Touring by h2e (1/10th, 190mm, 4wd)

#601

... ready to go on the car for the next series of tests. I am waiting for some tuning/update/repair carbon parts to arrive first. But I want to build the car with no self printed parts anymore - as if it was for customers already.

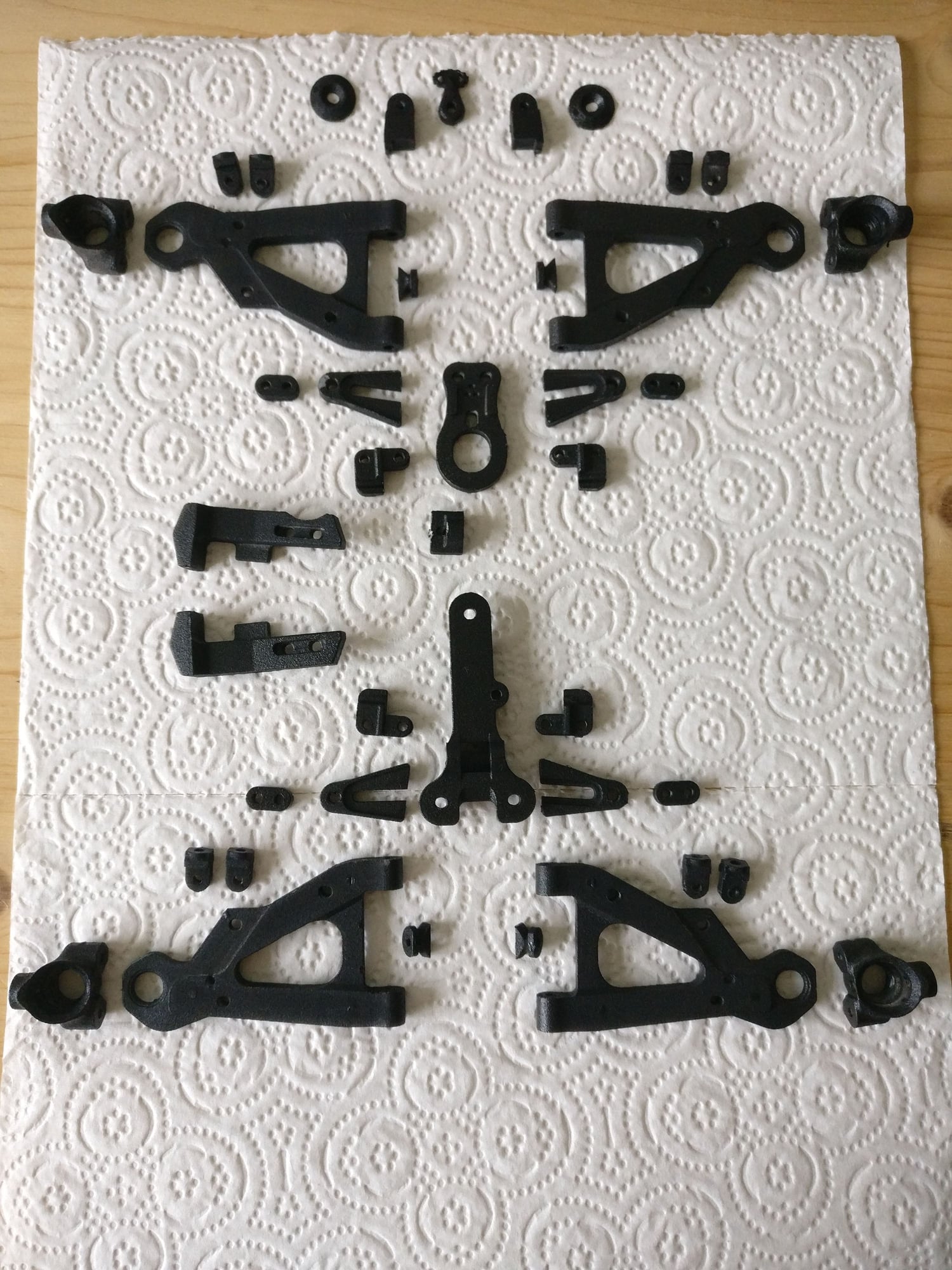

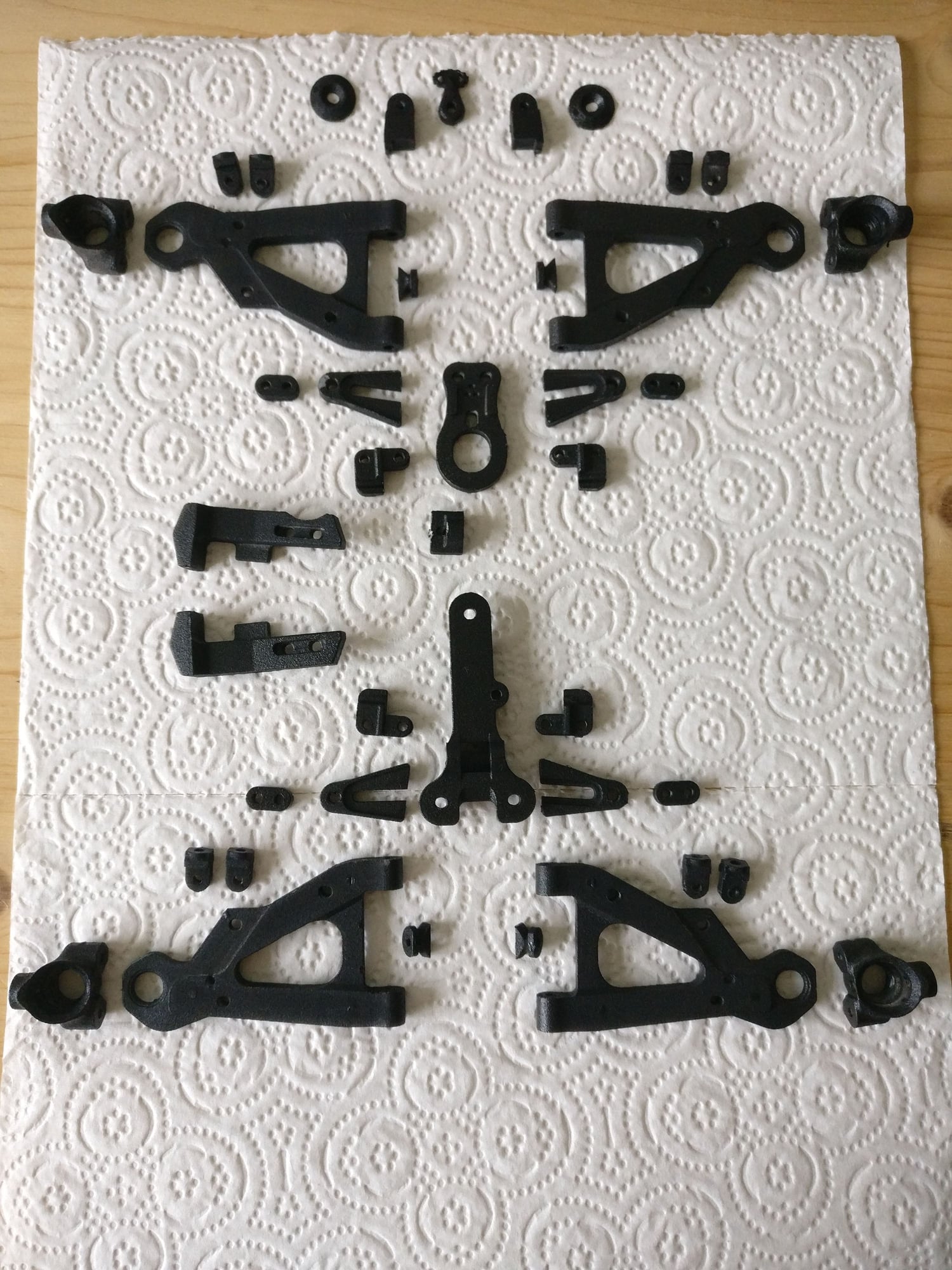

spare parts...

Full set of plastic parts prepared to go on the h2e four.

spare parts...

Full set of plastic parts prepared to go on the h2e four.

#602

Since the bumper was quite wasted from carpet testing, as well as the lower arms (a lot of material filed down due to loose screws), I wanted to update all before adding a clean body.

wasted bumper parts...

But I also took the chance to update some parts and prepare the limited edition production run:

- Wheelhubs: (should) need no hand filing to clear the lower ballhead screw anymore. Even if I had not one SLS part broken here I beefed it up slightly around the lower screws.

- Control arms: They are slightly revised to give more steering lock and allow for more rear caster (and adapt to the new wheelhub hole position)

- Lower arms: They are now 4x the same--> all 4 corners use identical parts except the bulkheads (L/R version here). They also allow more steering lock and are more beefy around some areas. I didn't have breakages here, but it sure helps.

- Upper Bumper: I beefed up the rearmost holes as they see the most bending in a crash.

- Rear body Holders: They fit nicer into bodies and give a bit more stiffness at lighter weight.

- Upper Arm mounts: I made a version with 3mm shorter upper arms for more camber gain (just to try).

- Steering linkage: I made it more robust and it now has an indicator system with dots to show the length of the bellcrank.

