Xray T4 18

|

|||

#661

Would explain it. Surprised they didn't attempt to disguise them more though.

#662

Tech Apprentice

The wiki (first sticky post) is all messed up for me, is that occurring for anyone else?

I was trying to work out the best spares to keep in hand, and if I should grab the graphite c-hubs and whatever else) for very low grip asphalt?

Anyone have a quick list, with part numbers, of what I should have for race days? And also, any feedback on the graphite components for low grip asphalt?

Cheers

I was trying to work out the best spares to keep in hand, and if I should grab the graphite c-hubs and whatever else) for very low grip asphalt?

Anyone have a quick list, with part numbers, of what I should have for race days? And also, any feedback on the graphite components for low grip asphalt?

Cheers

#663

Tech Adept

Has anyone ran alum arms on asphalt ? If so how did they felt ?

#664

Tech Initiate

Those of you using XR10 pro esc... how do you recalibrate

transmitter with motor already soldered? I switched transmitter and esc wont go to recalibration mode... thx

transmitter with motor already soldered? I switched transmitter and esc wont go to recalibration mode... thx

#665

. Make sure a sensor cable is attached properly. Also make sure that you do not have solder accidentally bridging connections between motor wires at the ESC, or on the motor. In extreme cases, I've seen solder drip down the contact and bridge the motor connections inside the motor.

. Make sure a sensor cable is attached properly. Also make sure that you do not have solder accidentally bridging connections between motor wires at the ESC, or on the motor. In extreme cases, I've seen solder drip down the contact and bridge the motor connections inside the motor. General calibration process:

1. Turn Transmitter ON, and make sure EPA is set to 100% for throttle and brake. Ensure trim and subtrim are set to 0.

2. With the ESC off and plugged into a battery and leaving the transmitter's throttle position at neutral, press and hold the power switch until the light begins to blink red, then release the button.

3. With throttle at neutral, click the button. You should hear a single beep.

4. Move and hold the transmitter to full throttle and click the button on the ESC. You should hear two beeps.

5. Move and hold the transmitter to full brake and click the button on the ESC. You should hear three beeps.

6. Move the throttle back to neutral and wait a 3-5 seconds. The ESC should operate correctly. If full throttle gives full brake instead, reverse the throttle channel on the transmitter and repeat the calibration process.

Hope that helps.

-Korey

#666

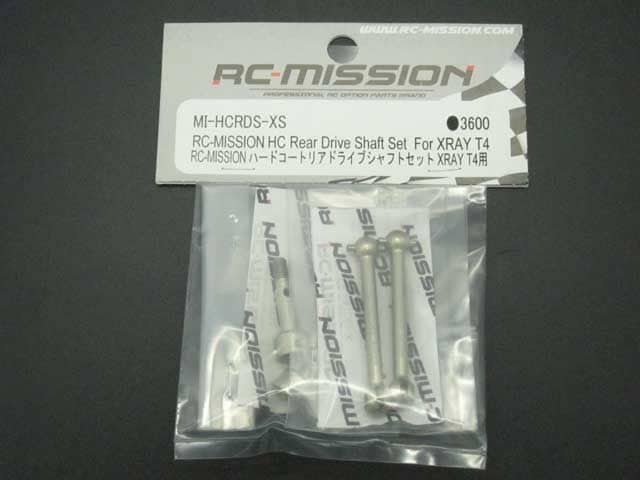

RC MISSION

New T4 Option Parts

T4'18 ULP Shock Shaft Ti-Coated 3x21mm ( Shorter 1mm than Original )

High Quality Progressive Shock Insert w/Piston for T4'18

Suspension Shaft Lubrication Coated for T4

Hard Coated Rear Drive Shaft Set for T4

Hard Coated Universal Dogbone for T4

4.25mm Wheel Hub for T4

Aluminum Center Pulley 20T for T4

#668

"Suspension Shaft Lubrication Coated for T4"

I never see the point in decreasing the friction of wishbone suspension shafts? They can be quite snug in the wishbone as they only rotate at the ball end in the suspension mount.

I always check my suspension is free and drops effortlessly under it's own weight but don't worry too much if the shaft is tight in the wishbone. Am I missing something?

I never see the point in decreasing the friction of wishbone suspension shafts? They can be quite snug in the wishbone as they only rotate at the ball end in the suspension mount.

I always check my suspension is free and drops effortlessly under it's own weight but don't worry too much if the shaft is tight in the wishbone. Am I missing something?

#669

"Suspension Shaft Lubrication Coated for T4"

I never see the point in decreasing the friction of wishbone suspension shafts? They can be quite snug in the wishbone as they only rotate at the ball end in the suspension mount.

I always check my suspension is free and drops effortlessly under it's own weight but don't worry too much if the shaft is tight in the wishbone. Am I missing something?

I never see the point in decreasing the friction of wishbone suspension shafts? They can be quite snug in the wishbone as they only rotate at the ball end in the suspension mount.

I always check my suspension is free and drops effortlessly under it's own weight but don't worry too much if the shaft is tight in the wishbone. Am I missing something?

#670

"Suspension Shaft Lubrication Coated for T4"

I never see the point in decreasing the friction of wishbone suspension shafts? They can be quite snug in the wishbone as they only rotate at the ball end in the suspension mount.

I always check my suspension is free and drops effortlessly under it's own weight but don't worry too much if the shaft is tight in the wishbone. Am I missing something?

I never see the point in decreasing the friction of wishbone suspension shafts? They can be quite snug in the wishbone as they only rotate at the ball end in the suspension mount.

I always check my suspension is free and drops effortlessly under it's own weight but don't worry too much if the shaft is tight in the wishbone. Am I missing something?

#671

When you add a load to the suspension, the force of friction increases between the suspension arm and the hinge pin regardless of quality of fitment. The coating on the hinge pins is ultra slippery (more so than just polishing), and allows the suspension to move more freely under load. They are some of my favorite parts from RC mission.

#674

Tech Initiate

Does anyone have any insight on if the 2019 car will be a T4, or a redesigned T5?

#675

262Likes

262Likes

)

)