Picco P7 Evo 2

#136

I run the ofna hot(picco) plug and at about 35-45 end point on throttle with a 8mm venturi I get 220 degrees and about 7.5 min+ on a 125 associated tank. When you limit the end point of the throttle ive found that it changes your tuning mindset a bit. Bottom end becomes more crucial than if you ran the motoro wide open.

#137

I read a series of articles by Ron Paris and here is what I consider the essence: It is very frequent at any track to see engines tuned very wrong, not only producing lower performance, but actually putting the motor's integrity in danger (or at least shortenning it's life).

Basically, many times you find the low end needle is too ritch, so you compensate with a higher throttle to avoid the motor from stalling. Then, you measure the temp...it's too low, so you lean the high end needle: DANGEROUS!!

Bottom line is: you are running with the HN too lean, equals poor lubrication and risk of overheating after running the motor a while.

If you lean the low end to the right proportion, your throttle will be easy to adjust (also better idle) and your high end will be in the right spot.

Still, I've been told to keep my Picco just a tiny bit ritch on the low end, and it seems to work better....

What's your opinion??

Basically, many times you find the low end needle is too ritch, so you compensate with a higher throttle to avoid the motor from stalling. Then, you measure the temp...it's too low, so you lean the high end needle: DANGEROUS!!

Bottom line is: you are running with the HN too lean, equals poor lubrication and risk of overheating after running the motor a while.

If you lean the low end to the right proportion, your throttle will be easy to adjust (also better idle) and your high end will be in the right spot.

Still, I've been told to keep my Picco just a tiny bit ritch on the low end, and it seems to work better....

What's your opinion??

#138

I read a series of articles by Ron Paris and here is what I consider the essence: It is very frequent at any track to see engines tuned very wrong, not only producing lower performance, but actually putting the motor's integrity in danger (or at least shortenning it's life).

Basically, many times you find the low end needle is too ritch, so you compensate with a higher throttle to avoid the motor from stalling. Then, you measure the temp...it's too low, so you lean the high end needle: DANGEROUS!!

Bottom line is: you are running with the HN too lean, equals poor lubrication and risk of overheating after running the motor a while.

If you lean the low end to the right proportion, your throttle will be easy to adjust (also better idle) and your high end will be in the right spot.

Still, I've been told to keep my Picco just a tiny bit ritch on the low end, and it seems to work better....

What's your opinion??

Basically, many times you find the low end needle is too ritch, so you compensate with a higher throttle to avoid the motor from stalling. Then, you measure the temp...it's too low, so you lean the high end needle: DANGEROUS!!

Bottom line is: you are running with the HN too lean, equals poor lubrication and risk of overheating after running the motor a while.

If you lean the low end to the right proportion, your throttle will be easy to adjust (also better idle) and your high end will be in the right spot.

Still, I've been told to keep my Picco just a tiny bit ritch on the low end, and it seems to work better....

What's your opinion??

#139

Kamikaze recommended the Jammin JP4 pipe for P7R .. I wonder if this pipe is good for it or if there is another thats suits best

input

input

#140

Hello there boys

there is a newer version of P7R Evo 2?

I got this pic from net. don't remember the website. if I am using someone pic please tell me

http://s133.photobucket.com/albums/q...t=qm62eua5.jpg

it shows a new graphic design for cooling head

there is a newer version of P7R Evo 2?

I got this pic from net. don't remember the website. if I am using someone pic please tell me

http://s133.photobucket.com/albums/q...t=qm62eua5.jpg

it shows a new graphic design for cooling head

#142

You can use the JP2 and the JP4 as well as the 069 and the 2046. These are the choices that you have for pipes. The 069 will give you more bottom with a softer top while the 2046 gives you more mid top and softens up the bottom. Please understand that the P7 has alot of bottom end as well from the start so you know. I have also run the JP2 and the pipe works well all around the JP4 I have not run yet for good info I have just seen them run. For the newest version it is all the same just a different heatsink graphic layout.

#143

Tech Regular

The best pipe that I've found that works the best for this motor and the JPX .21 is the Ofna 053 pipe or the JP2.

