Xray XB2 2WD Buggy Thread

|

|||

#1472

After reading the last 30 pages of posts, I realized why I stopped coming to RCTech. Jeeze people need to chill out. To the dude that broke a ther rear hinge pin holder. Yeah that looks defective. But also could be from over tightening. The screw is steal and the part is aluminum one eighth of a turn past tight will break just about any aluminum part. Did you put it together by hand or with a tool. I see guys with little drill/driver tools putting shit together all the time. It's cool to take stuff apart, but putting things together should be done by hand to avoid stripping or over heating plastic parts. On a side note, plain ivory soap is your friend, rub it on the screw threads before screwing it in to a new plastic/nylon part. A little hobby tip that seems to have been lost.

Now for my question. What's up with ECS's for the rear of a buggy? I see that they are being advertised and I cannot for the life of me see a benefit running them. On the front of a 4WD makes sense. But adding them to the rear seems like it just introduces another point of failure for no real benefit. So is anyone running them?

Now for my question. What's up with ECS's for the rear of a buggy? I see that they are being advertised and I cannot for the life of me see a benefit running them. On the front of a 4WD makes sense. But adding them to the rear seems like it just introduces another point of failure for no real benefit. So is anyone running them?

#1473

Now for my question. What's up with ECS's for the rear of a buggy? I see that they are being advertised and I cannot for the life of me see a benefit running them. On the front of a 4WD makes sense. But adding them to the rear seems like it just introduces another point of failure for no real benefit. So is anyone running them?

#1475

Tech Master

iTrader: (21)

After reading the last 30 pages of posts, I realized why I stopped coming to RCTech. Jeeze people need to chill out. To the dude that broke a ther rear hinge pin holder. Yeah that looks defective. But also could be from over tightening. The screw is steal and the part is aluminum one eighth of a turn past tight will break just about any aluminum part. Did you put it together by hand or with a tool. I see guys with little drill/driver tools putting shit together all the time. It's cool to take stuff apart, but putting things together should be done by hand to avoid stripping or over heating plastic parts. On a side note, plain ivory soap is your friend, rub it on the screw threads before screwing it in to a new plastic/nylon part. A little hobby tip that seems to have been lost.

Now for my question. What's up with ECS's for the rear of a buggy? I see that they are being advertised and I cannot for the life of me see a benefit running them. On the front of a 4WD makes sense. But adding them to the rear seems like it just introduces another point of failure for no real benefit. So is anyone running them?

Now for my question. What's up with ECS's for the rear of a buggy? I see that they are being advertised and I cannot for the life of me see a benefit running them. On the front of a 4WD makes sense. But adding them to the rear seems like it just introduces another point of failure for no real benefit. So is anyone running them?

I don't see the need for ecs shafts either. However my 26 degree brass front bulkhead and 50g lipo wait just arrived today. Will do some testing this weekend.

#1476

#1479

To answer your question, I assembled my entire car with a Mip 2.0 and 1.5 driver. I don't over tighten anything ever. The "cause" of the issue is not tightening the screws enough and they come loose (mine never did) and not using loctite. All of the rr braces have broken on the right side. It's becoming more and more talked about every weekend.

I don't see the need for ecs shafts either. However my 26 degree brass front bulkhead and 50g lipo wait just arrived today. Will do some testing this weekend.

I don't see the need for ecs shafts either. However my 26 degree brass front bulkhead and 50g lipo wait just arrived today. Will do some testing this weekend.

I am glad to know I'm not the only one that thinks the ECS's for the rear are a waste.

#1480

Tech Initiate

#1481

i am also of the thinking.. rear ECS shafts are a waste.. #1, the car dont have near enough droop to affect the angle.. the up travel.. isnt that much either.. so.. i would find a better way to use that money..

on this car.. there doesnt seem to really need alot of upgrades.. my car is still stock.. except the spur gear..

on this car.. there doesnt seem to really need alot of upgrades.. my car is still stock.. except the spur gear..

#1482

my most recent setup on xray website.. i went back to stock build.. and tried different things.. and have it pretty good.. still alot of grip.. but its getting there.. i have ordered the 23* front kickup plate.. im going to try that next..

also.. my ride height is higher than what malin setup is as well..

