2wd buggy CAD development

#31

Tech Elite

Thread Starter

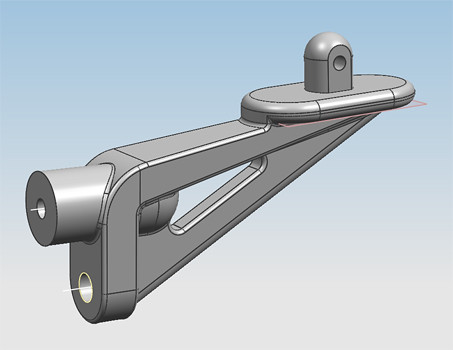

Ok....I'm actually going to have to read all these posts. Anyway, I almost done with the bulkhead. I have decided it will be similar to the 22 in that it will be mounted to the bottom of the chassis. I don't actually own the car though, so is this a solid design? (in your opinion)

#32

Tech Elite

Thread Starter

In regards to the chassis, it will most likely be aluminum. I believe it is just a better material for that spot. Also, I might want to make the motor be contained in the center of the rear shock tower. That way, it is a compromise between the two extremes.

#33

Tech Elite

Thread Starter

Not completely finished, still need to mill out some areas, and round it out, but will do that once I see how it attaches to the chassis.

#34

Yes Fred, we should care what the pro's do. Collectively they put in thousands of hours of design and testing that we simply dont have the time to do. This is why cars keep getting better. If the pros cant be faster or turn better lap times with mid motor, what makes you think the average joe can?

Have you ever noticed that the modern cars are heavy with low roll centers. That is very forgiving and easy to drive but in the end is solely based around modern track design which is dominated with very hard packed, high speed blue groove clay with large jumps. What has fundamentally changed about car design in the past 20 years? Seriously. Where do all those "millions in development" really go? Aside from added weight and stronger components, what has changed? Sure technology has in the electrics but I mean with fundamental car design itself. What is different? Let's examine this a bit. I've written on it before but people don't like to read on their own. They need a pro to read it to them!

Is arm length an advancement? Certainly this has evolved but they can only get so long and there is a tradeoff for everything. The XX had very long arms yet the XXX shortened them again and itself had a few options in length. The 22 is now back within that range somewhere. The RC10 had short arms, the B2 longer, the B3 longer still. The B4 is just a bit different but geometrically very similar. No fundamental geometry breakthroughs there!

How about wheelbase? ROAR gives us a range so you know it will be in there somewhere. People like to use whatever someone else runs rather than what works for them. The JRX-Pro SE had the option to run an 11.5" wheelbase. It was too long. Stable at speed but couldn't turn. People want the B4.1 longer +8 chassis today and many people running the 22 want a shorter wheelbase. How different can this really be? The reality is that there is no one perfect answer for every track. They are trying their hardest to meet in the middle though.

How about front kick? 20 degrees? 25, 30? It all stays in that range in 2wd. Adjustable? Been done before the 22. No real advancements there!

What about gearboxes? The standard 3 gear has been around for 25+ years but first showed up on the Tamiya Sand Scorcher before 1980. Internal ratios have changed but then again they've changed to accommodate motor technology (rpm and torque differences) which along with batteries is the only true advancement in decades. Now you might say gear diffs are an advancement. They were around before ball diffs. Nothing new there. Slippers have been around for a couple of decades too.

We do have better materials now which means things can be made stronger but with the cars moving at higher speeds, things need to be stronger. This is one area that makes new cars better. Strength. This was done out of necessity.

Shocks are making advancements. We've got big bores. When you have more weight and more speed with larger jumps, this too is just a logical move.

What about vehicle width? They started narrow, got wide, and are going back narrow again.

Chassis material? Plastic, aluminum, fiberglass, carbon fiber, composite. Nothing terribly groundbreaking with the new ones. Aluminum is a good choice solely based on strength.

So if suspension geometry is fairly similar among cars, since they all use A-arms, and wheelbase is pretty close, and gearbox design is nearly identical, and they are all pretty durable, what do you suggest be done to advance them and what would be considered an advancement? I'll tell you what I'd do. I'd change the way it looks, give it another piece of flair, tell people it's better because it's new, and then happily take their money because everyone knows that newer is better. That's business and you need to at least visually evolve or no one will believe it changed.

