Bending driveshafts back?

#1

Hello,

I have a little bend in a driveshaft of my Muggy.

It is not enough to replace it, but it is enough to anoy me

Is there an easy way to straighten it back a bit?

I know there will always be a weakspot, but it is just a little bent.

Does anyone know a adress where you can buy a couple of LST2/Muggy center driveshafts, for not that much money?

I have a couple of old ones, with worn down pins, I have the Mugen replacement pins for them, but I can't get myself over to spend 60 dollar on the tool when I only use it a couple of times.

Any one any DIY tips?

I saw a motorcycle chain tool for not that much, but shipping kills it for me, being in The Netherlands.

Thanks in advance!

Ruud

I have a little bend in a driveshaft of my Muggy.

It is not enough to replace it, but it is enough to anoy me

Is there an easy way to straighten it back a bit?

I know there will always be a weakspot, but it is just a little bent.

Does anyone know a adress where you can buy a couple of LST2/Muggy center driveshafts, for not that much money?

I have a couple of old ones, with worn down pins, I have the Mugen replacement pins for them, but I can't get myself over to spend 60 dollar on the tool when I only use it a couple of times.

Any one any DIY tips?

I saw a motorcycle chain tool for not that much, but shipping kills it for me, being in The Netherlands.

Thanks in advance!

Ruud

#2

I just picked these up last week: http://www.dollarhobbyz.com/products...e-shafts-boots

Not sure if the XXL shafts are longer than the LST2. But not bad for $33 for 2.

Not sure if the XXL shafts are longer than the LST2. But not bad for $33 for 2.

#3

Tech Fanatic

Just lay the driveshaft on a steel vice or something similar. Rotate it so the bent part sticks up. Take a hammer and tap it till it's flat. Then you can rotate and tap at the same time until it's perfect. I do this to my out drives on my RC8T when they bend. It seems like whenever I start jumping it and getting big air all it takes is one bad landing to bend a shaft. It's never been enough to notice while driving though.

Last edited by Micah78; 01-21-2016 at 01:09 PM.

#4

Just lay the driveshaft on a steel vice or something similar. Rotate it so the bent part sticks up. Take a hammer and tap it till it's flat. Then you can rotate and tap at the same time until it's perfect. I do this to my out drives on my RC8T when they bend. It seems like whenever I start jumping it and getting big air all it takes is one bad landing to bend a shaft. It's never been enough to notice while driving through.

#5

#6

It does, but unless the shaft is so bent it's a hard turn or is also twisted you'll never notice the decrease in strength. If anything it'll bend easier (at the previous bend) in an impact and if it does bend it back until it breaks.

I use the same method on shock shafts and haven't noticed any decrease in strength. And if you go slow with light taps you won't deform the shaft (at least not as much) decreasing the chance for leaks.

I use the same method on shock shafts and haven't noticed any decrease in strength. And if you go slow with light taps you won't deform the shaft (at least not as much) decreasing the chance for leaks.

#7

Tech Fanatic

It does, but unless the shaft is so bent it's a hard turn or is also twisted you'll never notice the decrease in strength. If anything it'll bend easier (at the previous bend) in an impact and if it does bend it back until it breaks.

I use the same method on shock shafts and haven't noticed any decrease in strength. And if you go slow with light taps you won't deform the shaft (at least not as much) decreasing the chance for leaks.

I use the same method on shock shafts and haven't noticed any decrease in strength. And if you go slow with light taps you won't deform the shaft (at least not as much) decreasing the chance for leaks.

#8

I think if driveshaft didn't bend, it's the outdrive cup of the diffs that would break !

you can continue to drive with a bent driveshaft, but not with a broken diff cup !

you can continue to drive with a bent driveshaft, but not with a broken diff cup !

#10

You are obvious not readin the right threads :P

For my MP9e:

-CVD's out!!

-Some degreses or WD40 alike!

-4mm socket and a hammer!

