TLR 22 3.0 Race Kit Thread!

|

|||

#1486

Tech Regular

iTrader: (13)

I'm trying to figure out my on power push problem. I'm looking for suggestions. What i plan to try, get the 0deg caster blocks, stiffer rear Springs, more anti squat, longer front links, Add a shim in the front shocks to get less droop, less toe in on the rear lengthen car length. Any other ideas?

#1487

I'm trying to figure out my on power push problem. I'm looking for suggestions. What i plan to try, get the 0deg caster blocks, stiffer rear Springs, more anti squat, longer front links, Add a shim in the front shocks to get less droop, less toe in on the rear lengthen car length. Any other ideas?

I'd try front or rear links, rear toe/anti squat.

#1488

B5 wheels will NOT work, they will bind up and not turn.

#1489

I'm trying to figure out my on power push problem. I'm looking for suggestions. What i plan to try, get the 0deg caster blocks, stiffer rear Springs, more anti squat, longer front links, Add a shim in the front shocks to get less droop, less toe in on the rear lengthen car length. Any other ideas?

#1490

I just have to give this buggy HUGE props on being awesome right out of the box. Buggy was built box stock with no upgrades other then pink springs in the rear and was ran with box setup. With very little practice on a brand new buggy ( not broken in and on new non broken in tires) I qualified 5th out of 20 for stock 17.5 buggy and finished 2nd today. Could not be happier and highly recommend this buggy.

#1491

Cost aside, is there any benefit/difference to running the Spektrum 6270 over the 6240?

#1492

6270 = Short servo, HV so it will run at 6 volts/7.4 volts/ and 8.4 volts.

The higher the voltage, the faster it is. 124 oz at 6 volts, 152 oz at 7.4/

174 oz at 8.4 volts.

I run the 6240 in my 3.0 and I'm very impressed with it.

#1493

Had my first official race with the 3.0 yesterday.

About the track. Our track is an outdoor carpet track. The lay out was changed over the holidays and had some new carpet with some mixture of the old carpet. Also not all the carpet is of the same type (and color) but is pretty much all short shag like you would find in an office or commercial building. The older carpet has some mold growing in it, so when it it dry and hard that carpet is coarse and provides really good traction . But if it rains, it can be like black ice.

With that being said, we had a great start of the race with dry weather and lots of sun, but by the second qualifier, we had a good 5 minute down poor that pretty much soaked the track. (this is why we have carpet) Though the carpet did its job of soaking up the water, it still left the track fairly damp and slippery in some areas, mainly where the old carpet is still at.

On to the race. In the first Qualifier the 3.0 was planted and felt great. I had the TQ. Well that was until the next heat and an AE took it away. 2nd Qualifier for the 17t stock went the same as we were just ahead of the rain. Once again the buggy felt great and was able to improve on my time, but still shy of the TQ.

The Main event. Well that AE guy that took the TQ wasn't able to make it to the line. Don't know if there was a mechanical issue or if they were just worried about having to drive on the damp track and was worried about being to slippery. I do know that when I placed my car on the line I realized that I never adjusted my slipper to accommodate for the slippery conditions. I punched it a couple of times and thought to myself that this was not going to be fun. At the sound of the tone I just gently squeezed the throttle only going to half throttle and watch the rest of the pack behind me punch it and getting all loose. Going through turn one the back end was wanting to back out but with throttle finesse I was able to keep it in check. From that point on the race was mine. From sound of the tone to finish your lap, I was never contested. I was nearly a full lap ahead. Though the buggy was getting loose in some areas it was very predictable and so drive-able.

I guess all I am trying to say is, the car drove better then me. If I had been using my prior buggy, this story would have been more about drowning my sorrows with a 6 pack. This buggy is amazing. I just hope that TQ guy doesn't decide to abandon ship and get one too.

