Tekno RC EB410 Thread

|

|||

#2851

Wonderful info sir thank you for your time on this.

I got my 13.5T Monster Max motor back from Trinity yesterday... just in time to get 1 qual and a main.. phew

Anyway, several things I've learned.

1) I thought I was having power fade issues and decided to send my motor into Trinity to have them look it over... they said nothing was wrong with the motor. I then went back and examined my car more closely to discover my loss of power was from a stripped hex on one of the front wheels. I had been using AVID +1mm hex spacers and this severely limited the amount of contact to the wheel, so I replaced them with the +1mm hexes for the SCT410: https://www.teknorc.com/shop/tkr1654...d-ae-sc10-4x4/

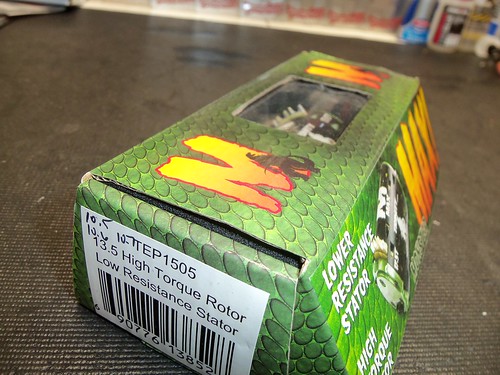

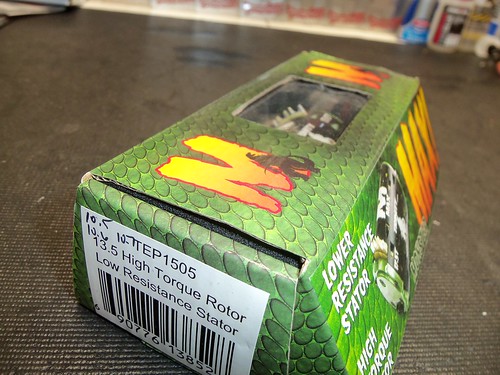

2) Kudos to Trinity on many counts, first I was happy with their honesty, they could've easily said something was wrong with the motor I wouldn't have known the wiser and would've bought whatever they said was broken... at first I was bummed that I sent in a perfectly good motor for service, but as it turned out, they noticed that I was running the TEP1112 (blue) rotor and had recommended that I upgrade to the TEP1119 (copper) rotor which I learned is roughly 1.5mm longer and offers a pinch more torque and is better suited for 4WD Buggy:

3) I had spoke with Kevin over the phone and he was extremely helpful, patient and answered all of my questions. He actually convinced me to invest in a motor analyzer. Simply put if anyone is going to run in 13.5T stock (regardless of the brand of motor) you need to put your motor on an analyzer and set the timing based on the amp draw. Every brand of motor has a different peak draw which I've seen range anywhere from 3-6A and Kevin explained that the MonsterMax does best at 5.6A

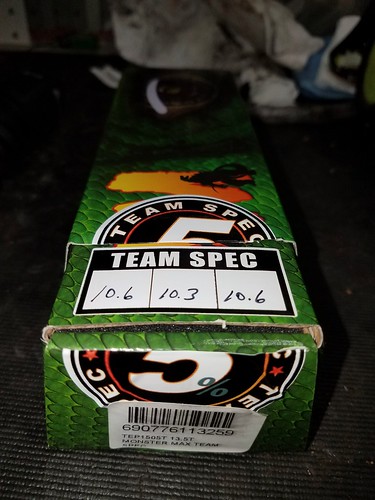

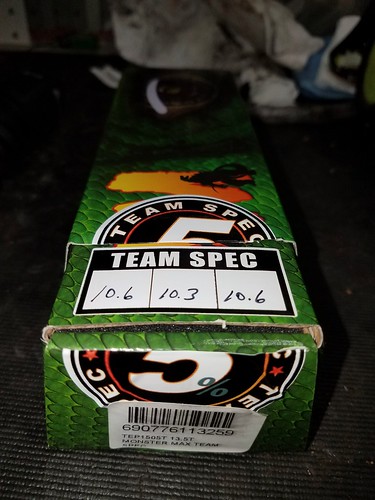

4) Kevin also explained what the markings where on the side of my box (10.5 + 10.6 + 10.7), they were hand written by Eric Anderson who tested/tuned the motor before he shipped it to me originally from Team EA Motorsports, and these markings are the amount of resistance. Apparently when you get a certified motor, they mark the resistance readings on those motors, where Eric Anderson provides this level of service for free. Kevin also mentioned that these resistance readings were exceptionally well for a non certified motor.

Here is a sample reading of a Team Spec motor which is guaranteed to be within the top 5% of motors produced:

5) Gearing was the last thing we discussed, I explained that I was running on turf with 24/81 gearing and Kevin confirmed this was too low, he said depending on track size that I should bump up to something between 26/81 to 28/81. I really didn't have any time to do any testing so I only ran 26/81 yesterday and was really pleased with the results. Now that I was running without a stripped hex, my lap times were back on pace and I was back in the mix at our local club. I will definitely try 27T and 28T pinions next time if have the opportunity for some practice!