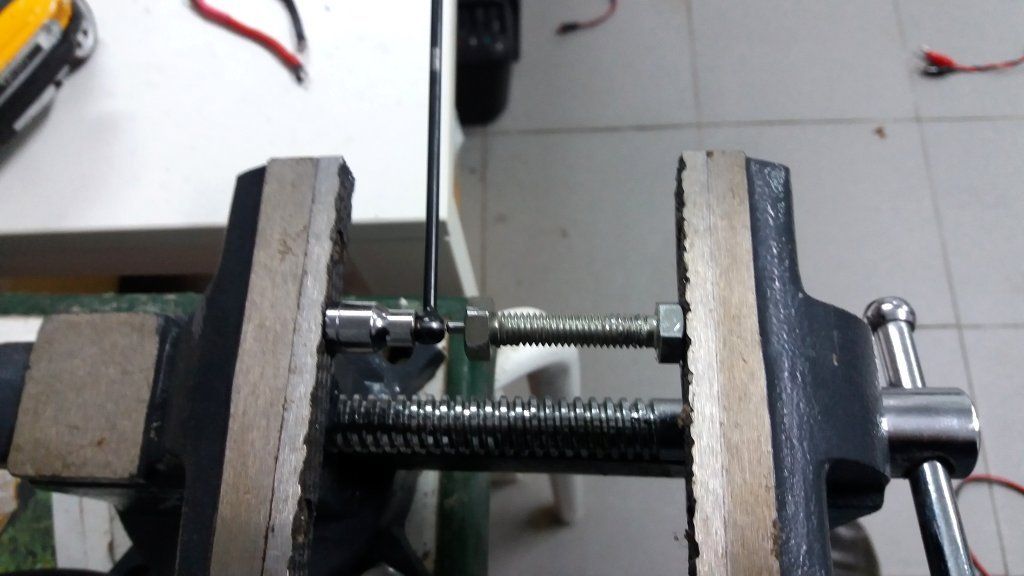

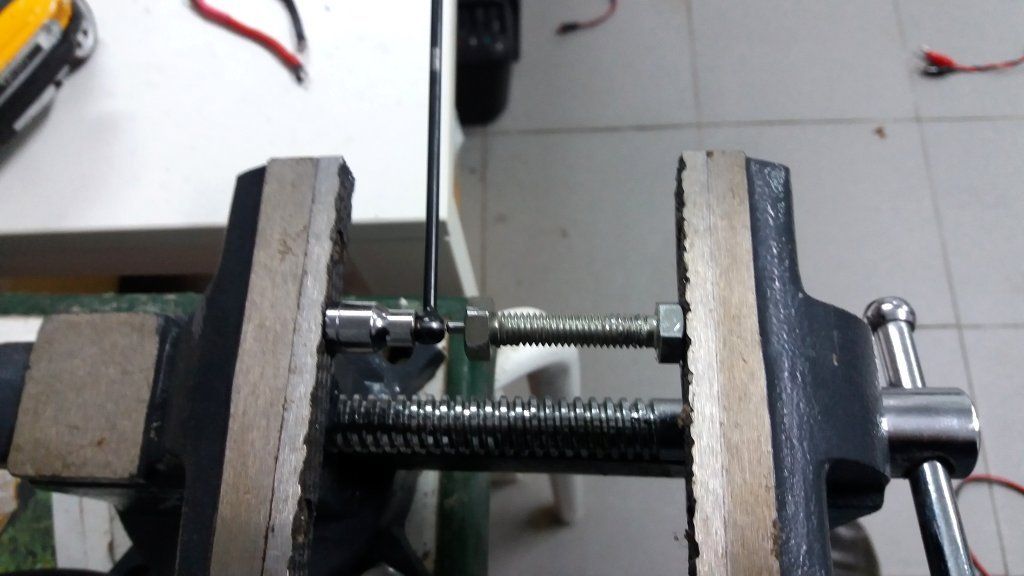

-Drill a 3mm hole on a heavy screw to fit the pin for not falling off the vice!