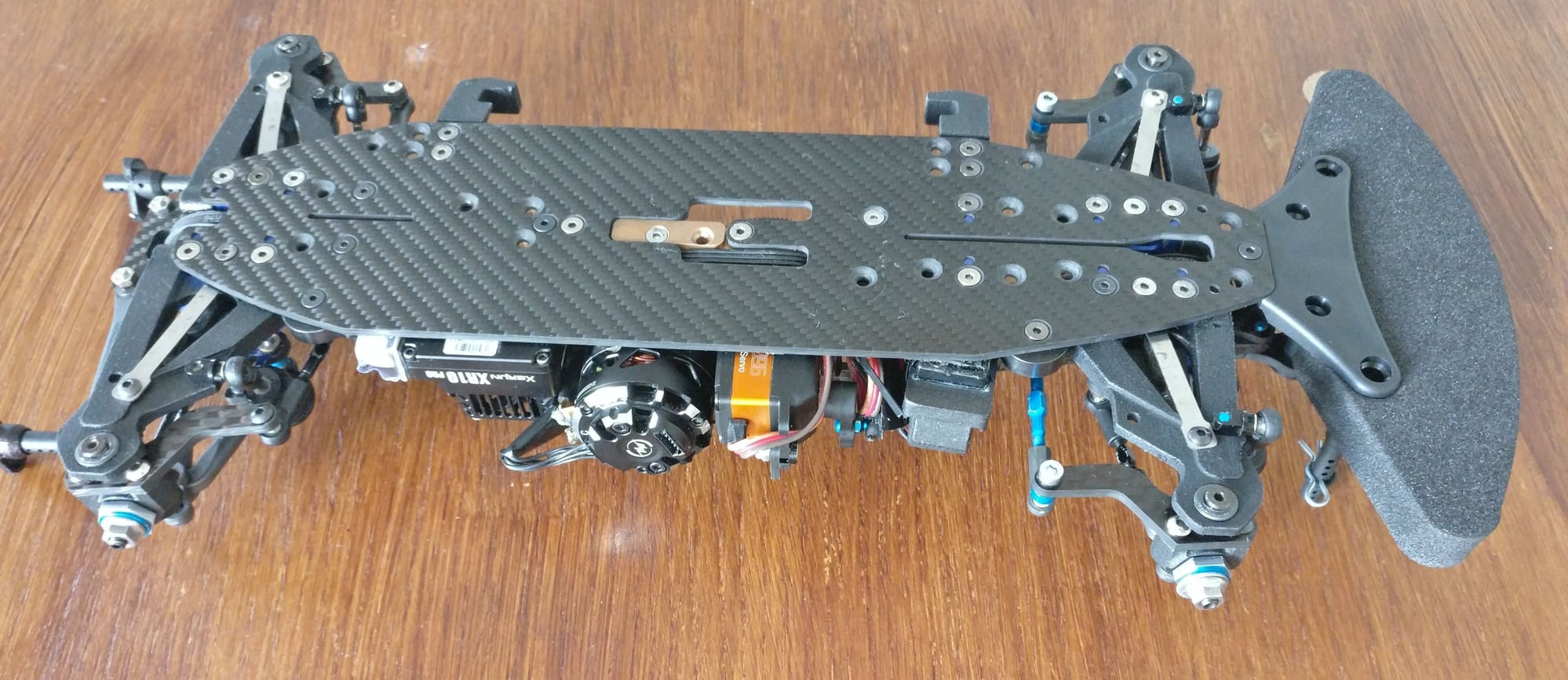

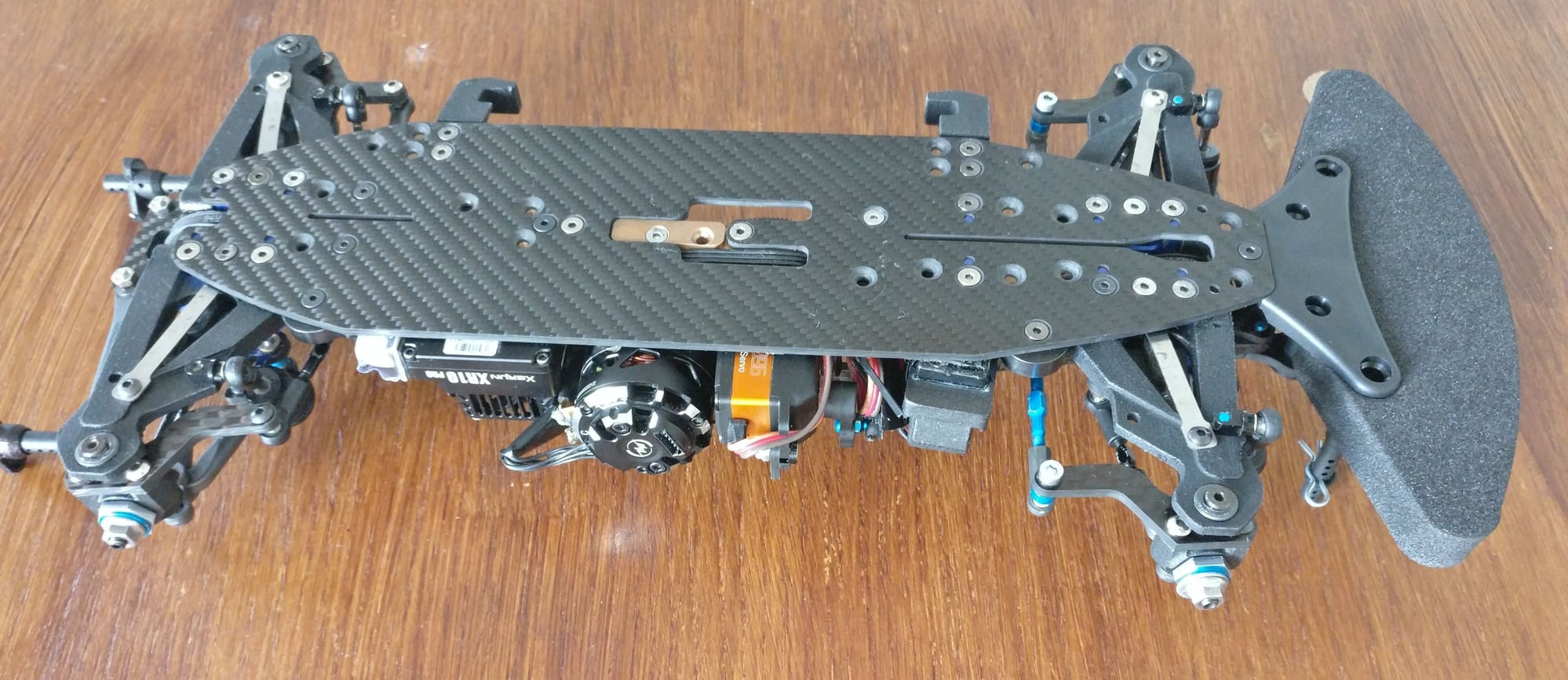

Side view. Note the battery ballast is now taped under the battery (no more ugly brass plate).