#144

the best pipe is a 086 on a short conical manifold.... 053 is very close but the 086 provides better overall power........ the JP-2 actually kills this motor pretty good...... I have X-Dyno reports on quite a few different pipes on this motor...

#145

Tech Master

iTrader: (66)

The JP2 pipe is a JP1 with a shortened expansion chamber and doesn't always tune right on alot of engines. Especially engines with higher transfer ports designed for higher RPM operation. I have always run a JP1 on most engines and I ran a P7 Evo 2 years ago and it loved the JP1 due to the high port timing stock and especially after I raised it to increase blowdown timing.

As far as the glow plugs are concerned, I recommend running the coldest plugs you can get away with. All of my engines that I modify love the cold plugs. I have had great success with the RB Concepts 8 and Novarossi 8 or 9 plugs which have the thickest filiment and keep the engine running cooler without the preignition problems. By doing this, I can get away with running 30% nitro with a .004" shim removed for increased throttle response and low end torque on high transfer timing engines such as the Piccp P7's and Rb S7's. The motors take a little longer to fire up and get to temp but for the extra 30 seconds it takes, it is alot more resiliant to rich tuning because the filiment stays hotter longer in between cycles due to the thicker filiment takes more time and more fuel to cool if off to the point of a flame out caused by too rich of settings. I DO NOT recommend the shim removal and higher nitro content unless you are a pro engine tuner. They detonate very easily and unless you have an ear for it and can hear the engine when it starts to change tune, i wouldn't do it. Running 30% is fine with stock shims in most engines if you run a colder plug but be very careful if you venture into the removing shims territory.

As far as temps, my Picco P7 always like to run between 250-260. I had a P3-28 that ran a solid 270-271 every race and even during the 90 minute endurance races it temped at 270 at the 10 minute mark and 271 at the 90 minutes mark. It loved every bit of it and it ran 8 gallons and I sold it to a guy in California last year and it is still running strong. I couldn't kill that motor if I wanted to.

Don't be overly concerned about engine temps. They are a good tuning reference but not the bible on where an engine likes to run. All engines are made from different qualities of metal which have different heat saturation properties along with different style heads with different cooling surface percentages. Alot of engines run similar temps but again not all will like what the other likes. It also depends on the vehicle its in and how much stress you are putting on the motor versus what type of air is getting the engine to cool it down during operaton. Alot of people tune the motor with the body off and get respectable temps and then race with the body on and the car runs the same, it just comes in 15-20 degress hotter because of the body lines pushing the air up and over the cooling head. The big concern is, does the motor respond well in all situations? , does it have good smoke all around? , does it sound good with no lean hesitation? If you can answer yes to all three answers, then chances are its tuned pretty decently and who cares if it comes in at 190 or 270. If it runs they way it should, the don't worry about it. Just use the temp as a reference to help determine possible problems in the future with that and only that engine.

The exhaust gas temperature is what builds the heat in the motor. If you were to put probes in the header like we did on are grass sleds, you would find the exhaust temp is usually between 1050 and 1200 degrees. The melting point of aluminum is 1400 so thats why I said not to worry about head temps too much if you think the motor runs and sounds good. I talked with the guys at Novarossi, Picco and OS and they all said the engines are built to handle temps well over 300 degrees head temp but obviously recommend cooler temps to stay on the conservative side and to keep their asses in check. thats another reason why running too rich isn't good for an engine either because the excess fuel burn in the pipe causing an overheating condition as well.

I know I get wordy sometimes fellas but I can't help myself. I take a bad running engine personally

Mark @ www.PowerHouseRCPerformance.com

As far as the glow plugs are concerned, I recommend running the coldest plugs you can get away with. All of my engines that I modify love the cold plugs. I have had great success with the RB Concepts 8 and Novarossi 8 or 9 plugs which have the thickest filiment and keep the engine running cooler without the preignition problems. By doing this, I can get away with running 30% nitro with a .004" shim removed for increased throttle response and low end torque on high transfer timing engines such as the Piccp P7's and Rb S7's. The motors take a little longer to fire up and get to temp but for the extra 30 seconds it takes, it is alot more resiliant to rich tuning because the filiment stays hotter longer in between cycles due to the thicker filiment takes more time and more fuel to cool if off to the point of a flame out caused by too rich of settings. I DO NOT recommend the shim removal and higher nitro content unless you are a pro engine tuner. They detonate very easily and unless you have an ear for it and can hear the engine when it starts to change tune, i wouldn't do it. Running 30% is fine with stock shims in most engines if you run a colder plug but be very careful if you venture into the removing shims territory.

