TC3 Forum

TC3 is a great VTA car. I finished 6th overall at the VTA nats with my TC3/Tekin/Pegasus Mustang. (With a little more luck, could have finished as high as 4th)

----------

On the front of my VTA TC3 I'm using version 2 a-arms (2 lower mounting holes). I had to file down the "bump" on the a-arm where the inside part of the caster block hits the a-arm (where the outside lower screw goes). Once I filed that part of the arm at a 45 degree angle, I gained back some down travel on the front arms. If you look at the previous front a-arms, they didn't have that "clearance" issue.

Another issue that can occur with the front a-arms is binding with the ball cups on the top of the caster blocks. Remove the front turnbuckles/camber links and see if the front a-arms drop down as needed. If you are using after-market or non-associated ball cups, try switching to associated ball cups on this part of the car. This should help with down travel.

If you are having issues with the rear arms not having enough down travel, make sure you don't have binding in the suspension parts. The molds on the TC3 aren't perfect and might require some filing to make everything move freely. I usually file a bit off the ends of the rear uprights and/or the a-arms to make sure they a free.

Spending some time making sure the TC3 suspension is free will make the car handle better. Also a little slop in the suspension doesn't seem to affect the handling on the car.

----------

On the front of my VTA TC3 I'm using version 2 a-arms (2 lower mounting holes). I had to file down the "bump" on the a-arm where the inside part of the caster block hits the a-arm (where the outside lower screw goes). Once I filed that part of the arm at a 45 degree angle, I gained back some down travel on the front arms. If you look at the previous front a-arms, they didn't have that "clearance" issue.

Another issue that can occur with the front a-arms is binding with the ball cups on the top of the caster blocks. Remove the front turnbuckles/camber links and see if the front a-arms drop down as needed. If you are using after-market or non-associated ball cups, try switching to associated ball cups on this part of the car. This should help with down travel.

If you are having issues with the rear arms not having enough down travel, make sure you don't have binding in the suspension parts. The molds on the TC3 aren't perfect and might require some filing to make everything move freely. I usually file a bit off the ends of the rear uprights and/or the a-arms to make sure they a free.

Spending some time making sure the TC3 suspension is free will make the car handle better. Also a little slop in the suspension doesn't seem to affect the handling on the car.

What spring rates do you guys use in VTA?

I used the kit springs and oil on my TC3 and they worked awesome.

Thanks for the reply IndyRC_Racer - I'll look into that this weekend!

Yep...found binding in the suspension. A little shaving here and there and it's all good now. Thanks for the tip!

I also was curious what the advantages are of running a rear shock tower on the front? I've seen this mentioned before but no real explanation of the advantages and why you would want to do this.

I also was curious what the advantages are of running a rear shock tower on the front? I've seen this mentioned before but no real explanation of the advantages and why you would want to do this.

The rear shock tower on the front gives you more positions to mount your front shocks.

The rear tower on the front primarily decreases overall shock downtravel, and the shock positions offer more stability so the car transitions smoothly. Some would say the rear tower on the front would make a car 'pushy', but that can also be driver setup/preference.

Ok, thanks DaveW. Maybe I'll give it a shot next weekend and see how I like it.

Is anyone interested in a DIY to change your Tc3 into a Tc3.5?

Basically, you use the Tc3 tub, steering rack, and suspension mounts. The rest comes off of a Tc4 (including arms, hingepins, etc), and is pretty damn tough. It also allows you to use modified Tc4 suspension mount shims for rollcenter adjustment, when combined with the optional Tc3 suspension mounts.

The best part is the chassis gets to shine once more with its lack of flex in comparison to the Tc4 tub. So far my only complaint, is the loss of a spur gear because i didnt double check the motor clamp tightness (Tc3 quirk). Overall, the car generates a lot of lateral grip and rear bite on sunny asphalt. With the small spur gears required for todays LiPo/brushless setups, chassis balance isnt much of an issue anymore.

Anyways, let me know. Ill take pics of the modified parts, and then show them assembled. I have three more parts that arent finished yet, but they solve something else about the car i havent liked for a while now. Ill include those as well once theyre done.

Basically, you use the Tc3 tub, steering rack, and suspension mounts. The rest comes off of a Tc4 (including arms, hingepins, etc), and is pretty damn tough. It also allows you to use modified Tc4 suspension mount shims for rollcenter adjustment, when combined with the optional Tc3 suspension mounts.

The best part is the chassis gets to shine once more with its lack of flex in comparison to the Tc4 tub. So far my only complaint, is the loss of a spur gear because i didnt double check the motor clamp tightness (Tc3 quirk). Overall, the car generates a lot of lateral grip and rear bite on sunny asphalt. With the small spur gears required for todays LiPo/brushless setups, chassis balance isnt much of an issue anymore.

Anyways, let me know. Ill take pics of the modified parts, and then show them assembled. I have three more parts that arent finished yet, but they solve something else about the car i havent liked for a while now. Ill include those as well once theyre done.

Tech Regular

iTrader: (7)

Hurry Up will ya

LOL aight. Ill tear it down and do the pix this week. Prolly Tuesday. Its gettin put back together right now to hopefully race tomorrow.

Tech Addict

iTrader: (12)

Hell yeah its nice to see people still rockin the TC3. I just got mine setup brushless style. I'll post pics of my set up later

Yep, the Tc3 holds its own in LiPo/brushless format... but needs a little work for the setups lighter weight. My car was 1390 ready to run w/o a body this past weekend... no added weight.

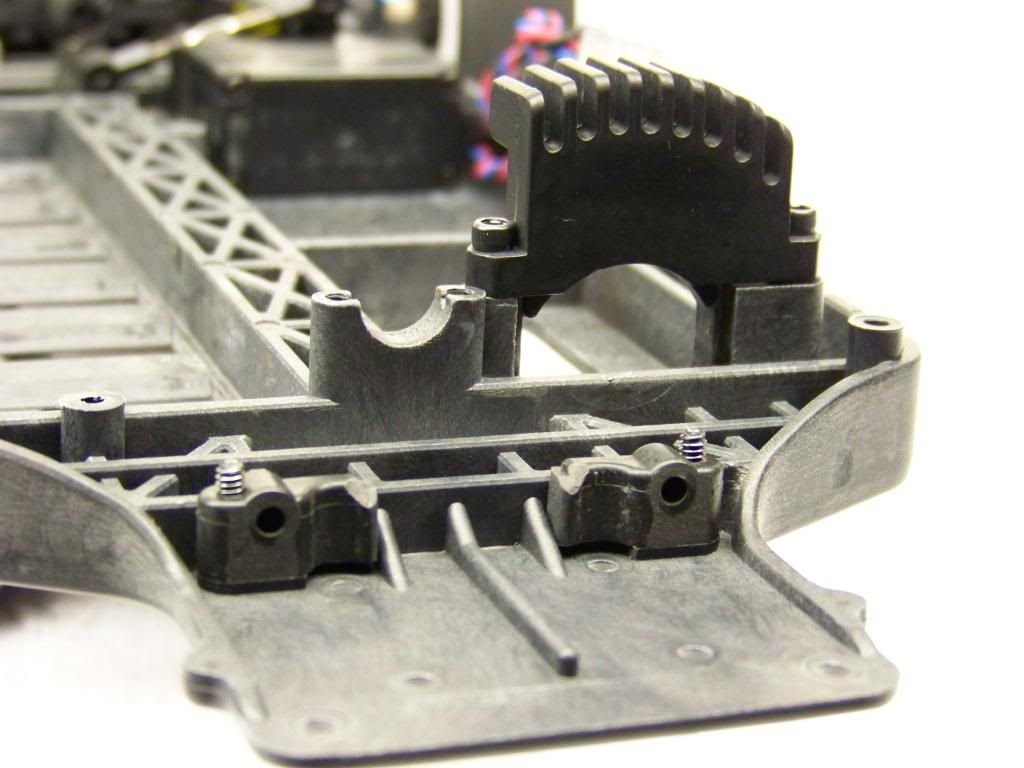

Ok as promised, pix of my modded Tc3. This collectively took me 12 hours to complete. I apologize for the pix, my camera doesnt have a Macro lense or the greatest light sensor.