New front bumper parts.

New wheelhub, lower arm and control arms.

Better view of the lower arms.

wasted bumper parts...

But I also took the chance to update some parts and prepare the limited edition production run:

- Wheelhubs: (should) need no hand filing to clear the lower ballhead screw anymore. Even if I had not one SLS part broken here I beefed it up slightly around the lower screws.

- Control arms: They are slightly revised to give more steering lock and allow for more rear caster (and adapt to the new wheelhub hole position)

- Lower arms: They are now 4x the same--> all 4 corners use identical parts except the bulkheads (L/R version here). They also allow more steering lock and are more beefy around some areas. I didn't have breakages here, but it sure helps.

- Upper Bumper: I beefed up the rearmost holes as they see the most bending in a crash.

- Rear body Holders: They fit nicer into bodies and give a bit more stiffness at lighter weight.

- Upper Arm mounts: I made a version with 3mm shorter upper arms for more camber gain (just to try).

- Steering linkage: I made it more robust and it now has an indicator system with dots to show the length of the bellcrank.

Side view. Note the battery ballast is now taped under the battery (no more ugly brass plate).

New front bumper parts.

New wheelhub, lower arm and control arms.

Better view of the lower arms.

Last edited by h2e; 02-16-2024 at 12:49 AM.

#603

looks very very nice!

