Losi 1/10 TEN-SCTE ARR 4x4 Short Course Truck Thread

Tech Adept

iTrader: (3)

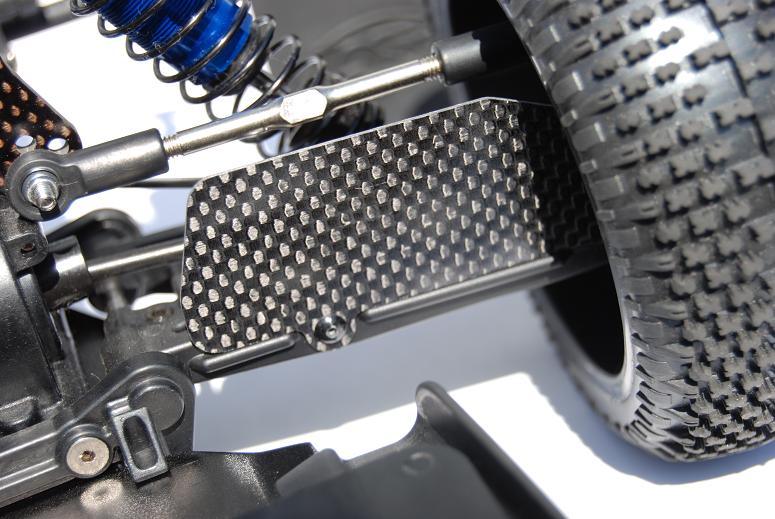

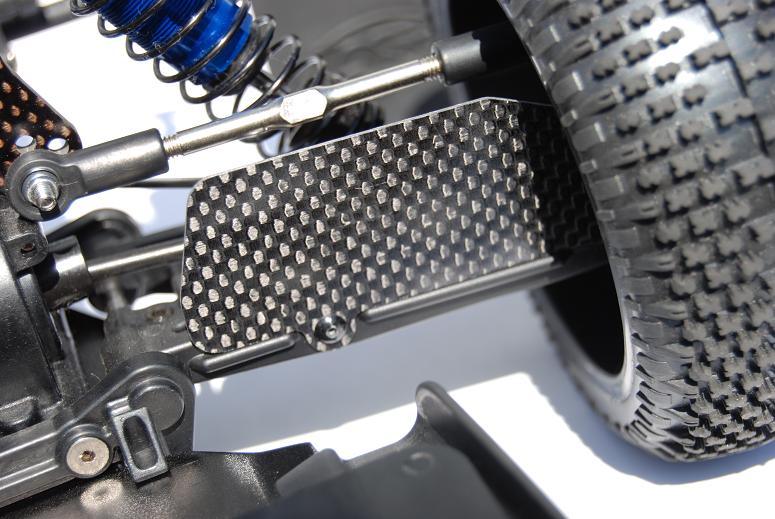

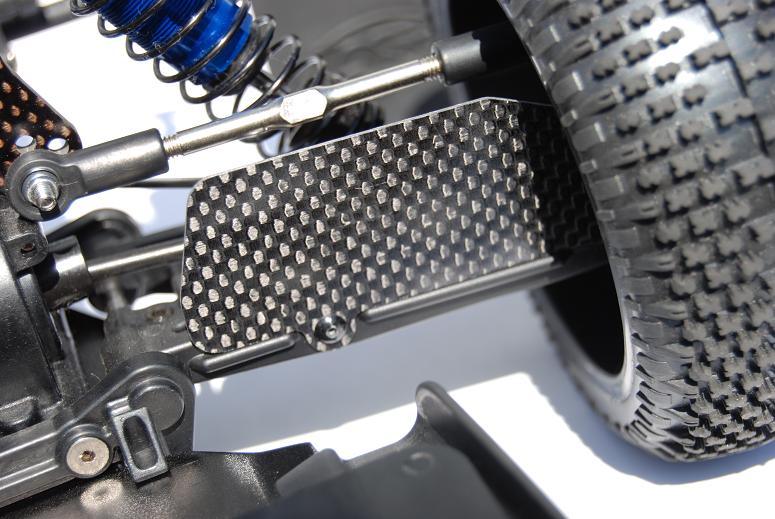

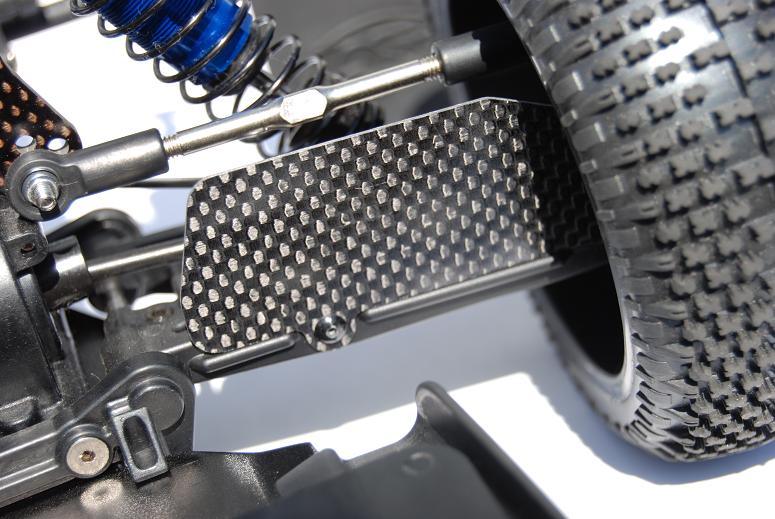

I've seen a few companies offer these mud guards for the rear a-arms. It looks like they basically try to protect the shock shaft. Who out there uses these and was this your reasoning? I am not too concerned about my A-Arms getting nicks in them, nor do I feel I should be concerned with the dog bone shafts as those are hard steel. But the shock shaft is a little more critical to precision as over time I'm sure nicks/chips/scratches cause it to leak, let dirt in, etc.

Example:

So that brings me to my next question. Those stupid little rubber boots are such a PITA to use. I bought a ton of them and it seems they tear pretty frequently, but I dont know if it is from stuff hitting them or more so when the bottom shock stand off piece comes lose from the shaft (falls off) or when the spring comes off of that and isn't centered. When that happens of course your shocks don't operate as intended and I can see them tearing up the rubber boot.

Any good suggestions on keeping those bottom shock stand offs staying on the rod end that is on the shock? I know there is a little notch and that lines up fine, but they do come off from time to time and I keep having to buy the whole kit just to get those little pieces. I have no need of the plastic shock caps or rings that come with it, I throw em out

These pieces third down from top (if you wondered):

Example:

So that brings me to my next question. Those stupid little rubber boots are such a PITA to use. I bought a ton of them and it seems they tear pretty frequently, but I dont know if it is from stuff hitting them or more so when the bottom shock stand off piece comes lose from the shaft (falls off) or when the spring comes off of that and isn't centered. When that happens of course your shocks don't operate as intended and I can see them tearing up the rubber boot.

Any good suggestions on keeping those bottom shock stand offs staying on the rod end that is on the shock? I know there is a little notch and that lines up fine, but they do come off from time to time and I keep having to buy the whole kit just to get those little pieces. I have no need of the plastic shock caps or rings that come with it, I throw em out

These pieces third down from top (if you wondered):

I've seen a few companies offer these mud guards for the rear a-arms. It looks like they basically try to protect the shock shaft. Who out there uses these and was this your reasoning? I am not too concerned about my A-Arms getting nicks in them, nor do I feel I should be concerned with the dog bone shafts as those are hard steel. But the shock shaft is a little more critical to precision as over time I'm sure nicks/chips/scratches cause it to leak, let dirt in, etc.

Example:

So that brings me to my next question. Those stupid little rubber boots are such a PITA to use. I bought a ton of them and it seems they tear pretty frequently, but I dont know if it is from stuff hitting them or more so when the bottom shock stand off piece comes lose from the shaft (falls off) or when the spring comes off of that and isn't centered. When that happens of course your shocks don't operate as intended and I can see them tearing up the rubber boot.