To do these mods, all you will need are the obvious Tc4 parts, two NEW drillbits, a pair of mics, a pin vise, a flat sanding surface with 400 grit paper, a dremel with reinforced cutting wheel and sanding drum, and MISC screws to complete the conversion. Oh yeah... some patience goes a long way too.

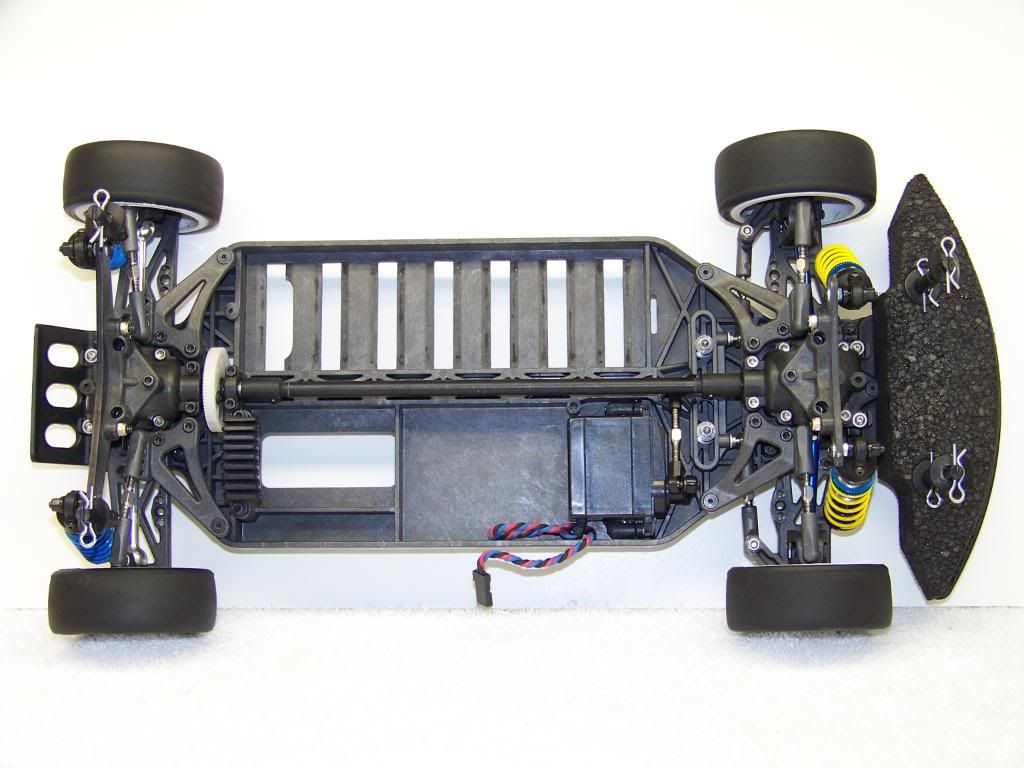

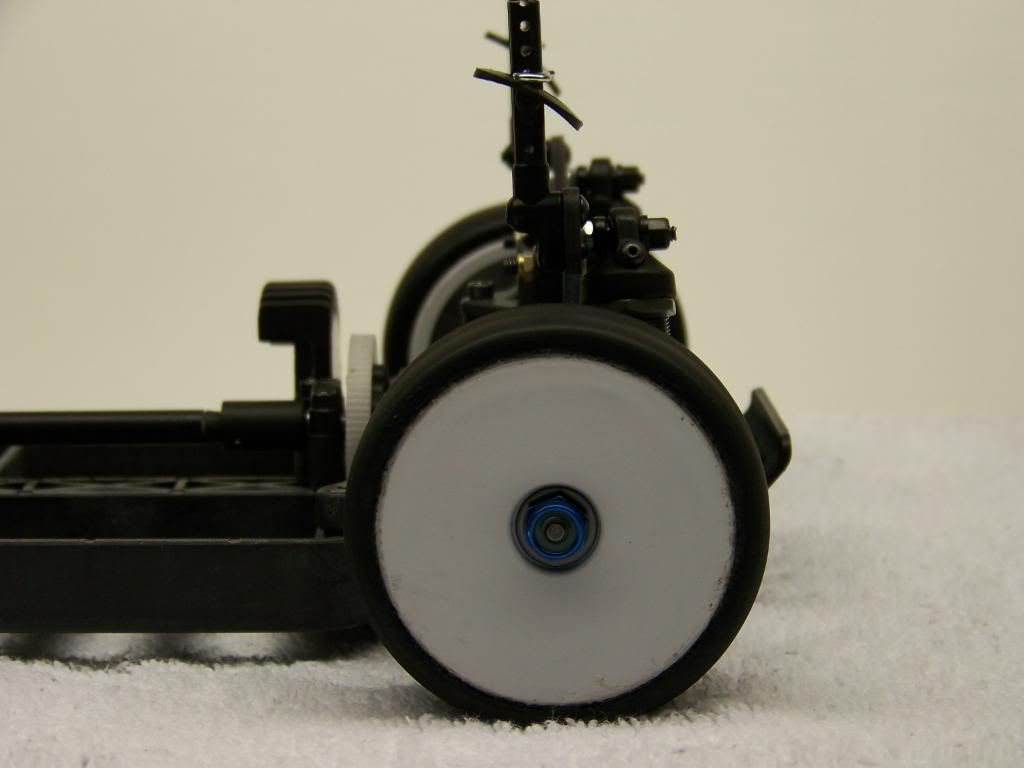

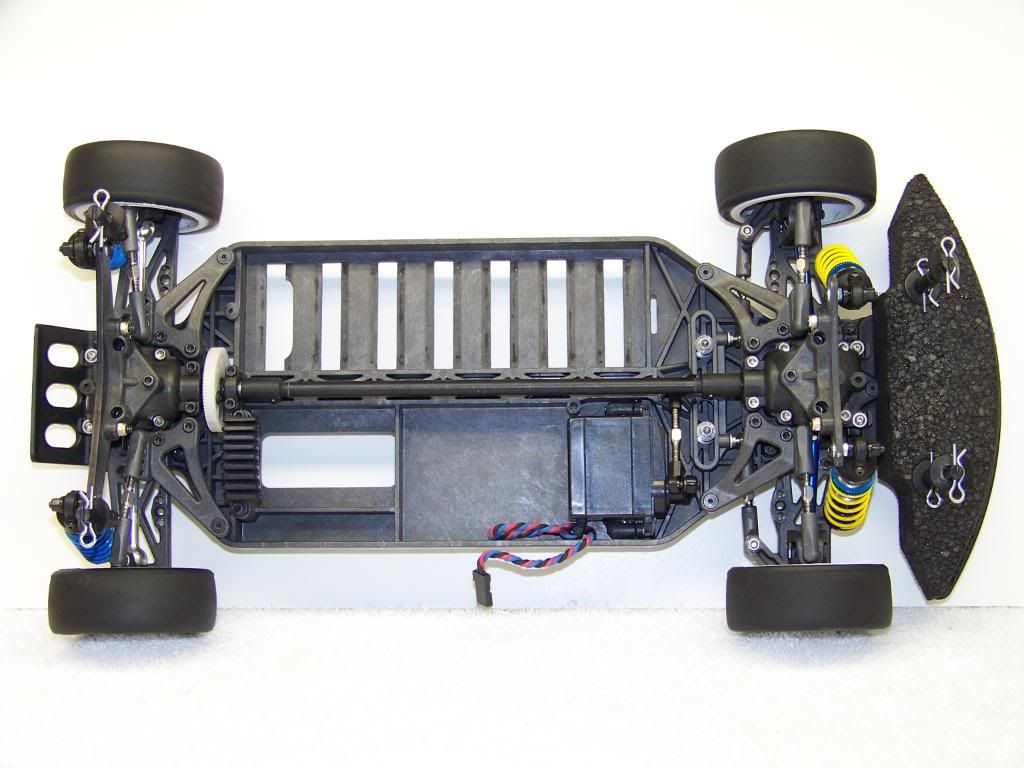

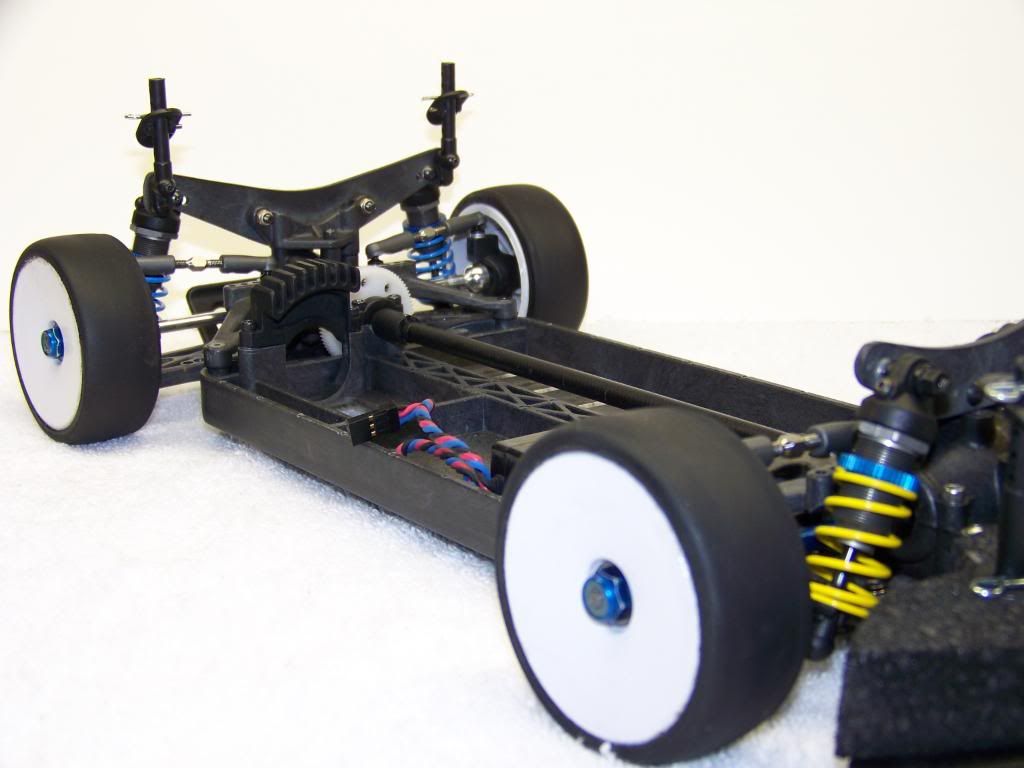

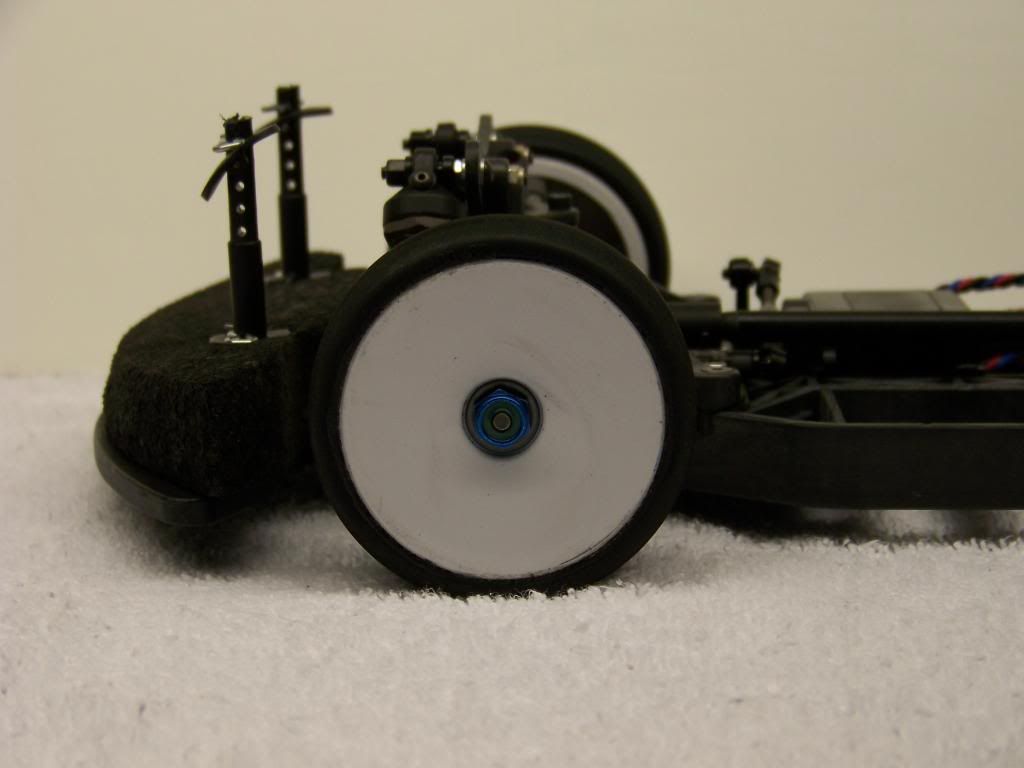

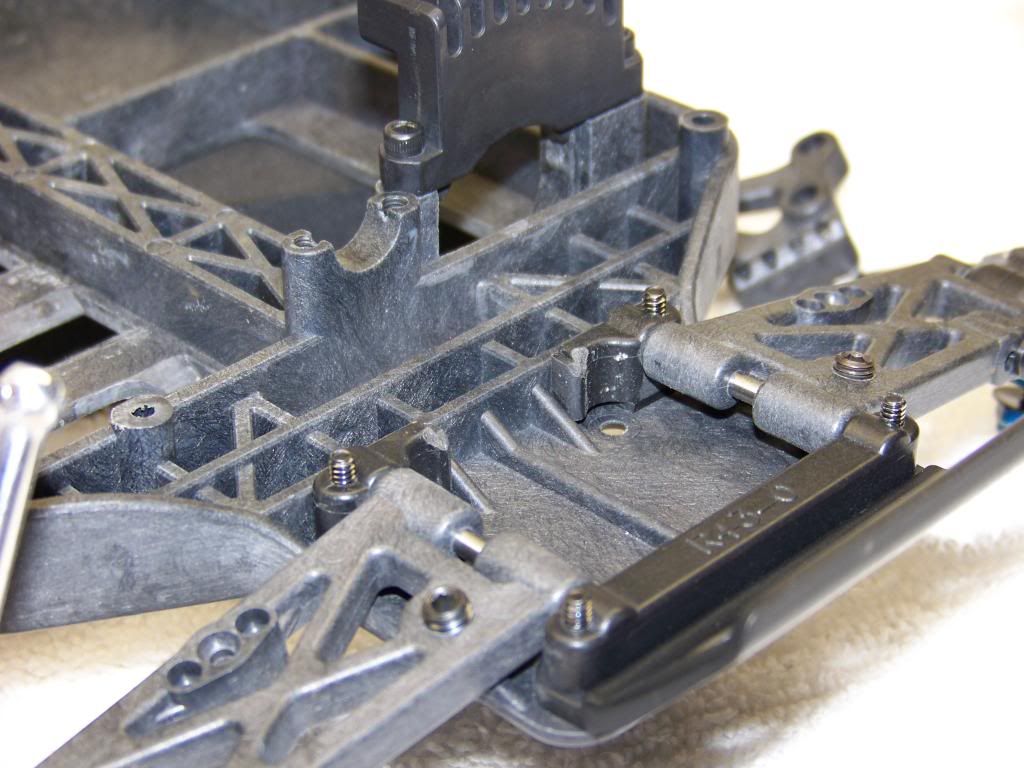

Overlook of the car...