Nope don't care one bit what the pros do unless they are doing something we haven't seen before.

#35

Tech Elite

Thread Starter

When the pros start driving a decent mid motor car then maybe they'll start to do better with them! It certainly isn't the 22 or 210. Build them rear motor. That's what they are good at. They are poorly laid out for mid motor on anything but high grip tracks. You'll need to look at X Factory for a better setup in mid motor.

Have you ever noticed that the modern cars are heavy with low roll centers. That is very forgiving and easy to drive but in the end is solely based around modern track design which is dominated with very hard packed, high speed blue groove clay with large jumps. What has fundamentally changed about car design in the past 20 years? Seriously. Where do all those "millions in development" really go? Aside from added weight and stronger components, what has changed? Sure technology has in the electrics but I mean with fundamental car design itself. What is different? Let's examine this a bit. I've written on it before but people don't like to read on their own. They need a pro to read it to them!

Is arm length an advancement? Certainly this has evolved but they can only get so long and there is a tradeoff for everything. The XX had very long arms yet the XXX shortened them again and itself had a few options in length. The 22 is now back within that range somewhere. The RC10 had short arms, the B2 longer, the B3 longer still. The B4 is just a bit different but geometrically very similar. No fundamental geometry breakthroughs there!

How about wheelbase? ROAR gives us a range so you know it will be in there somewhere. People like to use whatever someone else runs rather than what works for them. The JRX-Pro SE had the option to run an 11.5" wheelbase. It was too long. Stable at speed but couldn't turn. People want the B4.1 longer +8 chassis today and many people running the 22 want a shorter wheelbase. How different can this really be? The reality is that there is no one perfect answer for every track. They are trying their hardest to meet in the middle though.

How about front kick? 20 degrees? 25, 30? It all stays in that range in 2wd. Adjustable? Been done before the 22. No real advancements there!

What about gearboxes? The standard 3 gear has been around for 25+ years but first showed up on the Tamiya Sand Scorcher before 1980. Internal ratios have changed but then again they've changed to accommodate motor technology (rpm and torque differences) which along with batteries is the only true advancement in decades. Now you might say gear diffs are an advancement. They were around before ball diffs. Nothing new there. Slippers have been around for a couple of decades too.

We do have better materials now which means things can be made stronger but with the cars moving at higher speeds, things need to be stronger. This is one area that makes new cars better. Strength. This was done out of necessity.

Shocks are making advancements. We've got big bores. When you have more weight and more speed with larger jumps, this too is just a logical move.

What about vehicle width? They started narrow, got wide, and are going back narrow again.

Chassis material? Plastic, aluminum, fiberglass, carbon fiber, composite. Nothing terribly groundbreaking with the new ones. Aluminum is a good choice solely based on strength.

So if suspension geometry is fairly similar among cars, since they all use A-arms, and wheelbase is pretty close, and gearbox design is nearly identical, and they are all pretty durable, what do you suggest be done to advance them and what would be considered an advancement? I'll tell you what I'd do. I'd change the way it looks, give it another piece of flair, tell people it's better because it's new, and then happily take their money because everyone knows that newer is better. That's business and you need to at least visually evolve or no one will believe it changed.

Nope don't care one bit what the pros do unless they are doing something we haven't seen before.

Have you ever noticed that the modern cars are heavy with low roll centers. That is very forgiving and easy to drive but in the end is solely based around modern track design which is dominated with very hard packed, high speed blue groove clay with large jumps. What has fundamentally changed about car design in the past 20 years? Seriously. Where do all those "millions in development" really go? Aside from added weight and stronger components, what has changed? Sure technology has in the electrics but I mean with fundamental car design itself. What is different? Let's examine this a bit. I've written on it before but people don't like to read on their own. They need a pro to read it to them!

Is arm length an advancement? Certainly this has evolved but they can only get so long and there is a tradeoff for everything. The XX had very long arms yet the XXX shortened them again and itself had a few options in length. The 22 is now back within that range somewhere. The RC10 had short arms, the B2 longer, the B3 longer still. The B4 is just a bit different but geometrically very similar. No fundamental geometry breakthroughs there!

