Team Associated TC6 Thread

#2659

Tech Apprentice

Hi All, I just finished building my TC6 and also have the hinge pin problem that was mentioned quite a few pages back. Im off to buy another set to be able to make sure all the hingepins have the same diameter. There is quite a bit of play in the caster block where the hingepin holding it in the arm is the smaller diamater.

Ive noticed with my kit if you are on the throttle while holding the car in your hand and turn the wheel fully the thing makes a gawdawful noise similar to cogging except its constant while the wheel is fully turned and full throttle is applied. When there is no steering involved the car revs up beautifully.

Will this problem disappear once the suspension has some load on it?

Could this be caused by the smaller diameter hingepin?

Or is there something else i should be checking. Ive tried several things and its driving me crazy trying to figure it out. Im going to the track tomorrow to do my first shakedown with the car, just want to make sure i dont damage anything in the process.

TIA.

Ive noticed with my kit if you are on the throttle while holding the car in your hand and turn the wheel fully the thing makes a gawdawful noise similar to cogging except its constant while the wheel is fully turned and full throttle is applied. When there is no steering involved the car revs up beautifully.

Will this problem disappear once the suspension has some load on it?

Could this be caused by the smaller diameter hingepin?

Or is there something else i should be checking. Ive tried several things and its driving me crazy trying to figure it out. Im going to the track tomorrow to do my first shakedown with the car, just want to make sure i dont damage anything in the process.

TIA.

Last edited by Mandirigma; 05-21-2011 at 08:47 AM. Reason: added info

#2660

The vibration is normal. It comes from extreme angle of the Universals, when combined with a spool. You can reduce vibration by removing the set screw that holds the pin in place in the universal and glue you retaining ring with a tiny drop of CA glue.

You should also try to shy away from ever running full lock on your car. Work on setting up your car a little more aggresively so that you can decrease steering lock helps reducing the vibration as well.

Ultimately, a lot of people end up either using a Gear diff in the front or getting some sort of Double Jointed/ True CVS Shafts if they really want to eliminate the in the front of their car.

You should also try to shy away from ever running full lock on your car. Work on setting up your car a little more aggresively so that you can decrease steering lock helps reducing the vibration as well.

Ultimately, a lot of people end up either using a Gear diff in the front or getting some sort of Double Jointed/ True CVS Shafts if they really want to eliminate the in the front of their car.

#2661

The vibration is normal. It comes from extreme angle of the Universals, when combined with a spool. You can reduce vibration by removing the set screw that holds the pin in place in the universal and glue you retaining ring with a tiny drop of CA glue.

You should also try to shy away from ever running full lock on your car. Work on setting up your car a little more aggresively so that you can decrease steering lock helps reducing the vibration as well.

Ultimately, a lot of people end up either using a Gear diff in the front or getting some sort of Double Jointed/ True CVS Shafts if they really want to eliminate the in the front of their car.

You should also try to shy away from ever running full lock on your car. Work on setting up your car a little more aggresively so that you can decrease steering lock helps reducing the vibration as well.

Ultimately, a lot of people end up either using a Gear diff in the front or getting some sort of Double Jointed/ True CVS Shafts if they really want to eliminate the in the front of their car.

#2662

Tech Master

iTrader: (16)