-New in, old out!!

-Don't need the screw anymore!

-New pin on the axle!

Now for the front of the MP9e...

-Some minutes on WD40 alike....

~

-Socket 4mm and an hammer...

-See?

Done!

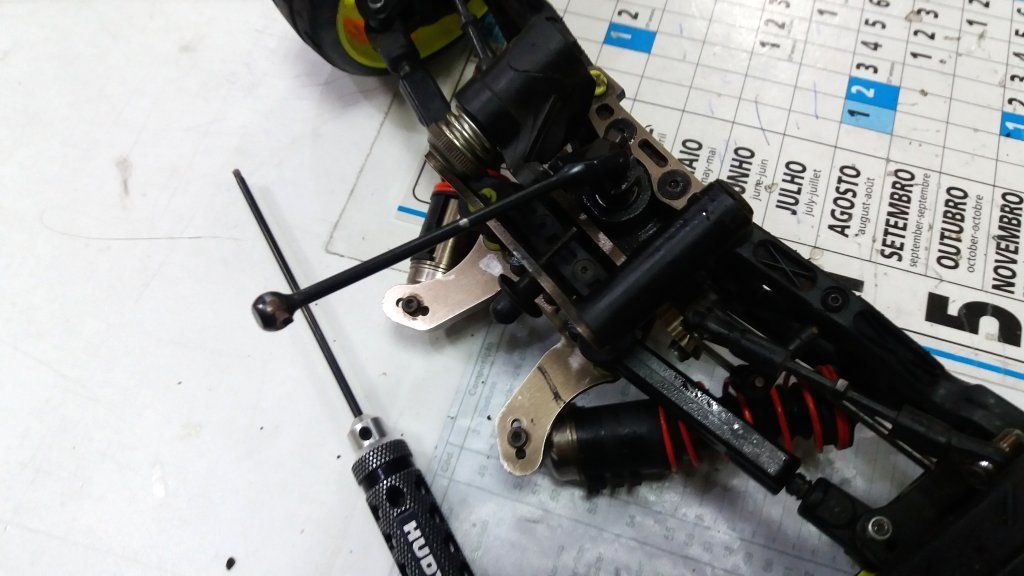

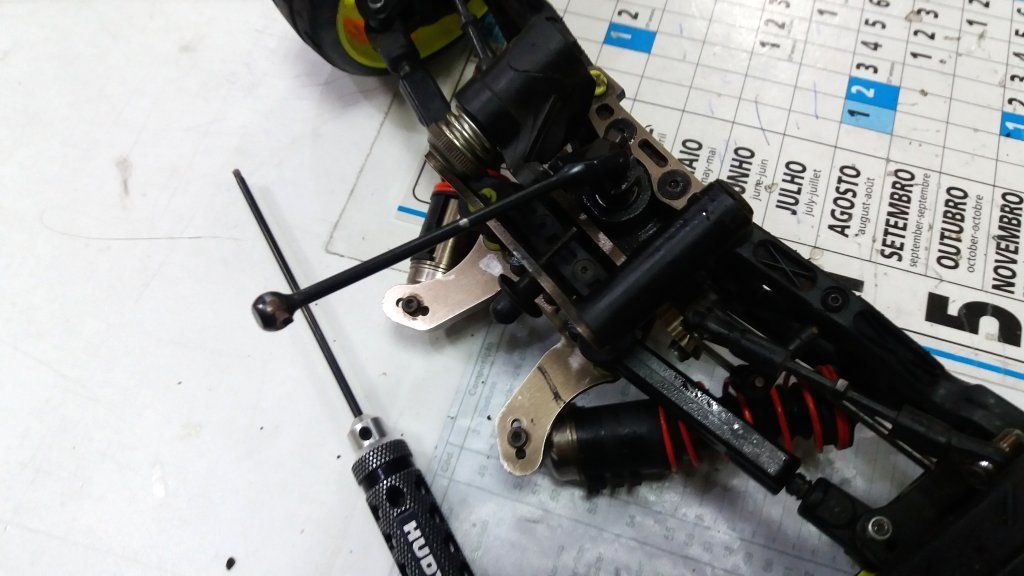

NOW for my Xray808e...