How about wheelbase? ROAR gives us a range so you know it will be in there somewhere. People like to use whatever someone else runs rather than what works for them. The JRX-Pro SE had the option to run an 11.5" wheelbase. It was too long. Stable at speed but couldn't turn. People want the B4.1 longer +8 chassis today and many people running the 22 want a shorter wheelbase. How different can this really be? The reality is that there is no one perfect answer for every track. They are trying their hardest to meet in the middle though.

How about front kick? 20 degrees? 25, 30? It all stays in that range in 2wd. Adjustable? Been done before the 22. No real advancements there!

What about gearboxes? The standard 3 gear has been around for 25+ years but first showed up on the Tamiya Sand Scorcher before 1980. Internal ratios have changed but then again they've changed to accommodate motor technology (rpm and torque differences) which along with batteries is the only true advancement in decades. Now you might say gear diffs are an advancement. They were around before ball diffs. Nothing new there. Slippers have been around for a couple of decades too.

We do have better materials now which means things can be made stronger but with the cars moving at higher speeds, things need to be stronger. This is one area that makes new cars better. Strength. This was done out of necessity.

Shocks are making advancements. We've got big bores. When you have more weight and more speed with larger jumps, this too is just a logical move.

What about vehicle width? They started narrow, got wide, and are going back narrow again.

Chassis material? Plastic, aluminum, fiberglass, carbon fiber, composite. Nothing terribly groundbreaking with the new ones. Aluminum is a good choice solely based on strength.

So if suspension geometry is fairly similar among cars, since they all use A-arms, and wheelbase is pretty close, and gearbox design is nearly identical, and they are all pretty durable, what do you suggest be done to advance them and what would be considered an advancement? I'll tell you what I'd do. I'd change the way it looks, give it another piece of flair, tell people it's better because it's new, and then happily take their money because everyone knows that newer is better. That's business and you need to at least visually evolve or no one will believe it changed.

Nope don't care one bit what the pros do unless they are doing something we haven't seen before.

I would like to have a design where the kickup is adjustable via a turnbuckle. Besides the possibility of the turnbuckle being highly stressed, any other problems with this that jumps out?

Last edited by rcboy1; 05-22-2012 at 03:45 PM.

#36

Tech Elite

Thread Starter

#37

Tech Elite

Thread Starter

#38

Tech Elite

Thread Starter

would you guys rather see it with a saddle pack layout, or a shorty layout? I know standard packs are more common, but with my design i would rather use the smaller ones.

also, Fred, what did you have in mind for a new tranny? I was thinking of using a pinion and ring gear like on 4wd vehicles, but then there would be torque twist. Could a belt work? We've been using 3 gears for so long it's difficult for me to think anything else up...and that's why I'm doing it.

also, Fred, what did you have in mind for a new tranny? I was thinking of using a pinion and ring gear like on 4wd vehicles, but then there would be torque twist. Could a belt work? We've been using 3 gears for so long it's difficult for me to think anything else up...and that's why I'm doing it.

#39

Tech Elite

Thread Starter

#40

I hope no one takes what I say to mean I think the pros are idiots. They certainly aren't. If you follow the tuning thread then you know I am all about learning for yourself and not copying others which is why I say I don't care what the pros do. What I mean by that is that their setups are irrelevant to me. We certainly care if they come with something new or improved and there have been improvements made even though the basic fundamental geometry of the cars has remained very similar for the past 25 years. Many things have been tried and the fundamental design aspects were decided long ago because of reliability and ease of adjustability.

In terms of design, flexibility is key and what I mean by that isn't with chassis flex but rather options. Design it in a way that would allow any battery layout with little trouble.

A belt drive would work. It too has been done before. I actually have an old Bullet Racing Power Glide belt drive from 1989 for the RC10. Then again I was on the team. It's a simple design. The Kyosho Vantage used dual belts in the mid 90's. Team Pit Stop had a chain drive for the RC10 in the 80's but it had a number of issues not including the fact that it was a chain! A 3 gear box is standard because it works and it is about as simple as can be. Simple is king.

I love the fact that you want to design your own car. I think it's cool. I tinker with all kinds of things just to learn or be unique. It's going to be difficult to design something that is truly different unless you think truly different. It depends what your goals are. If you just want to design your own car then by all means use aspects of other cars that work well.

