Tekno RC EB410 Thread

|

|||

#2806

I'm currently debating on buying raceform shock towers, I just like the durability aspect but will these affect handling due to the flex? Has anyone tried these yet?

#2807

Tech Master

iTrader: (49)

Completed my build last night, just waiting for the body.

I only have 2 complaints, about my kit,

1. The wheel hexes we're too tight on the axles, I had to sand away the anodizing in the inside the hole to make them fit.

2. The kit didn't come with the 3x3mm set screws for the hexes, they were all 3x5mm which are too long and don't allow the wheel to go in without damaging it.(I double checked every set screw in the kit to make certain I didn't miss them and install the shorter ones somewhere else.)

I only have 2 complaints, about my kit,

1. The wheel hexes we're too tight on the axles, I had to sand away the anodizing in the inside the hole to make them fit.

2. The kit didn't come with the 3x3mm set screws for the hexes, they were all 3x5mm which are too long and don't allow the wheel to go in without damaging it.(I double checked every set screw in the kit to make certain I didn't miss them and install the shorter ones somewhere else.)

#2808

Tech Master

iTrader: (90)

Completed my build last night, just waiting for the body.

I only have 2 complaints, about my kit,

1. The wheel hexes we're too tight on the axles, I had to sand away the anodizing in the inside the hole to make them fit.

2. The kit didn't come with the 3x3mm set screws for the hexes, they were all 3x5mm which are too long and don't allow the wheel to go in without damaging it.(I double checked every set screw in the kit to make certain I didn't miss them and install the shorter ones somewhere else.)

I only have 2 complaints, about my kit,

1. The wheel hexes we're too tight on the axles, I had to sand away the anodizing in the inside the hole to make them fit.

2. The kit didn't come with the 3x3mm set screws for the hexes, they were all 3x5mm which are too long and don't allow the wheel to go in without damaging it.(I double checked every set screw in the kit to make certain I didn't miss them and install the shorter ones somewhere else.)

#2809

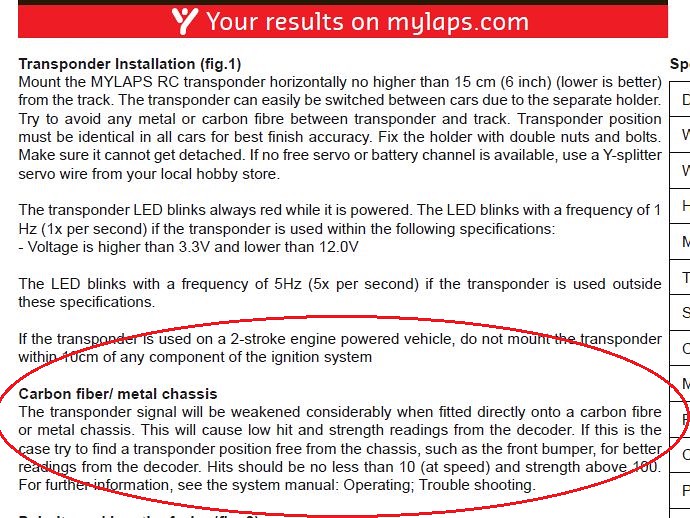

Huh? Been running my transponder on the chassis in Tekno's recommended position since mid-October. Not a single lap was missed. You'll find many others here who have mounted theirs in the same position w/o issue.

#2811

#2814

...The kit didn't come with the 3x3mm set screws for the hexes, they were all 3x5mm which are too long and don't allow the wheel to go in without damaging it.(I double checked every set screw in the kit to make certain I didn't miss them and install the shorter ones somewhere else.)...

Bags F and H have 2 different size set screws, be sure to use the smaller 3x3mm screws for the hexes or you may run into problems installing wheels over the hex if you use the longer 3x4mm screws

#2816

I couldn't tell a difference in handling after switching from the Tekno carbon towers (running on low to med bite hard packed dirt). They are supposed to offer a bit more flex when crashing to help absorb some of the force going to the bulkhead though. The clear look is also unique

#2817

Completed my build last night, just waiting for the body.

I only have 2 complaints, about my kit,

1. The wheel hexes we're too tight on the axles, I had to sand away the anodizing in the inside the hole to make them fit.

2. The kit didn't come with the 3x3mm set screws for the hexes, they were all 3x5mm which are too long and don't allow the wheel to go in without damaging it.(I double checked every set screw in the kit to make certain I didn't miss them and install the shorter ones somewhere else.)

I only have 2 complaints, about my kit,

1. The wheel hexes we're too tight on the axles, I had to sand away the anodizing in the inside the hole to make them fit.

2. The kit didn't come with the 3x3mm set screws for the hexes, they were all 3x5mm which are too long and don't allow the wheel to go in without damaging it.(I double checked every set screw in the kit to make certain I didn't miss them and install the shorter ones somewhere else.)

2421Likes

2421Likes