AE B6.2D / B6.2 Thread

|

|||

#2431

Tech Addict

I see the B6.3 manual has been released so will have a look re parts etc. Not planning on changing, just interested in the overlap etc. Spare towers etc I'd rather order the B6.3 options going forward etc.

#2432

Tech Regular

#2433

Tech Master

Running 3 deg in the rear now also did ray Mundays arm shortening trick went from being 4 sec of the pace to being 1 sec off the pace the car is much more driveable now. I think i need to change the pinion from 25 teeth to 23 teeth. Also I had done 12 races on the same setof mezzos with out the grip dropping off

You might well have to drop down on the pinion with the Mezzos as they are a reasonable amount larger in diameter than Darts, I'd only go down 1 tooth at a time though.

#2434

ok guys. Son hit the wall last night in practice. He sheered off 1 of the screws in the front ball stud mount, part #91766. I thought instead of trying to find a way to get that screw out I'd just pay $5 for a new mount. But everywhere I'm seeing it says they're discontinued, even AE's website. Why would they discontinue this and is there a new AE alternative? Are there any better aftermarket options? Thanks

#2435

Tech Addict

ok guys. Son hit the wall last night in practice. He sheered off 1 of the screws in the front ball stud mount, part #91766. I thought instead of trying to find a way to get that screw out I'd just pay $5 for a new mount. But everywhere I'm seeing it says they're discontinued, even AE's website. Why would they discontinue this and is there a new AE alternative? Are there any better aftermarket options? Thanks

#2437

Tech Regular

Is there a bad batch of ball diff screws going around i snapped one after 3 races...

Has tried schumacher Mezzos with the tubby inserts it is supposed to improve side bite?

Has tried schumacher Mezzos with the tubby inserts it is supposed to improve side bite?