We've had a-arm suspensions forever now but there have been variations in there. Losi had the VLA arms on a variation of the XXX that had dual kingpin locations that allowed you to effectively have different length arms just by moving the pin. My mid motor car has them and I run the shorter setting in the rear and the longer in front. Camber link locations have changed over the years to allow more fine tuning. The inner locations used to be on shock towers facing sideways. Now they sit in a manner that puts them vertical which means even a washer under the ball can make a fine adjustment that moving on the old shock tower location couldn't.

2 cars have the option of going either mid or rear motor but I personally believe their designs to be too compromising in mid motor for low grip tracks but the idea is in the right direction.

Durango has the 3 or 4 gear option in the same case to more easily run either configuration and to allow either same or counter rotation of the motor in relation to the wheels. My old Tamiya Fox, despite all of it's flaws, could rotate really well in the air using motor torque since the motor turned the same direction as the wheels. There were few other positives about that car!

I am a huge fan of an adjustable front end kick and I personally believe few if any truly understand how to tune for it. Perhaps it's just my tuning method but I find that I want less front end rake than any 2wd buggy can currently give me, including the 22. I'd like to see an infinitely adjustable rake just so the option is there. Most will set it at 25-30 degrees and be done with it though.

The trend among cars today is with 2 main things. One is the number of fine tuning options and the other is with durability. Most people won't take advantage of every possible feature that the car can offer because they won't need to. Different tracks require different setups though which is why options are good. Losi wanted to hit the American and European markets and they designed around them. Mid motor for Europe and rear for the US. Tracks over there tend to be much higher grip so while their mid layout isn't optimal for many looser tracks here, it doesn't really matter since we can run rear motor. Durango has done the same thing.

I personally want to design a simple car that goes back to basics. A clean sheet design that keeps things light rather than heavy. The problem is that tires today aren't well suited to light cars. I've got some ideas and for all I know none of them will work! It's the fun of it though. Have fun!

In terms of design, flexibility is key and what I mean by that isn't with chassis flex but rather options. Design it in a way that would allow any battery layout with little trouble.

A belt drive would work. It too has been done before. I actually have an old Bullet Racing Power Glide belt drive from 1989 for the RC10. Then again I was on the team. It's a simple design. The Kyosho Vantage used dual belts in the mid 90's. Team Pit Stop had a chain drive for the RC10 in the 80's but it had a number of issues not including the fact that it was a chain! A 3 gear box is standard because it works and it is about as simple as can be. Simple is king.

I love the fact that you want to design your own car. I think it's cool. I tinker with all kinds of things just to learn or be unique. It's going to be difficult to design something that is truly different unless you think truly different. It depends what your goals are. If you just want to design your own car then by all means use aspects of other cars that work well.

We've had a-arm suspensions forever now but there have been variations in there. Losi had the VLA arms on a variation of the XXX that had dual kingpin locations that allowed you to effectively have different length arms just by moving the pin. My mid motor car has them and I run the shorter setting in the rear and the longer in front. Camber link locations have changed over the years to allow more fine tuning. The inner locations used to be on shock towers facing sideways. Now they sit in a manner that puts them vertical which means even a washer under the ball can make a fine adjustment that moving on the old shock tower location couldn't.

2 cars have the option of going either mid or rear motor but I personally believe their designs to be too compromising in mid motor for low grip tracks but the idea is in the right direction.

Durango has the 3 or 4 gear option in the same case to more easily run either configuration and to allow either same or counter rotation of the motor in relation to the wheels. My old Tamiya Fox, despite all of it's flaws, could rotate really well in the air using motor torque since the motor turned the same direction as the wheels. There were few other positives about that car!

I am a huge fan of an adjustable front end kick and I personally believe few if any truly understand how to tune for it. Perhaps it's just my tuning method but I find that I want less front end rake than any 2wd buggy can currently give me, including the 22. I'd like to see an infinitely adjustable rake just so the option is there. Most will set it at 25-30 degrees and be done with it though.

The trend among cars today is with 2 main things. One is the number of fine tuning options and the other is with durability. Most people won't take advantage of every possible feature that the car can offer because they won't need to. Different tracks require different setups though which is why options are good. Losi wanted to hit the American and European markets and they designed around them. Mid motor for Europe and rear for the US. Tracks over there tend to be much higher grip so while their mid layout isn't optimal for many looser tracks here, it doesn't really matter since we can run rear motor. Durango has done the same thing.

