Team Associated T5M Discussion

#3318

Couple of notes first. I highly highly recommend drilling a 3rd outer hole in the front arm. This calms down the steering so much which the truck needs. It also allows you to run a softer spring and you'll need to add about 1mm more droop in the front shocks.

I always prefer the 4 gear in these conditions. However, if you feel like you still need the truck to hookup more a great mod is to raise the transmission 1mm. This is very easy. Just use plastic shims in the 2 forward transmission screws because they need to be trimmed to fit behind the C block. Then you need the other 2 on the bottom plus 2 at the rear of the case that mounts to the tower. Then for the bottom of the waterfall I just grind the bottom nubs flat and use an aluminum 1mm washer between it and the cradle. His transformed my truck on low bite!

Now, if you don't want to shim the tranny a simple way to gain grip is slot the 2 outside ribs of the waterfall using a cutting wheel on a dremel to gain flex.

Also, I prefer to use the kit springs (buggy springs) I feel these are much better in rough/bumpy conditions than the newer truck springs.

Front:

1.6 piston 35 oil 1 limiter 28mm stroke. Blue spring. Mounted middle tower/3rd hole on arm.

Camber link inside/inside with 3mm under ball stud. -1 camber

Front bulkhead and kickup 25/5

4mm trailing spindles.

1mm on steering rack

Rear:

1.7 piston 30 oil 1 limiter 34.75mm stroke. White spring(or green) Mounted inside tower inside on arm.

Camber block flipped down with 1mm under ball stud.

Plastic rear hubs middle hole with the .5M inserts for more toe

-2 camber

Brass C block 3+1

Alum D block (brass for more forward bite)

Hubs spaced forward and arms spaced to the rear.

I used a Reedy 5300 shorty with 50g weight plate underneath... Or use a square/saddle pack with no additional weight.

Battery all the way back or 1 thin pad forward.

It's also very important on med-low grip and bumpy tracks to get the brake and throttle dialed in just right. I always use as much brakes as possible without it upsetting the car when used hard. This usual means I dial it back a touch on the esc and usually -25% on my radio. For the throttle I adjust the drive frequency to match the grip level and size of the track. I start at the least aggressive which happens to be 16000hz. If it's too flat I go up a step.

#3319

Here's a setup I had a lot of success with this summer on many outdoor tracks ranging from very low to med grip loose dirt. Dry and wet conditions, medium sized to big 8th scale blown out tracks. tires used ranging from Double Dees to Flipouts to goosebumps. My T5m outdoors has been fantastic!

Couple of notes first. I highly highly recommend drilling a 3rd outer hole in the front arm. This calms down the steering so much which the truck needs. It also allows you to run a softer spring and you'll need to add about 1mm more droop in the front shocks.

I always prefer the 4 gear in these conditions. However, if you feel like you still need the truck to hookup more a great mod is to raise the transmission 1mm. This is very easy. Just use plastic shims in the 2 forward transmission screws because they need to be trimmed to fit behind the C block. Then you need the other 2 on the bottom plus 2 at the rear of the case that mounts to the tower. Then for the bottom of the waterfall I just grind the bottom nubs flat and use an aluminum 1mm washer between it and the cradle. His transformed my truck on low bite!

Now, if you don't want to shim the tranny a simple way to gain grip is slot the 2 outside ribs of the waterfall using a cutting wheel on a dremel to gain flex.

Also, I prefer to use the kit springs (buggy springs) I feel these are much better in rough/bumpy conditions than the newer truck springs.

Front:

1.6 piston 35 oil 1 limiter 28mm stroke. Blue spring. Mounted middle tower/3rd hole on arm.

Camber link inside/inside with 3mm under ball stud. -1 camber

Front bulkhead and kickup 25/5

4mm trailing spindles.

1mm on steering rack

Rear:

1.7 piston 30 oil 1 limiter 34.75mm stroke. White spring(or green) Mounted inside tower inside on arm.

Camber block flipped down with 1mm under ball stud.

Plastic rear hubs middle hole with the .5M inserts for more toe

-2 camber

Brass C block 3+1

Alum D block (brass for more forward bite)

Hubs spaced forward and arms spaced to the rear.