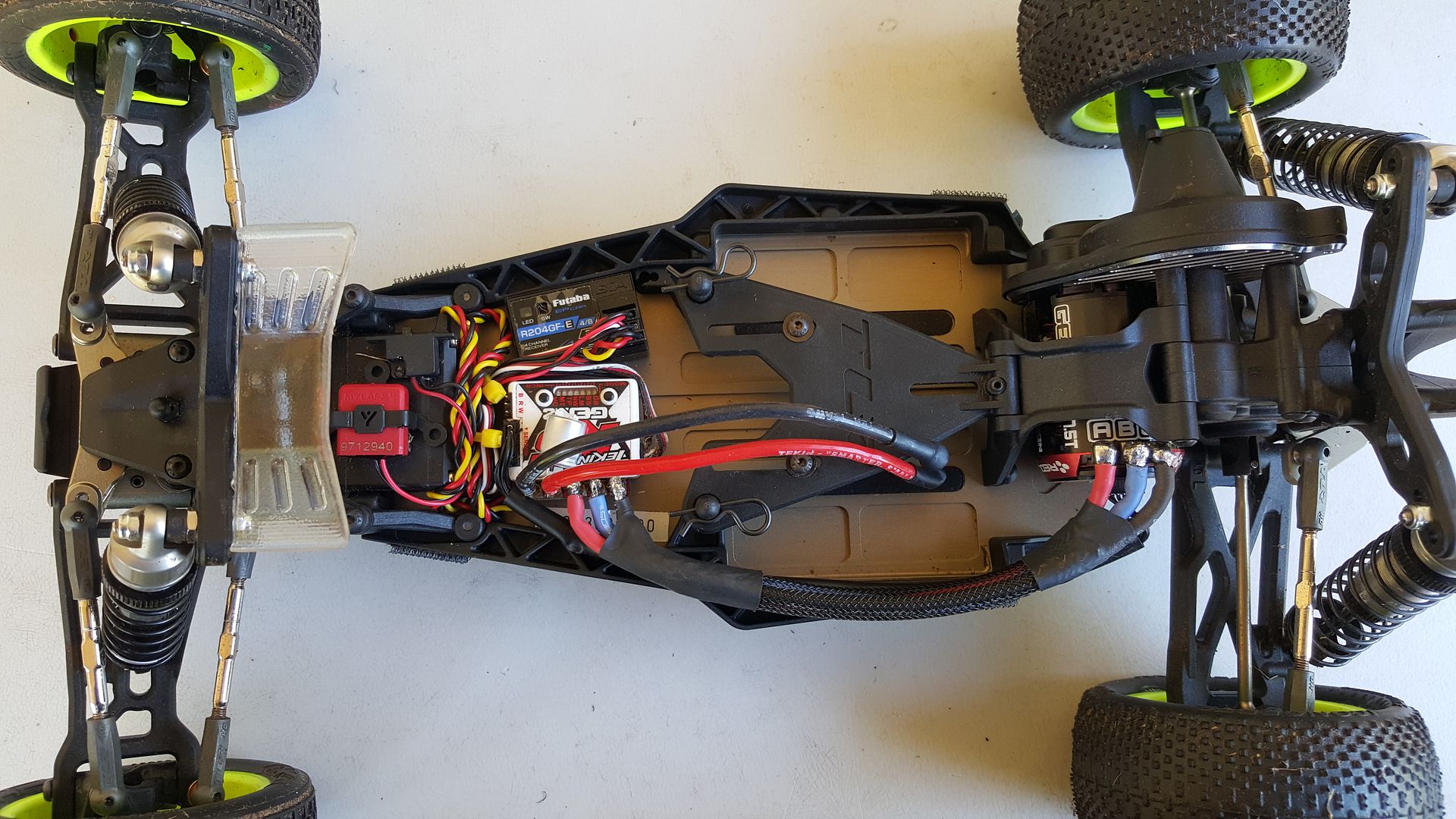

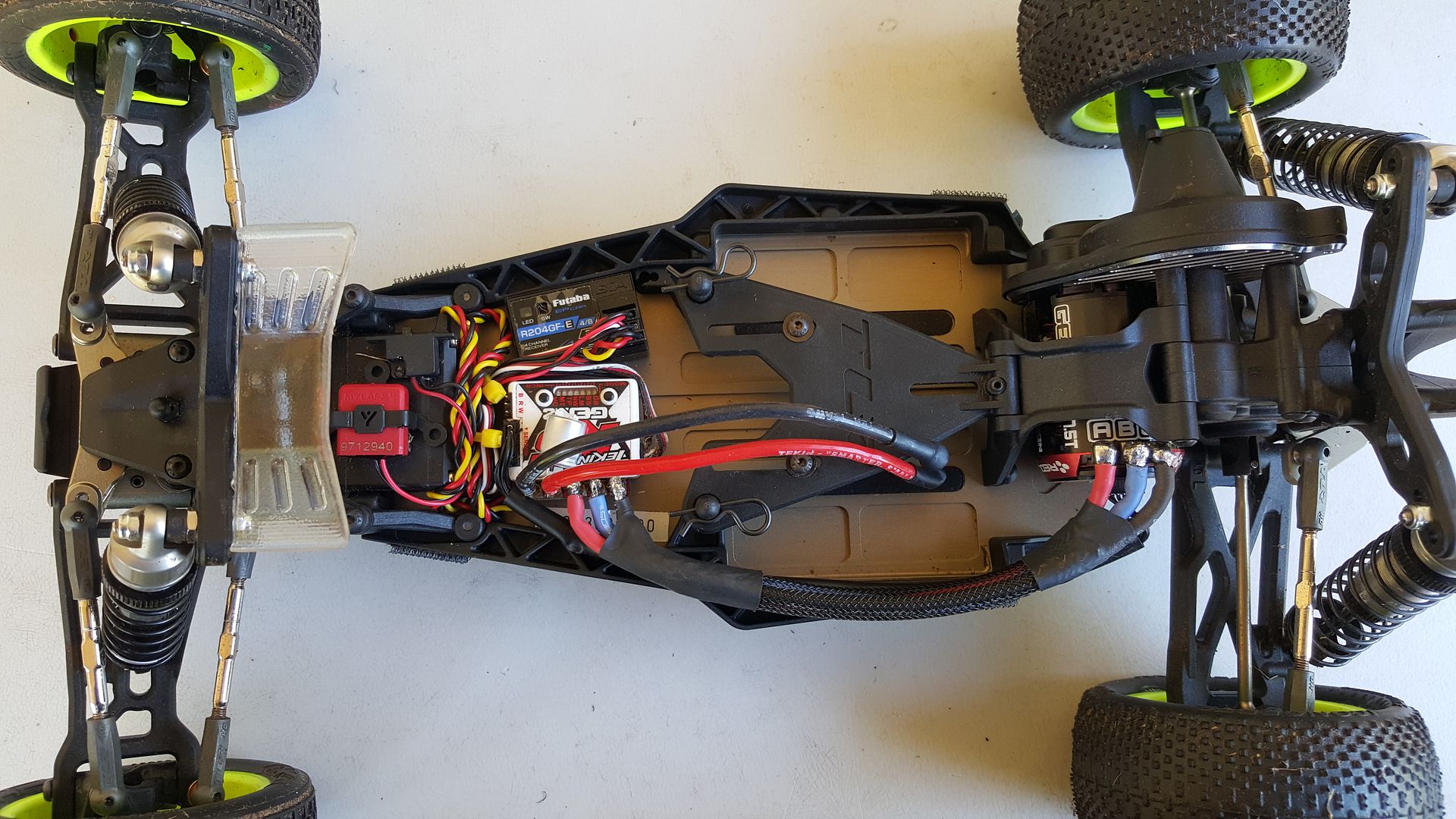

Also for those weight watchers, my buggy weighed in at 1529 grams. Things I added where, titanium ball studs / shock mounts, aluminum front axles / rear drive shafts / front pivot support / front camber block, Schelle slipper and a front wing. I run a Tekin RS GENII with a GEN III motor. Servo is a Hitec HS5685 . Futaba R204GF-E receiver. Battery SMC shorty.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

About the track. Our track is an outdoor carpet track. The lay out was changed over the holidays and had some new carpet with some mixture of the old carpet. Also not all the carpet is of the same type (and color) but is pretty much all short shag like you would find in an office or commercial building. The older carpet has some mold growing in it, so when it it dry and hard that carpet is coarse and provides really good traction . But if it rains, it can be like black ice.