I personally want to design a simple car that goes back to basics. A clean sheet design that keeps things light rather than heavy. The problem is that tires today aren't well suited to light cars. I've got some ideas and for all I know none of them will work! It's the fun of it though. Have fun!

#41

Suspended

would you guys rather see it with a saddle pack layout, or a shorty layout? I know standard packs are more common, but with my design i would rather use the smaller ones.

also, Fred, what did you have in mind for a new tranny? I was thinking of using a pinion and ring gear like on 4wd vehicles, but then there would be torque twist. Could a belt work? We've been using 3 gears for so long it's difficult for me to think anything else up...and that's why I'm doing it.

also, Fred, what did you have in mind for a new tranny? I was thinking of using a pinion and ring gear like on 4wd vehicles, but then there would be torque twist. Could a belt work? We've been using 3 gears for so long it's difficult for me to think anything else up...and that's why I'm doing it.

As fredswain said above, we have already seen "ring and pinion gear," "belt drive", "chain drive," "6-gear," "5-gear," "direct drive", etc. gearboxes in the past, there were all kinds of things being tried, but it was soon hit upon (I think it was the MIP tranny, late 1980s early 90s) that a 3-gear gearbox was the overall best combo for a rear motor design. For midmotor, if that is your intent, a 4-gear gearbox is the ticket.

#42

Tech Elite

Thread Starter

I hope no one takes what I say to mean I think the pros are idiots. They certainly aren't. If you follow the tuning thread then you know I am all about learning for yourself and not copying others which is why I say I don't care what the pros do. What I mean by that is that their setups are irrelevant to me. We certainly care if they come with something new or improved and there have been improvements made even though the basic fundamental geometry of the cars has remained very similar for the past 25 years. Many things have been tried and the fundamental design aspects were decided long ago because of reliability and ease of adjustability.

In terms of design, flexibility is key and what I mean by that isn't with chassis flex but rather options. Design it in a way that would allow any battery layout with little trouble.

A belt drive would work. It too has been done before. I actually have an old Bullet Racing Power Glide belt drive from 1989 for the RC10. Then again I was on the team. It's a simple design. The Kyosho Vantage used dual belts in the mid 90's. Team Pit Stop had a chain drive for the RC10 in the 80's but it had a number of issues not including the fact that it was a chain! A 3 gear box is standard because it works and it is about as simple as can be. Simple is king.

I love the fact that you want to design your own car. I think it's cool. I tinker with all kinds of things just to learn or be unique. It's going to be difficult to design something that is truly different unless you think truly different. It depends what your goals are. If you just want to design your own car then by all means use aspects of other cars that work well.

We've had a-arm suspensions forever now but there have been variations in there. Losi had the VLA arms on a variation of the XXX that had dual kingpin locations that allowed you to effectively have different length arms just by moving the pin. My mid motor car has them and I run the shorter setting in the rear and the longer in front. Camber link locations have changed over the years to allow more fine tuning. The inner locations used to be on shock towers facing sideways. Now they sit in a manner that puts them vertical which means even a washer under the ball can make a fine adjustment that moving on the old shock tower location couldn't.

2 cars have the option of going either mid or rear motor but I personally believe their designs to be too compromising in mid motor for low grip tracks but the idea is in the right direction.

Durango has the 3 or 4 gear option in the same case to more easily run either configuration and to allow either same or counter rotation of the motor in relation to the wheels. My old Tamiya Fox, despite all of it's flaws, could rotate really well in the air using motor torque since the motor turned the same direction as the wheels. There were few other positives about that car!

I am a huge fan of an adjustable front end kick and I personally believe few if any truly understand how to tune for it. Perhaps it's just my tuning method but I find that I want less front end rake than any 2wd buggy can currently give me, including the 22. I'd like to see an infinitely adjustable rake just so the option is there. Most will set it at 25-30 degrees and be done with it though.

The trend among cars today is with 2 main things. One is the number of fine tuning options and the other is with durability. Most people won't take advantage of every possible feature that the car can offer because they won't need to. Different tracks require different setups though which is why options are good. Losi wanted to hit the American and European markets and they designed around them. Mid motor for Europe and rear for the US. Tracks over there tend to be much higher grip so while their mid layout isn't optimal for many looser tracks here, it doesn't really matter since we can run rear motor. Durango has done the same thing.