Any good suggestions on keeping those bottom shock stand offs staying on the rod end that is on the shock? I know there is a little notch and that lines up fine, but they do come off from time to time and I keep having to buy the whole kit just to get those little pieces. I have no need of the plastic shock caps or rings that come with it, I throw em out

These pieces third down from top (if you wondered):

Example:

So that brings me to my next question. Those stupid little rubber boots are such a PITA to use. I bought a ton of them and it seems they tear pretty frequently, but I dont know if it is from stuff hitting them or more so when the bottom shock stand off piece comes lose from the shaft (falls off) or when the spring comes off of that and isn't centered. When that happens of course your shocks don't operate as intended and I can see them tearing up the rubber boot.

Any good suggestions on keeping those bottom shock stand offs staying on the rod end that is on the shock? I know there is a little notch and that lines up fine, but they do come off from time to time and I keep having to buy the whole kit just to get those little pieces. I have no need of the plastic shock caps or rings that come with it, I throw em out

These pieces third down from top (if you wondered):

Not sure if this is any help but here you go...

I was having the same issue with my 8IGHT (same shock design) after rebuilding all 4 shocks once; until I realized that the little emboss in these pieces (third down from top) had to face outside (towards the wheels).

The other way round, they kept ripping off.

Shock boots: I gave up on these unless under severe muddy conditions.

Mud guards: these are pretty cool (using DE on my 8IGHT and just ordered a set for my SCTe) as if you are running no boots, they will slow down the damage to the shock shafts and do protect the overall A ARM, Shock etc...

V

At the very least put the split in the spring cup facing the wheel. Less chance of losing it. Also a small zip tie around the spring end and cup keeps them together.

Building my second SCTE. First one has a BEC chassis and I love that thing. On the back up I'm going to try the Bump Chassis w/ TLR tuning kit. My question is Do I really need the extended rear brace (RC8) or is this chassis stiff enough by it's self. I don't have one on my #1 truck and I like the way it drives.

Tech Addict

iTrader: (11)

Like others have said have the slot in the spring cup facing out towards the wheel. That will help.

I've done away with shock boots on all my vehicles. They can tear or get twisted around the shaft. They seem to be more trouble than they're worth to me. Just remember you may need to rebuild your shocks more often.

Those guards are nice, but DE makes some plastic ones I use.

I've done away with shock boots on all my vehicles. They can tear or get twisted around the shaft. They seem to be more trouble than they're worth to me. Just remember you may need to rebuild your shocks more often.

Those guards are nice, but DE makes some plastic ones I use.

Tech Addict

iTrader: (11)

I pulled my rear diff out the other night and noticed there is a good bit of play between the ring and pinion gears, but the diff is tight side to side. I put a 1mm washer between the pinion gear and the inner bearing and that tightened things up slightly. Is this common?

Tech Master

iTrader: (40)

Drill a lil hole un the spring retainer and zip tie it to the spring helps until the zip tie breaks ! Boots are useless !! Toss em they bind up your shocks!

Tech Adept

iTrader: (3)

I pulled my rear diff out the other night and noticed there is a good bit of play between the ring and pinion gears, but the diff is tight side to side. I put a 1mm washer between the pinion gear and the inner bearing and that tightened things up slightly. Is this common?

Tech Addict

iTrader: (11)

I dont know if this is what you are referring to, but if you put the pinion in and then put the diff in, close the case up and attempt to put the drive shaft on and tighten the set screw, it can be very hard to get the cup all the way in. The way I do it is I take the rear gear housing, I put the bearings in, then put the pinion in, push on it, put the drive shaft and cup on the other end, dab of blue loc-tite on the set screw, push the cup all the way in, tighten, then put the diff with the ring gear on it in. Makes it much easier to get everything together. Just how i do it...