#604

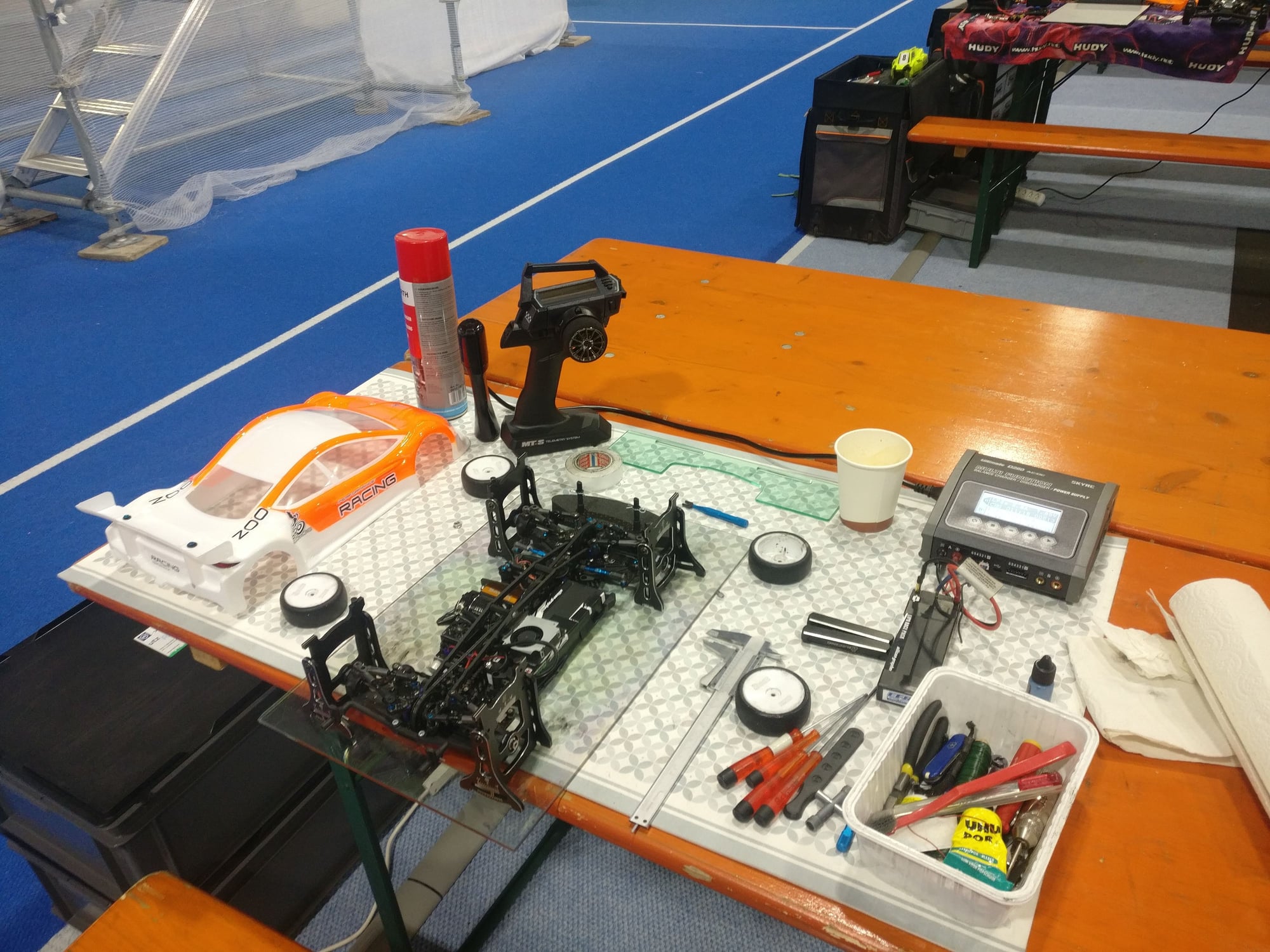

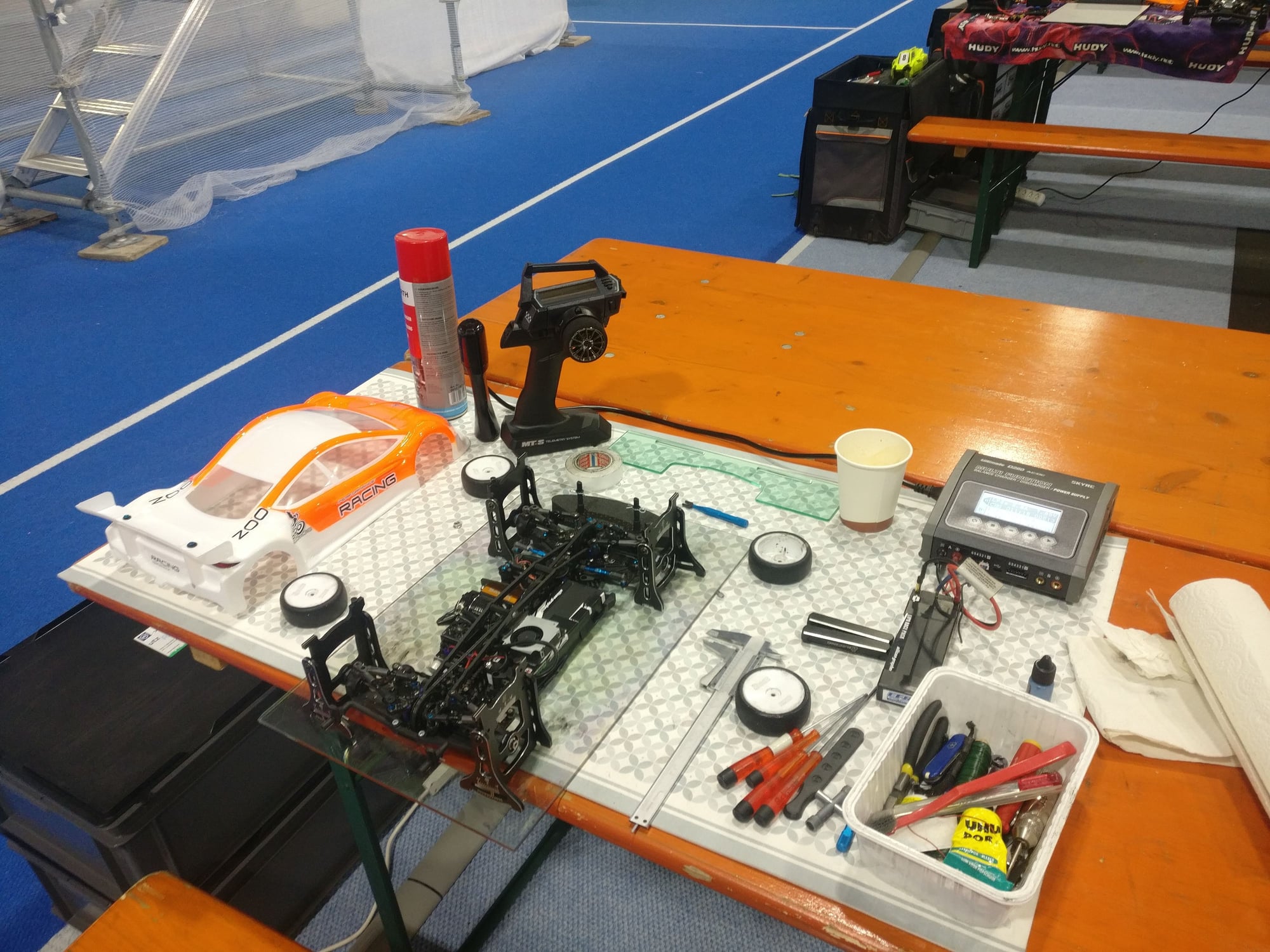

Today I went to Wädenswil for the last time before closure this season (won't have the chance to visit till end of Feb). I enjoyed a really really great finale!

Impressive car on a less impressive pit area.

First of all, I was excited to test the new plastics, to see if they behave well and the new designs haven't messed up anything. Also, I had a new Wolverine MAX 0.7 bodyshell mounted, moved 6mm forward compared to the last time, but also 6mm lower in the rear section compared to the last body (!).

I found out some things today:

- The new plastic parts work great, and the battery holders lasted in crashes, where the home-printed parts would have failed for sure. The lower arms work well, but some of the geometry gets filed off in crashes, or when I have reduced track width setups. The new wheelhubs have a bit more play than the old ones, but that's down to my eager post-fabrication quality checks... Overall - no h2e plastic part broken in 165 laps.

- The car is really robust still: I had a really nasty full-throttle corner clipper (small overlap, rigid barrier (SORB)). Normally this would rip off an entire corner plus the bumper. Fortunately it only meant that the Schumacher lower outer ball joint gave in. Not even the wheelhub or control arm or lower arm broke! Unfortunately, the bulkheads got bent in the process. Thank god I left enough left-right play for the spool so it would spin freely even with bent bulkheads

Schumacher lower balljoint that didn't survive the SORB test. The only part I broke tonight

- I can still go faster on some already old MATRIX tyres. They have >20packs in them and they start to become uneven in quality due to too many fixes, showing their ring of death - and yet I can improve my laptimes! How good is that?