Tought job!

-First thing. Remove the central shafts!

-Go for the rear now! :P

-It must be an heavy hammer. A normal hammer won't do nothing... just tickles! Used an 4mm socket to hold the shaft on hammering!

-The easy part is done.

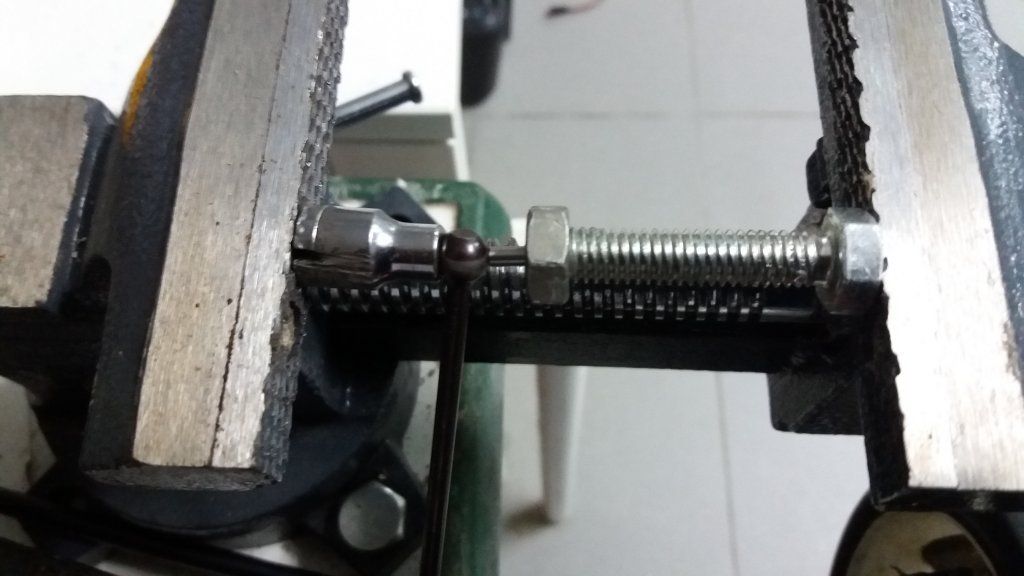

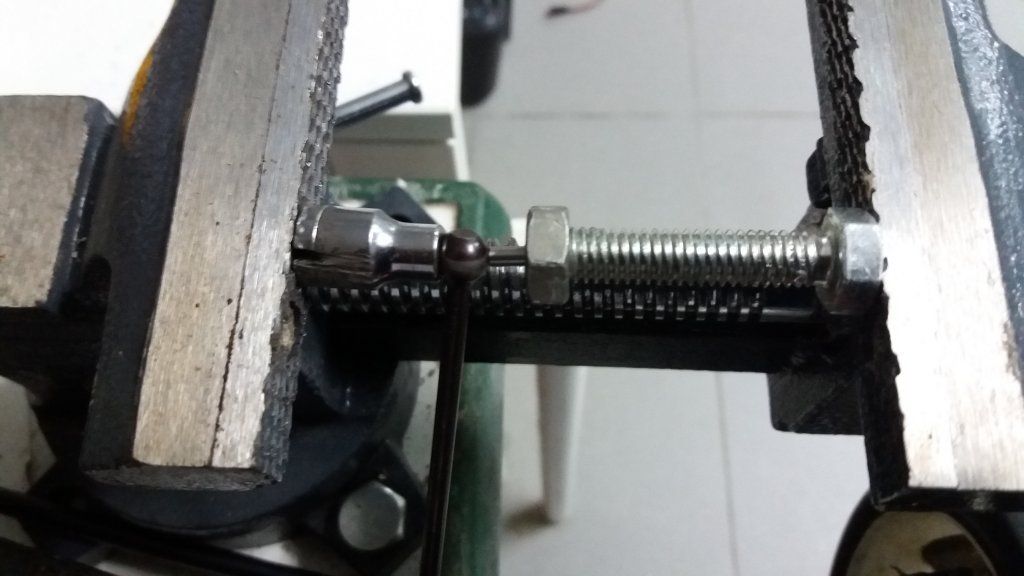

-That screw with a pin, i used a 3mm steel drill to make the hole for the pin! Reason is to hold it on the vise.