I used a Reedy 5300 shorty with 50g weight plate underneath... Or use a square/saddle pack with no additional weight.

Battery all the way back or 1 thin pad forward.

It's also very important on med-low grip and bumpy tracks to get the brake and throttle dialed in just right. I always use as much brakes as possible without it upsetting the car when used hard. This usual means I dial it back a touch on the esc and usually -25% on my radio. For the throttle I adjust the drive frequency to match the grip level and size of the track. I start at the least aggressive which happens to be 16000hz. If it's too flat I go up a step.

Couple of notes first. I highly highly recommend drilling a 3rd outer hole in the front arm. This calms down the steering so much which the truck needs. It also allows you to run a softer spring and you'll need to add about 1mm more droop in the front shocks.

I always prefer the 4 gear in these conditions. However, if you feel like you still need the truck to hookup more a great mod is to raise the transmission 1mm. This is very easy. Just use plastic shims in the 2 forward transmission screws because they need to be trimmed to fit behind the C block. Then you need the other 2 on the bottom plus 2 at the rear of the case that mounts to the tower. Then for the bottom of the waterfall I just grind the bottom nubs flat and use an aluminum 1mm washer between it and the cradle. His transformed my truck on low bite!

Now, if you don't want to shim the tranny a simple way to gain grip is slot the 2 outside ribs of the waterfall using a cutting wheel on a dremel to gain flex.

Also, I prefer to use the kit springs (buggy springs) I feel these are much better in rough/bumpy conditions than the newer truck springs.

Front:

1.6 piston 35 oil 1 limiter 28mm stroke. Blue spring. Mounted middle tower/3rd hole on arm.

Camber link inside/inside with 3mm under ball stud. -1 camber

Front bulkhead and kickup 25/5

4mm trailing spindles.

1mm on steering rack

Rear:

1.7 piston 30 oil 1 limiter 34.75mm stroke. White spring(or green) Mounted inside tower inside on arm.

Camber block flipped down with 1mm under ball stud.

Plastic rear hubs middle hole with the .5M inserts for more toe

-2 camber

Brass C block 3+1

Alum D block (brass for more forward bite)

Hubs spaced forward and arms spaced to the rear.

I used a Reedy 5300 shorty with 50g weight plate underneath... Or use a square/saddle pack with no additional weight.

Battery all the way back or 1 thin pad forward.

It's also very important on med-low grip and bumpy tracks to get the brake and throttle dialed in just right. I always use as much brakes as possible without it upsetting the car when used hard. This usual means I dial it back a touch on the esc and usually -25% on my radio. For the throttle I adjust the drive frequency to match the grip level and size of the track. I start at the least aggressive which happens to be 16000hz. If it's too flat I go up a step.