#1484

Manual for the XB2 Dirt Edition can now be downloaded here:

http://www.teamxray.com/xb2/2016/download/

Bent

http://www.teamxray.com/xb2/2016/download/

Bent

#1485

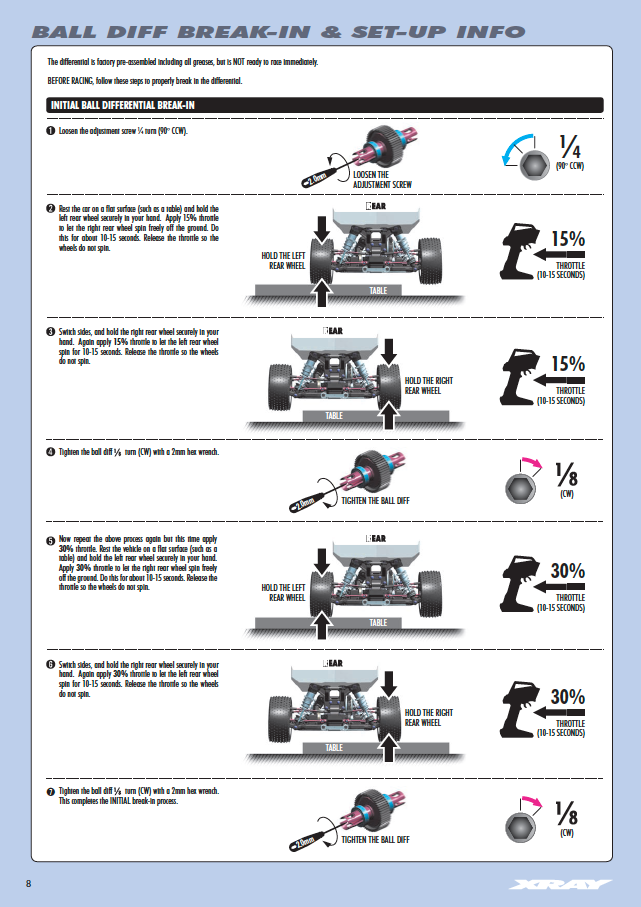

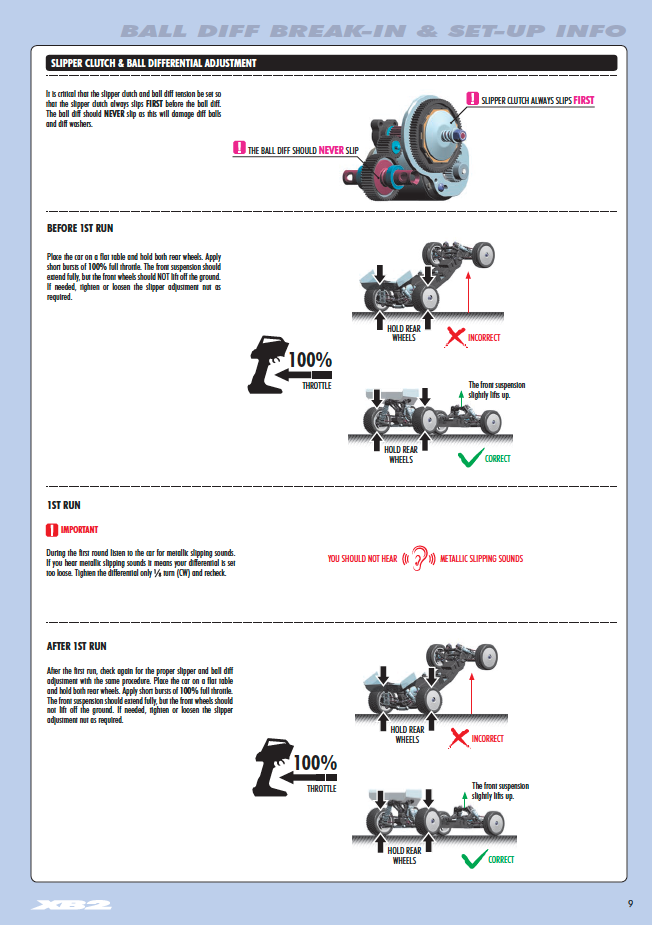

