Team Associated TC5

#8641

...I must confess to not being wild about not having the "leg" in the bulkhead ahead of the motor to screw down to the chassis. I can see on your mule that at one point you must have because the chassis has been drilled where the new screw would go to pick up this leg. Correct me if I'm mistaken, but my guess is the leg was eliminated to users wouldn't have to locate, drill and countersink a hole (whose location is critical to proper fit) in their chassis. All the other screws appear to be as-located by AE. I would offer that if you made a paper template from your "mule" chassis shown that identified where the screw would live that customers could hit this easily enough. OR...I'd bet you could pick up chassis plates at dealer cost somewhere, drill and countersink them, and offer them as an extra cost option for users who lack the confidence to do that drilling.

I can imagine that the top plate provides enough bridge to keep longitudinal flex under control without this leg, but I am not at all crazy about the mass of the motor being so unsupported. It is hanging clear out ahead of the screws. My concern would be that in a hard side impact the mass of the motor could pretty easily bend the bulkhead, inertia being what it is. I've seen similar thickness 1/12 bulkheads bent due to the motor mass and they're supported all the way around and fairly close to the motor.

If you guys were to go back to (and I'm certain it was there at least at some point in development) the forward leg ahead of the motor I'd be ALL over these bulkheads, as it is I have substantial concern on this point. You'd still be "losing" the rear foot from the original AE motor mount, I just think too big a bite has been taken by eliminating that front foot.

I look forward to your responses. I think you guys are just THIS close to having a great product that I wouldn't hesitate to purchase.

Thanks,

Scottrik

I can imagine that the top plate provides enough bridge to keep longitudinal flex under control without this leg, but I am not at all crazy about the mass of the motor being so unsupported. It is hanging clear out ahead of the screws. My concern would be that in a hard side impact the mass of the motor could pretty easily bend the bulkhead, inertia being what it is. I've seen similar thickness 1/12 bulkheads bent due to the motor mass and they're supported all the way around and fairly close to the motor.

If you guys were to go back to (and I'm certain it was there at least at some point in development) the forward leg ahead of the motor I'd be ALL over these bulkheads, as it is I have substantial concern on this point. You'd still be "losing" the rear foot from the original AE motor mount, I just think too big a bite has been taken by eliminating that front foot.

I look forward to your responses. I think you guys are just THIS close to having a great product that I wouldn't hesitate to purchase.

Thanks,

Scottrik

The idea is that rear chassis flex is not equal side to side when the motor mount is mounted with both screws resulting in different handling characteristics in right and left hand corners. With the screw removed and the front part of the mount ground 1mm, you can flex the chassis side to side and see how the holes no longer line up and how the 1mm gap increases and decreases.

These changes are very small and you still have servo mounts with affect flex the same way plus all the installed radio gear and battery, but this design is a good start!

#8643

The distance from the front hinge pin mount to the rear will affect what toe you get from each shim.

Do corally and x-ray use the same distance as the tc5?

#8644

Calculating it out was what we were HOPING to avoid, but are prepared to execute absent anyone being able to point at any of AE's literature (Josh and/or Rick may have access to the designers and/or their notes?) stating what their spec is.

THAT'S the best comeback I've heard in a long while. That's what keeps me getting up every morning...the hope that I'll get a good belly laugh out of someone during the day! Thank you.

#8645

The National Caliper Calibration Society (NCCS) consults with me on a daily basis to ensure that their equipment is accurate.

The distance from the front hinge pin mount to the rear will affect what toe you get from each shim.

Do corally and x-ray use the same distance as the tc5?

The distance from the front hinge pin mount to the rear will affect what toe you get from each shim.

Do corally and x-ray use the same distance as the tc5?

I don't know if it is the same distance. What I can say though is I took a shim from Xray at 1.5mm and put it on my TC5 and the total rear toe was 2 degree's. I took a .75mm shim and put it on my TC5 and it was 1 degree. I was using a Hudy Setup Station to check my measurement's. I will do the check again on my son's car in the next day or two and report my finding's.

#8647

Tech Master

iTrader: (40)

I feel like I have been spanked by a wet noodle.

I don't know if it is the same distance. What I can say though is I took a shim from Xray at 1.5mm and put it on my TC5 and the total rear toe was 2 degree's. I took a .75mm shim and put it on my TC5 and it was 1 degree. I was using a Hudy Setup Station to check my measurement's. I will do the check again on my son's car in the next day or two and report my finding's.

I don't know if it is the same distance. What I can say though is I took a shim from Xray at 1.5mm and put it on my TC5 and the total rear toe was 2 degree's. I took a .75mm shim and put it on my TC5 and it was 1 degree. I was using a Hudy Setup Station to check my measurement's. I will do the check again on my son's car in the next day or two and report my finding's.

