Shenzhen Surpass Tech Co. Ltd

#33

I just got my 13.5 v6. Looks awsome. As soon as i hand spun and checked for center of field i could tell it definitly needed reshimming. The rotor wanted to be closer to the back. I tried reshimming and found the rotor was actually contacking the rear plate. Not great. So i made rotor not legal and ground about 1 ish mm off shaft to get the clearance i needed. Reshimmed.( all in front). Feel about perfect now. Did gain over 200 rpm with timing at factory 28.

#34

I just got my 13.5 v6. Looks awsome. As soon as i hand spun and checked for center of field i could tell it definitly needed reshimming. The rotor wanted to be closer to the back. I tried reshimming and found the rotor was actually contacking the rear plate. Not great. So i made rotor not legal and ground about 1 ish mm off shaft to get the clearance i needed. Reshimmed.( all in front). Feel about perfect now. Did gain over 200 rpm with timing at factory 28.

I noticed the same rubbing, as well as on some other motors. Are you going to adjust the timing? I believe they like to be around 45*-48*. I can't remember right now. I guess I can look it up, but I'm too lazy right now. LOL....

#35

I am actually running it first at an event that allows boost. So i have the endbell at 25 with 15 boost and 5 turbo. I may add a bit more. Its spinning just over 30k. Locked i will start at 45 also. Excited to see how it does. It is like a nicey (better) made slot machine.

I am using sky toro 160 with dongle and app to phone. It shows the boost coming on live so you can set it very nicey. Reving and watching boost climb at the correct times.

I am using sky toro 160 with dongle and app to phone. It shows the boost coming on live so you can set it very nicey. Reving and watching boost climb at the correct times.

Last edited by jasburrito; 03-15-2024 at 09:20 PM.

#36

Update. The motor works good. I TQed the carpet sprint car class Up against some heavy hitters. Velocity TLR offset sprint, Fantom 6400 pro battery. On track rpm was 23000rpm. Free revs were 30000. Which is pretty close to 10000 rpm difference desired. So maybe I could have ran a tad more total timing.

Last edited by jasburrito; 03-26-2024 at 07:08 PM.

#37

Tech Initiate

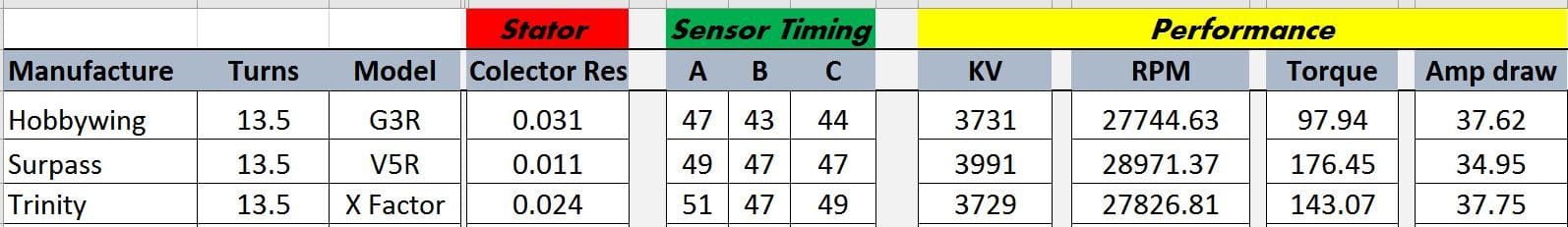

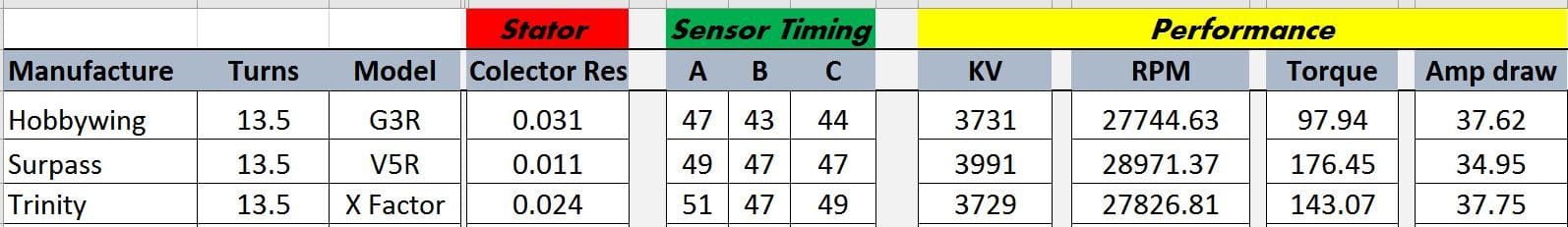

I have been running Surpass motors for about 12 years now both on and off road. The big difference you will find is that Surpass uses some of the strongest magnets I have ever seen and the sensors are vertical rather than the industry standard of horizontal. They also do an interesting thing of using a boss on the adjustment side of the end bell that inserts into the center of the bearing keeping the timing adjustment moving symmetrical with the rotor. I dyno tune motors all the time for people so I have seen about every brand all done on a Minipro motor dyno on a regulated power supply. The regulated power supply ensures I am using the same voltage to compare and tune the motor. When tuned they produce 60 more newton meters of torque than anything I have seen to include some of the hand selected motors. This becomes important because torque with carry the weight of the car faster out of the turns and accelerate on the face of the jumps. If you gear down with a high RPM motor that has low torque to achieve acceleration them you loose the RPM. Things I have noticed that are happening with other brands is a trend to eliminate shimming on the sensor side of the motor by adding a shank or boss to the rotor that rides against the bearing. This eliminated some tuning and adds rotating weight the rotor. The only thing I can see is that this makes assembly post manufacturing cheaper because it requires only shimming on the pinion side, but doesn't improve the motor. Those that I have tuned with this new rotor are OK but never come out as the upper tier of RPM and torque.

#39

Tech Initiate

Its the trend toward removing the ability to shim on the sensor side that I am not in favor of. It would make assembly at the plant much easier but short changes the tuning for the racer.

#41

Tech Adept

iTrader: (12)

With both the 17.5 and 13.5 V6 motors I've found it almost impossible to find the sweet spot gearing and timing for 1/12 1s classes. I get completely destroyed by pretty much all other brands of motors. I spent the last 2 big trophy races chasing rollouts just to end up as much as 4 laps off the pace. Last year running a different brand motor I was in A main at both races in the same classes and on the lead lap with the same chassis set up and battery. I tried to bounce ideas off a lot of different racers over the last 3 months to find some improvements....but in the end I found nothing. Still brutally slow.....

#42

With both the 17.5 and 13.5 V6 motors I've found it almost impossible to find the sweet spot gearing and timing for 1/12 1s classes. I get completely destroyed by pretty much all other brands of motors. I spent the last 2 big trophy races chasing rollouts just to end up as much as 4 laps off the pace. Last year running a different brand motor I was in A main at both races in the same classes and on the lead lap with the same chassis set up and battery. I tried to bounce ideas off a lot of different racers over the last 3 months to find some improvements....but in the end I found nothing. Still brutally slow.....

What is the motor temp when coming off the track?

#44

Strong rotors are not good for light 1/12 with 1s. Maybe try baking the rotor to lose some strength? 13.5t non spec outlaw all like smaller and weaker rotors. Cannot run high timing with big strong rotors 13.5t. Pull to many amps.

#45

I wonder if there is something else wrong. I know of a couple other guys who are part of consistently some of the fastest using the same motor. You can try running the lighter rotor in it. I know that will add a few hundred RPMs. It might be better with the 1s voltage.

24Likes

24Likes