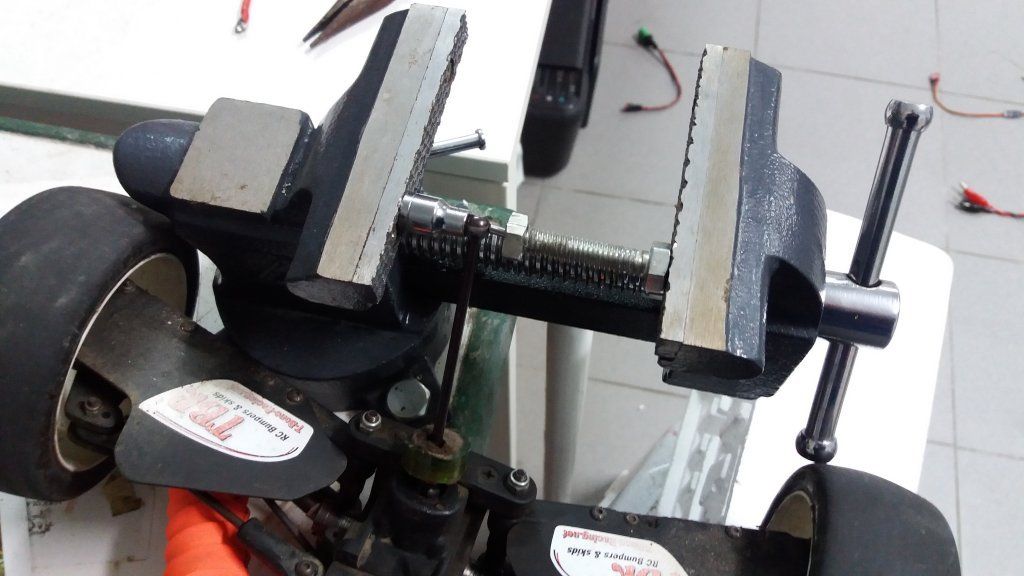

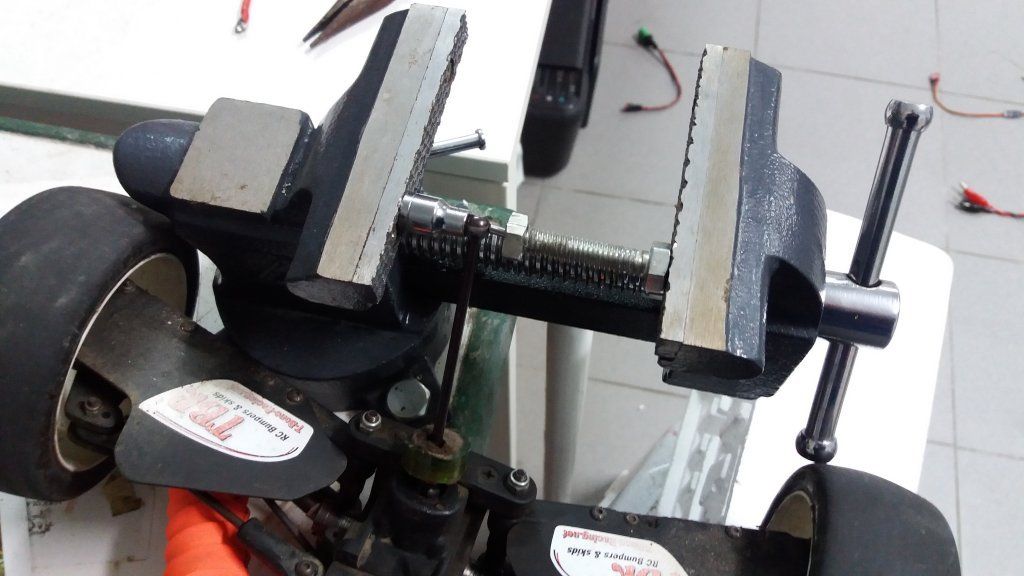

-All aligned and brute force on the vice...

-Since the new pin starts and grabs the hole, i prefer to remove them from the vice and hammer on the sock!

-Did the same to the front!

-Done!

NOW for My Mugen MBX6T

-New pin on the front CVD.

New pin on the rear cvd to!

-Done! New Pins on the center CVD's.

Hope that helps...

Also see these videos:

-Bare hands....

-With tools...

For my MP9e:

-CVD's out!!

-Some degreses or WD40 alike!

-4mm socket and a hammer!

-Drill a 3mm hole on a heavy screw to fit the pin for not falling off the vice!

-New in, old out!!

-Don't need the screw anymore!

-New pin on the axle!

Now for the front of the MP9e...

-Some minutes on WD40 alike....

~

-Socket 4mm and an hammer...

-See?

Done!

NOW for my Xray808e...

Tought job!

-First thing. Remove the central shafts!

-Go for the rear now! :P

-It must be an heavy hammer. A normal hammer won't do nothing... just tickles! Used an 4mm socket to hold the shaft on hammering!

-The easy part is done.

-That screw with a pin, i used a 3mm steel drill to make the hole for the pin! Reason is to hold it on the vise.

-All aligned and brute force on the vice...

-Since the new pin starts and grabs the hole, i prefer to remove them from the vice and hammer on the sock!

-Did the same to the front!

-Done!

NOW for My Mugen MBX6T

-New pin on the front CVD.

New pin on the rear cvd to!

-Done! New Pins on the center CVD's.

Hope that helps...

Also see these videos:

| + YouTube Video | |

| + YouTube Video | |