I'm far from the best driver in my area, but every now and then I get a pretty good run. I'd like to think that the stronger rotor and higher gearing I ran this week helped contributed to me getting on the podium (aside from running Tekno, ha!) in a field of 19 drivers ( to a C Main) but the car definitely had some hole shot and this would actually mean the difference between finishing 3rd (after a costly bobble) to a nail biter "Superman Pass" into 2nd on the last jump of the last lap in the main, it was a risky move, but I had nothing to lose and it paid off, thanks Tekno!

https://www.youtube.com/watch?v=-xFvn1gfSCU

I'm the guy on the far right in the pic so you know which car is mine in the video clip:

Anyway, several things I've learned.

1) I thought I was having power fade issues and decided to send my motor into Trinity to have them look it over... they said nothing was wrong with the motor. I then went back and examined my car more closely to discover my loss of power was from a stripped hex on one of the front wheels. I had been using AVID +1mm hex spacers and this severely limited the amount of contact to the wheel, so I replaced them with the +1mm hexes for the SCT410: https://www.teknorc.com/shop/tkr1654...d-ae-sc10-4x4/

2) Kudos to Trinity on many counts, first I was happy with their honesty, they could've easily said something was wrong with the motor I wouldn't have known the wiser and would've bought whatever they said was broken... at first I was bummed that I sent in a perfectly good motor for service, but as it turned out, they noticed that I was running the TEP1112 (blue) rotor and had recommended that I upgrade to the TEP1119 (copper) rotor which I learned is roughly 1.5mm longer and offers a pinch more torque and is better suited for 4WD Buggy:

3) I had spoke with Kevin over the phone and he was extremely helpful, patient and answered all of my questions. He actually convinced me to invest in a motor analyzer. Simply put if anyone is going to run in 13.5T stock (regardless of the brand of motor) you need to put your motor on an analyzer and set the timing based on the amp draw. Every brand of motor has a different peak draw which I've seen range anywhere from 3-6A and Kevin explained that the MonsterMax does best at 5.6A

4) Kevin also explained what the markings where on the side of my box (10.5 + 10.6 + 10.7), they were hand written by Eric Anderson who tested/tuned the motor before he shipped it to me originally from Team EA Motorsports, and these markings are the amount of resistance. Apparently when you get a certified motor, they mark the resistance readings on those motors, where Eric Anderson provides this level of service for free. Kevin also mentioned that these resistance readings were exceptionally well for a non certified motor.

Here is a sample reading of a Team Spec motor which is guaranteed to be within the top 5% of motors produced:

5) Gearing was the last thing we discussed, I explained that I was running on turf with 24/81 gearing and Kevin confirmed this was too low, he said depending on track size that I should bump up to something between 26/81 to 28/81. I really didn't have any time to do any testing so I only ran 26/81 yesterday and was really pleased with the results. Now that I was running without a stripped hex, my lap times were back on pace and I was back in the mix at our local club. I will definitely try 27T and 28T pinions next time if have the opportunity for some practice!

I'm far from the best driver in my area, but every now and then I get a pretty good run. I'd like to think that the stronger rotor and higher gearing I ran this week helped contributed to me getting on the podium (aside from running Tekno, ha!) in a field of 19 drivers ( to a C Main) but the car definitely had some hole shot and this would actually mean the difference between finishing 3rd (after a costly bobble) to a nail biter "Superman Pass" into 2nd on the last jump of the last lap in the main, it was a risky move, but I had nothing to lose and it paid off, thanks Tekno!

https://www.youtube.com/watch?v=-xFvn1gfSCU

| + YouTube Video | |

I'm the guy on the far right in the pic so you know which car is mine in the video clip:

#2852

Tech Master

I got my 13.5T Monster Max motor back from Trinity yesterday... just in time to get 1 qual and a main.. phew

Anyway, several things I've learned.

1) I had been using AVID +1mm hex spacers and this severely limited the amount of contact to the wheel, so I replaced them with the +1mm hexes for the SCT410: https://www.teknorc.com/shop/tkr1654...d-ae-sc10-4x4/

Anyway, several things I've learned.

1) I had been using AVID +1mm hex spacers and this severely limited the amount of contact to the wheel, so I replaced them with the +1mm hexes for the SCT410: https://www.teknorc.com/shop/tkr1654...d-ae-sc10-4x4/

#2853

That stripped out wheel is pretty old anyway, been remounting tires on it for over a year now, ha!

#2857

#2859

#2865

Can anyone compare/contrast on the driving characteristics and durability of the Tekno vs the B64D? Thinking about switching as i run alot on a rough, predominantly 1/8 outdoor offroad track that has done a number on my B64. Thanks

2421Likes

2421Likes