Xray T1FK05

#1336

Originally posted by jdwca

As far as building the shocks, simply follow the instructions. I've built these shocks for a number of different kits. (Ask Tag, he's always getting me to build shocks for his cars.) They're actually really easy to build and super smooth. I never have air bubbles and generally I rebuild my shocks once a month.

As far as building the shocks, simply follow the instructions. I've built these shocks for a number of different kits. (Ask Tag, he's always getting me to build shocks for his cars.) They're actually really easy to build and super smooth. I never have air bubbles and generally I rebuild my shocks once a month.

Filling and bleeding the shocks wasn't too bad at all.

#1337

Hey, Shane. What a pleasant post dude...just kinda checking in to chat about building cars...no quelling an angry mob or breaking up a fight about ROAR...just a nice, simple post. Right on.

Anyway, yeah, I hate the rod ends too. My secret will be the tap idea. I just ordered myself one.

The only way to do it effectively without the tap is to take a pair of small wire cutters, like the manual suggests, put them at the very top of the threads, ones you won't be using, and then use an allen driver in the rod end and just crank till you have a millimeter to spare.

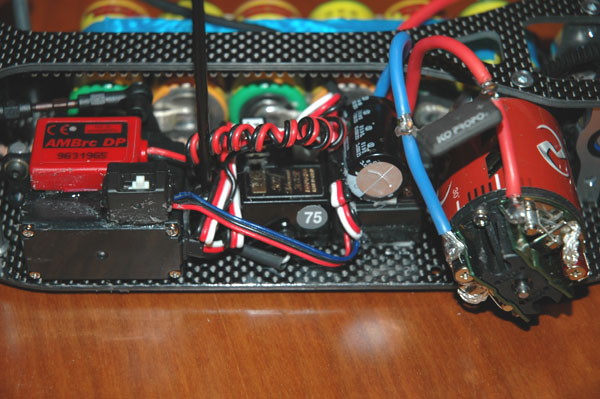

Weird...everything else on the kit is so mint, but those ball ends are nasty. Actually, to be honest, the dorky antenna mount that takes up crucial room by the receiver is not such a hot idea. I use a nice thin aluminum one that looks trick and takes up very little room.

Anyway, yeah, I hate the rod ends too. My secret will be the tap idea. I just ordered myself one.

The only way to do it effectively without the tap is to take a pair of small wire cutters, like the manual suggests, put them at the very top of the threads, ones you won't be using, and then use an allen driver in the rod end and just crank till you have a millimeter to spare.

Weird...everything else on the kit is so mint, but those ball ends are nasty. Actually, to be honest, the dorky antenna mount that takes up crucial room by the receiver is not such a hot idea. I use a nice thin aluminum one that looks trick and takes up very little room.

#1338

Originally posted by futureal

How, pray tell, did you get the rod ends onto the shock shafts? I had more trouble with those than with any other shock on the market, and I've built them all, many times over.

Filling and bleeding the shocks wasn't too bad at all.

How, pray tell, did you get the rod ends onto the shock shafts? I had more trouble with those than with any other shock on the market, and I've built them all, many times over.

Filling and bleeding the shocks wasn't too bad at all.

Use one of the kits 2mm button head screws to pre thread the shock end, then ensure you leave avout 2mm of thread showing above the shock end, they fit so tight there is no need to screw them all the way, and if you do you risk cracking the shock end.

#1339

Yea, to both of you. And no angry mob here, thankfully. haha

I did pre-thread them but man, it was a pain. I got one far in on the rod but then had to go back and back it off to make the shocks equal lengths because I couldn't get the others to go on that far. What a pain!

Other than that, everything else on the kits is flawless.

I did pre-thread them but man, it was a pain. I got one far in on the rod but then had to go back and back it off to make the shocks equal lengths because I couldn't get the others to go on that far. What a pain!

Other than that, everything else on the kits is flawless.

#1340

Tech Master

Try www.teamtamale.com

They have a tool that clamps on to the shock shaft. Actually all it is a pair of vice grips with pads that don't scar up the shaft. Haven't tried one yet but looks promising.

They have a tool that clamps on to the shock shaft. Actually all it is a pair of vice grips with pads that don't scar up the shaft. Haven't tried one yet but looks promising.

#1342

Originally posted by Besercoe

Use one of the kits 2mm button head screws to pre thread the shock end, then ensure you leave avout 2mm of thread showing above the shock end, they fit so tight there is no need to screw them all the way, and if you do you risk cracking the shock end.

Use one of the kits 2mm button head screws to pre thread the shock end, then ensure you leave avout 2mm of thread showing above the shock end, they fit so tight there is no need to screw them all the way, and if you do you risk cracking the shock end.

Although, the manuals tells you to leave a millimeter of space. I don't think you can thread the shock end all the way, without cracking / ripping it.

Although, the manuals tells you to leave a millimeter of space. I don't think you can thread the shock end all the way, without cracking / ripping it.

#1343

Originally posted by futureal

Yea, to both of you. And no angry mob here, thankfully. haha

I did pre-thread them but man, it was a pain. I got one far in on the rod but then had to go back and back it off to make the shocks equal lengths because I couldn't get the others to go on that far. What a pain!

Other than that, everything else on the kits is flawless.

