Ball Diff vs Gear Diff

#166

I only have a couple vehicles that actually have center diffs -- a Losi Ten-SCBE, a HPI Bullet with a custom-modified WR8 center diff, and a Traxxas Slash 4x4. Obviously they are all standard bevel-gear diffs since that's the only option that exists. I run all of them with 100k - 200k diff oil, so they only diff-out just enough to let the front wheels rotate faster in corners -- and in the HPI Bullet's case, to prevent crazy wheelies. I also have a custom-modified Tamiya XV-01 that has an underdrive pulley on the front gearbox (where the motor is attached) and a one-way pulley on the rear gearbox, so it functions as part-time-4WD -- the rear wheels only get power when the front wheels start to spin.

Torsen diffs would be a sweet upgrade, but a more easily-achievable goal that I'd like to see would be different ring/pinion ratios, so I could configure the drivetrain to spin the front wheels slightly faster than the rear wheels. This would bias the drivetrain to send more torque to the front wheels, with the center diff reconciling the different drive ratios between the front and rear axles. The only companies I've seen offer different ring/pinion gear ratios are HPI and Axial (because Axial "borrowed" a lot of drivetrain design elements from the HPI Wheely King), but the different drive ratios are +/- 10%, and that's too much of a difference. +/- 2.5% and +/- 5% options for the ring/pinion gears would be great for the purpose I have in mind.

Torsen diffs would be a sweet upgrade, but a more easily-achievable goal that I'd like to see would be different ring/pinion ratios, so I could configure the drivetrain to spin the front wheels slightly faster than the rear wheels. This would bias the drivetrain to send more torque to the front wheels, with the center diff reconciling the different drive ratios between the front and rear axles. The only companies I've seen offer different ring/pinion gear ratios are HPI and Axial (because Axial "borrowed" a lot of drivetrain design elements from the HPI Wheely King), but the different drive ratios are +/- 10%, and that's too much of a difference. +/- 2.5% and +/- 5% options for the ring/pinion gears would be great for the purpose I have in mind.

#167

The newest generation of 1/10 buggies and trucks have slipper clutches instead of center diffs because center diffs don't allow the drivetrain to dissipate excess torque from the monstrous brushless motors people run nowadays, unless some of the wheels are up in the air, and that obviously is not the case when the buggy is landing a jump and all four wheels are mashed against the ground. Because there isn't enough room for a slipper clutch and a center diff on 1/10 chassis, people opt for the slipper clutch, because at least with a slipper clutch they won't destroy their drivetrains when landing jumps with the wheels spinning wildly for in-air attitude control. They accept the inferior handling characteristics caused by not having a center diff because that's the only viable option given the parts available, not because they like it.

#168

The newest generation of 1/10 buggies and trucks have slipper clutches instead of center diffs because center diffs don't allow the drivetrain to dissipate excess torque from the monstrous brushless motors people run nowadays, unless some of the wheels are up in the air, and that obviously is not the case when the buggy is landing a jump and all four wheels are mashed against the ground. Because there isn't enough room for a slipper clutch and a center diff on 1/10 chassis, people opt for the slipper clutch, because at least with a slipper clutch they won't destroy their drivetrains when landing jumps with the wheels spinning wildly for in-air attitude control. They accept the inferior handling characteristics caused by not having a center diff because that's the only viable option given the parts available, not because they like it.

Which produced the fastest lap times for you in back to back testing, a slipper or a center diff?

#169

Companies started putting center diffs on their 1/10th scale 4wd buggies in 2013, well after brushless motors were common. HB, Xray, AE and many others came standard with center diffs, but now the cars come with slippers instead because slippers make the cars easier to drive at the limit. A slipper makes the car much more predictable because the torque is always 50/50.

Which produced the fastest lap times for you in back to back testing, a slipper or a center diff?

Which produced the fastest lap times for you in back to back testing, a slipper or a center diff?

