:

- Daughter was able to detach the front spindle on a hit from the carrier intact. I bolted it up again, I am assuming this is an area to go with the cnc parts, should it be the carrier or the spindle, or both?

- Buddy had a rear dogbone pop out, cvd time?

- noticed some "chatter" in the wheels upon turning, thinking this is due to the stock servo saver setting. We are running the metal gear servos, what do you recommend to tigthen the saver up to? (stock i think is like 1mm)

- should get the alloy steering components?

- who makes an alloy servo horn that could be minimally modified?

#1099

Tech Apprentice

I ran aluminum spindle and carrier, cvds are a good upgrade early, and I ran the servo saver tighter than most but risks servo and that helped with chatter and wandering (threadlock in place). never ran the alloy steering, but something needs to break in a crash lol. leave the horn plastic, just find a good one.

I was tired of always popping and putting the front end back together(cause I'm a terrible driver) and the Track i was at was for 1/10th so the landings were often hard.

So, https://tboneracing.net/collections/...per-tacon-soar pretty much fixed all of my problems.

It still let me line up jumps and take off at any angle, but on the way down - it really helped from ripping a wheel off.

#1100

thanks for the info!

strodedawg, when you say you use threadlock, are you talking about on the adjustment nut so the spring doesn't back out?

Yeah I am thinking then getting the carrier at a minimum.

Anyone thing the rear hubs could use the alloy treatment?

As for the dogbone popping out, I am thinking maybe some fuel tubing or some orings to keep them in place? say some on the either diff cup or axle side so they don't push in too much and alloy flex to have them pop free. Maybe the diff cup.

strodedawg, when you say you use threadlock, are you talking about on the adjustment nut so the spring doesn't back out?

Yeah I am thinking then getting the carrier at a minimum.

Anyone thing the rear hubs could use the alloy treatment?

As for the dogbone popping out, I am thinking maybe some fuel tubing or some orings to keep them in place? say some on the either diff cup or axle side so they don't push in too much and alloy flex to have them pop free. Maybe the diff cup.

#1102

yeah we as a group will probably need to see about getting an order of them, but in the mean time I am thinking the tubing or o-ring stuff could be an option. I am going to at least try it out as it reminds of when I had the academy vehicles, one had the same problem. so o-rings took care of that.

Oh, one other thing, my daughter who likes to hit stuff was popping off the ball cups. It was understanderable but I am wondering if there are better ball cup options to put on that offer a pass thru for the 2mm wrench for easy stud removal, or, an RPM option if not.

Oh, one other thing, my daughter who likes to hit stuff was popping off the ball cups. It was understanderable but I am wondering if there are better ball cup options to put on that offer a pass thru for the 2mm wrench for easy stud removal, or, an RPM option if not.

#1104

Tech Apprentice

Has Thumb RC run Black Friday or Cyber Monday sales in the past?

#1105

Rear hubs definitely don't need aluminum. I've broken the stock plastic spindles and spindle carriers twice on my truggy. They break were the screws thread in to hold the carrier and spindle together. These were both after hard hits where the pressure was concentrated on them, I hit a car tire at an angle and the other time a curb at an angle.

#1106

Thanks! Have you drilled them at all so you can access the ball stud via a hex driver or does it matter with the RPM ends (they don't slop out basically by being put on and off)

Thanks. We are looking to do an order of parts here so looking for upgrade items to grab. The rear hubs in plastic seem fine.

I may have an option to help keep the front spindles and carriers together. Looking at the issue my daughter had, it appears that the screw is just small enough that with enough flex in the hub carrier it can pull through the hole. I ended up sourcing a 0.25mm shim that is slightly larger than the screw head and looks to take up the size of the opening. I went with the small size for clearance on a buggy as the screw sizes available it looked like I needed to use the stock screw for now to get clearance right for what i had on hand.

However, for a truggy wheel size, going with same a 1mm shim would be fine and a longer screw. This should in theory help with any pulling through.