#2438

Tech Addict

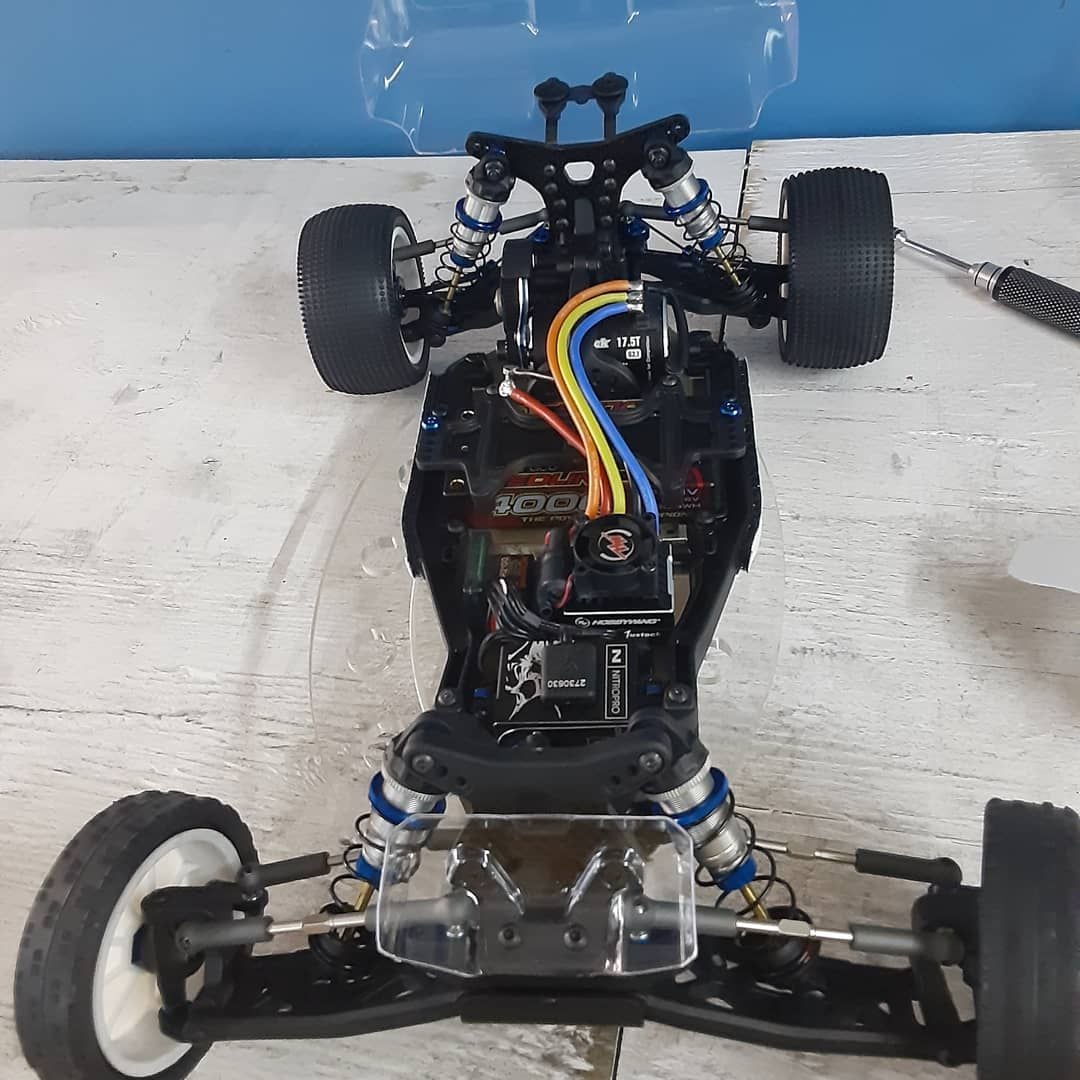

Built the B6.2 shocks from the kit and have fitted them to my B6.1 DL with the lower tower, will see how I get on this weekend.

Shame there isn't stock of any HobbyWing 7.5T motors anywhere.

#2439

Delete

#2440

Tech Regular

Confused with the chassis. Which one is the shorter one. The b6.2d and b6.1 are they the same? What about the b6.3d?

#2442

Tech Regular

#2443

Tech Apprentice

iTrader: (3)

In case anyone was looking to upgrade parts to 6.3 spec the front servo mount is pretty easy. Order the Associated #91887 kit, it's the Factory Team version and includes the new blue ano aluminum chassis mounted servo mounts, carbon top cross plate, and all hardware required. The AE website had them for around $34 when I ordered a week or so go. There is no photo so it's hard to know if this part number has everything - it does.

To mount I drilled the holes in my 6.2 chassis using the existing side rail mounts as a guide; I just went down through them and then through the chassis. Use a counter sink bit on the underside for clearance then buzz off the old mounts with a cut off wheel from the side rails. Reinstall rails along with new mount and you're up and running. Took about 20 min total.

To mount I drilled the holes in my 6.2 chassis using the existing side rail mounts as a guide; I just went down through them and then through the chassis. Use a counter sink bit on the underside for clearance then buzz off the old mounts with a cut off wheel from the side rails. Reinstall rails along with new mount and you're up and running. Took about 20 min total.

#2444

Tech Master

Using the B6.1/B6.2 side rails that you already have you can mount the servo the conventional way until you get the upgraded servo mount.

#2445

Tech Master

iTrader: (16)

In case anyone was looking to upgrade parts to 6.3 spec the front servo mount is pretty easy. Order the Associated #91887 kit, it's the Factory Team version and includes the new blue ano aluminum chassis mounted servo mounts, carbon top cross plate, and all hardware required. The AE website had them for around $34 when I ordered a week or so go. There is no photo so it's hard to know if this part number has everything - it does.

To mount I drilled the holes in my 6.2 chassis using the existing side rail mounts as a guide; I just went down through them and then through the chassis. Use a counter sink bit on the underside for clearance then buzz off the old mounts with a cut off wheel from the side rails. Reinstall rails along with new mount and you're up and running. Took about 20 min total.

To mount I drilled the holes in my 6.2 chassis using the existing side rail mounts as a guide; I just went down through them and then through the chassis. Use a counter sink bit on the underside for clearance then buzz off the old mounts with a cut off wheel from the side rails. Reinstall rails along with new mount and you're up and running. Took about 20 min total.

Last edited by Silverbullet555; 05-04-2021 at 06:14 AM.

1409Likes

1409Likes