#170

The newest generation of 1/10 buggies and trucks have slipper clutches instead of center diffs because center diffs don't allow the drivetrain to dissipate excess torque from the monstrous brushless motors people run nowadays, unless some of the wheels are up in the air, and that obviously is not the case when the buggy is landing a jump and all four wheels are mashed against the ground. Because there isn't enough room for a slipper clutch and a center diff on 1/10 chassis, people opt for the slipper clutch, because at least with a slipper clutch they won't destroy their drivetrains when landing jumps with the wheels spinning wildly for in-air attitude control. They accept the inferior handling characteristics caused by not having a center diff because that's the only viable option given the parts available, not because they like it.

#171

I'm sure a low profile, slipper-to-centre-diff design must be possible, surely? Slipper clutches aren't really something you can live without on an electric car. All the torque comes in instantly on an electric motor and decreases as the motor builds rpms, so you can't really drive your way around this problem. The slippers make the cars driveable and save your drive-line.

Regards over driving front/rear axles on 4wd, I had a chain drive Kyosho Rocky, where you could overdrive either end of the car by using a 1 tooth larger sprocket. I tried over driving the rear and the front, but settled with 50/50 out of the 3 options. Optimas (that had tvp's!) and Optima mids could do the same. The Le Man stock motor the rocky came with was awesome compared to Tamiya's Black motor sprints and gold motors. I used to run 8.4v through a Futaba ESC which at the time was state of the art compared to the old resistor type mechanical speed controllers. That Rocky was lots of fun and cheap too comparitively. My Pro Cat had one way front drive shafts, so that car was rear drive until the rear started to spin then the front would kick in. Happy times!

Regards over driving front/rear axles on 4wd, I had a chain drive Kyosho Rocky, where you could overdrive either end of the car by using a 1 tooth larger sprocket. I tried over driving the rear and the front, but settled with 50/50 out of the 3 options. Optimas (that had tvp's!) and Optima mids could do the same. The Le Man stock motor the rocky came with was awesome compared to Tamiya's Black motor sprints and gold motors. I used to run 8.4v through a Futaba ESC which at the time was state of the art compared to the old resistor type mechanical speed controllers. That Rocky was lots of fun and cheap too comparitively. My Pro Cat had one way front drive shafts, so that car was rear drive until the rear started to spin then the front would kick in. Happy times!

#172

Slippers are not a necessity either.

Slipper eliminators are very common now a days. You just have to be a good driver to not break stuff when running no slipper. Your throttle finger is the traction control.

Slipper eliminators are very common now a days. You just have to be a good driver to not break stuff when running no slipper. Your throttle finger is the traction control.

#173

I only have a couple vehicles that actually have center diffs -- a Losi Ten-SCBE, a HPI Bullet with a custom-modified WR8 center diff, and a Traxxas Slash 4x4. Obviously they are all standard bevel-gear diffs since that's the only option that exists. I run all of them with 100k - 200k diff oil, so they only diff-out just enough to let the front wheels rotate faster in corners -- and in the HPI Bullet's case, to prevent crazy wheelies. I also have a custom-modified Tamiya XV-01 that has an underdrive pulley on the front gearbox (where the motor is attached) and a one-way pulley on the rear gearbox, so it functions as part-time-4WD -- the rear wheels only get power when the front wheels start to spin.

Torsen diffs would be a sweet upgrade, but a more easily-achievable goal that I'd like to see would be different ring/pinion ratios, so I could configure the drivetrain to spin the front wheels slightly faster than the rear wheels. This would bias the drivetrain to send more torque to the front wheels, with the center diff reconciling the different drive ratios between the front and rear axles. The only companies I've seen offer different ring/pinion gear ratios are HPI and Axial (because Axial "borrowed" a lot of drivetrain design elements from the HPI Wheely King), but the different drive ratios are +/- 10%, and that's too much of a difference. +/- 2.5% and +/- 5% options for the ring/pinion gears would be great for the purpose I have in mind.