#3320

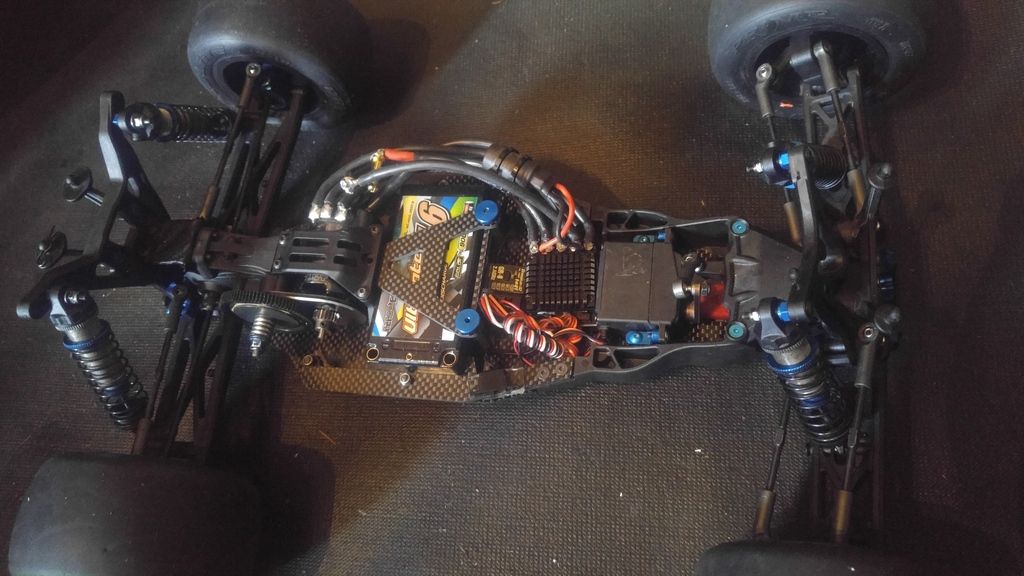

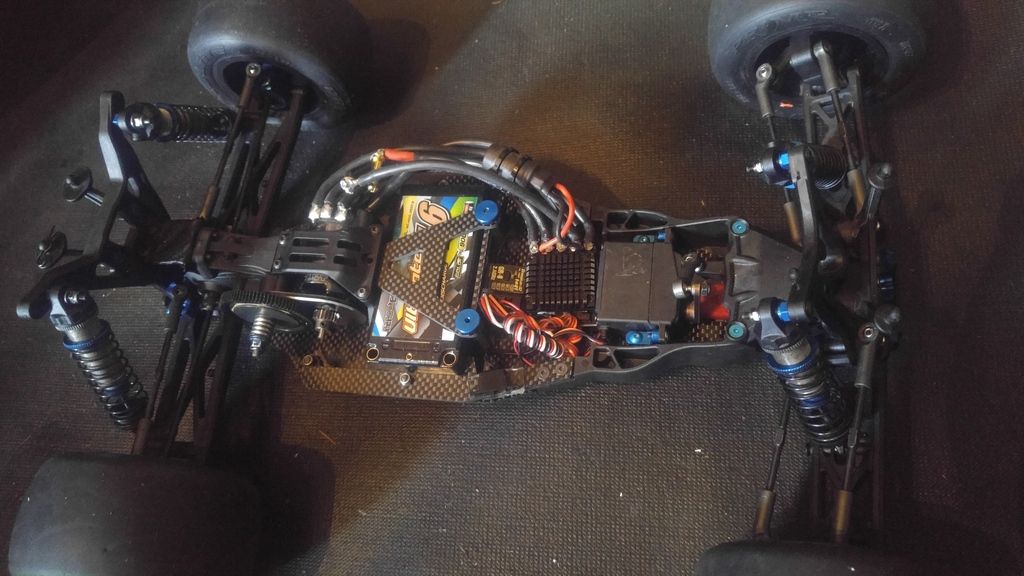

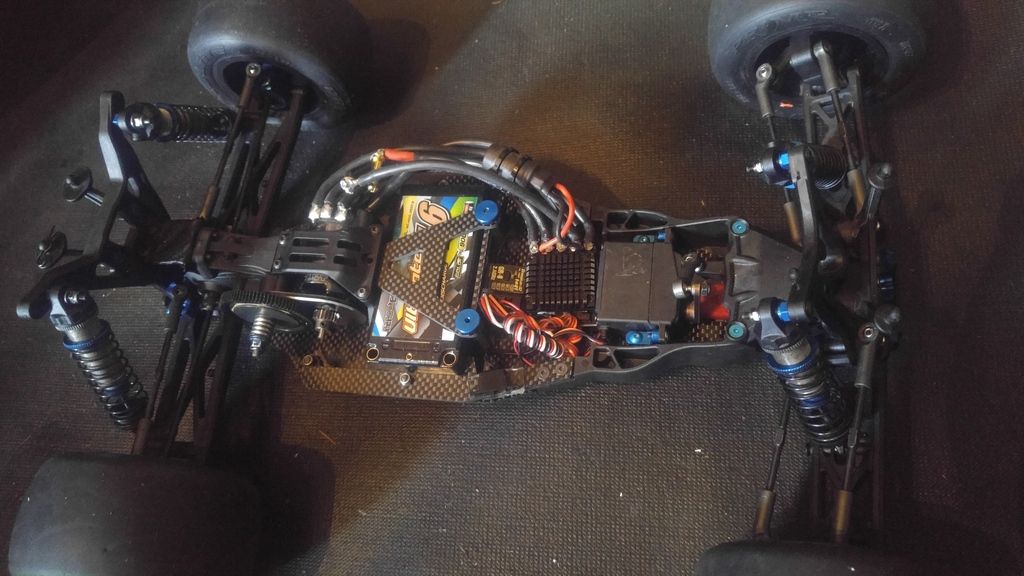

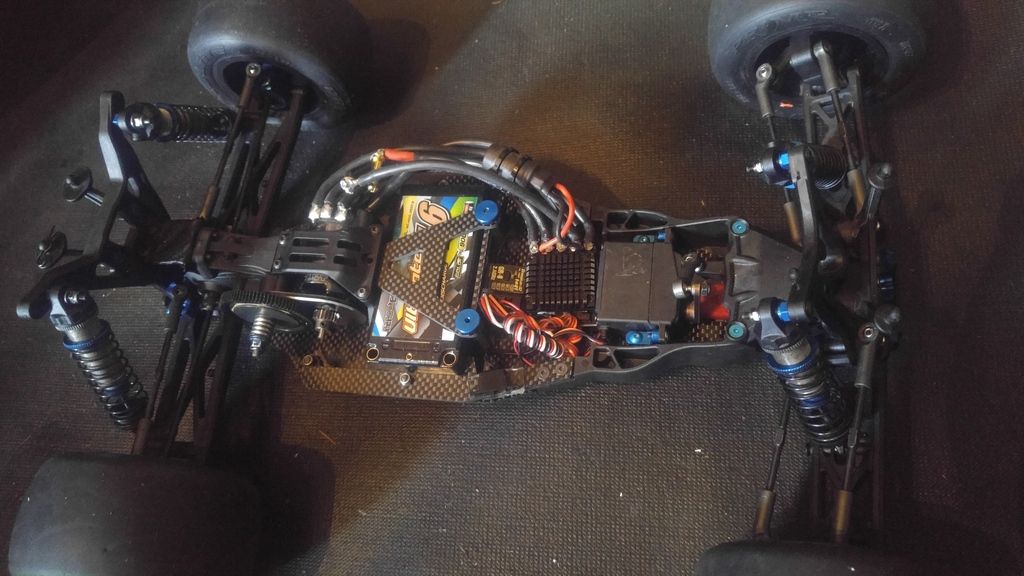

Just want to share my laydown tranny conversion using YZ2 transmission case and, waterfall from xb2.. I didnt want to drill too many holes on my infinity chassis so the transmission is held by only 2 screws instead of 4, tested it with the stock chassis last weekend and had no problems.. Altogether I only had to drill 2 holes on the chassis for the waterfall which is unavoidable... i think she looks pretty kick a$$

#3321

Tech Adept

iTrader: (9)

Just want to share my laydown tranny conversion using YZ2 transmission case and, waterfall from xb2.. I didnt want to drill too many holes on my infinity chassis so the transmission is held by only 2 screws instead of 4, tested it with the stock chassis last weekend and had no problems.. Altogether I only had to drill 2 holes on the chassis for the waterfall which is unavoidable... i think she looks pretty kick a$$

#3323

Tech Adept

Running my T5m in a 17.5 stock class at a local club track. I am interested in switching my drive train to a MIP puck system. I also have a B5m 17.5 stock buggy that I will do the same mod. I found the "shiny" puck system for the B5m (mip pn/ 14190). I can't find the same system for the T5m. The only thing I can find for the T5m is a "bi-metal" cvd kit (mip pn/ 15040). What is the difference in these two kits and what is the correct pn/kit that I need for my T5m to perform this upgrade. Are there any other parts outside of the kit that I would need to integrate the kit with my existing truck?

#3324

Tech Adept

Also, both cars already have the lightweight top shaft, diff gear and idler gears...

#3325

#3326

Is a new truck coming out?

#3328

Anyone having issues breaking servos? I have replaced my aluminum servo horn with an aluminum with a plastic insert, now I am stripping the plastic insert.

#3330

Tech Regular

I don't think I've seen anyone break a servo. Usually the bellcrank will break (or bend if you have the aluminum) before anything happens to the servo. What servo are you using? And maybe you should just use the stock plastic horn instead.

108Likes

108Likes