We did our practice session yesterday, we still need to do some work on getting the carpet to sit down properly as it was shifting, but running the vehicles I was able to setup, they performed well. I ended up with the following so far for setup:

Buggy

* NOTE: Has Tenshock motor, Metal Gear servo as upgrades

- did the little spring in the diff cup mod to keep the rear bones in

- 500cst Front, 400cst Rear PT Racing Oils

- Stock pistons look to be 4 x 1.0 pistons

- 7K front, 3K rear diff

- Front shocks inner hole on tower, outer hole on arm

- Rear shocks outer hole on tower, outer hole on arm

- Front camber link upper position on tower

- Rear camber link lowest position on tower, longer position on hub carrier

- 1.2mm sway bars front and rear

- LC Racing Rally car tires, unsauced, no gluing

The buggy drove well. The tires did provide a ton of grip but as they broke in they allowed more of a drift feel. I am thinking gluing the outer edge of the fronts and maybe trying the next higher sway bar front and rear will do the trick. But I could easily put down some seriously fast lap times. These vehicles just haul!

Truggy

- 650cst Front, 500cst Rear PT Racing Oils

- Stock pistons look to be 4 x 1.0 pistons

- 7K front, 3K rear diff

- Front shocks inner hole on tower, outer hole on arm

- Rear shocks outer hole on tower, outer hole on arm

- Front camber link upper position on tower

- Rear camber link lowest position on tower, longer position on hub carrier

- 1.2mm sway bars front and rear

- LC Racing stock tires

This also worked well, but the stock tires are a bit too grippy for the surface. A buddy of mine ran the widening adapters with buggy primes and it worked excellent so I am going to go to that as well as a stiffer swaybar setup, I will also do the spring-diff cup mod to keep the bones in.

The only issues that popped up were popping ball ends off, a squeaking coming from possibly a bad bearing in the rear of the buggy, and one of the pistons came free on the buggy front end (hate eclips).

But outside of that, real winners here. A guy who came out with a RTR LC Racing SCT had it going fairly well. Not a fan of the kit radio needs a few more features but it did the job.

I may also pick up some of the mini-8ight springs here, just not sure the stiffness in comparison to what is stock on the vehicles right now.

Rear hubs definitely don't need aluminum. I've broken the stock plastic spindles and spindle carriers twice on my truggy. They break were the screws thread in to hold the carrier and spindle together. These were both after hard hits where the pressure was concentrated on them, I hit a car tire at an angle and the other time a curb at an angle.

I may have an option to help keep the front spindles and carriers together. Looking at the issue my daughter had, it appears that the screw is just small enough that with enough flex in the hub carrier it can pull through the hole. I ended up sourcing a 0.25mm shim that is slightly larger than the screw head and looks to take up the size of the opening. I went with the small size for clearance on a buggy as the screw sizes available it looked like I needed to use the stock screw for now to get clearance right for what i had on hand.

However, for a truggy wheel size, going with same a 1mm shim would be fine and a longer screw. This should in theory help with any pulling through.

We did our practice session yesterday, we still need to do some work on getting the carpet to sit down properly as it was shifting, but running the vehicles I was able to setup, they performed well. I ended up with the following so far for setup:

Buggy

* NOTE: Has Tenshock motor, Metal Gear servo as upgrades

- did the little spring in the diff cup mod to keep the rear bones in

- 500cst Front, 400cst Rear PT Racing Oils

- Stock pistons look to be 4 x 1.0 pistons

- 7K front, 3K rear diff

- Front shocks inner hole on tower, outer hole on arm

- Rear shocks outer hole on tower, outer hole on arm

- Front camber link upper position on tower

- Rear camber link lowest position on tower, longer position on hub carrier

- 1.2mm sway bars front and rear

- LC Racing Rally car tires, unsauced, no gluing

The buggy drove well. The tires did provide a ton of grip but as they broke in they allowed more of a drift feel. I am thinking gluing the outer edge of the fronts and maybe trying the next higher sway bar front and rear will do the trick. But I could easily put down some seriously fast lap times. These vehicles just haul!

Truggy

- 650cst Front, 500cst Rear PT Racing Oils

- Stock pistons look to be 4 x 1.0 pistons

- 7K front, 3K rear diff

- Front shocks inner hole on tower, outer hole on arm

- Rear shocks outer hole on tower, outer hole on arm

- Front camber link upper position on tower

- Rear camber link lowest position on tower, longer position on hub carrier

- 1.2mm sway bars front and rear

- LC Racing stock tires

This also worked well, but the stock tires are a bit too grippy for the surface. A buddy of mine ran the widening adapters with buggy primes and it worked excellent so I am going to go to that as well as a stiffer swaybar setup, I will also do the spring-diff cup mod to keep the bones in.

