Bleeders for Mini-T Aluminum shocks

#1

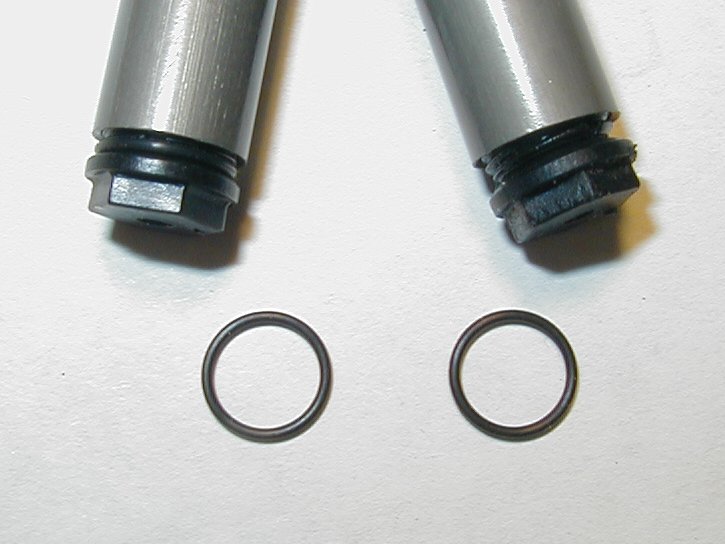

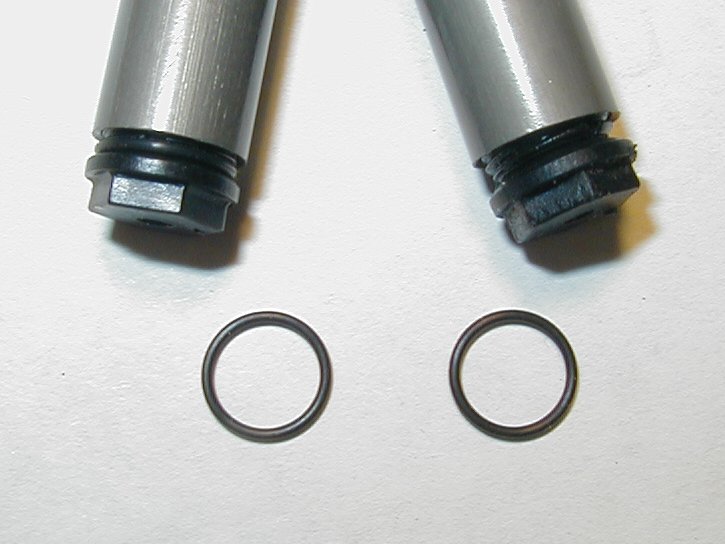

I modified some Mini-T aluminum shocks to add bleeders like on the slider shocks. Here's a pic of the shock bodies:

I use these along with my cartridge/shock body o-ring seals to get the shocks built nicely with no leaks:

Here's a pic of one of them mounted on my slider:

http://s92437987.onlinehome.us/ebayp...nted-shock.jpg

and a pic of a shock body mounted in the milling machine to be drilled for the bleeder:

http://s92437987.onlinehome.us/ebayp...ling-shock.jpg

I use these along with my cartridge/shock body o-ring seals to get the shocks built nicely with no leaks:

Here's a pic of one of them mounted on my slider:

http://s92437987.onlinehome.us/ebayp...nted-shock.jpg

and a pic of a shock body mounted in the milling machine to be drilled for the bleeder:

http://s92437987.onlinehome.us/ebayp...ling-shock.jpg

#2

nice work, especially the polishing of the shock bodies

but I have never had a leakage problem using two of the included plastic seals

but I have never had a leakage problem using two of the included plastic seals

#3

As long as you only removed and polished the outside. That coat covering actually has some chemicals in it to reduce friction on the piston to make the shock act more consistent.

#4

and wouldn't that coating rub off rather quickly

with the pistons sliding up and down repeatedly?

#5

Thats why its a hard coating. And yes, it does eventually wear away (hence when a racer buys new ones, though shouldn't happen very often if shocks taken care off/rebuilt enough). Im pretty sure those are teflon coated like the AE ones as well since they had that grey/green sheen to them. I dont know how AE is doing it these days since their FT shocks seem to be blue. But anyhoo, separate topic.

#6

Tech Master

iTrader: (89)

Thats why its a hard coating. And yes, it does eventually wear away (hence when a racer buys new ones, though shouldn't happen very often if shocks taken care off/rebuilt enough). Im pretty sure those are teflon coated like the AE ones as well since they had that grey/green sheen to them. I dont know how AE is doing it these days since their FT shocks seem to be blue. But anyhoo, separate topic.

#7

The standard plastic seals last one or two rebuilds for me then don't seal as well so I went with the O-rings.

#8

Actually, the shocks in the pic are the dynamite clear anodized ones. They were cheap, so I figured I'd try those before hacking away at my anodized shock bodies.

The standard plastic seals last one or two rebuilds for me then don't seal as well so I went with the O-rings.

The standard plastic seals last one or two rebuilds for me then don't seal as well so I went with the O-rings.

#9

Tech Apprentice

iTrader: (2)

Nice work! I wish I had a mill like that!

not directly related, but the coating commonly used on motorcycles and mt. bike suspension is a titanium/nitride coating, used to reduce friction and promote durability. I highly doubt this process is used on Losi shocks though, due to the immense cost involved....

not directly related, but the coating commonly used on motorcycles and mt. bike suspension is a titanium/nitride coating, used to reduce friction and promote durability. I highly doubt this process is used on Losi shocks though, due to the immense cost involved....

#10

Tech Master

iTrader: (89)

Nice work! I wish I had a mill like that!

not directly related, but the coating commonly used on motorcycles and mt. bike suspension is a titanium/nitride coating, used to reduce friction and promote durability. I highly doubt this process is used on Losi shocks though, due to the immense cost involved....

not directly related, but the coating commonly used on motorcycles and mt. bike suspension is a titanium/nitride coating, used to reduce friction and promote durability. I highly doubt this process is used on Losi shocks though, due to the immense cost involved....

They do have Ti Nitride shock shafts, http://www.amainhobbies.com/product_...ducts_id/15463 Associated has switched to this as well over their unobtanium coating they used to use. Both Losi and Associated are pretty big companies

#11

Tech Apprentice

iTrader: (2)

They do have Ti Nitride shock shafts, http://www.amainhobbies.com/product_...ducts_id/15463 Associated has switched to this as well over their unobtanium coating they used to use. Both Losi and Associated are pretty big companies

I guess I underestimate though, haha.

I know on a set of Marzocchi triple clamp DH forks for an MTB, the Ti-Ni coating is typically a few hundo as an upgrade, even more on MX, sometimes only reserved to factory works bikes.

#12

Nice work! I wish I had a mill like that!

not directly related, but the coating commonly used on motorcycles and mt. bike suspension is a titanium/nitride coating, used to reduce friction and promote durability. I highly doubt this process is used on Losi shocks though, due to the immense cost involved....

not directly related, but the coating commonly used on motorcycles and mt. bike suspension is a titanium/nitride coating, used to reduce friction and promote durability. I highly doubt this process is used on Losi shocks though, due to the immense cost involved....

the inside of the shocks, no