TLR 22-4 2.0 Race Kit Thread!

|

|||

#901

Anyone know of another steering rod end that will fit that's a little longer than 231029?

Mine stripped today, and looking at it there's not a whole lot of threads being used, so I think a longer one would work better.

Mine stripped today, and looking at it there's not a whole lot of threads being used, so I think a longer one would work better.

#902

#903

No one is running this buggy on carpet??

#904

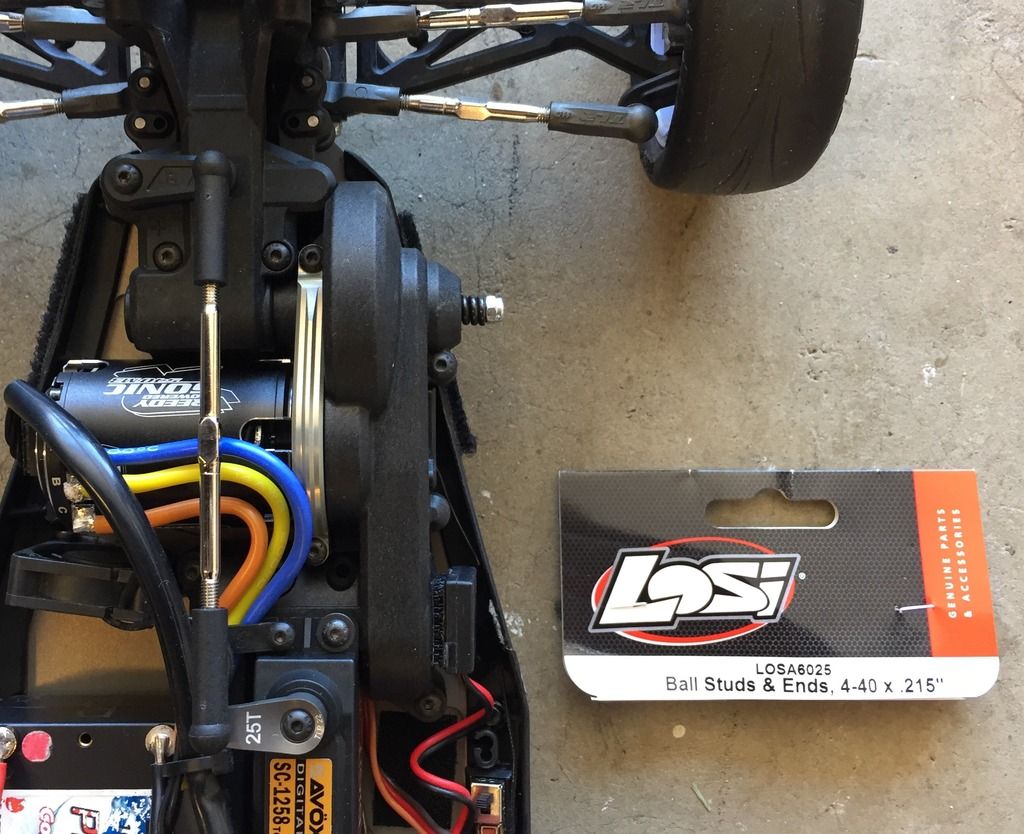

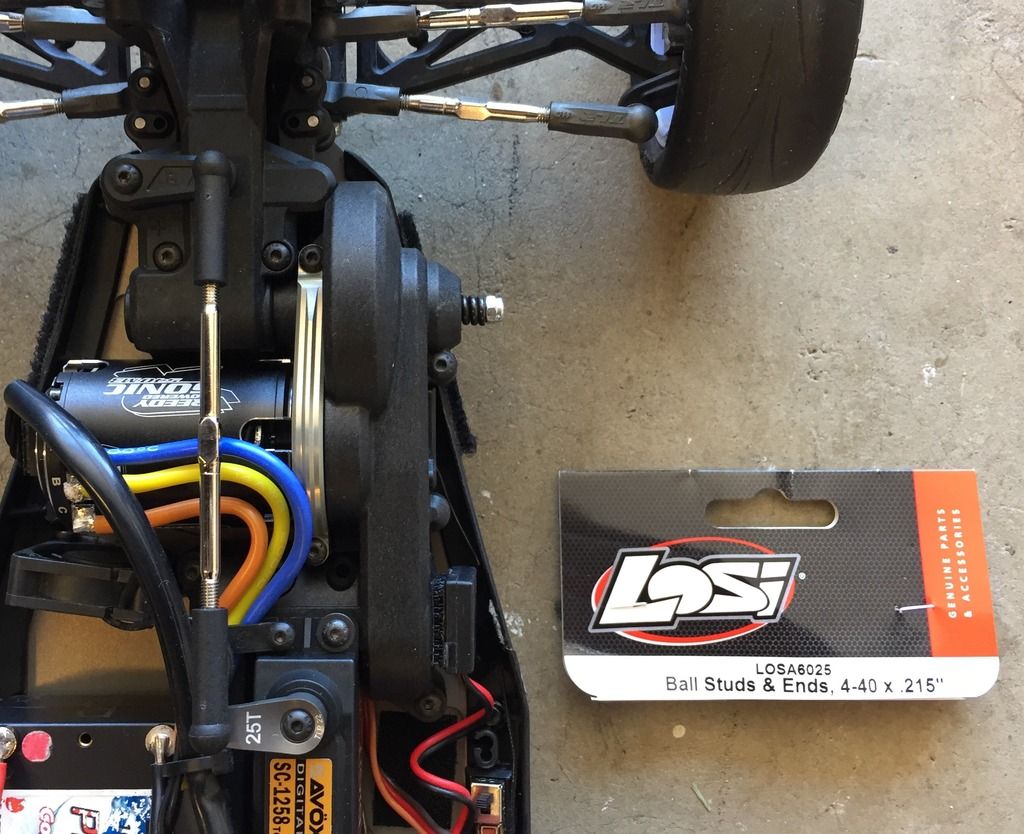

Ok, for stripping steering link rod ends, this works pretty good.

I had some old school Losi HD ballcups for 3/16" ball studs, part number LOSA6025.

Then I used a 3.5x75mm TLR turnbuckle, part number TLR234038.

It is crazy beefy now, might start breaking other parts, but the rod ends ain't coming out!

Finished product:

I had some old school Losi HD ballcups for 3/16" ball studs, part number LOSA6025.

Then I used a 3.5x75mm TLR turnbuckle, part number TLR234038.

It is crazy beefy now, might start breaking other parts, but the rod ends ain't coming out!

Finished product:

Last edited by tsair; 12-03-2016 at 10:29 PM.

#905

Lol....thanks for your info

J/k

J/k

#906

Tech Rookie

Can someone give me some insight on the gearing. I saw in the O.P. That recommends running a 76-78 spur with a 13.5 which is what I am running. I built the kit as is and seems to be quick but not sure if I am missing out on some power. TIA

#907

What is your question? Start with stock gearing, gear higher for more top end or lower for more low end or if your motor is running too hot. That's about it.

#910

I run 27-29/84 with a Fantom 13.5. I seem to like the 29 the best. 76/26 is virtually the same as 84/29. More than anything it depends on your tracks size and surface. Motors are also not all the same. You need to run the car and gear it to where you like it and it doesn't catch on fire after 5-7 minutes (however long your mains are).

#911

Tech Rookie

I run 27-29/84 with a Fantom 13.5. I seem to like the 29 the best. 76/26 is virtually the same as 84/29. More than anything it depends on your tracks size and surface. Motors are also not all the same. You need to run the car and gear it to where you like it and it doesn't catch on fire after 5-7 minutes (however long your mains are).