Laptimes improved over last month's testing.

Just love the car. Not only because it's my design - but also because it just lets me drive drive drive!

Impressive car on a less impressive pit area.

First of all, I was excited to test the new plastics, to see if they behave well and the new designs haven't messed up anything. Also, I had a new Wolverine MAX 0.7 bodyshell mounted, moved 6mm forward compared to the last time, but also 6mm lower in the rear section compared to the last body (!).

I found out some things today:

- The new plastic parts work great, and the battery holders lasted in crashes, where the home-printed parts would have failed for sure. The lower arms work well, but some of the geometry gets filed off in crashes, or when I have reduced track width setups. The new wheelhubs have a bit more play than the old ones, but that's down to my eager post-fabrication quality checks... Overall - no h2e plastic part broken in 165 laps.

- The car is really robust still: I had a really nasty full-throttle corner clipper (small overlap, rigid barrier (SORB)). Normally this would rip off an entire corner plus the bumper. Fortunately it only meant that the Schumacher lower outer ball joint gave in. Not even the wheelhub or control arm or lower arm broke! Unfortunately, the bulkheads got bent in the process. Thank god I left enough left-right play for the spool so it would spin freely even with bent bulkheads

Schumacher lower balljoint that didn't survive the SORB test. The only part I broke tonight

- I can still go faster on some already old MATRIX tyres. They have >20packs in them and they start to become uneven in quality due to too many fixes, showing their ring of death - and yet I can improve my laptimes! How good is that?

Laptimes improved over last month's testing.

Just love the car. Not only because it's my design - but also because it just lets me drive drive drive!

Last edited by h2e; 02-17-2024 at 01:33 PM.

#605

After the chat with some Schumacher guys I was checking the spy shots of the Mi9 again. It seems that after wtcc and me they have adopted the same style hub with two lower screws fore/aft of the driveshaft axle that attach the control arm.

Mi9 spy shot (upper) and h2e four rear left corner. The control arms seem attached the same way. The h2e four has the outer ballheads further out (because the inner points are more spaced apart, too).

Mi9 spy shot (upper) and h2e four rear left corner. The control arms seem attached the same way. The h2e four has the outer ballheads further out (because the inner points are more spaced apart, too).

#606

Tech Adept

Interesting car I tired out yesterday. It was a mtc2 with the awsomatix upper arm style conversion. All I can say it was night and day difference how the car reacted compared my mtc2r. Same tires, body, setup very similar but the conversion made the car rotate so nicely. It was unreal how well balanced the conversion. I'm going to convert mine and see what type of long term results I achieve.

#607

Once you're at it, also try out the Schumacher Top links. They will be the middle ground between AMX and MTC2 in terms of stiffness...

#608

Tech Adept

I tried the 3racing arms. bought a of them so I can do some long term testing. But the feel was phenomenal. I would assume that how an awsomatix feels but with a bit more roll.

#609

#610

Did any of you wonder when looking at the h2e four design, how high the CG of that top deck must be? Well for me it was clear that the vertical design meant a compromise to be able to apply the steering system with the moved-back servo.

Today I went to compare two center chassis structures:

A800MMX single topdeck vs. h2e four vertical topdeck. My findings were as follows:

CG and mass analysis of center chassis section - h2e four vs. A800MMX

So when I look at the data, the CG of the h2e four system is a fraction higher, despite having more ballast overall, which is typically mounted near the chassis. What I also found, is that my beloved 2°angle of the battery is actually the elephant in the room. If I mount the battery flat to the chassis, its CG goes to 9.5mm height, hence the data looks like this:

CG and mass analysis of center chassis section - h2e four vs. A800MMX - h2e battery moved to chassis instead 2° angle.

So this really is the game changer, if I have my battery flat on the chassis. Even if I use all stiffeners on my topdeck (to get sufficient torsion stiffness), the CG of the mentioned components can be lower than on an Awe A800MMX. As soon as I go outdoor, I can remove some stiffeners and lower the CG even more. Who would have thought that?

Today I went to compare two center chassis structures:

A800MMX single topdeck vs. h2e four vertical topdeck. My findings were as follows:

CG and mass analysis of center chassis section - h2e four vs. A800MMX

So when I look at the data, the CG of the h2e four system is a fraction higher, despite having more ballast overall, which is typically mounted near the chassis. What I also found, is that my beloved 2°angle of the battery is actually the elephant in the room. If I mount the battery flat to the chassis, its CG goes to 9.5mm height, hence the data looks like this:

CG and mass analysis of center chassis section - h2e four vs. A800MMX - h2e battery moved to chassis instead 2° angle.

So this really is the game changer, if I have my battery flat on the chassis. Even if I use all stiffeners on my topdeck (to get sufficient torsion stiffness), the CG of the mentioned components can be lower than on an Awe A800MMX. As soon as I go outdoor, I can remove some stiffeners and lower the CG even more. Who would have thought that?

#611

Tech Adept

sorry for the late response. But I got all the parts from 3racing and listed them below

SAK-C173 upper arm links

3RAC-TR325 25mm Titanium turnbuckle

3RAC-TR328 28mm Titanium turnbuckle

SAK-C114 4.8mm suspension ball

The set was about the same price as 4 mtc2 arms. Relatively cheap parts to test out.

SAK-C173 upper arm links

3RAC-TR325 25mm Titanium turnbuckle

3RAC-TR328 28mm Titanium turnbuckle

SAK-C114 4.8mm suspension ball

The set was about the same price as 4 mtc2 arms. Relatively cheap parts to test out.