Torsen diffs would be a sweet upgrade, but a more easily-achievable goal that I'd like to see would be different ring/pinion ratios, so I could configure the drivetrain to spin the front wheels slightly faster than the rear wheels. This would bias the drivetrain to send more torque to the front wheels, with the center diff reconciling the different drive ratios between the front and rear axles. The only companies I've seen offer different ring/pinion gear ratios are HPI and Axial (because Axial "borrowed" a lot of drivetrain design elements from the HPI Wheely King), but the different drive ratios are +/- 10%, and that's too much of a difference. +/- 2.5% and +/- 5% options for the ring/pinion gears would be great for the purpose I have in mind.

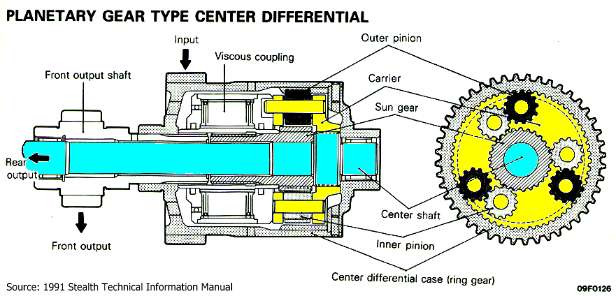

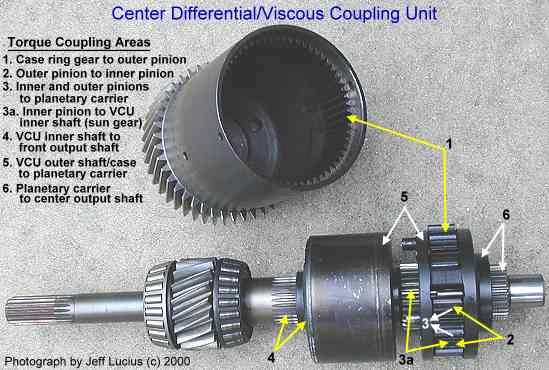

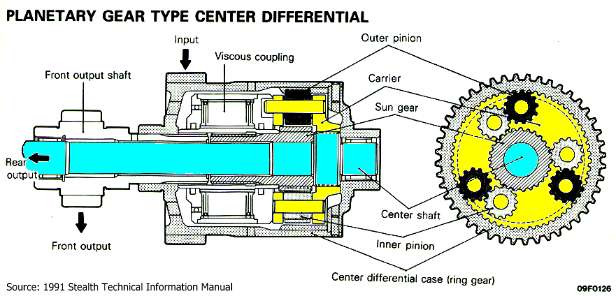

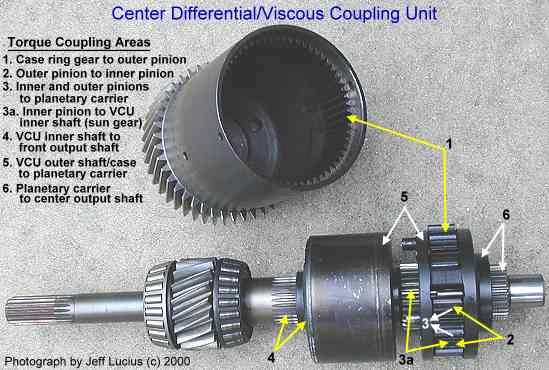

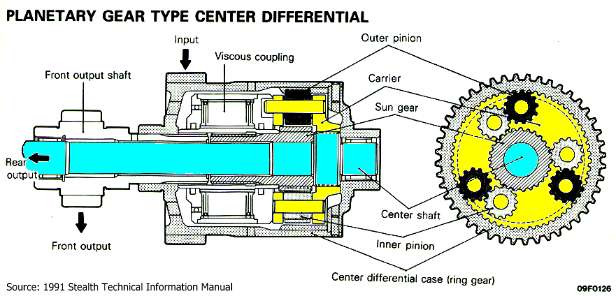

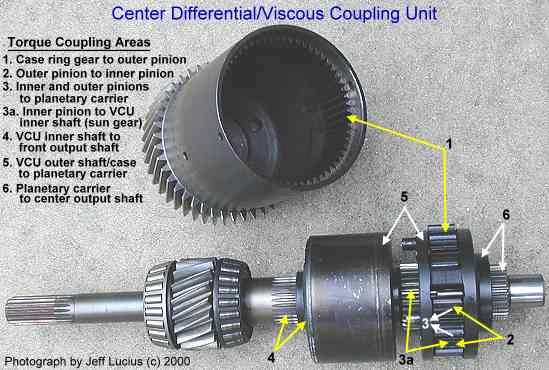

However, I think what you want is a constant torque split, which is better served with what is known as an epicyclic center gear differential. Used in full sized automobiles in the 80s and 90s, it is deceptively simple looking but fearsomely complex in principle!