With that being said, we had a great start of the race with dry weather and lots of sun, but by the second qualifier, we had a good 5 minute down poor that pretty much soaked the track. (this is why we have carpet) Though the carpet did its job of soaking up the water, it still left the track fairly damp and slippery in some areas, mainly where the old carpet is still at.

On to the race. In the first Qualifier the 3.0 was planted and felt great. I had the TQ. Well that was until the next heat and an AE took it away. 2nd Qualifier for the 17t stock went the same as we were just ahead of the rain. Once again the buggy felt great and was able to improve on my time, but still shy of the TQ.

The Main event. Well that AE guy that took the TQ wasn't able to make it to the line. Don't know if there was a mechanical issue or if they were just worried about having to drive on the damp track and was worried about being to slippery. I do know that when I placed my car on the line I realized that I never adjusted my slipper to accommodate for the slippery conditions. I punched it a couple of times and thought to myself that this was not going to be fun. At the sound of the tone I just gently squeezed the throttle only going to half throttle and watch the rest of the pack behind me punch it and getting all loose. Going through turn one the back end was wanting to back out but with throttle finesse I was able to keep it in check. From that point on the race was mine. From sound of the tone to finish your lap, I was never contested. I was nearly a full lap ahead. Though the buggy was getting loose in some areas it was very predictable and so drive-able.

I guess all I am trying to say is, the car drove better then me. If I had been using my prior buggy, this story would have been more about drowning my sorrows with a 6 pack. This buggy is amazing. I just hope that TQ guy doesn't decide to abandon ship and get one too.

Also for those weight watchers, my buggy weighed in at 1529 grams. Things I added where, titanium ball studs / shock mounts, aluminum front axles / rear drive shafts / front pivot support / front camber block, Schelle slipper and a front wing. I run a Tekin RS GENII with a GEN III motor. Servo is a Hitec HS5685 . Futaba R204GF-E receiver. Battery SMC shorty.

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]

Last edited by PIHGUAM1; 01-10-2016 at 03:52 PM. Reason: Spelling

#1494

I'm trying to figure out my on power push problem. I'm looking for suggestions. What i plan to try, get the 0deg caster blocks, stiffer rear Springs, more anti squat, longer front links, Add a shim in the front shocks to get less droop, less toe in on the rear lengthen car length. Any other ideas?

#1496

Tech Fanatic

iTrader: (13)

I'm trying to figure out my on power push problem. I'm looking for suggestions. What i plan to try, get the 0deg caster blocks, stiffer rear Springs, more anti squat, longer front links, Add a shim in the front shocks to get less droop, less toe in on the rear lengthen car length. Any other ideas?

#1497

OK guys, another question. I apologize if this has already been covered but as these threads get longer my memory gets shorter, haha! We've always been pretty decent at building shocks and I know I have read about this somewhere before but didn't really pay a lot of attention to it as it hadn't been a problem in the past but we have been building our shocks with little to no rebound but at the moment we are having a lot of negative rebound in them. As soon as we cycle the shock and check rebound when we pull the shaft out it sucks back into the shock. Not all the way but about halfish or so. I don't think that this is supposed to happen is it, and if not what are we doing wrong? The shocks are about a month old.

#1498

Wow. That's as much as 4mm higher than kit position (& what most are running south of you @ Trackside). You're still getting good sidebite with that?

#1499

OK guys, another question. I apologize if this has already been covered but as these threads get longer my memory gets shorter, haha! We've always been pretty decent at building shocks and I know I have read about this somewhere before but didn't really pay a lot of attention to it as it hadn't been a problem in the past but we have been building our shocks with little to no rebound but at the moment we are having a lot of negative rebound in them. As soon as we cycle the shock and check rebound when we pull the shaft out it sucks back into the shock. Not all the way but about halfish or so. I don't think that this is supposed to happen is it, and if not what are we doing wrong? The shocks are about a month old.

#1500

The only way I can see to "fix" it is to use a bladder and ventilate the cap so that the air behind it can normalize with movement.

26Likes

26Likes