Yea, to both of you. And no angry mob here, thankfully. haha

I did pre-thread them but man, it was a pain. I got one far in on the rod but then had to go back and back it off to make the shocks equal lengths because I couldn't get the others to go on that far. What a pain!

Other than that, everything else on the kits is flawless.

If, you use the nose of standard pliers to hold the shock end by the hole, you'll be able to thread them on, easily. Save your fingers, dude.

#1345

Dude, I love the Tamale aluminum c-hubs. I used 'em on my car at the Nats and they were dialed. I had the same pair of 6* hubs on since the January Jam at Madness and not a scratch on 'em.

Having said that, I'm a little skeptical about the shock shaft thing-a-ma-jig. I try to stay far away from putting anything on the non-threaded portion while building my shocks. Better bet is to again use the top 1mm of threads and hold it tight with wire cutters. You should be leaving a millimeter of thread when putting the ends on anyway.

BTW, anyone tried that tool yet?

Got another little tip that may help some of yas out while building the XRAY shocks. Regarding compression and rebound: I took a Losi shock rebound comparison jig (the one with the little compass at the bottom). I took out the stock screws (4/40s I believe) and replaced them with 3mm bolts and nuts. I used a dremel cutting wheel and cut off the bolts until there was just enough thread showing so you could screw the shocks onto them for comparison.

It's really a great tool to make sure the compression and rebound of all your shocks are identical.

Having said that, I'm a little skeptical about the shock shaft thing-a-ma-jig. I try to stay far away from putting anything on the non-threaded portion while building my shocks. Better bet is to again use the top 1mm of threads and hold it tight with wire cutters. You should be leaving a millimeter of thread when putting the ends on anyway.

BTW, anyone tried that tool yet?

Got another little tip that may help some of yas out while building the XRAY shocks. Regarding compression and rebound: I took a Losi shock rebound comparison jig (the one with the little compass at the bottom). I took out the stock screws (4/40s I believe) and replaced them with 3mm bolts and nuts. I used a dremel cutting wheel and cut off the bolts until there was just enough thread showing so you could screw the shocks onto them for comparison.

It's really a great tool to make sure the compression and rebound of all your shocks are identical.

Last edited by jdwca; 03-30-2005 at 09:22 PM.

#1347

Originally posted by kewdawg

If, you use the nose of standard pliers to hold the shock end by the hole, you'll be able to thread them on, easily. Save your fingers, dude.

If, you use the nose of standard pliers to hold the shock end by the hole, you'll be able to thread them on, easily. Save your fingers, dude.

But, maybe it's just me? I dunno.

#1349

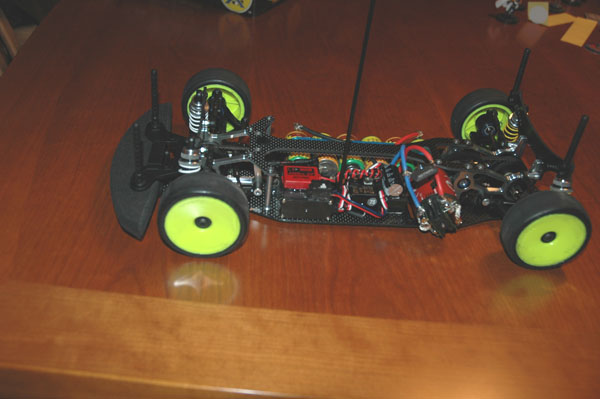

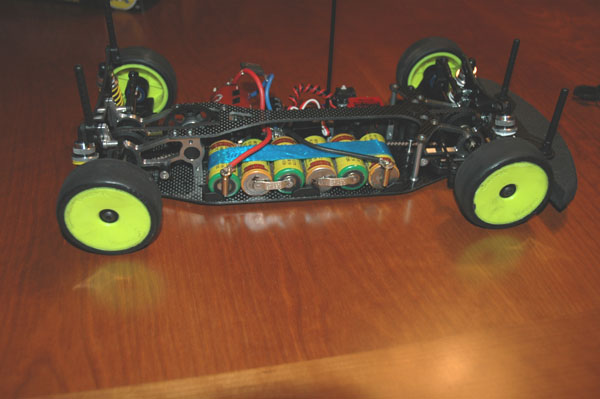

OPTION PARTS

ASIDE FROM THE CARBON BATTERY STRAP IS THERE ANYMORE HOP-UP OPTION I SHOULD BUY FOR THIS BEAUTY

THANKS..........

THANKS..........

THANKS..........

THANKS..........

#1350

Originally posted by futureal

Even doing that, and holding the shaft by the threads with side cutters, the shaft would begin to slip after the rod end got about 75% on. And that is *with* pre-threading. I tried a few different things and I just don't see how anybody could not have problems with them, unless they left about 40% of the threads exposed.

But, maybe it's just me? I dunno.

Even doing that, and holding the shaft by the threads with side cutters, the shaft would begin to slip after the rod end got about 75% on. And that is *with* pre-threading. I tried a few different things and I just don't see how anybody could not have problems with them, unless they left about 40% of the threads exposed.

But, maybe it's just me? I dunno.

Buboy: sway bars are needed and maybe the aluminum shock bodies also

1Likes

1Likes