-Bare hands....

-With tools...

| + YouTube Video | |

| + YouTube Video | |

| + YouTube Video | |

#11

Thanks for the tips guys!

The XXL axles are longer, I could try one, but I am afraid it will break a cup when the chassis flexes, if it fits.

So the advice is, if the bent is not to bad, don't remove it, so you don't make that spot weaker?

It is just I slight bent, so not in one specific place?

That is what I was afraid for to.

Thanks for the awesome write up for the pins!

I will have to try that out!

When you are mounting the pins in, do you use Loctite?

I saw the Mugen tool indeed, but 50 bucks for the couple of times I use is to much for me unfortunaly.

Just to be sure, you hammer it out half way, and then put a new pin in the heavy screw, line it up, and then press it in?

When I am home, I will watch the videos!

Thanks guys!

The XXL axles are longer, I could try one, but I am afraid it will break a cup when the chassis flexes, if it fits.

So the advice is, if the bent is not to bad, don't remove it, so you don't make that spot weaker?

It is just I slight bent, so not in one specific place?

That is what I was afraid for to.

Thanks for the awesome write up for the pins!

I will have to try that out!

When you are mounting the pins in, do you use Loctite?

I saw the Mugen tool indeed, but 50 bucks for the couple of times I use is to much for me unfortunaly.

Just to be sure, you hammer it out half way, and then put a new pin in the heavy screw, line it up, and then press it in?

When I am home, I will watch the videos!

Thanks guys!