#8648

Tech Master

iTrader: (38)

I have a regular tc5 and just got it ready to go but when i was adjusting my end points i noticed i was getting some wheel chatter at full steer. It turns out the belt is rubbing the servo saver post, it doesn't apper to be that much. Is there any fixes for this or won't this be a problem? I should add I didn't get on the track yet with the car. Oh and I made sure the belt was on the right side of the post. so there's no confustion the motor side.

#8649

Tech Master

iTrader: (5)

I have a regular tc5 and just got it ready to go but when i was adjusting my end points i noticed i was getting some wheel chatter at full steer. It turns out the belt is rubbing the servo saver post, it doesn't apper to be that much. Is there any fixes for this or won't this be a problem? I should add I didn't get on the track yet with the car. Oh and I made sure the belt was on the right side of the post. so there's no confustion the motor side.

#8650

#8652

Suspended

I shall get a picture up of where the top is done when I get onto my computer.

#8654

Suspended

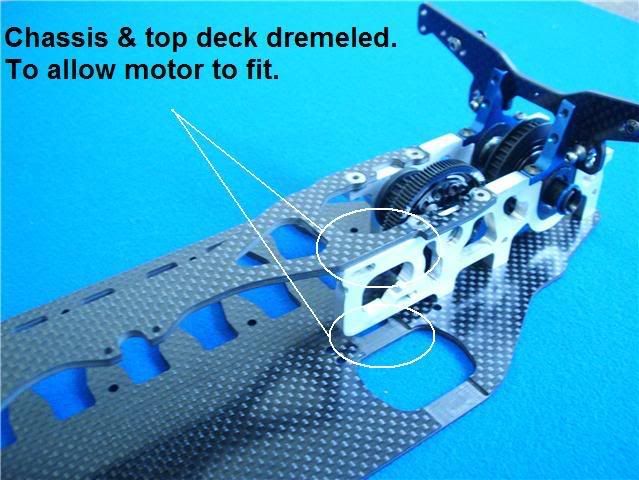

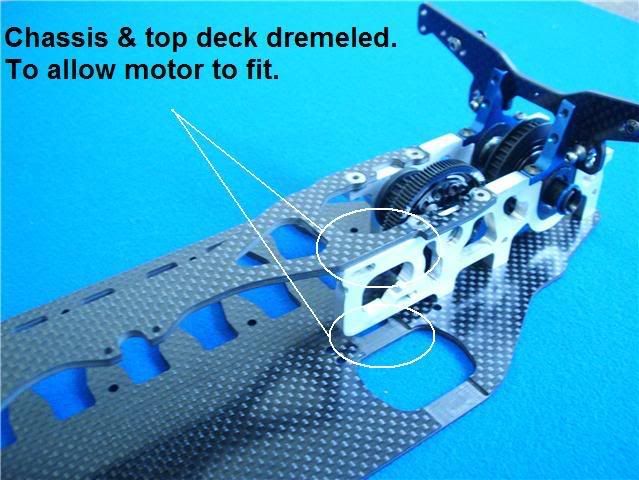

For anybody curious or can't make it out on the current pictures, this is where the chassis/top deck are modified. (This one was machined for higher quality, dremeling was the example used for the guy I made the picture for)

Cheers Nick

Cheers Nick

#8655

Tech Fanatic

iTrader: (13)

hey bro I have the same shims on car I think it's fine I've run my car from novak 17.5 brushless to 7700kv mamba max with lipos I never changed my rear toe-in. I see your from Manila (kumusta) I grew up in Pateros now I'm residing here in San Diego CA. Goodluck on your car it's a really good car wins a lot of local parking lot races here in San Diego.

why Im setting it up for maximum straight line speed so I eat our neighbor's

v-One Rs.

Reading from the posts about toe-in, I have to balance my stability vs drag

drag of having 3 deg toe in. The manual says reducing toe-in reduces rear grip. The setup sheet is confusing, it says "toe-in" total.

What does that mean? 1.5deg on each side? Last night I changed the shims

to 2mm plus 1mm shims (3 deg toe in on both sides) but I can feel

some drag when I push it, without the pinion of course.

Ill just probably go back to 2mm shim on both sides for less drag

on straights but still stable.

I really dont like too much flex on the chassis thats why Im not using

the o-ring combination. Ill use softer springs instead.

I want to replace my diff nut and bolt to a longer stronger ones, can I

use some from other kits like from HB or Serpent or Tamiya?

Has anybody done this?

Cheers ü