As far as temps, my Picco P7 always like to run between 250-260. I had a P3-28 that ran a solid 270-271 every race and even during the 90 minute endurance races it temped at 270 at the 10 minute mark and 271 at the 90 minutes mark. It loved every bit of it and it ran 8 gallons and I sold it to a guy in California last year and it is still running strong. I couldn't kill that motor if I wanted to.

Don't be overly concerned about engine temps. They are a good tuning reference but not the bible on where an engine likes to run. All engines are made from different qualities of metal which have different heat saturation properties along with different style heads with different cooling surface percentages. Alot of engines run similar temps but again not all will like what the other likes. It also depends on the vehicle its in and how much stress you are putting on the motor versus what type of air is getting the engine to cool it down during operaton. Alot of people tune the motor with the body off and get respectable temps and then race with the body on and the car runs the same, it just comes in 15-20 degress hotter because of the body lines pushing the air up and over the cooling head. The big concern is, does the motor respond well in all situations? , does it have good smoke all around? , does it sound good with no lean hesitation? If you can answer yes to all three answers, then chances are its tuned pretty decently and who cares if it comes in at 190 or 270. If it runs they way it should, the don't worry about it. Just use the temp as a reference to help determine possible problems in the future with that and only that engine.

The exhaust gas temperature is what builds the heat in the motor. If you were to put probes in the header like we did on are grass sleds, you would find the exhaust temp is usually between 1050 and 1200 degrees. The melting point of aluminum is 1400 so thats why I said not to worry about head temps too much if you think the motor runs and sounds good. I talked with the guys at Novarossi, Picco and OS and they all said the engines are built to handle temps well over 300 degrees head temp but obviously recommend cooler temps to stay on the conservative side and to keep their asses in check. thats another reason why running too rich isn't good for an engine either because the excess fuel burn in the pipe causing an overheating condition as well.

I know I get wordy sometimes fellas but I can't help myself. I take a bad running engine personally