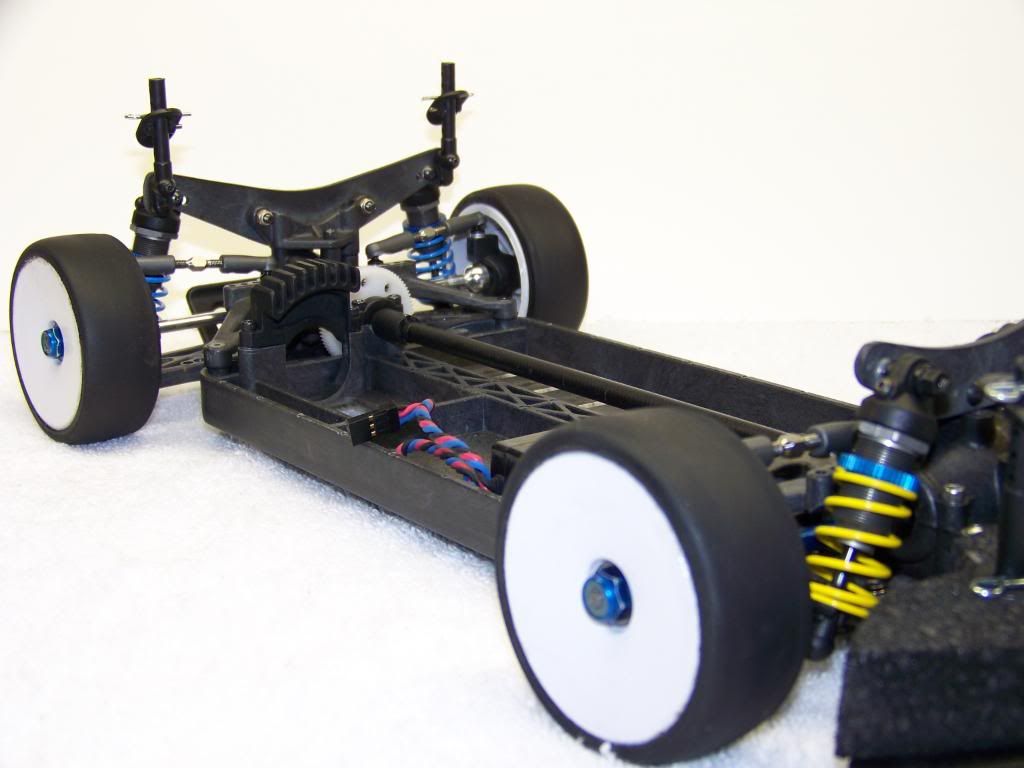

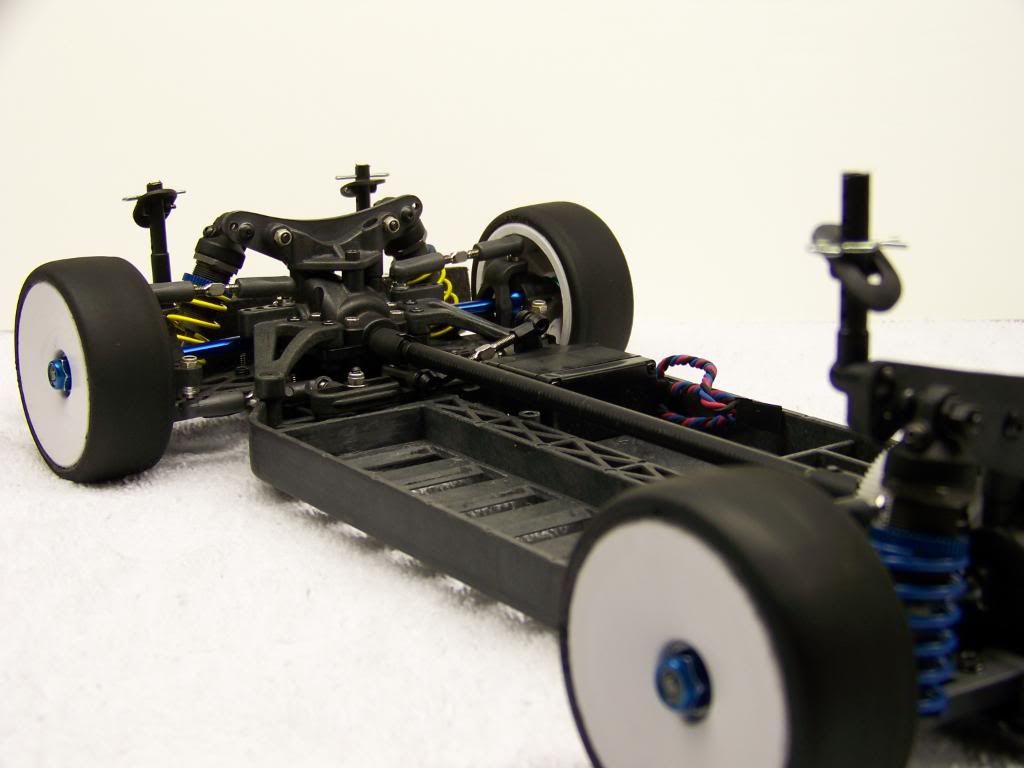

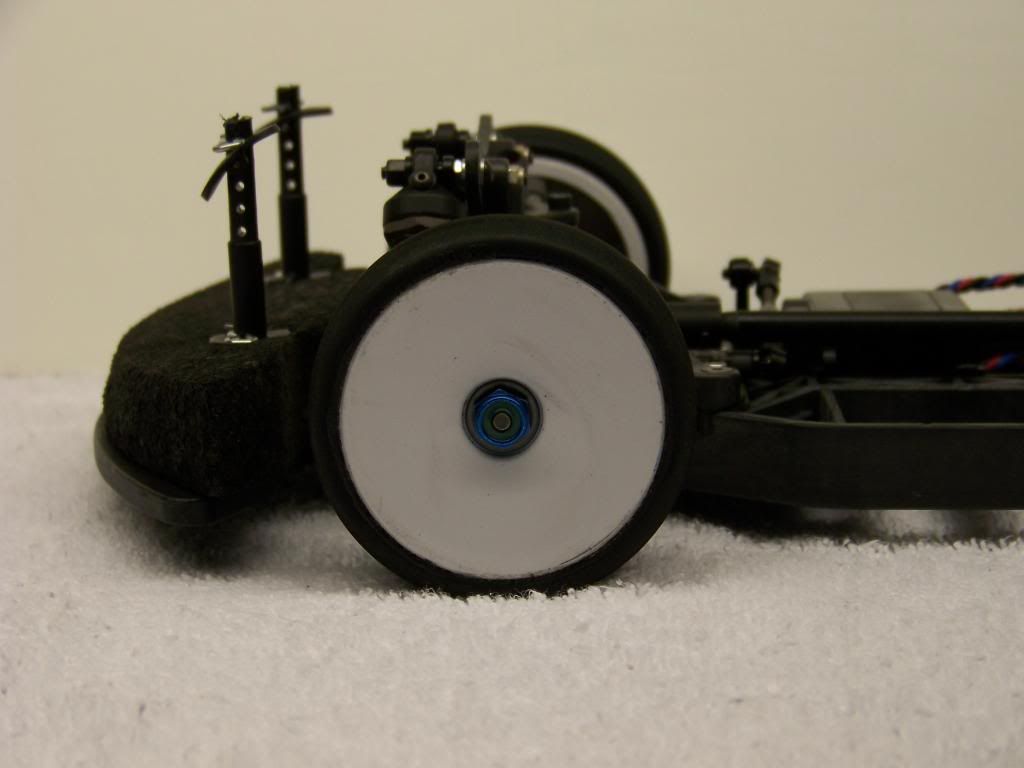

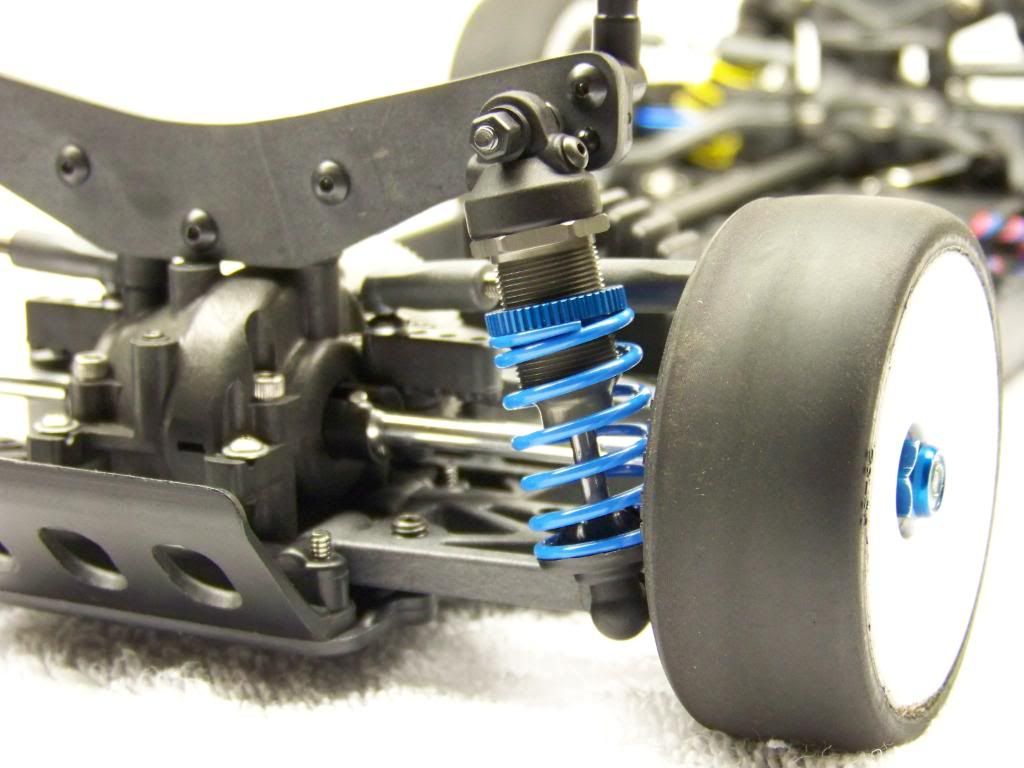

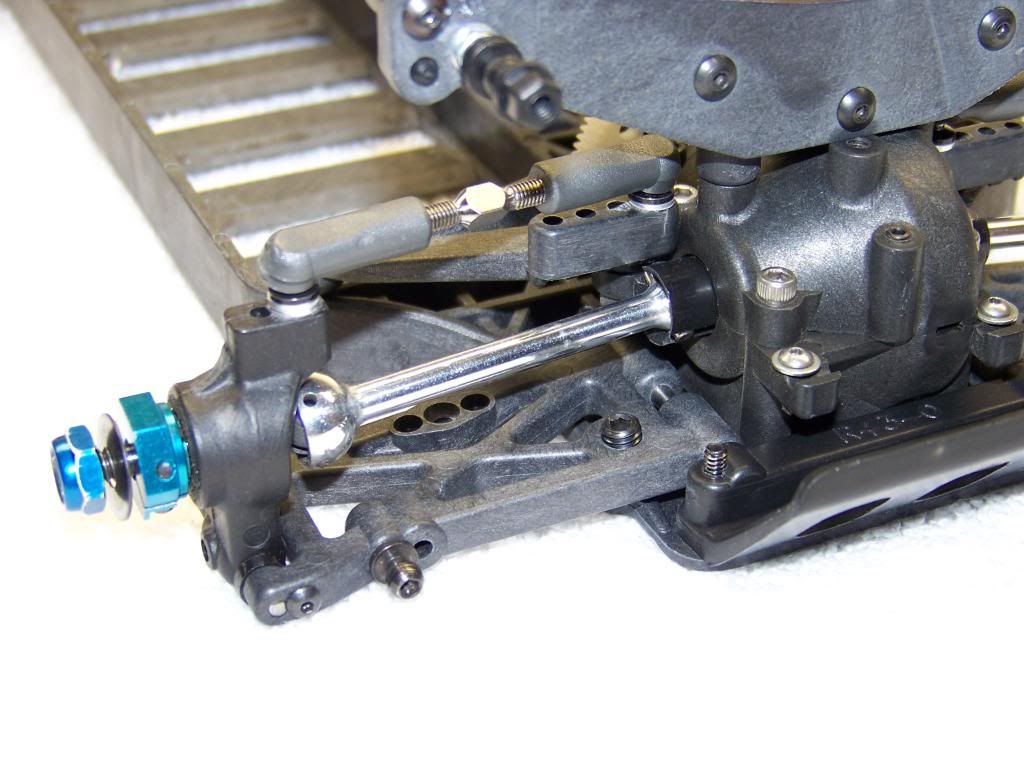

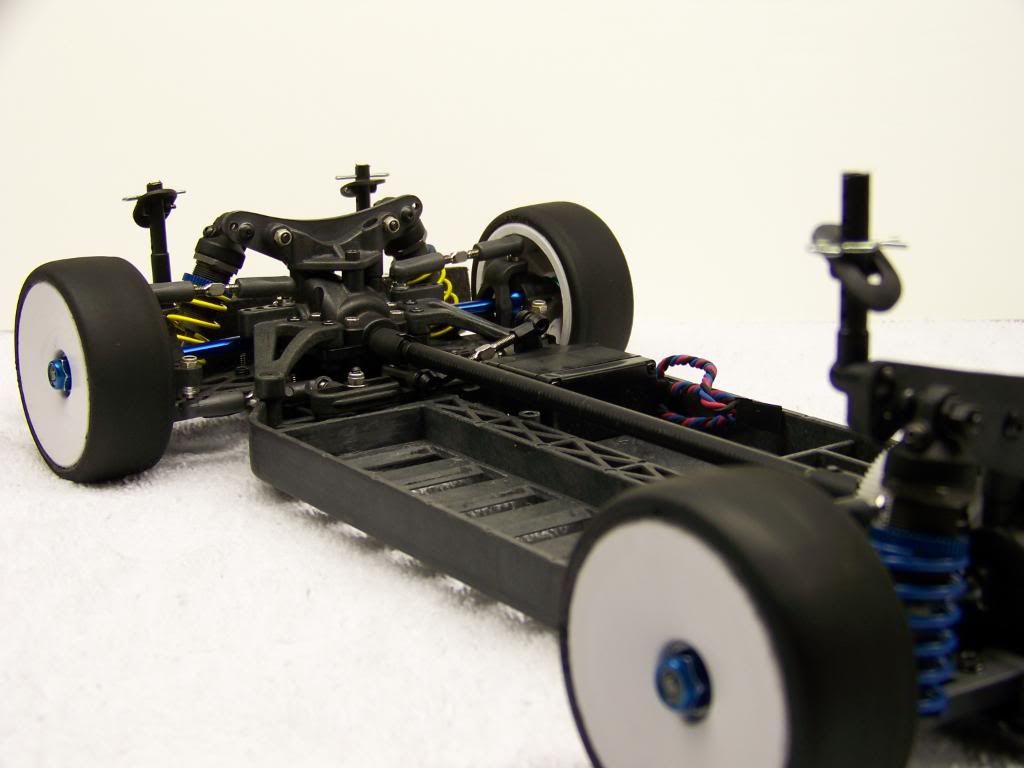

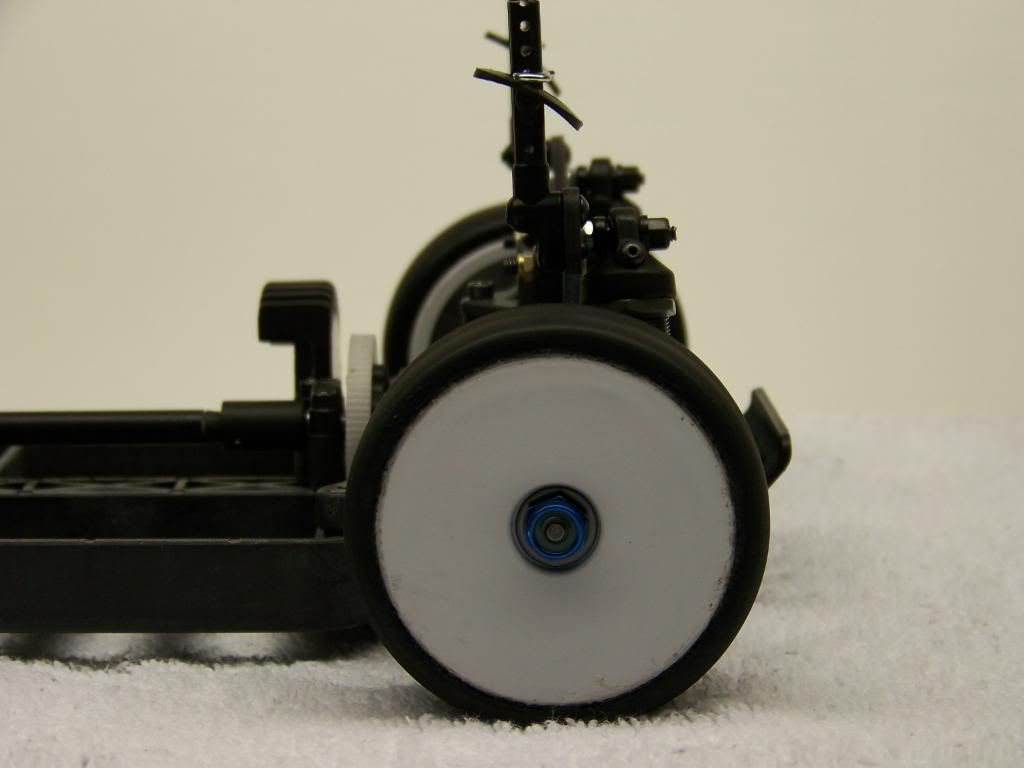

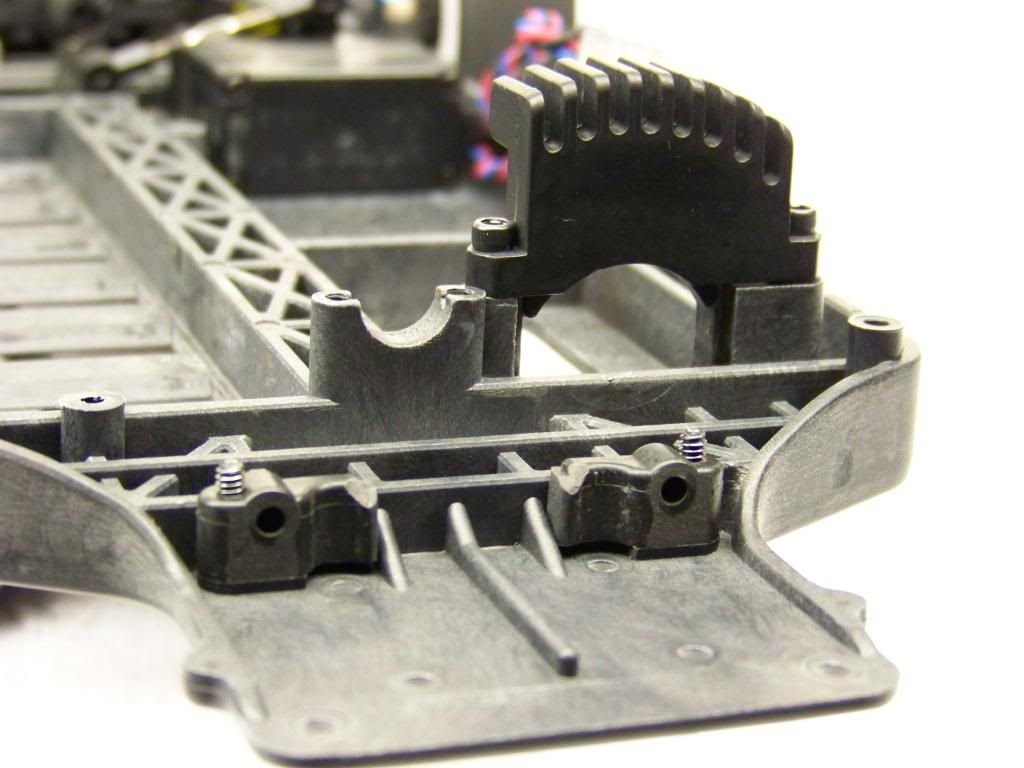

