Xray t4'15

#901

Many times drivers use anti-dive on front arms. How or where do they measure down-stop in this situation?

#902

#903

My son drives modified with a T4'15. He is OK, but does not drive flawlessly like the "pros".

We like to try the alu chassis, as many seems to try them.

At the recent DHI Cup, most of the top drivers either tested the alu chassis or used one.

My question: how much beating can such an alu chassis take before it bends and becomes useless?

Or is alu chassis just the latest "new thing", forgotten tomorrow?

We like to try the alu chassis, as many seems to try them.

At the recent DHI Cup, most of the top drivers either tested the alu chassis or used one.

My question: how much beating can such an alu chassis take before it bends and becomes useless?

Or is alu chassis just the latest "new thing", forgotten tomorrow?

#904

Anyone else running roche racing driveshafts? For the second race now, while leading tonight, it was lost because a small tap, not enough to do damage or even dirty the body, and the nut and axle and snapped off, sending the wheel flying and ending my race prematurely. What's with the crap material used in these?! And where can I get Spare parts for the Roche axles?

Maybe they've changed the materials. How long have you had them? Are they the latest ones with the holes drilled in the cage?

#905

#906

I'm unsure what ya mean holes drilled in the cage? For the round clips to hold the pin in?

These axles are not even 4 months old.

These axles are not even 4 months old.

#907

My son drives modified with a T4'15. He is OK, but does not drive flawlessly like the "pros".

We like to try the alu chassis, as many seems to try them.

At the recent DHI Cup, most of the top drivers either tested the alu chassis or used one.

My question: how much beating can such an alu chassis take before it bends and becomes useless?

Or is alu chassis just the latest "new thing", forgotten tomorrow?

We like to try the alu chassis, as many seems to try them.

At the recent DHI Cup, most of the top drivers either tested the alu chassis or used one.

My question: how much beating can such an alu chassis take before it bends and becomes useless?

Or is alu chassis just the latest "new thing", forgotten tomorrow?

#908

Anyone else running roche racing driveshafts? For the second race now, while leading tonight, it was lost because a small tap, not enough to do damage or even dirty the body, and the nut and axle and snapped off, sending the wheel flying and ending my race prematurely. What's with the crap material used in these?! And where can I get Spare parts for the Roche axles?

Could easily have been another much harder crash that broke it, and it was just holding together. The little tap finished it off. I've had this happen a lot in off-road. Downside a jump perfectly, and an arm breaks. Wasn't the landing that broke it, it was something earlier. It just happened to give up at that moment.

#909

#910

That's the trouble you land in when trying to copy setups. I am using a square to measure and that is my reference, I don't use a downstop gauge. You'll need to work out your own reference.

#911

double post

#912

I've been using Roche DCJ's for about 14 months and have only broken one axle shaft, specifically the ball end on the axle shaft. So far they have been fantastic. I haven't found a "Go to" store in the U.S. that stocks them so I had to order directly from Roche.

#913

Tech Champion

iTrader: (32)

Join Date: Aug 2001

Location: In a land of mini-mighty mental giants

Posts: 8,854

Trader Rating: 32 (100%+)

Looks like Spec-R has a new motor mount/layshaft/ARS mount for the '15. Might be a nice option for lower grip or more even chassis flex.

http://www.spec-r.com/default/index....roducts_id=739

http://www.spec-r.com/default/index....roducts_id=739

#915

Tech Regular

iTrader: (3)

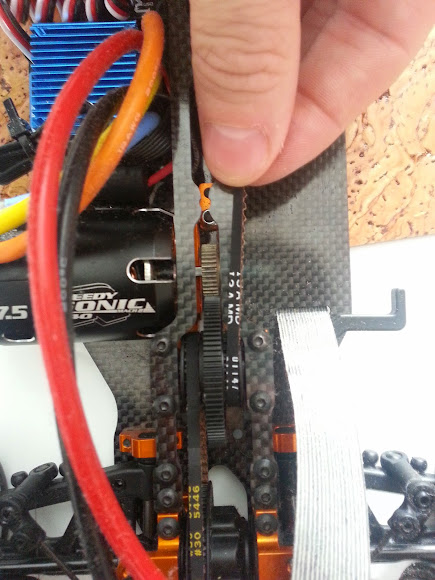

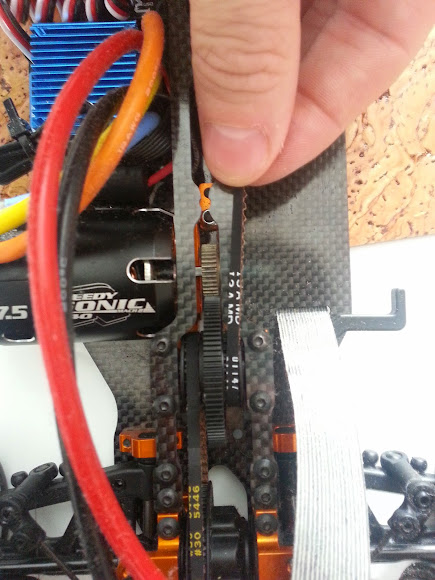

The manual emphasizes in two separate diagrams that the narrow side of the offset spur gear should go on the side with the spacer, which should go on the side of the short belt (motor side). See this album, for the diagrams in question, and photos of how I've built it:

https://plus.google.com/photos/+Pier...37555285064881

But check out how freakishly close that comes to the top deck (and how much of the motor shaft):

I'm pretty sure I should relax, I'm just not sure if I should relax about a) how close this comes to the top deck, or b) following the manual closely.

https://plus.google.com/photos/+Pier...37555285064881

But check out how freakishly close that comes to the top deck (and how much of the motor shaft):

I'm pretty sure I should relax, I'm just not sure if I should relax about a) how close this comes to the top deck, or b) following the manual closely.

4Likes

4Likes