Xray XB2 2WD Buggy Thread

|

|||

#886

#888

The XB2 already have all the boxes ticked in the form of very light weight (no need for expensive options to lighten it) and an incredibly smooth running and lightweight drivetrain.

ECS double jointed rear drive shafts will also be available any time now and with the ultra lightweight and smooth gear diff it's a perfect base for a winning stock platform

Bent

ECS double jointed rear drive shafts will also be available any time now and with the ultra lightweight and smooth gear diff it's a perfect base for a winning stock platform

Bent

A lot of guys run the MIP pucks system in stock because it's lighter and even though the gear diff might be better it's too heavy (for their platform). On the XB2 the gear diff is super light and works super smoothly without modification. That's another bonus for stock.

Wouldn't the ECS driveshafts have less bind, causing the rear of the car to be less flat under power?

#889

Hi Bent

I'm building my Carpet Ed these days. Malin's performance convinced me this is the right car for me. I just have to paint it pink now

On a more serious note. Is the quote above reflecting the latest and greatest way to ballpark the slipper settings for such late gen cars with masses forward as the Xb2? I won't be using the ball diff, but the trick is, hold rear, throttle, loosen slipper until front doesn't lift?

Other than that, the build quality is stunning... nothing less than I expected from Juraj and the boyz (and girlz ).

).

My next step is to go to the xray website and pick up a setup for mid-grip carpet...

Thanks,

Paul

I'm building my Carpet Ed these days. Malin's performance convinced me this is the right car for me. I just have to paint it pink now

On a more serious note. Is the quote above reflecting the latest and greatest way to ballpark the slipper settings for such late gen cars with masses forward as the Xb2? I won't be using the ball diff, but the trick is, hold rear, throttle, loosen slipper until front doesn't lift?

Other than that, the build quality is stunning... nothing less than I expected from Juraj and the boyz (and girlz

).

).My next step is to go to the xray website and pick up a setup for mid-grip carpet...

Thanks,

Paul

Sounds good

And congrats on picking up an XB2......you won't be disappointed

Yes that's the way I prefer to set the slipper.

Setting it this way will allow you to be quite aggressive on throttle when landing and out of turns.

Bent

#890

#892

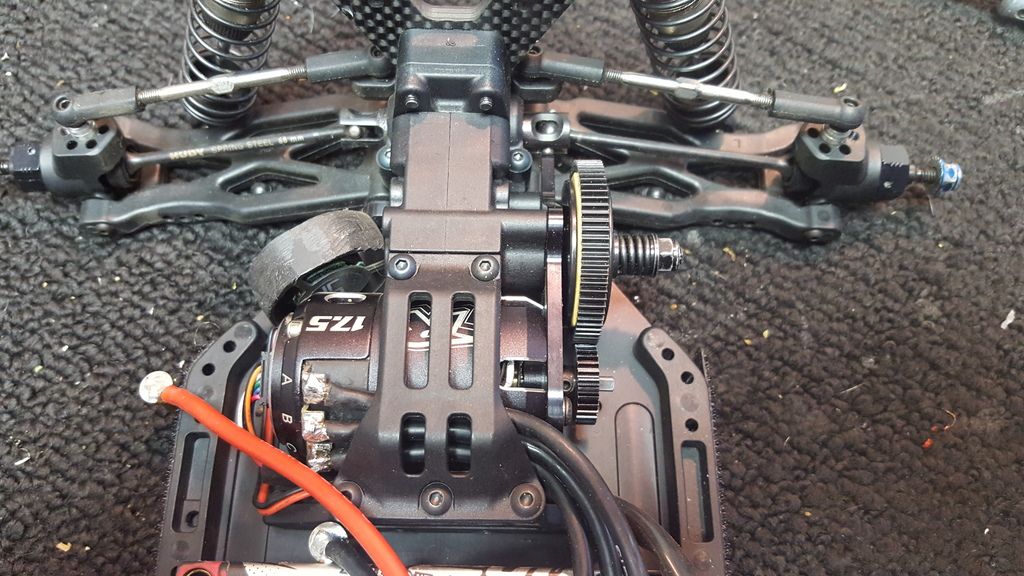

how i did it.