Behold the center diff from a Mitsubishi 3000GT VR-4:

Front to rear torque split is controlled by the number of gear teeth on the respective shafts.

Another variation on the theme.

#174

The newest generation of 1/10 buggies and trucks have slipper clutches instead of center diffs because center diffs don't allow the drivetrain to dissipate excess torque from the monstrous brushless motors people run nowadays, unless some of the wheels are up in the air, and that obviously is not the case when the buggy is landing a jump and all four wheels are mashed against the ground. Because there isn't enough room for a slipper clutch and a center diff on 1/10 chassis, people opt for the slipper clutch, because at least with a slipper clutch they won't destroy their drivetrains when landing jumps with the wheels spinning wildly for in-air attitude control. They accept the inferior handling characteristics caused by not having a center diff because that's the only viable option given the parts available, not because they like it.

#175

#176

Lighter weight, more direct feel of the throttle, and less points of failure. Also one less adjustment to get wrong.

I only use the slipper to protect ball diffs. Sometimes the quickest way over a jump is to send it to flat and keep the car spooled up on landing to load the suspension. I always set my slipper tight enough to pull wheelies and use my throttle finger to control traction and wheelies.

I only use the slipper to protect ball diffs. Sometimes the quickest way over a jump is to send it to flat and keep the car spooled up on landing to load the suspension. I always set my slipper tight enough to pull wheelies and use my throttle finger to control traction and wheelies.

#177

Companies started putting center diffs on their 1/10th scale 4wd buggies in 2013, well after brushless motors were common. HB, Xray, AE and many others came standard with center diffs, but now the cars come with slippers instead because slippers make the cars easier to drive at the limit. A slipper makes the car much more predictable because the torque is always 50/50.

Which produced the fastest lap times for you in back to back testing, a slipper or a center diff?

Which produced the fastest lap times for you in back to back testing, a slipper or a center diff?

Believe what you want. You won't convince anyone and they won't convince you. That much is obvious at this point.

Last edited by fyrstormer; 05-26-2019 at 01:52 PM.

#178

I believe the more modern buggies have the space to run some kind of combination slipper and differential. The crown gear on the diff can be eliminated and replaced by a backing plate which also serves as the slipper plate. Then slipper pad, spur, slipper pad, slipper plate, spring, thrust bearing and nut. One of the outdrives is gonna have to be super long and threaded along part of its length for the nut. And the spur will have to ride on the outdrive. Possibly a third diff carrier and bearing may be needed.

#179

Underdrive options tend to be found in buggies only, even then in 1/8th nitro offroad, or old TRF buggies. I believe JQ had an underdrive option, and a few others I can't remember off the top off my head. Perhaps you could experiment there.....

However, I think what you want is a constant torque split, which is better served with what is known as an epicyclic center gear differential. Used in full sized automobiles in the 80s and 90s, it is deceptively simple looking but fearsomely complex in principle!

Behold the center diff from a Mitsubishi 3000GT VR-4:

Front to rear torque split is controlled by the number of gear teeth on the respective shafts.

Another variation on the theme.

However, I think what you want is a constant torque split, which is better served with what is known as an epicyclic center gear differential. Used in full sized automobiles in the 80s and 90s, it is deceptively simple looking but fearsomely complex in principle!

Behold the center diff from a Mitsubishi 3000GT VR-4:

Front to rear torque split is controlled by the number of gear teeth on the respective shafts.

Another variation on the theme.

#180

RC Monster made a "slipperential".

88Likes

88Likes