Now for a breakdown of the rear, to show the modifications.

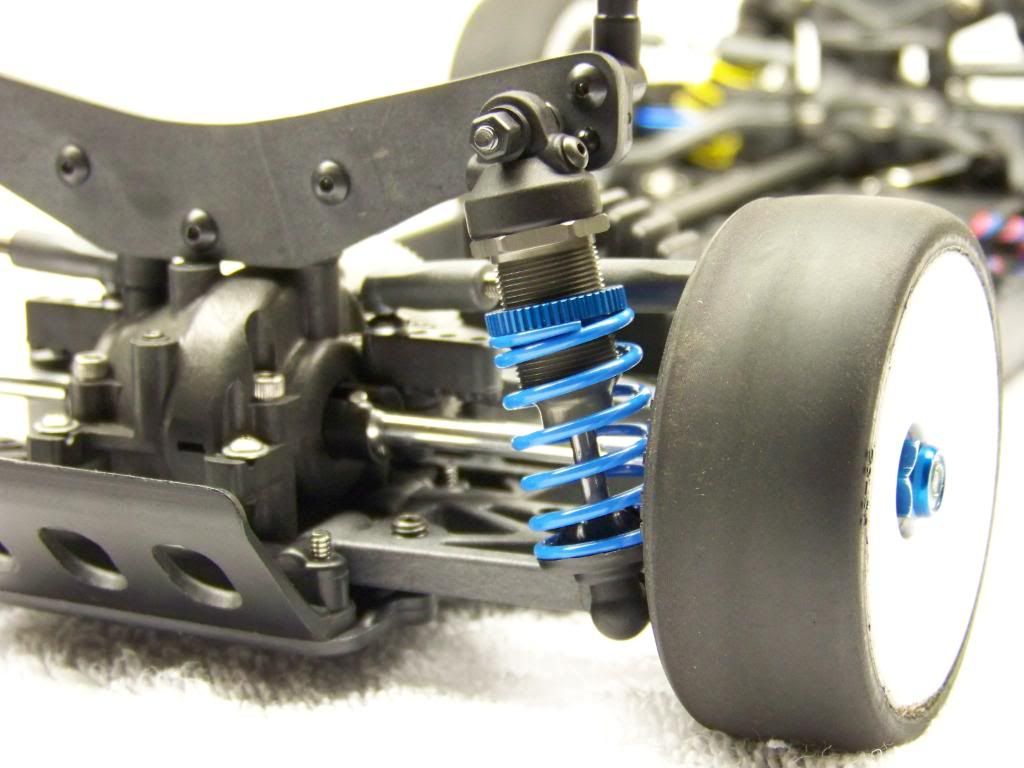

Longer screws are used to attach the suspension blocks to the chassis for several reasons. The first is to allow use of modified Tc4 suspension shims for rollcenter adjustment. More on that later. The second is to reinforce the lower arm and suspension block setup as a whole, tying it to the chassis. The screws come very close to the Tc4 hingepins in the suspension blocks, so once it is all tightened down, it lessens the chance of suspension block failure. I used tool steel stock for hingepins (stock Tc4 thickness, modified length), and with that you can imagine the strength in the setup.