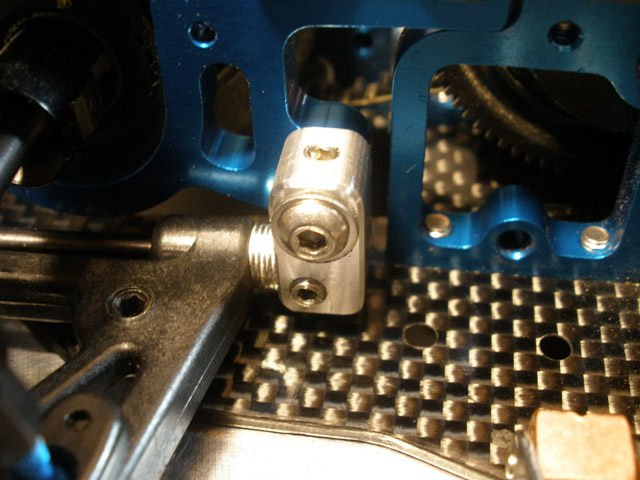

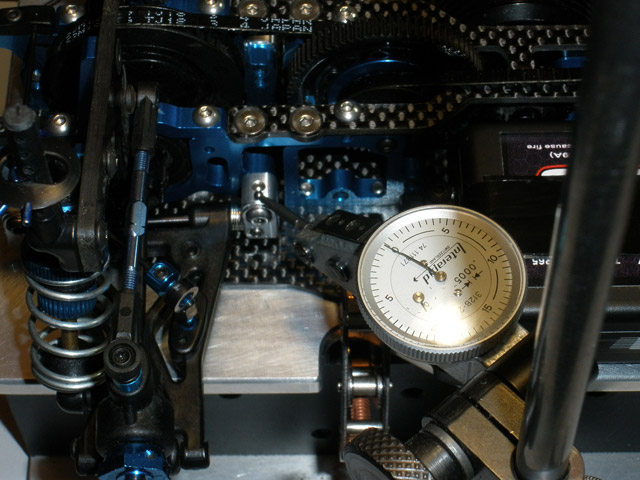

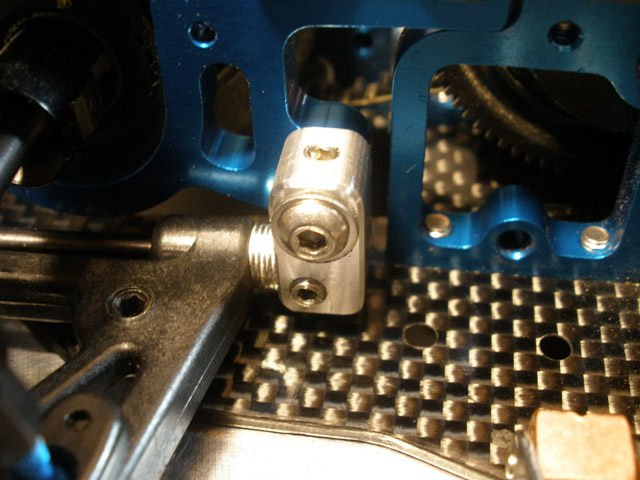

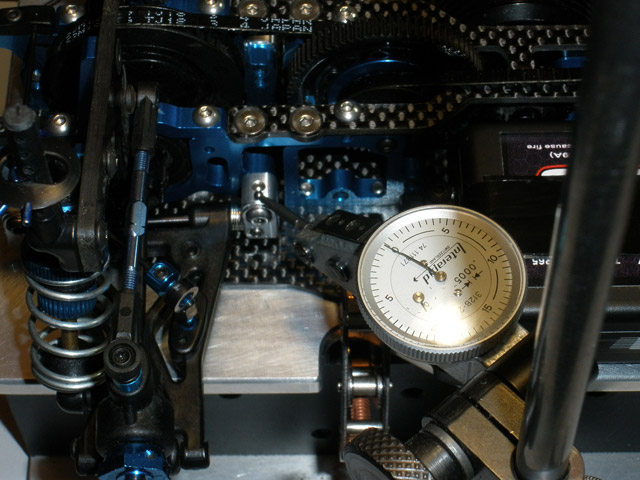

After running a few race weekends I found what others have noticed, a weakness in the arm mount blocks. They easily pivot, have excessive play, with fit between bushing and block, then again at pin. Mine was slop free at assembly but even the tightest I could get them would still move. Others have had the entire arm come loose. I set out to solve this, and as I posted several weeks ago adding a set screw to the block at pin stopped it, but the blocks are too weak to hold the screw.

So onto the REAL fix. I have designed a block that solves the problem, but the quandary was how many blocks to build for tuning options. This could get real expensive fast. So....after long thought, and some drafting work I have resolved that issue and also added a very nice tuning option. I named it Dial-a-Grip because it is just that. A single block that moves the Xray equivalent +/-.75 (.030) mm each direction from the 0 block mount location. Now you can dial a little to full anti / pro dive and anti / pro squat with a single screw adjustment just like droop. This will be fast and handy for quick testing or for changing track temps as you can really fine tune the amount. The travel goes 30% beyond the Kevin Hebert setup that use A3 anti dive in front so it should be all the travel needed for the current popular B0 mount location. Also, they are 1mm thicker per side so standard setup of 1mm shim is NOT needed.

I have several sets going to Reedy for further testing but am entirely confident this IS the cats meow!

These sets are already reserved so please don't ask as I have very limited quantities. There will be a few sets extra I'll put up next week, but thats it for now until I can make the production run.

Don't ask how much...they cost me a bundle to make, and I'm looking at another way to tool to save machine time...for now thats just a small hurdle.