#612

It's always a fun thing to log on each day and see your updates!

#613

After about 2 years not going, I went back to the (for me) infamous Dagmersellen track. Last time I was here I managed to destroy the h2e five (!) at almost every run, with wheels flying around, bumpers breaking, batteries flying etc. So I was a bit uneasy to come back here. But then after Wädenswil track is closed now, this was the only nearby indoor option.

I went running the h2e-M (MX-5 RWD chasssis) first, until I broke a part that I didn't have a spare for. The M chassis was better than last time here, but still a handful. Especially against the Awesomatix-derived RWD M-Chassis of Guido, my car had no chance. The AMX M-RWD chassis was as light as mine (due to my extra 50g motor weight), so he had plenty of punch, but thanks to double wishbones at the back he had much more rear grip and nice tracking vs. my solid rear axle design.

Then I went to the h2e four, checked the setup from last time and gave it a go. As I knew I would touch the barriers more I went back to the beaten-up body which was mounted too far back and with the rear a bit high. I realised the gearing of 5.07 as well as the brakes were too aggressive for the small track and I went to 5.97 and from 118%brakes to 95%. These were the only changes to the setup since last time. With the worn-out Matrix tyres I had no traction roll issues as last time here with the Mi8. These are the laptimes I managed to achieve.

h2e four Dagmersellen testing (CW, left). Right is old times from 19.2.2022.

So I beat my old h2e five (which was a CCW race, that are typically faster) and TA07RCLabHK (CW) laptimes at the first attempt after a long break. The Mi8 laptimes I almost beat, but just almost. I didn't feel very comfortable driving today, as switching between the M-chassis and touring car didn't give me a particularly good rythm, and I was a bit afraid of the barriers.

BUT: I didn't break A SINGLE PART on the h2e four! This is a huuge step forward to last time I was here, and I have to say in one inside corner clipping, the car went flying in a 720° rotation about the vertical axis, and not even the battery got dislocated. So the h2e four is really a robust car! Also the end-of-straight sideways barrier taps I managed to replicate - there the only weak point right now are the bulkheads that do start to bend in a little in such incidents. I have an improved design ready but need manufacture still.

I went running the h2e-M (MX-5 RWD chasssis) first, until I broke a part that I didn't have a spare for. The M chassis was better than last time here, but still a handful. Especially against the Awesomatix-derived RWD M-Chassis of Guido, my car had no chance. The AMX M-RWD chassis was as light as mine (due to my extra 50g motor weight), so he had plenty of punch, but thanks to double wishbones at the back he had much more rear grip and nice tracking vs. my solid rear axle design.

Then I went to the h2e four, checked the setup from last time and gave it a go. As I knew I would touch the barriers more I went back to the beaten-up body which was mounted too far back and with the rear a bit high. I realised the gearing of 5.07 as well as the brakes were too aggressive for the small track and I went to 5.97 and from 118%brakes to 95%. These were the only changes to the setup since last time. With the worn-out Matrix tyres I had no traction roll issues as last time here with the Mi8. These are the laptimes I managed to achieve.

h2e four Dagmersellen testing (CW, left). Right is old times from 19.2.2022.

So I beat my old h2e five (which was a CCW race, that are typically faster) and TA07RCLabHK (CW) laptimes at the first attempt after a long break. The Mi8 laptimes I almost beat, but just almost. I didn't feel very comfortable driving today, as switching between the M-chassis and touring car didn't give me a particularly good rythm, and I was a bit afraid of the barriers.

BUT: I didn't break A SINGLE PART on the h2e four! This is a huuge step forward to last time I was here, and I have to say in one inside corner clipping, the car went flying in a 720° rotation about the vertical axis, and not even the battery got dislocated. So the h2e four is really a robust car! Also the end-of-straight sideways barrier taps I managed to replicate - there the only weak point right now are the bulkheads that do start to bend in a little in such incidents. I have an improved design ready but need manufacture still.