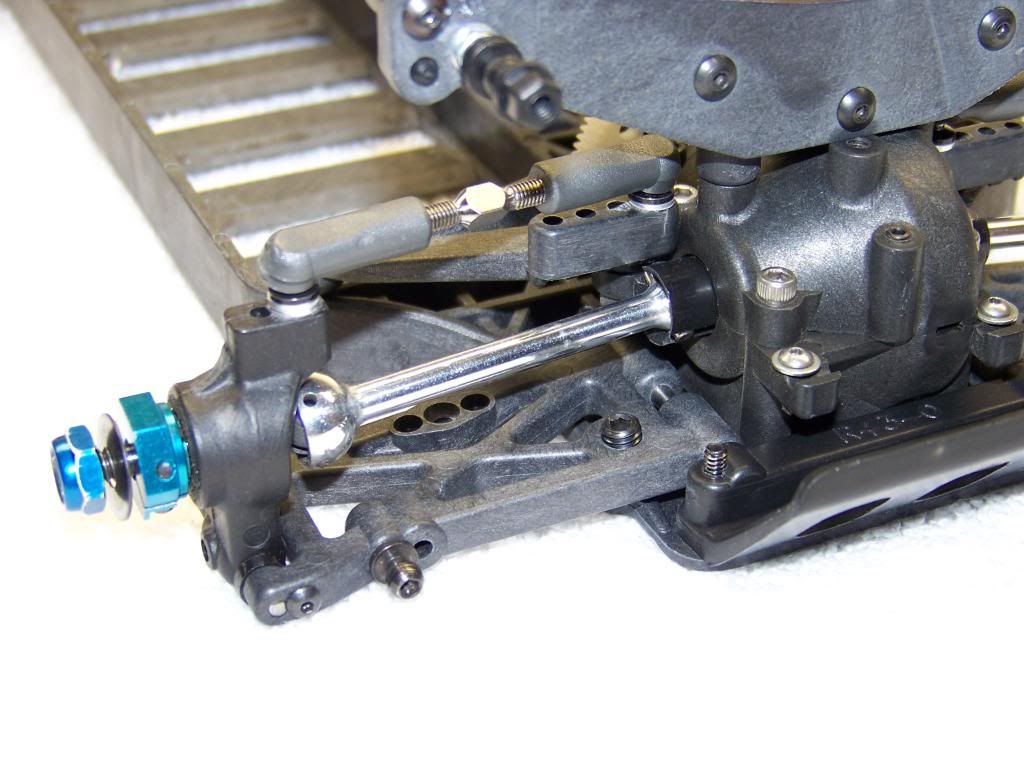

To see how much the suspension blocks need to be modified to accept the Tc4 arms, mount the F block (before part modification to ease assembly speed/manipulation) and your choice of rear block. After they are mounted, use your mics to get a measurement between the mounts where the arms would be located. You could use Tc3 arms, but the idea is to avoid the slop so common with those parts. Write those measurements down and compare those to the measurements you take from the Tc4 arms. The difference is what needs to be removed from the suspension block arm facing. This is where you use the flat sanding surface, and 400 grit paper. Mic regularly for consistency.

I chose to flatten the 'F' suspension blocks (you can see this in the pix) and mic them out where the arms would sit, to allow equal and precise arm fitment. The rest of the measurement difference was removed from the block attached to either the front for rear bumper, as they are easiest to replace if they DO break.

After you have the arm gap measured from your suspension blocks, measure the depth of the pin holes in the blocks. Add front and rear block pin hole depth to your previously mentioned arm gap measurement, and you have the length of your modified hingepins. The rear pins will be slightly longer, due to the rear toe in.

Drilling out the pin holes for the larger Tc4 pins is very easy. A NEW drillbit the same thickness of the Tc4 pin mounted in the hand pin vise will center itself, and stop cutting once you hit the bottom of the hole. Of course, squaring up the drillbit and taking your time is important here. If you make sure the drillbit is 90 degrees of the suspension block at all axis, you will be fine.

Once you have drilled and measured and sanded and cut till you think you can do no more, your Tc4 arms should fit with zero slop, and fall naturally in their useful range of motion, WITH THE COMPLETED STEERING/CASTER HUB or REAR HUB attached. If the hubs arent attached, the arms should not fall naturally.

To drill the holes for the screws to attach the suspension blocks in place, use a NEW drill bit the same thickness of a 4/40 screw. Again use the pin vise, and square it up in the hole. It will cut on through with little effort. Once you mount the blocks to the chassis, the screw will thread the hole as it would in any other.

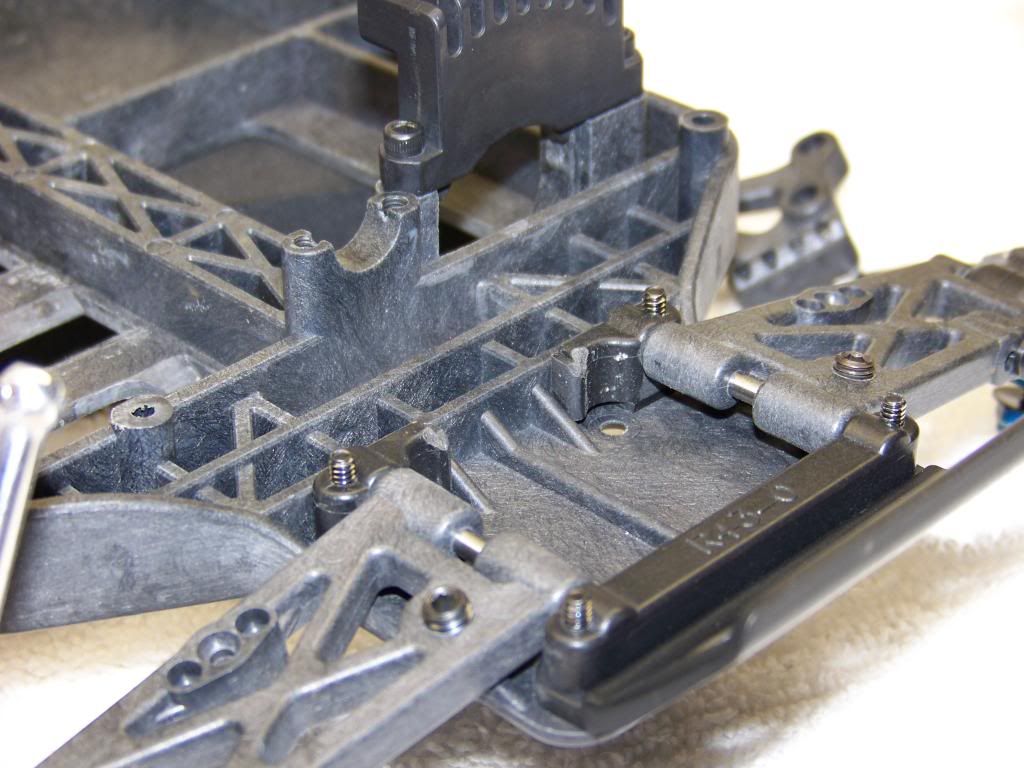

Now, for suspension block choice. The stock 'F' block goes in the front, rear position, and in the rear, front position as well. This is the block that is cut in two pieces in the pix.