Mark @ www.PowerHouseRCPerformance.com

#146

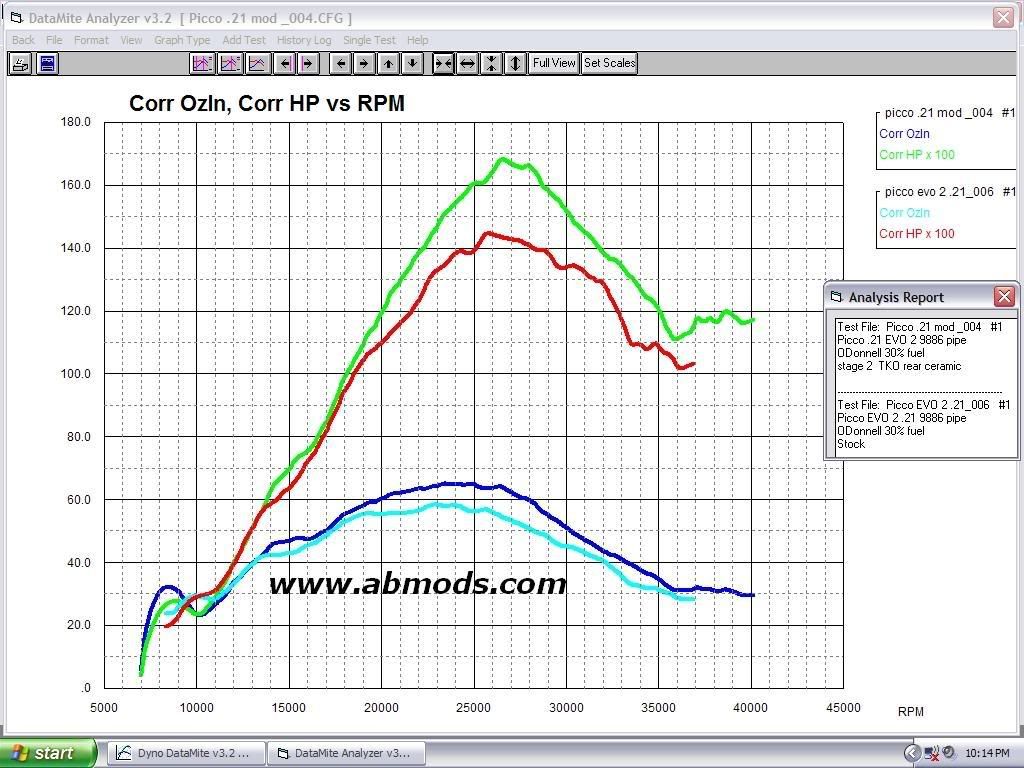

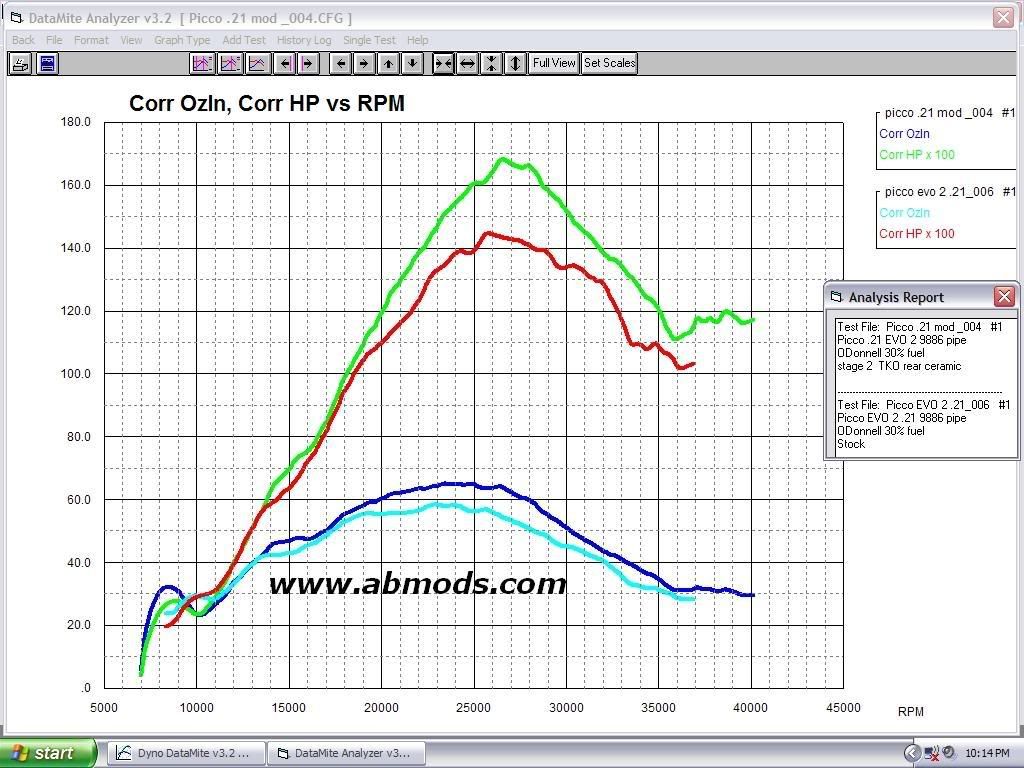

From my X-Dyno testing I have found the P7R to really favor the 9886 pipe. Its hard to really know exactly what pipe set is making the best power when your on a track trying to get ur setup right etc. This is where a dyno becomes the most one of the most valuable pieces of equipment that you can own! ESPECIALLY when your modifying these little nitro engines! With the dyno you know exactly what RPM ranges the engine wants to run in and exactly where u have made improvements or maybe even HURT performance..

I do agree with powerhouse on the use of a colder plug on these engines. The P7Rs do like the cooler plugs for sure Heres a dyno sheet of one of my modified P7Rs layed over top of the engine when it was stock with a 9886 pipe set and cold plug for you all to see its power and its curve with the 86 pipe.

