View Poll Results: what's your tire choice?

Protoform

46

30.67%

HPI

104

69.33%

Voters: 150. You may not vote on this poll

U.S. Vintage Trans-Am Racing Part 2

#6196

Fairly confident its the sensor wire. Novak motors have horrible sensor wire ports. I ended up using a small zip tie around the part that sticks out. Its like the motor is made perfectly for that. Eventually got a Novak sensor wire and solved the problem.

Also, you can test this theory by giving the car a push start before you give it throttle. I bet it will work just fine once its rolling.

Also, you can test this theory by giving the car a push start before you give it throttle. I bet it will work just fine once its rolling.

#6197

Hypothetical question: if the HPI Gittin Mustang had not been Gittin styled, but was normal on the hood and nose with more typical decals, then would you have considered it for the list? Was there a 69 stang in the historic series? Are there any other features about the Gittin Mustang besides the hood flutes and covered headlights that would cause you to dismiss it. I know this shell has been discussed already and I am not asking for it to be on the list. Honestly I have not been able to find one. If I did, I am sure that I could at least run it at club level where everything is pretty casual and it's all among good friends. Even so I wish HPI would have produced a more production looking 69. If you look at some of the 66 Mustangs, there is no more difference between them than a hood scoop and some decals. Yet they spent the money to tool another mold.

#6198

I guess some people are expecting you to show up and hold a tribunal if they don't run the body list.

Hypothetical question: if the HPI Gittin Mustang had not been Gittin styled, but was normal on the hood and nose with more typical decals, then would you have considered it for the list? Was there a 69 stang in the historic series? Are there any other features about the Gittin Mustang besides the hood flutes and covered headlights that would cause you to dismiss it. I know this shell has been discussed already and I am not asking for it to be on the list. Honestly I have not been able to find one. If I did, I am sure that I could at least run it at club level where everything is pretty casual and it's all among good friends. Even so I wish HPI would have produced a more production looking 69. If you look at some of the 66 Mustangs, there is no more difference between them than a hood scoop and some decals. Yet they spent the money to tool another mold.

Hypothetical question: if the HPI Gittin Mustang had not been Gittin styled, but was normal on the hood and nose with more typical decals, then would you have considered it for the list? Was there a 69 stang in the historic series? Are there any other features about the Gittin Mustang besides the hood flutes and covered headlights that would cause you to dismiss it. I know this shell has been discussed already and I am not asking for it to be on the list. Honestly I have not been able to find one. If I did, I am sure that I could at least run it at club level where everything is pretty casual and it's all among good friends. Even so I wish HPI would have produced a more production looking 69. If you look at some of the 66 Mustangs, there is no more difference between them than a hood scoop and some decals. Yet they spent the money to tool another mold.