[QUOTE=AgroAMG;10262583]I've seen a few companies offer these mud guards for the rear a-arms. It looks like they basically try to protect the shock shaft. Who out there uses these and was this your reasoning? I am not too concerned about my A-Arms getting nicks in them, nor do I feel I should be concerned with the dog bone shafts as those are hard steel. But the shock shaft is a little more critical to precision as over time I'm sure nicks/chips/scratches cause it to leak, let dirt in, etc.

Example:

So that brings me to my next question. Those stupid little rubber boots are such a PITA to use. I bought a ton of them and it seems they tear pretty frequently, but I dont know if it is from stuff hitting them or more so when the bottom shock stand off piece comes lose from the shaft (falls off) or when the spring comes off of that and isn't centered. When that happens of course your shocks don't operate as intended and I can see them tearing up the rubber boot.

Any good suggestions on keeping those bottom shock stand offs staying on the rod end that is on the shock? I know there is a little notch and that lines up fine, but they do come off from time to time and I keep having to buy the whole kit just to get those little pieces. I have no need of the plastic shock caps or rings that come with it, I throw em out

These pieces third down from top (if you wondered):

I still use the boots. When I install the I use a drop or two of shock oil directly into the boot. Then I work the oil throughout the boot squeesing the excess out of the bottom. When you install the boot the oil keeps the boot from sticking to the shaft and tearing the boot when your truck is on the track. Also when I blow out I'm carefull to not hit the boot because the compressed air will tear the boot. They still don't last a real long time but this will give them some extra life.

I also run the mud guards and would not run without them. The guards keep the mud off the rear shocks and arms area. The is especially good when they water the track and you have to run when it's not quite dry yet.

Example:

So that brings me to my next question. Those stupid little rubber boots are such a PITA to use. I bought a ton of them and it seems they tear pretty frequently, but I dont know if it is from stuff hitting them or more so when the bottom shock stand off piece comes lose from the shaft (falls off) or when the spring comes off of that and isn't centered. When that happens of course your shocks don't operate as intended and I can see them tearing up the rubber boot.

Any good suggestions on keeping those bottom shock stand offs staying on the rod end that is on the shock? I know there is a little notch and that lines up fine, but they do come off from time to time and I keep having to buy the whole kit just to get those little pieces. I have no need of the plastic shock caps or rings that come with it, I throw em out

These pieces third down from top (if you wondered):

I still use the boots. When I install the I use a drop or two of shock oil directly into the boot. Then I work the oil throughout the boot squeesing the excess out of the bottom. When you install the boot the oil keeps the boot from sticking to the shaft and tearing the boot when your truck is on the track. Also when I blow out I'm carefull to not hit the boot because the compressed air will tear the boot. They still don't last a real long time but this will give them some extra life.

I also run the mud guards and would not run without them. The guards keep the mud off the rear shocks and arms area. The is especially good when they water the track and you have to run when it's not quite dry yet.

Building my second SCTE. First one has a BEC chassis and I love that thing. On the back up I'm going to try the Bump Chassis w/ TLR tuning kit. My question is Do I really need the extended rear brace (RC8) or is this chassis stiff enough by it's self. I don't have one on my #1 truck and I like the way it drives.

Tech Adept

iTrader: (3)

Yeah, I see what you mean. What I'm referring to though is with the pinion pushed all the way in. Basically with everything in place there is a good bit of play if you hold the driveshaft and wiggle the diff back and forth. I put a washer on the pinion before sliding it through the bearings and some of that play is gone.

I experienced this when I didnt push the pinion from the back (the inside where the groves are) so that the shaft is pushed OUT as hard as possible, then attach the drive shaft like that. There is no way for the pinion to move in and out as you've pushed it in all the way (from inside where the grease is) and pushed the drive shaft cup on totally tight. But dunno.

Yeah, I see what you mean. What I'm referring to though is with the pinion pushed all the way in. Basically with everything in place there is a good bit of play if you hold the driveshaft and wiggle the diff back and forth. I put a washer on the pinion before sliding it through the bearings and some of that play is gone.

9Likes

9Likes