*FRONT*

For STD or low rollcenter you will use the previously mentioned 'F' block, and the F+0 block that mounts to the bumper. This setup is flat, with no kickup or squat.

For "high" rollcenter you will use the same 'F' block, and the F+2 block that mounts to the bumper. You must use a modified '1 bump' shim under the 'F' block that gives you barely .010 of kickup.

*REAR*

For STD or low rollcenter you will use the previously mentioned 'F' block, and the R+3+2 block that mounts to the bumper. This setup is flat, with no kickup or squat.

For "high" rollcenter you will use the same 'F' block, and the R+3+0 block that mounts to the bumper. You must use a modified '2 bump' shim under the 'F' block that gives you barely .010 of squat.

Both R+3+2 and the R+3+0 blocks with the 'F' block net 1.5 degrees of rear toe.

You can of course do any combination of modded Tc4 shims and Tc3 blocks for your choice of rollcenter, dive, or squat. These are the basics.

I know i mentioned the use of modified Tc4 shims, in the pix you can see they must be cut to clear the mounting points of the tranny cases. You can use metal shims or washers, but i found they tend to press into the plastic of the blocks once mounted and cause inconsistencies.

Keep in mind, since since an arm is the part that will likely break with this setup (not the suspension blocks), all your mods need to be made to the suspension mounts. You want to be able to use a stock Tc4 arm that needs no modification for replacement.

Also, i almost forgot... i found that Tc5 slipper spool pads fit a Tc3/Tc4 diff without modification. You have to use the original steel outdrives (not the lightened ones) and the usual parts to assemble one, using the pads in place of the diff balls and rings.

EDIT: Each Tc5 slipper spool pad must be .84mm thick to work. Apparently there was a control issue with my first set of pads, one was much thicker than the other. The second set i had to take down in thickness. Use a flat surface, 400 grit sandpaper, and the flat outdrive going in a figure 8 to do so. Measure frequently.

.84mm will allow you to tighten the slipper spool up after seating, and let you drop it in the tranny case using a standard Tc3/4 diff shim for each diff bearing, and give you proper gear mesh/case spacing.

Happy dremeling!!

Ok as promised, pix of my modded Tc3. This collectively took me 12 hours to complete. I apologize for the pix, my camera doesnt have a Macro lense or the greatest light sensor.

To do these mods, all you will need are the obvious Tc4 parts, two NEW drillbits, a pair of mics, a pin vise, a flat sanding surface with 400 grit paper, a dremel with reinforced cutting wheel and sanding drum, and MISC screws to complete the conversion. Oh yeah... some patience goes a long way too.

Overlook of the car...

Now for a breakdown of the rear, to show the modifications.

Longer screws are used to attach the suspension blocks to the chassis for several reasons. The first is to allow use of modified Tc4 suspension shims for rollcenter adjustment. More on that later. The second is to reinforce the lower arm and suspension block setup as a whole, tying it to the chassis. The screws come very close to the Tc4 hingepins in the suspension blocks, so once it is all tightened down, it lessens the chance of suspension block failure. I used tool steel stock for hingepins (stock Tc4 thickness, modified length), and with that you can imagine the strength in the setup.

To see how much the suspension blocks need to be modified to accept the Tc4 arms, mount the F block (before part modification to ease assembly speed/manipulation) and your choice of rear block. After they are mounted, use your mics to get a measurement between the mounts where the arms would be located. You could use Tc3 arms, but the idea is to avoid the slop so common with those parts. Write those measurements down and compare those to the measurements you take from the Tc4 arms. The difference is what needs to be removed from the suspension block arm facing. This is where you use the flat sanding surface, and 400 grit paper. Mic regularly for consistency.

I chose to flatten the 'F' suspension blocks (you can see this in the pix) and mic them out where the arms would sit, to allow equal and precise arm fitment. The rest of the measurement difference was removed from the block attached to either the front for rear bumper, as they are easiest to replace if they DO break.

After you have the arm gap measured from your suspension blocks, measure the depth of the pin holes in the blocks. Add front and rear block pin hole depth to your previously mentioned arm gap measurement, and you have the length of your modified hingepins. The rear pins will be slightly longer, due to the rear toe in.

Drilling out the pin holes for the larger Tc4 pins is very easy. A NEW drillbit the same thickness of the Tc4 pin mounted in the hand pin vise will center itself, and stop cutting once you hit the bottom of the hole. Of course, squaring up the drillbit and taking your time is important here. If you make sure the drillbit is 90 degrees of the suspension block at all axis, you will be fine.

Once you have drilled and measured and sanded and cut till you think you can do no more, your Tc4 arms should fit with zero slop, and fall naturally in their useful range of motion, WITH THE COMPLETED STEERING/CASTER HUB or REAR HUB attached. If the hubs arent attached, the arms should not fall naturally.

To drill the holes for the screws to attach the suspension blocks in place, use a NEW drill bit the same thickness of a 4/40 screw. Again use the pin vise, and square it up in the hole. It will cut on through with little effort. Once you mount the blocks to the chassis, the screw will thread the hole as it would in any other.

Now, for suspension block choice. The stock 'F' block goes in the front, rear position, and in the rear, front position as well. This is the block that is cut in two pieces in the pix.

*FRONT*

For STD or low rollcenter you will use the previously mentioned 'F' block, and the F+0 block that mounts to the bumper. This setup is flat, with no kickup or squat.

For "high" rollcenter you will use the same 'F' block, and the F+2 block that mounts to the bumper. You must use a modified '1 bump' shim under the 'F' block that gives you barely .010 of kickup.

*REAR*

For STD or low rollcenter you will use the previously mentioned 'F' block, and the R+3+2 block that mounts to the bumper. This setup is flat, with no kickup or squat.

For "high" rollcenter you will use the same 'F' block, and the R+3+0 block that mounts to the bumper. You must use a modified '2 bump' shim under the 'F' block that gives you barely .010 of squat.

Both R+3+2 and the R+3+0 blocks with the 'F' block net 1.5 degrees of rear toe.

You can of course do any combination of modded Tc4 shims and Tc3 blocks for your choice of rollcenter, dive, or squat. These are the basics.

I know i mentioned the use of modified Tc4 shims, in the pix you can see they must be cut to clear the mounting points of the tranny cases. You can use metal shims or washers, but i found they tend to press into the plastic of the blocks once mounted and cause inconsistencies.

Keep in mind, since since an arm is the part that will likely break with this setup (not the suspension blocks), all your mods need to be made to the suspension mounts. You want to be able to use a stock Tc4 arm that needs no modification for replacement.

Also, i almost forgot... i found that Tc5 slipper spool pads fit a Tc3/Tc4 diff without modification. You have to use the original steel outdrives (not the lightened ones) and the usual parts to assemble one, using the pads in place of the diff balls and rings.

EDIT: Each Tc5 slipper spool pad must be .84mm thick to work. Apparently there was a control issue with my first set of pads, one was much thicker than the other. The second set i had to take down in thickness. Use a flat surface, 400 grit sandpaper, and the flat outdrive going in a figure 8 to do so. Measure frequently.

.84mm will allow you to tighten the slipper spool up after seating, and let you drop it in the tranny case using a standard Tc3/4 diff shim for each diff bearing, and give you proper gear mesh/case spacing.

Happy dremeling!!

Last edited by DaveW; 06-17-2010 at 11:49 AM.

Tech Master

iTrader: (89)

Excellent work and great write up on that DaveW. Your time in doing so is appreciated for sure.

Tech Master

iTrader: (12)

Guess i'll show my lack of knowledge on the subject...

What do the slipper pads do and when should a person use a setup like that? Is that mod just for the front diff or both?

Looks interesting and worth a try...

What do the slipper pads do and when should a person use a setup like that? Is that mod just for the front diff or both?

Looks interesting and worth a try...

65Likes

65Likes