http://www.historictransam.com/Drive...Mustang83.html

#6199

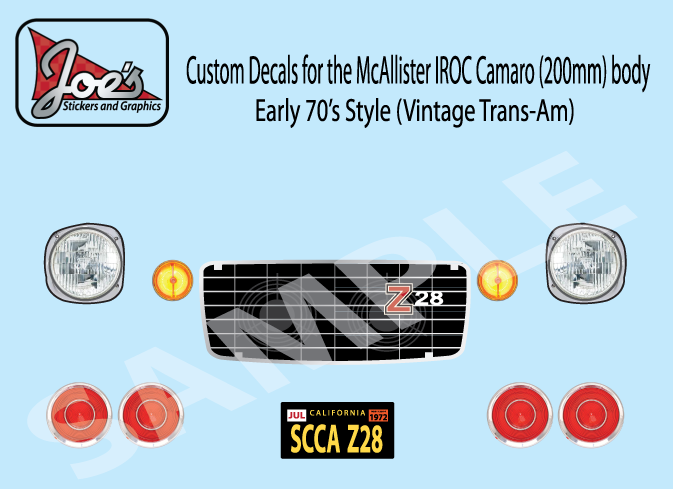

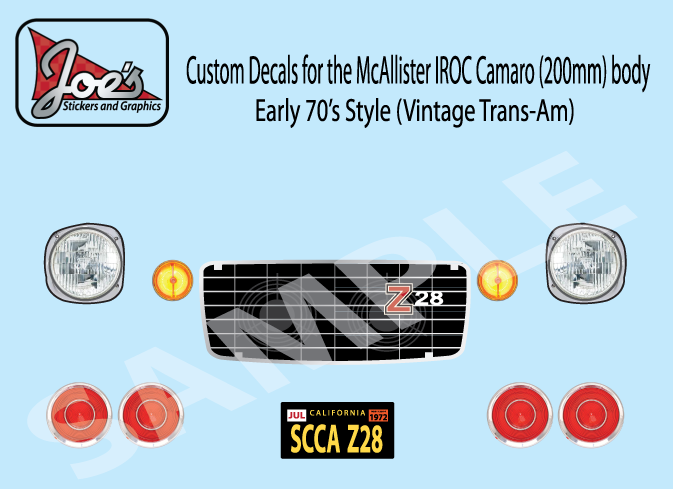

For myself, and a few of those others who like playing w/ a vintage looking car - but aren't racing in "sanctioned" USVTA events - I'm working on a decal set for the McAllister IROC Camaro to give it more of a VTA look and feel. (Even though it's a later 70's body - the body platform is the same as the earlier one - with a little effort I think the earlier look can be pulled off.

The earlier 70's Camaro didn't wrap the rear window, I believe the rear window mask can just be trimmed to make this effect.

The earlier 70's Camaro didn't wrap the rear window, I believe the rear window mask can just be trimmed to make this effect.

#6200

Tech Fanatic

Hobbywing Just Stock which is programmed exactly like the one in my USGT car I ran Sunday. Same senor wire I was using with a 21.5 before the 25.5 showed up and the 21.5 work fine.

#6201

This is the inspiration for my current paint, it is a '69 as you can see. I don't think many can tell the difference on the HPI '70 though

http://www.historictransam.com/Drive...Mustang83.html

http://www.historictransam.com/Drive...Mustang83.html

| + YouTube Video | |

#6202

Tech Fanatic

Have you tried slightly loosening the 3 screws for the sensor, slowly spin the motor shaft and re-tighten, but not to tight?

I know it sounds odd, sometimes the alignment on the sensor end gets goofy from adjusting the timing, and under a load sounds like a coffee grinder if it is out of whack.

I know it sounds odd, sometimes the alignment on the sensor end gets goofy from adjusting the timing, and under a load sounds like a coffee grinder if it is out of whack.

#6203

Whiteside is a fountain of knowledge. We are all just lucky he wants to help.

VTA C main Snowbirds

Sorry I don't have the B. I was MIA.

VTA C main Snowbirds

| + YouTube Video | |

Sorry I don't have the B. I was MIA.

#6204

BINGO You nailed it!! Thanks Very much. I've been playing with brushless motors since 2006 and never had to do that to a motor to make it run after changing the timing. In fact never heard of anyone having to do that to make their motor run after changing the timing. Where did you hear of that trick?

I got lucky once after the same issue

.

.To be honest, I believe it is just a case of "stack up" tolerance's. The Sensor "holder", is probably a little on the small side and the end bell a little large which lets the sensor assembly walk a little.

I think sometimes, with any motor as well, over tightening the sensor end may/could cause a shift in the actual sensor towards the rotor, which can or may cause an issue after tightening ( I saw this with a much more motor, that actually caused it to shut down after hard braking).

At least on the Novak motor's, make sure the shimming is correct on the sensor end of the rotor.

It doesn't happen very often and can usually be fixed with the loosening and re-snug

#6206

Thanks. I don't know why I thought those side scoops were factory. On another note I got the Snowbird A main up to youtube. My Camera angle of it anyway. Shows Dirla getting the bad end of a pileup.

| + YouTube Video | |

i also love the whine of the shaft drive down the straight...

#6207

One thing that I think may be overlooked with the ballistic series motors is the center ring and it's true function, as I see it.

Ill try to explain the best I can. ROAR has an overall length dimension for the 540 motors being "X" mm. The Ballistic motor, being essentially a 3 piece design ( 2 end bells and center ring) to achieve the specified length. The center ring acts as a spacer/shim. Due to the nature of high speed stamped lamination's (there are variations in stack height) and the ROAR spec for the maximum stator height, the center ring makes sure the overall length of the motor does not fall below specified minimum.

If the stack height is on the "high" side, the center ring is loose, if it is on the low side, it is tight. I prefer about .3mm end play in the rotor to eliminate any binding from heat expansion within the motor.

