TLR 22-4 2.0 Race Kit Thread!

|

|||

#1666

Tech Master

iTrader: (46)

Well, Im selling my baby if anyone is interested..

http://www.rctech.net/forum/r-c-item...es-spares.html

http://www.rctech.net/forum/r-c-item...es-spares.html

#1667

Tech Regular

iTrader: (3)

Okay, I've been scouring the forum while waiting for my 22-4 2.0 kit to be delivered...

Am I right in assuming that for the rear suspension on the setup sheet:

22 hub/hex is the 2.0 kit hub & hex (same as 22 3.0)??

22-4 hub/hex is the hub & hex from 22-4 1.0??

Cheers for all the tips & advice on here folks!!

Am I right in assuming that for the rear suspension on the setup sheet:

22 hub/hex is the 2.0 kit hub & hex (same as 22 3.0)??

22-4 hub/hex is the hub & hex from 22-4 1.0??

Cheers for all the tips & advice on here folks!!

So what's the advantage of running one over the other??

#1670

I see a few setups calling for kyosho orange springs, however on the charts I've seen there is no orange rating. Gold or yellow would be the closest. Can anyone confirm the actual front spring used in the newest jake Thayer setup?

#1672

Tech Regular

I am seeing on some carpet setups that guys are raising the spindle 2mm. How is this being achieved? Is the material being removed from the spindle or the caster block or both?

#1678

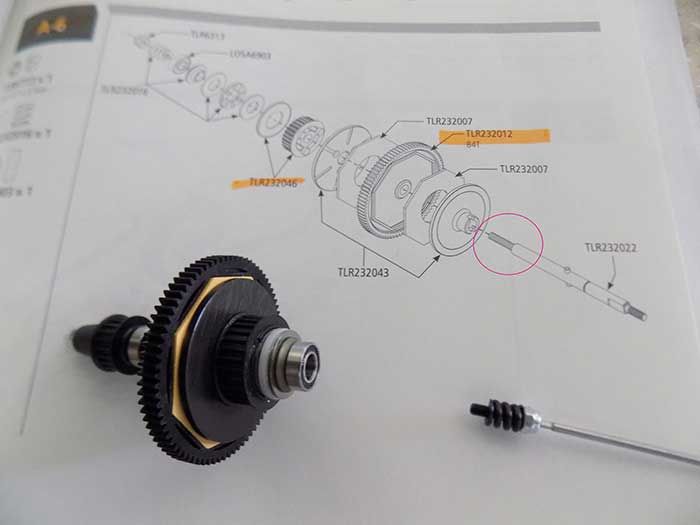

Is anyone else snapping pins running the MIP layshafts? I only run 13.5 and fell victim to the snap. I've seen mod guys break the pin but not in 13.5  The pin in the MIP is hallow. Could a solid pin be run and still enjoy the lighter weight? Looks like I'll test fit some pins before Friday.

The pin in the MIP is hallow. Could a solid pin be run and still enjoy the lighter weight? Looks like I'll test fit some pins before Friday.

The pin in the MIP is hallow. Could a solid pin be run and still enjoy the lighter weight? Looks like I'll test fit some pins before Friday.

The pin in the MIP is hallow. Could a solid pin be run and still enjoy the lighter weight? Looks like I'll test fit some pins before Friday.

#1679

T-works alum shafts have a solid steel pin in them. No issues so far!

https://www.rc-tworks.com/collection...t-for-tlr-22-4

https://www.rc-tworks.com/collection...t-for-tlr-22-4

#1680

T-works alum shafts have a solid steel pin in them. No issues so far!

https://www.rc-tworks.com/collection...t-for-tlr-22-4

https://www.rc-tworks.com/collection...t-for-tlr-22-4

243Likes

243Likes