#614

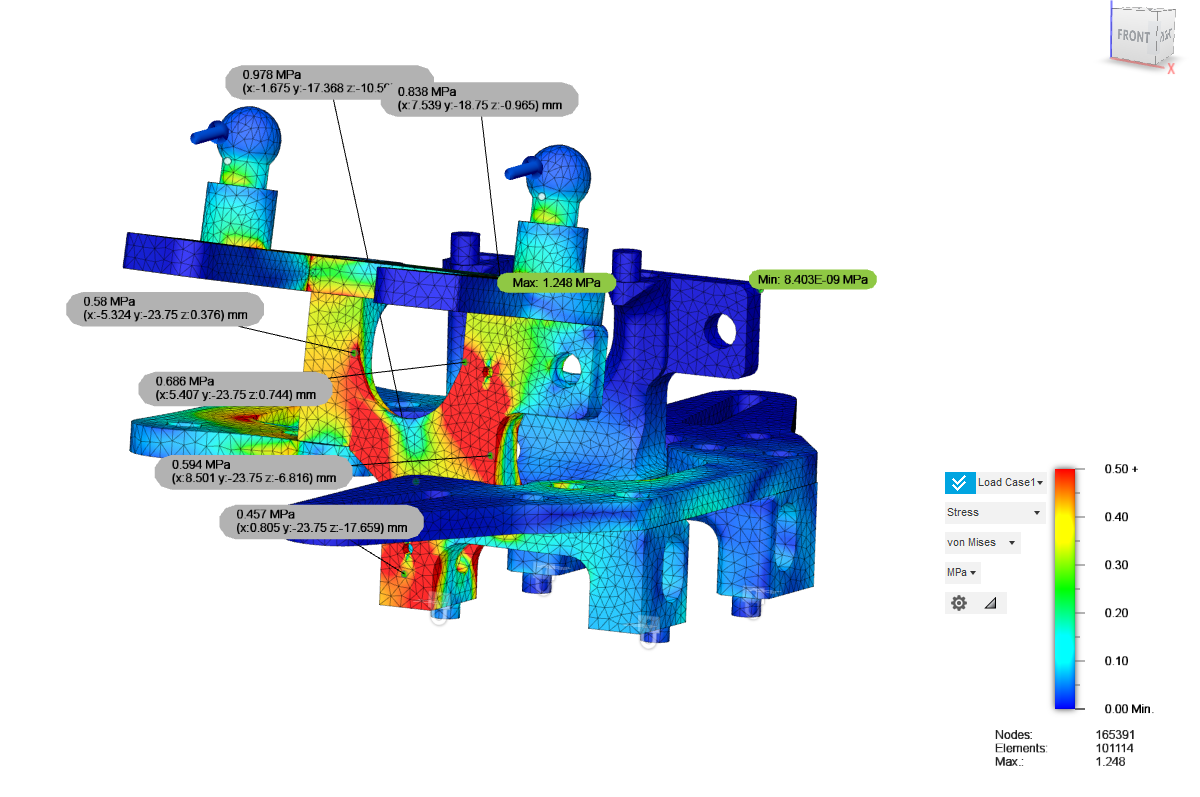

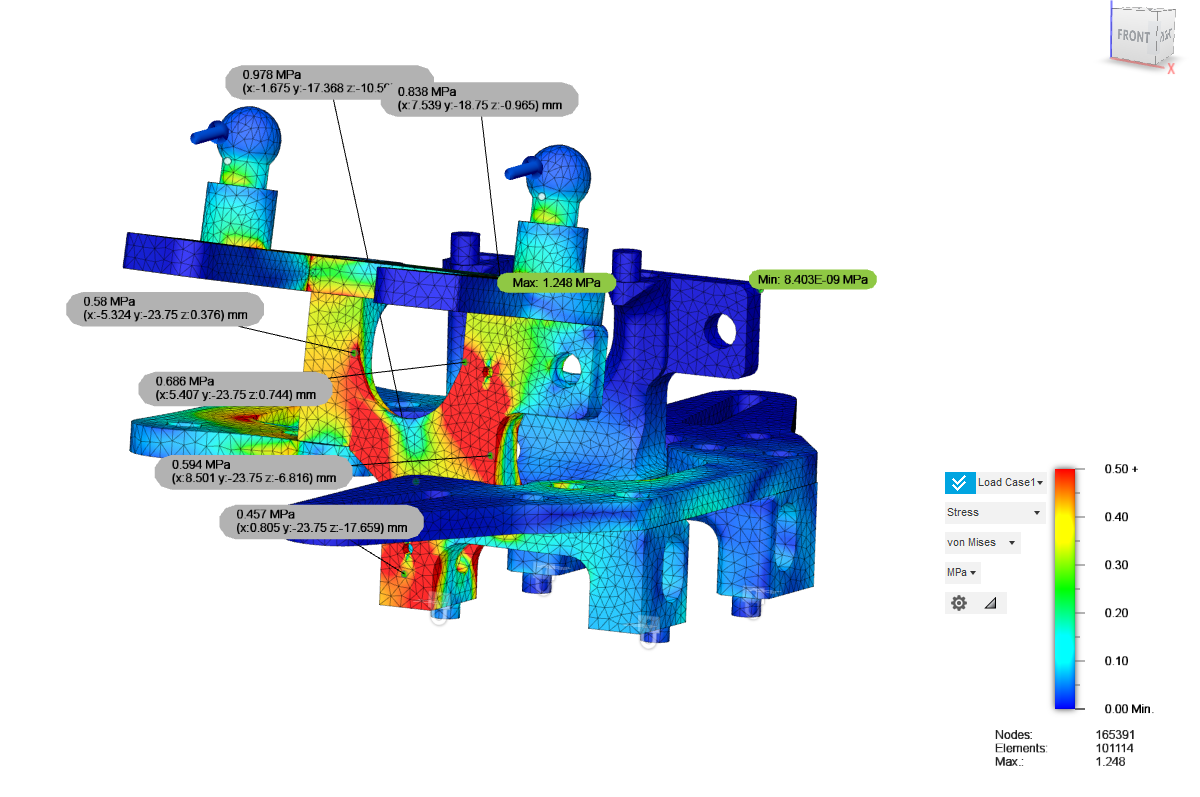

Finalized the bulkhead update: At the cost of 1g more bulkhead weight per part (+20%), I reduced the stress in 6 key areas by 35%.

Stress distribution at lateral load on upper Ballheads (existing design).

Stress distribution at lateral load on upper Ballheads (existing design).

#615

Tech Adept

Im curious as to what your FEA parameters were, if you don't mind sharing. I personally want to gain more knowledge on FEA. Lucky I have a friend who is a PE but his background is with pump systems. He does know how to great a mesh once he understands the problem and how to analyze what is important.

718Likes

718Likes