#912

That's where I got confused because I was doing the calculations and they are basically the same mathematically speaking but I wasn't sure if there was advantage running a smaller spur and larger pinion. Motor temps are good after 5-6 minutes so I'm good on that end. Thanks for all the input!

#914

Tech Adept

Hey Guys,

Sorry it took so long to add info to the "1st post". The 22-4 2.0 has been the result of a lot of work by our team here at TLR, and I think you guys are really going to dig the car.

Web Page:

http://www.tlracing.com/Products/Def...rodId=TLR03007

Product Video:

https://www.youtube.com/watch?v=nYYcc11938I

Frank Root's Live Q&A (from morning of announcement):

I don't think I can actually grab a link, so, then find the TLR's Frank Root 22-4 2.0 video.

Images:

Setup Sheets:

http://www.tlracing.com/Products/Def...007#prodSetups

Here are some good build tips and notes from b1narych0ice (thank you):

Specific build step comments/warnings, including areas I replaced stock parts -- Think of this as a FAQ that answers questions I had from other builders about each step:

A-3: You can instead use TLR Aluminum Servo Mount here.

A-5: Be sure to get the shorter screw in the correct hole.

A-6: Use a 76 or 78T spur if you are running a 13.5T-21.5T motor instead of the 84 in the kit! and...

A-6: The plastic washer between the pulley and the thrust assembly should be oriented so that the flat side goes toward the pulley, and the side with the ring goes towards the thrust assembly's metal washer. Diagram in instructions is correct, you just can't see that this washer isn't flat on both sides from the illustration.

A-7: Be sure the nut holding the Full-Time 4WD assembly is nice and tight, I have seen it get loose in the 1.0 car!

A-9: Put the gears on the jackshaft before the c-clips, so that you don't have to deal with getting the c-clips off to put the gears on

B-2: It seems to be possible to push the outdrives on so tight that they bind when spun, be sure to ensure that they spin freely as the manual notes.

B-7: You're screwing the 1.3mm screws into metal, don't crank so hard you strip the heads on the screws. While this is metal-on-metal, the manual doesn't call for loctite here.

B-8: The rear diff has fewer/bigger teeth, the front diff has more/smaller teeth.

C-3/C-4: TLR Aluminum Bellcranks and Exotek steering rack can be used here to increase durability/reduce steering slop

C-8: TLR Aluminum A/B Horn can be used to increase durability/reduce steering slop.

D-2: Don't worry about the kingpins sticking out the front even when the nut is tight, the bumper will push them in and keep them there.

D-5: Shock tower screws were the tightest plastic part on my kit, look from the side when tightening down the tower at the gap between the tower and the front bulkhead, tighten until this gap is closed.

D-6/D-7: Don't mix up the CVA pins and the hex pins, should be easy because hex pins are black and CVA pins are silver.

D-8/D-9: Use a toothpick to get threadlock in the metal block instead of applying it to the shoulder bolt, so that you don't get it between the plastic spindle and the metal block.

E-1/E-2: Don't mix up the 10mm pins for the rear hexes with the 11mm pins for the rear CVAs! They are packaged together and both silver, so it's easy to think you just have 4 pins that are the same!

G-1: No need to install the post on the right side if you are running a shorty and use velcro to attach the body to the mud guards. You can move the right post up or down a little so that it snugly fits your shorty battery.

G-2: Aluminum Servo Horn can be used here.

G-4: Adjust the length of the link and the servo horn position so that both the servo horn and the horn on the bellcranks are parallel with each other, and perpendicular with the link.

Hope this helps some of you that are putting your kits together, and thanks to Frank and the TLR crew for a solid kit!

Sorry it took so long to add info to the "1st post". The 22-4 2.0 has been the result of a lot of work by our team here at TLR, and I think you guys are really going to dig the car.