I drilled out ae 72 to fit

got 2 pairs, 4 total AE high torque slipper pads

Glued 2 together , repeat , so i had 2 extra thick slipper pads

eliminate 3rd disk pad,

allows you to tighten down without outer slipper disk bottoming out on shaft.

hope this help everyone,

ill post a pic

I drilled out ae 72 to fit

got 2 pairs, 4 total AE high torque slipper pads

Glued 2 together , repeat , so i had 2 extra thick slipper pads

eliminate 3rd disk pad,

allows you to tighten down without outer slipper disk bottoming out on shaft.

hope this help everyone,

ill post a pic

#893

Thank you for bringing these questions directly to us. This is good support, and we appreciate it. Dare I answer for the guys in the North West.

I have seen some guys running a 72, but only for the taller geared losi cars. I would venture to say that 95% of the guys running 17.5 run a 69 spur. It is the only spur I have run in the class in the last 4 years in my kyosho and AE cars. I think some would like the 72, just to fine tune motor position.

There are no super stock 13.5 classes for buggy up here. I would say more than half the 17.5 drivers run eliminators. They are pretty popular, but are not a must have. (I love mine)

1499 minimum weight. Most guys run their cars between 1500 and 1600. I prefer my cars around 1550. I think you guys have nailed the weight of the car. Keep it a tad light, and then we can ballast for balance and not be heavy.

1499 minimum weight. Most guys run their cars between 1500 and 1600. I prefer my cars around 1550. I think you guys have nailed the weight of the car. Keep it a tad light, and then we can ballast for balance and not be heavy.

#894

how i did it.

I drilled out ae 72 to fit

got 2 pairs, 4 total AE high torque slipper pads

Glued 2 together , repeat , so i had 2 extra thick slipper pads

eliminate 3rd disk pad,

allows you to tighten down without outer slipper disk bottoming out on shaft.

hope this help everyone,

ill post a pic

I drilled out ae 72 to fit

got 2 pairs, 4 total AE high torque slipper pads

Glued 2 together , repeat , so i had 2 extra thick slipper pads

eliminate 3rd disk pad,

allows you to tighten down without outer slipper disk bottoming out on shaft.

hope this help everyone,

ill post a pic

#897

back in the day.. i always adjusted the slipper.. so it slipped before the ball diff slipped.. i would hold left rear wheel.. and put a finger on the spur.. then turn the right rear wheel forward.. make sure the slipper slipped.. and adjust from there..  that shows how long its been for me..

that shows how long its been for me..

that shows how long its been for me..

that shows how long its been for me..

#899

Almost ready for first club race. And noticed that the on power is really noisy. I've got a Orion 13.5 with aluminum 28 pinion. But the stock spur gear that the kit comes with is rather firm plastic and makes a horrible noise. And yes I checked the mesh and my diff case is not too tight or loose. And I'm running the gear diff. Anyone else think that it's really noisy?

#900

Tech Regular

iTrader: (1)

Mine isn't particularly loud. It's slightly louder than non covered gears in 2wd buggy but to notice it you'd have to be pretty picky.

One thing I discovered a couple of years ago is that all pinion are not made equal. I have a compete set of pinions but not from the same manufacturer and some of them are super loud ! They didn't harm the spur but my god the noise makes it very worrying. The loudest I have is one that looks like the titanium ultimate racing ones. I can't confirm you that's the brand as it's not written on them and I bough it 5-6years ago so I can't remembrer, but it's the loudest hands down by a lot !

One thing I discovered a couple of years ago is that all pinion are not made equal. I have a compete set of pinions but not from the same manufacturer and some of them are super loud ! They didn't harm the spur but my god the noise makes it very worrying. The loudest I have is one that looks like the titanium ultimate racing ones. I can't confirm you that's the brand as it's not written on them and I bough it 5-6years ago so I can't remembrer, but it's the loudest hands down by a lot !

333Likes

333Likes