The only issues that popped up were popping ball ends off, a squeaking coming from possibly a bad bearing in the rear of the buggy, and one of the pistons came free on the buggy front end (hate eclips).

But outside of that, real winners here. A guy who came out with a RTR LC Racing SCT had it going fairly well. Not a fan of the kit radio needs a few more features but it did the job.

I may also pick up some of the mini-8ight springs here, just not sure the stiffness in comparison to what is stock on the vehicles right now.

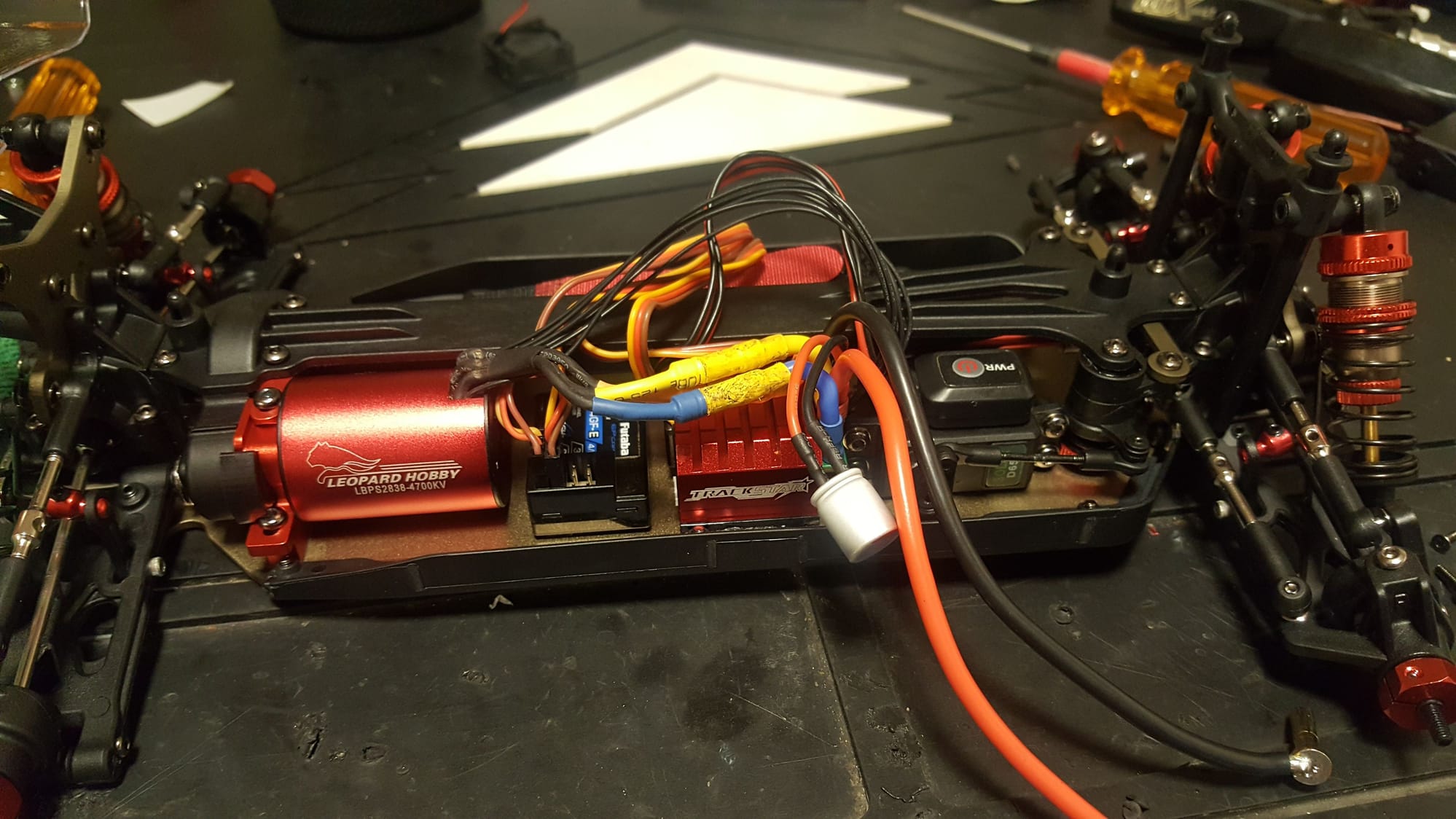

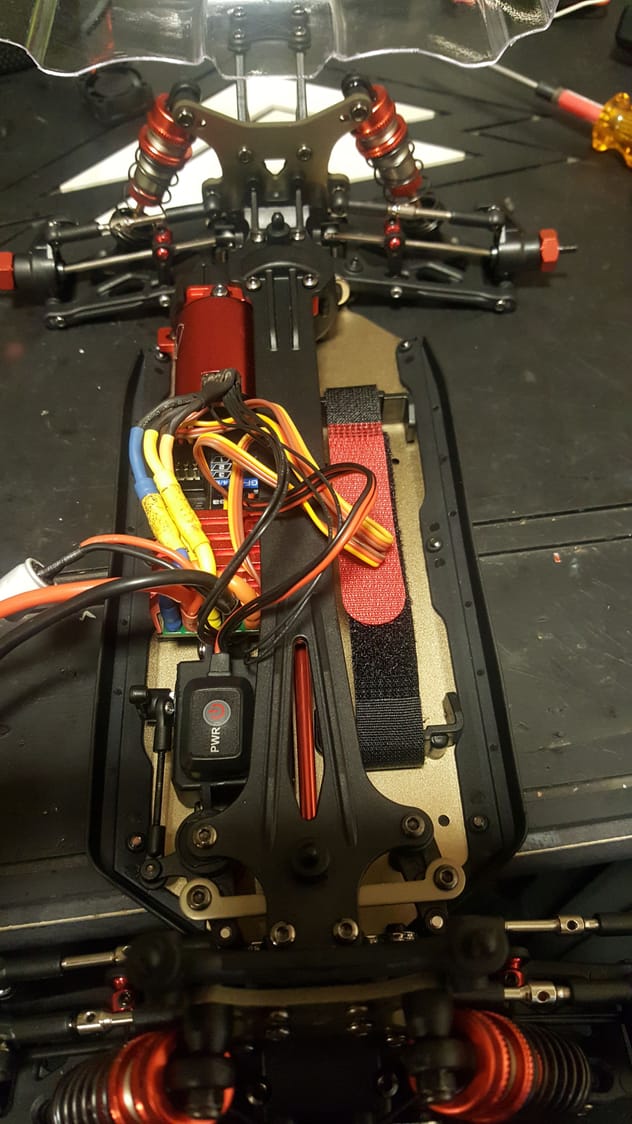

#1107

Such an awesome thread guys! Very helpful. Been reading as I can and so far on page 45 lol.

I just put together my truggy last night (didn't see a dedicated thread for it) and wow it's amazing. We have 2 M8T from losi and found the quality from the LC is so much nicer. The truck rolls super smooth to. I did the bearing upgrade on the rear pinion on the diff housing at the same time.

The truck setup so far is

45/40 f/r shock oil

7k/3k f/r diff fluid

Leopard hobby 4700kv 4 pole sensored motor

Turnigy trackstar 60a esc

17t pinion stock spur

1.5 camber all around

1* of toe in

Jconcepts b5m wing

I drove the truck really quick last night outside and damn is super smooth and quiet!

If you guys have any tips or tricks I should do for off-road racing please let me know!

I also will be getting another truggy kit and converting it into the LWB buggy since the short buggy wouldn't do to well on some tracks out here.

I just put together my truggy last night (didn't see a dedicated thread for it) and wow it's amazing. We have 2 M8T from losi and found the quality from the LC is so much nicer. The truck rolls super smooth to. I did the bearing upgrade on the rear pinion on the diff housing at the same time.

The truck setup so far is

45/40 f/r shock oil

7k/3k f/r diff fluid

Leopard hobby 4700kv 4 pole sensored motor

Turnigy trackstar 60a esc

17t pinion stock spur

1.5 camber all around

1* of toe in

Jconcepts b5m wing

I drove the truck really quick last night outside and damn is super smooth and quiet!

If you guys have any tips or tricks I should do for off-road racing please let me know!

I also will be getting another truggy kit and converting it into the LWB buggy since the short buggy wouldn't do to well on some tracks out here.

#1109

#1110

The pics are before started to clean the wires up.

595Likes

595Likes