The new BOSS, eliminates the need for the center spacer ring and allows for heat expansion of the stator within the end bells. I think "float" is a better phrase.

Moving the rotor closer to the sensor, in effect, will give it a "advance" of sorts (as explained to me by Charlie). We can only get so close though because of the machined step in the rotor, about 1 mm or so.

I have tried re-shimming the rotors towards and away from the sensor. The gains or losses have really been minimal, what is interesting is watching "were" the rpm shift happens.

Hope that helps somewhat, in my head it makes sense anyway

#6209

Tech Fanatic

I'll check on that size, both sensor end and pinion end.

One thing that I think may be overlooked with the ballistic series motors is the center ring and it's true function, as I see it.

Ill try to explain the best I can. ROAR has an overall length dimension for the 540 motors being "X" mm. The Ballistic motor, being essentially a 3 piece design ( 2 end bells and center ring) to achieve the specified length. The center ring acts as a spacer/shim. Due to the nature of high speed stamped lamination's (there are variations in stack height) and the ROAR spec for the maximum stator height, the center ring makes sure the overall length of the motor does not fall below specified minimum.

If the stack height is on the "high" side, the center ring is loose, if it is on the low side, it is tight. I prefer about .3mm end play in the rotor to eliminate any binding from heat expansion within the motor.

The new BOSS, eliminates the need for the center spacer ring and allows for heat expansion of the stator within the end bells. I think "float" is a better phrase.

Moving the rotor closer to the sensor, in effect, will give it a "advance" of sorts (as explained to me by Charlie). We can only get so close though because of the machined step in the rotor, about 1 mm or so.

I have tried re-shimming the rotors towards and away from the sensor. The gains or losses have really been minimal, what is interesting is watching "were" the rpm shift happens.

Hope that helps somewhat, in my head it makes sense anyway

One thing that I think may be overlooked with the ballistic series motors is the center ring and it's true function, as I see it.

Ill try to explain the best I can. ROAR has an overall length dimension for the 540 motors being "X" mm. The Ballistic motor, being essentially a 3 piece design ( 2 end bells and center ring) to achieve the specified length. The center ring acts as a spacer/shim. Due to the nature of high speed stamped lamination's (there are variations in stack height) and the ROAR spec for the maximum stator height, the center ring makes sure the overall length of the motor does not fall below specified minimum.

If the stack height is on the "high" side, the center ring is loose, if it is on the low side, it is tight. I prefer about .3mm end play in the rotor to eliminate any binding from heat expansion within the motor.

The new BOSS, eliminates the need for the center spacer ring and allows for heat expansion of the stator within the end bells. I think "float" is a better phrase.

Moving the rotor closer to the sensor, in effect, will give it a "advance" of sorts (as explained to me by Charlie). We can only get so close though because of the machined step in the rotor, about 1 mm or so.

I have tried re-shimming the rotors towards and away from the sensor. The gains or losses have really been minimal, what is interesting is watching "were" the rpm shift happens.

Hope that helps somewhat, in my head it makes sense anyway

. You obviously know these motors very well. Took my BOSS 25.5 out today for a test run on the driveway and it is running great for once. Now we'll see what happens Saturday after it gets hot during/after a race. BTW I emailed your advice to Novak and Charlie responded that he had never heard of anyone having a problem like mine before (difficult to believe from all the chatter about it here and the Novak thread on RCTECH). Anyway, I suggested that NOVAK add your advice to their trouble shooting guide to avoid future disgruntled customers like me.

. You obviously know these motors very well. Took my BOSS 25.5 out today for a test run on the driveway and it is running great for once. Now we'll see what happens Saturday after it gets hot during/after a race. BTW I emailed your advice to Novak and Charlie responded that he had never heard of anyone having a problem like mine before (difficult to believe from all the chatter about it here and the Novak thread on RCTECH). Anyway, I suggested that NOVAK add your advice to their trouble shooting guide to avoid future disgruntled customers like me.

#6210

Does anyone have a setup for a T4'13 running Reflex Racings conversion?

We'll be running a one off meeting next weekend and for fun we have one heat of an 'HPI Challenge' class.

We'll be running 17.5 blinky on this track (different layout though);

We'll be running a one off meeting next weekend and for fun we have one heat of an 'HPI Challenge' class.

We'll be running 17.5 blinky on this track (different layout though);

| + YouTube Video | |

4318Likes

4318Likes