Web Page:

http://www.tlracing.com/Products/Def...rodId=TLR03007

Product Video:

https://www.youtube.com/watch?v=nYYcc11938I

Frank Root's Live Q&A (from morning of announcement):

I don't think I can actually grab a link, so, then find the TLR's Frank Root 22-4 2.0 video.

Images:

Setup Sheets:

http://www.tlracing.com/Products/Def...007#prodSetups

Here are some good build tips and notes from b1narych0ice (thank you):

Specific build step comments/warnings, including areas I replaced stock parts -- Think of this as a FAQ that answers questions I had from other builders about each step:

A-3: You can instead use TLR Aluminum Servo Mount here.

A-5: Be sure to get the shorter screw in the correct hole.

A-6: Use a 76 or 78T spur if you are running a 13.5T-21.5T motor instead of the 84 in the kit! and...

A-6: The plastic washer between the pulley and the thrust assembly should be oriented so that the flat side goes toward the pulley, and the side with the ring goes towards the thrust assembly's metal washer. Diagram in instructions is correct, you just can't see that this washer isn't flat on both sides from the illustration.

A-7: Be sure the nut holding the Full-Time 4WD assembly is nice and tight, I have seen it get loose in the 1.0 car!

A-9: Put the gears on the jackshaft before the c-clips, so that you don't have to deal with getting the c-clips off to put the gears on

B-2: It seems to be possible to push the outdrives on so tight that they bind when spun, be sure to ensure that they spin freely as the manual notes.

B-7: You're screwing the 1.3mm screws into metal, don't crank so hard you strip the heads on the screws. While this is metal-on-metal, the manual doesn't call for loctite here.

B-8: The rear diff has fewer/bigger teeth, the front diff has more/smaller teeth.

C-3/C-4: TLR Aluminum Bellcranks and Exotek steering rack can be used here to increase durability/reduce steering slop

C-8: TLR Aluminum A/B Horn can be used to increase durability/reduce steering slop.

D-2: Don't worry about the kingpins sticking out the front even when the nut is tight, the bumper will push them in and keep them there.

D-5: Shock tower screws were the tightest plastic part on my kit, look from the side when tightening down the tower at the gap between the tower and the front bulkhead, tighten until this gap is closed.

D-6/D-7: Don't mix up the CVA pins and the hex pins, should be easy because hex pins are black and CVA pins are silver.

D-8/D-9: Use a toothpick to get threadlock in the metal block instead of applying it to the shoulder bolt, so that you don't get it between the plastic spindle and the metal block.

E-1/E-2: Don't mix up the 10mm pins for the rear hexes with the 11mm pins for the rear CVAs! They are packaged together and both silver, so it's easy to think you just have 4 pins that are the same!

G-1: No need to install the post on the right side if you are running a shorty and use velcro to attach the body to the mud guards. You can move the right post up or down a little so that it snugly fits your shorty battery.

G-2: Aluminum Servo Horn can be used here.

G-4: Adjust the length of the link and the servo horn position so that both the servo horn and the horn on the bellcranks are parallel with each other, and perpendicular with the link.

Hope this helps some of you that are putting your kits together, and thanks to Frank and the TLR crew for a solid kit!

Thanks!

#915

Hi guys. I am not new to RC but am somewhat new to RC trucks. I would like to ask for a functional and/or performance comparison between the 22-4 buggy and the TEN-SCBE other than the fact that the SCBE comes RTR. I also understand that one could build the SCTE V3 and convert to a buggy.

Since I still mostly do airborne RC, I am leaning towards the TEN-SCBE but may go the 22-4 route. I'd like to have a durable quality off road vehicle that could be raced but also just for fun. We do have a local outdoor dirt track for 1/10 scale electric.

I have a DX4S to operate with.

Since I still mostly do airborne RC, I am leaning towards the TEN-SCBE but may go the 22-4 route. I'd like to have a durable quality off road vehicle that could be raced but also just for fun. We do have a local outdoor dirt track for 1/10 scale electric.

I have a DX4S to operate with.

243Likes

243Likes