I personally want to design a simple car that goes back to basics. A clean sheet design that keeps things light rather than heavy. The problem is that tires today aren't well suited to light cars. I've got some ideas and for all I know none of them will work! It's the fun of it though. Have fun!

In terms of design, flexibility is key and what I mean by that isn't with chassis flex but rather options. Design it in a way that would allow any battery layout with little trouble.

A belt drive would work. It too has been done before. I actually have an old Bullet Racing Power Glide belt drive from 1989 for the RC10. Then again I was on the team. It's a simple design. The Kyosho Vantage used dual belts in the mid 90's. Team Pit Stop had a chain drive for the RC10 in the 80's but it had a number of issues not including the fact that it was a chain! A 3 gear box is standard because it works and it is about as simple as can be. Simple is king.

I love the fact that you want to design your own car. I think it's cool. I tinker with all kinds of things just to learn or be unique. It's going to be difficult to design something that is truly different unless you think truly different. It depends what your goals are. If you just want to design your own car then by all means use aspects of other cars that work well.

We've had a-arm suspensions forever now but there have been variations in there. Losi had the VLA arms on a variation of the XXX that had dual kingpin locations that allowed you to effectively have different length arms just by moving the pin. My mid motor car has them and I run the shorter setting in the rear and the longer in front. Camber link locations have changed over the years to allow more fine tuning. The inner locations used to be on shock towers facing sideways. Now they sit in a manner that puts them vertical which means even a washer under the ball can make a fine adjustment that moving on the old shock tower location couldn't.

2 cars have the option of going either mid or rear motor but I personally believe their designs to be too compromising in mid motor for low grip tracks but the idea is in the right direction.

Durango has the 3 or 4 gear option in the same case to more easily run either configuration and to allow either same or counter rotation of the motor in relation to the wheels. My old Tamiya Fox, despite all of it's flaws, could rotate really well in the air using motor torque since the motor turned the same direction as the wheels. There were few other positives about that car!

I am a huge fan of an adjustable front end kick and I personally believe few if any truly understand how to tune for it. Perhaps it's just my tuning method but I find that I want less front end rake than any 2wd buggy can currently give me, including the 22. I'd like to see an infinitely adjustable rake just so the option is there. Most will set it at 25-30 degrees and be done with it though.

The trend among cars today is with 2 main things. One is the number of fine tuning options and the other is with durability. Most people won't take advantage of every possible feature that the car can offer because they won't need to. Different tracks require different setups though which is why options are good. Losi wanted to hit the American and European markets and they designed around them. Mid motor for Europe and rear for the US. Tracks over there tend to be much higher grip so while their mid layout isn't optimal for many looser tracks here, it doesn't really matter since we can run rear motor. Durango has done the same thing.

I personally want to design a simple car that goes back to basics. A clean sheet design that keeps things light rather than heavy. The problem is that tires today aren't well suited to light cars. I've got some ideas and for all I know none of them will work! It's the fun of it though. Have fun!

Would you like to help? If you want to design your own car as well...

Would you like to help? If you want to design your own car as well...

I think ROAR passed a rule, something about you can not have a vehicle designed only to use shorty packs.

As fredswain said above, we have already seen "ring and pinion gear," "belt drive", "chain drive," "6-gear," "5-gear," "direct drive", etc. gearboxes in the past, there were all kinds of things being tried, but it was soon hit upon (I think it was the MIP tranny, late 1980s early 90s) that a 3-gear gearbox was the overall best combo for a rear motor design. For midmotor, if that is your intent, a 4-gear gearbox is the ticket.

As fredswain said above, we have already seen "ring and pinion gear," "belt drive", "chain drive," "6-gear," "5-gear," "direct drive", etc. gearboxes in the past, there were all kinds of things being tried, but it was soon hit upon (I think it was the MIP tranny, late 1980s early 90s) that a 3-gear gearbox was the overall best combo for a rear motor design. For midmotor, if that is your intent, a 4-gear gearbox is the ticket.

#44

Here's something a bit different from what you'd see today. Here are a couple of pics of a car that I'm starting to build right now. It is going to be the old RC10 that isn't. Back in the day you could get so many mods for the car that you could build an aftermarket RC10 using no original RC10 parts. What do you really call it at that point? Here's one of them that I'm working on. It uses Bullet Racing trailing arms, belt drive, and chassis.