Here is a link to the design followed with pics...welcome to Dial-a-Grip.

http://www.ppdbillet.com/TC6-LOCK-BLOCK.pdf

So onto the REAL fix. I have designed a block that solves the problem, but the quandary was how many blocks to build for tuning options. This could get real expensive fast. So....after long thought, and some drafting work I have resolved that issue and also added a very nice tuning option. I named it Dial-a-Grip because it is just that. A single block that moves the Xray equivalent +/-.75 (.030) mm each direction from the 0 block mount location. Now you can dial a little to full anti / pro dive and anti / pro squat with a single screw adjustment just like droop. This will be fast and handy for quick testing or for changing track temps as you can really fine tune the amount. The travel goes 30% beyond the Kevin Hebert setup that use A3 anti dive in front so it should be all the travel needed for the current popular B0 mount location. Also, they are 1mm thicker per side so standard setup of 1mm shim is NOT needed.

I have several sets going to Reedy for further testing but am entirely confident this IS the cats meow!

These sets are already reserved so please don't ask as I have very limited quantities. There will be a few sets extra I'll put up next week, but thats it for now until I can make the production run.

Don't ask how much...they cost me a bundle to make, and I'm looking at another way to tool to save machine time...for now thats just a small hurdle.

Here is a link to the design followed with pics...welcome to Dial-a-Grip.

http://www.ppdbillet.com/TC6-LOCK-BLOCK.pdf

#2663

Tech Apprentice

So the noise isn't that I built it wrong or could damage the car? Whew.

Hopefully the noise will reduce once things loosen up. This is the first time ive run a spool so the noise really scared me.

Many thanks.

#2664

Tech Apprentice

So im guessing from this you dont put the set screw back after you add a bit of CA glue to retaining ring?

#2668

After running a few race weekends I found what others have noticed, a weakness in the arm mount blocks. They easily pivot, have excessive play, with fit between bushing and block, then again at pin. Mine was slop free at assembly but even the tightest I could get them would still move. Others have had the entire arm come loose. I set out to solve this, and as I posted several weeks ago adding a set screw to the block at pin stopped it, but the blocks are too weak to hold the screw.

So onto the REAL fix. I have designed a block that solves the problem, but the quandary was how many blocks to build for tuning options. This could get real expensive fast. So....after long thought, and some drafting work I have resolved that issue and also added a very nice tuning option. I named it Dial-a-Grip because it is just that. A single block that moves the Xray equivalent +/-.75 (.030) mm each direction from the 0 block mount location. Now you can dial a little to full anti / pro dive and anti / pro squat with a single screw adjustment just like droop. This will be fast and handy for quick testing or for changing track temps as you can really fine tune the amount. The travel goes 30% beyond the Kevin Hebert setup that use A3 anti dive in front so it should be all the travel needed for the current popular B0 mount location. Also, they are 1mm thicker per side so standard setup of 1mm shim is NOT needed.

I have several sets going to Reedy for further testing but am entirely confident this IS the cats meow!

These sets are already reserved so please don't ask as I have very limited quantities. There will be a few sets extra I'll put up next week, but thats it for now until I can make the production run.

Don't ask how much...they cost me a bundle to make, and I'm looking at another way to tool to save machine time...for now thats just a small hurdle.

Here is a link to the design followed with pics...welcome to Dial-a-Grip.

http://www.ppdbillet.com/TC6-LOCK-BLOCK.pdf

So onto the REAL fix. I have designed a block that solves the problem, but the quandary was how many blocks to build for tuning options. This could get real expensive fast. So....after long thought, and some drafting work I have resolved that issue and also added a very nice tuning option. I named it Dial-a-Grip because it is just that. A single block that moves the Xray equivalent +/-.75 (.030) mm each direction from the 0 block mount location. Now you can dial a little to full anti / pro dive and anti / pro squat with a single screw adjustment just like droop. This will be fast and handy for quick testing or for changing track temps as you can really fine tune the amount. The travel goes 30% beyond the Kevin Hebert setup that use A3 anti dive in front so it should be all the travel needed for the current popular B0 mount location. Also, they are 1mm thicker per side so standard setup of 1mm shim is NOT needed.

I have several sets going to Reedy for further testing but am entirely confident this IS the cats meow!

These sets are already reserved so please don't ask as I have very limited quantities. There will be a few sets extra I'll put up next week, but thats it for now until I can make the production run.

Don't ask how much...they cost me a bundle to make, and I'm looking at another way to tool to save machine time...for now thats just a small hurdle.

Here is a link to the design followed with pics...welcome to Dial-a-Grip.

http://www.ppdbillet.com/TC6-LOCK-BLOCK.pdf

20Likes

20Likes