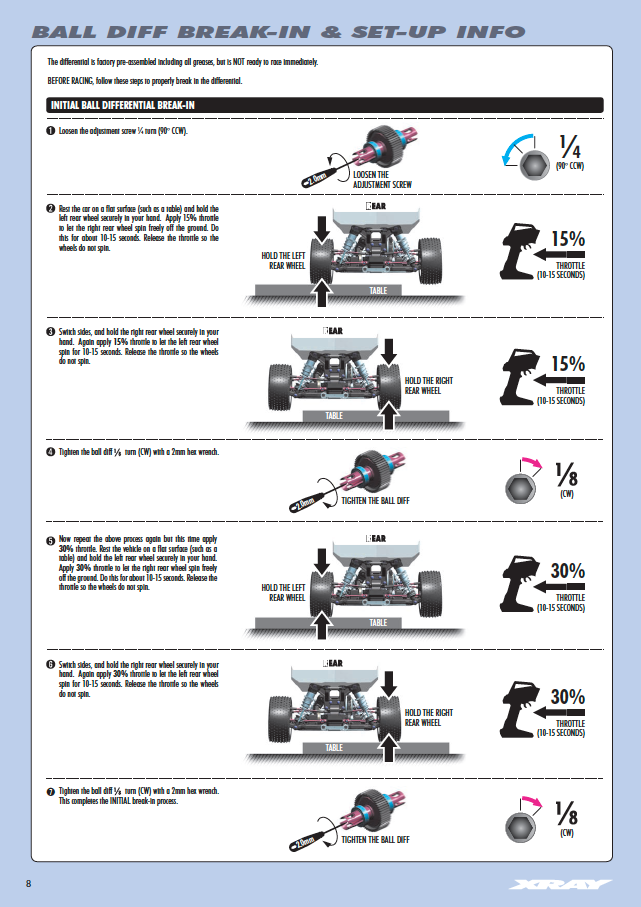

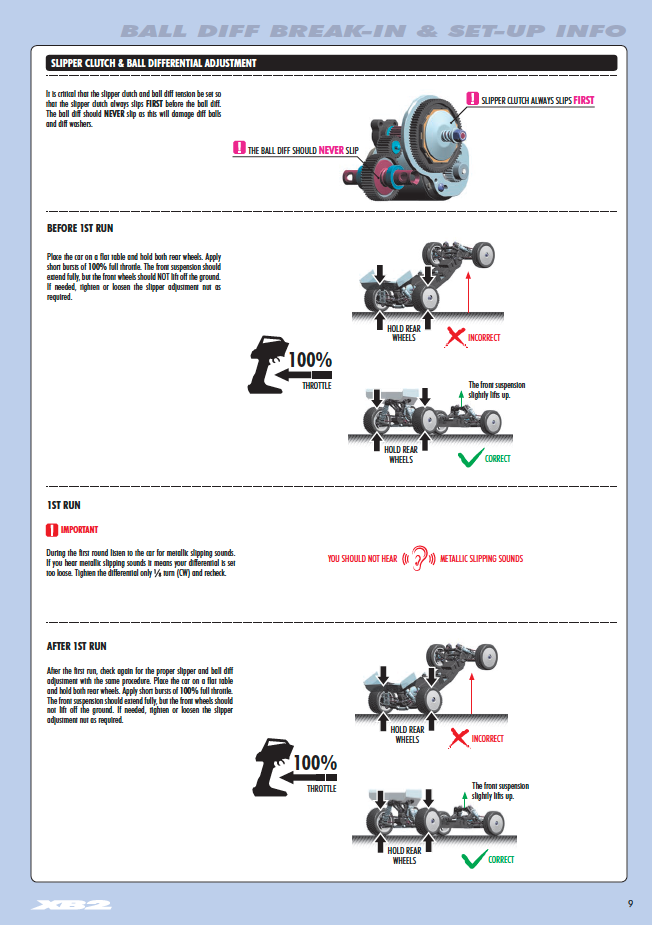

Hopefully people will appreciate this guide to breaking in and adjusting the ball differential and slipper clutch on the XB2

Bent

Bent

333Likes

333Likes