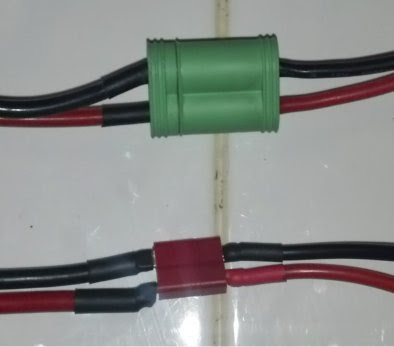

New Castle Connectors

#16

#18

#19

I bought four packs of them and have been soldering them up to everything. So far they're definitely quality.. *very* tight fitting. TBH i don't plug them in all the way so i have a chance of disconnecting them again without tools lol.

I've been using them with 12awg which is on my batteries and most of my charge leads/escs. It's a small gauge to use with them but it works fine. They come with a small strip of braided copper and no mention of it in the instructions. I'm thinking maybe it's meant to be used inside to help out with conductivity on smaller AWG wire?

I've been using them with 12awg which is on my batteries and most of my charge leads/escs. It's a small gauge to use with them but it works fine. They come with a small strip of braided copper and no mention of it in the instructions. I'm thinking maybe it's meant to be used inside to help out with conductivity on smaller AWG wire?

The braided copper is solder wick, it used to clean solder on outside of pin if solder spills outside of cup, since if you don't clean it off it will be useless.

Erm... they're quite easy once you get the hang of it. The battery side is the female bullet which is big enough to just stand up on a sturdy surface. You can well up some solder in it and push the wire right down and hold it there. Don't even need anything special to hold it.

The male side needs something to hold it. The instructions recommend drilling a hole in a piece of wood and using that. Again after that it's really easy to fill it up with some solder and put the wire in.

Overall i would say definitely easier than deans. You don't even need heat shrink. Traxxas i think would be easier if i could understand exactly how to get them right.

I think traxxas better IMHO. You don't need heat shrink if everything is the right length. You don't need to slip the plastic over first so you can't forget or put it on wrong. They're easier to connect/disconnect.

I think these are for when you really really need 200a continuous and don't have as many options.

The male side needs something to hold it. The instructions recommend drilling a hole in a piece of wood and using that. Again after that it's really easy to fill it up with some solder and put the wire in.

Overall i would say definitely easier than deans. You don't even need heat shrink. Traxxas i think would be easier if i could understand exactly how to get them right.

I think traxxas better IMHO. You don't need heat shrink if everything is the right length. You don't need to slip the plastic over first so you can't forget or put it on wrong. They're easier to connect/disconnect.

I think these are for when you really really need 200a continuous and don't have as many options.

#20

Tech Master

iTrader: (39)

I've been having issues with amp loads frying connectors. I've ruined a set of deans, melted a set of trx connectors, and unsoldered a set of 5.5 bullets.

I soldered up a set of castle polarized connectors, and wowza. I've found my new connector. 6.5 bullets, rated at 200a continuous, they were slightly warm to the touch after running. They snap together with vengeance however. I am hoping they free up a little bit after some use

I soldered up a set of castle polarized connectors, and wowza. I've found my new connector. 6.5 bullets, rated at 200a continuous, they were slightly warm to the touch after running. They snap together with vengeance however. I am hoping they free up a little bit after some use

#26

I use em on all my 4 cells and bigger. They are amazing! But now back ordered. Puts me in a real bind! Now what? And just a pointer on the plugs. They won't let up after use. Lightly close the male sides with some needle nose and they still hold great but don't require a winch to pull em apart! Lol

#27

Tech Fanatic

iTrader: (53)

Erm... they're quite easy once you get the hang of it. The battery side is the female bullet which is big enough to just stand up on a sturdy surface. You can well up some solder in it and push the wire right down and hold it there. Don't even need anything special to hold it.

The male side needs something to hold it. The instructions recommend drilling a hole in a piece of wood and using that. Again after that it's really easy to fill it up with some solder and put the wire in.

Overall i would say definitely easier than deans. You don't even need heat shrink. Traxxas i think would be easier if i could understand exactly how to get them right.

I think traxxas better IMHO. You don't need heat shrink if everything is the right length. You don't need to slip the plastic over first so you can't forget or put it on wrong. They're easier to connect/disconnect.

I think these are for when you really really need 200a continuous and don't have as many options.

The male side needs something to hold it. The instructions recommend drilling a hole in a piece of wood and using that. Again after that it's really easy to fill it up with some solder and put the wire in.

Overall i would say definitely easier than deans. You don't even need heat shrink. Traxxas i think would be easier if i could understand exactly how to get them right.

I think traxxas better IMHO. You don't need heat shrink if everything is the right length. You don't need to slip the plastic over first so you can't forget or put it on wrong. They're easier to connect/disconnect.

I think these are for when you really really need 200a continuous and don't have as many options.

#30

I set mine on a vise & using a bolt(female)/4way wrench(male) tap them in, the female ends will go in too far if hit too hard.