Heres a dyno sheet of one of my modified P7Rs layed over top of the engine when it was stock with a 9886 pipe set and cold plug for you all to see its power and its curve with the 86 pipe.

Powerhouse its good to see another engine modifier on here. You have some interesting theorys with what your doin with these engines..... I read over your website and I can tell you have messed with the bigger 2 stroke engines quite a bit. I just wanted to take the time to say hi and to also wish you the best of luck with your business!

I do agree with powerhouse on the use of a colder plug on these engines. The P7Rs do like the cooler plugs for sure

Heres a dyno sheet of one of my modified P7Rs layed over top of the engine when it was stock with a 9886 pipe set and cold plug for you all to see its power and its curve with the 86 pipe.

Heres a dyno sheet of one of my modified P7Rs layed over top of the engine when it was stock with a 9886 pipe set and cold plug for you all to see its power and its curve with the 86 pipe.

Powerhouse its good to see another engine modifier on here. You have some interesting theorys with what your doin with these engines..... I read over your website and I can tell you have messed with the bigger 2 stroke engines quite a bit. I just wanted to take the time to say hi and to also wish you the best of luck with your business!

#147

Tech Master

iTrader: (66)

Thanks AB mods for your warm welcome to the site. I have messed around with the bigger engines quite abit. I was lucky enough to have the privilage to work for a company that designed and built engines for factory polaris. I was able to be apart of the design and casting process of cylinders, pistons, combustion chambers, carberation systems, exhaust systems, exhaust power valve developement etc. We built everything from 50cc Y-zinger race motors all the way up to 502 cubic inch blower motors for offshore power boats. I have spent more time in the dyno than I can shake a stick at and it is a great tool to have for engine R+D and as an engine guy yourself you also know that a dyno can point you in the right direction but it can't simulate what happens in the field. An engine on the dyno is under a different type of load than in a car, plane, boat, heli etc. First you get it working on the dyno and then you make it work in the field. I unfortunately don't have a dyno at home so I just skip to step 2. I have been on the down low the last 5 years just racing like any other guy constantly testing different engine designs, clutching etc. I used to get laughed at because I had a different engine in my cars just about every week and the funny part was, noone was laughing after they fired up and I took a few warm up laps. the best part was, over 60 engines ended up in local racers vehicles. That was my real test, putting these engines in the hands of the potential customer. You get the whole spektrum with that. You got the guys who can tune and who can't and the guys who can drive and the guys who can't etc. Two years ago I decided to get started with my little side business when the guy who couldn't tune a stock motor sais to me that my motors were very easy to tune and hold a tune and they guy who said he never made it past the D main qualifies for the B main 2 weeks later because he said the motor spooled up power so smooth that it kept the buggy hooked up better than any motor he has ever tried. So here I am trying to make it in a world of a bunch of engine modifiers, most of which have been around for years and are very reputable. I guess what I'm looking to do is get a piece of the pie. If I win a few customers from people who jump ship, great, if not, I'll be happy just building my own customer base from word of mouth and a little luck. If anyone out there has any questions or new ideas they would like to spitball, feel free to shout them out. An average engine design team consists of at least 5 people because everyone has something different they can bring to the table. I don't know anyone who has the time to try every single possible combination out there and we the engine guys rely on the very important feedback from you the racers to help us further advance our engine developement. I don't possibly think I can limit myself to 2 sentences on this topic lol. Have fun gentlemen!!

Mark @ www.PowerHouseRCPerformance.com

Mark @ www.PowerHouseRCPerformance.com

#148

I run my p7 evo2 R with a jp3 pipe and a 13t bell and have had no probs no flame outs nothing the motor rips and holds a canstant tune never never has it seen more than 210 with the 30% sidewinder(morgan) I run. regards losi 8

#149

Agreed I also run a JP3 with my Jammin JPX21 and OS P# Plugs. Runs well no flameouts. Good powerband.

PS: This is the most consistant engine I have run to date. It refuses to flame out.

#150

Picco has an awsome lineup out right now! there .12-.21 and .28 engines are top of the line IMO! I think there lower prices is what makes them not as popular among some.. When some see the price tag they think these engines cant perform like the higher $ engines.. Well thats is VERY VERY wrong..