TLR 8IGHT E 3.0 THREAD

#691

Tech Master

iTrader: (29)

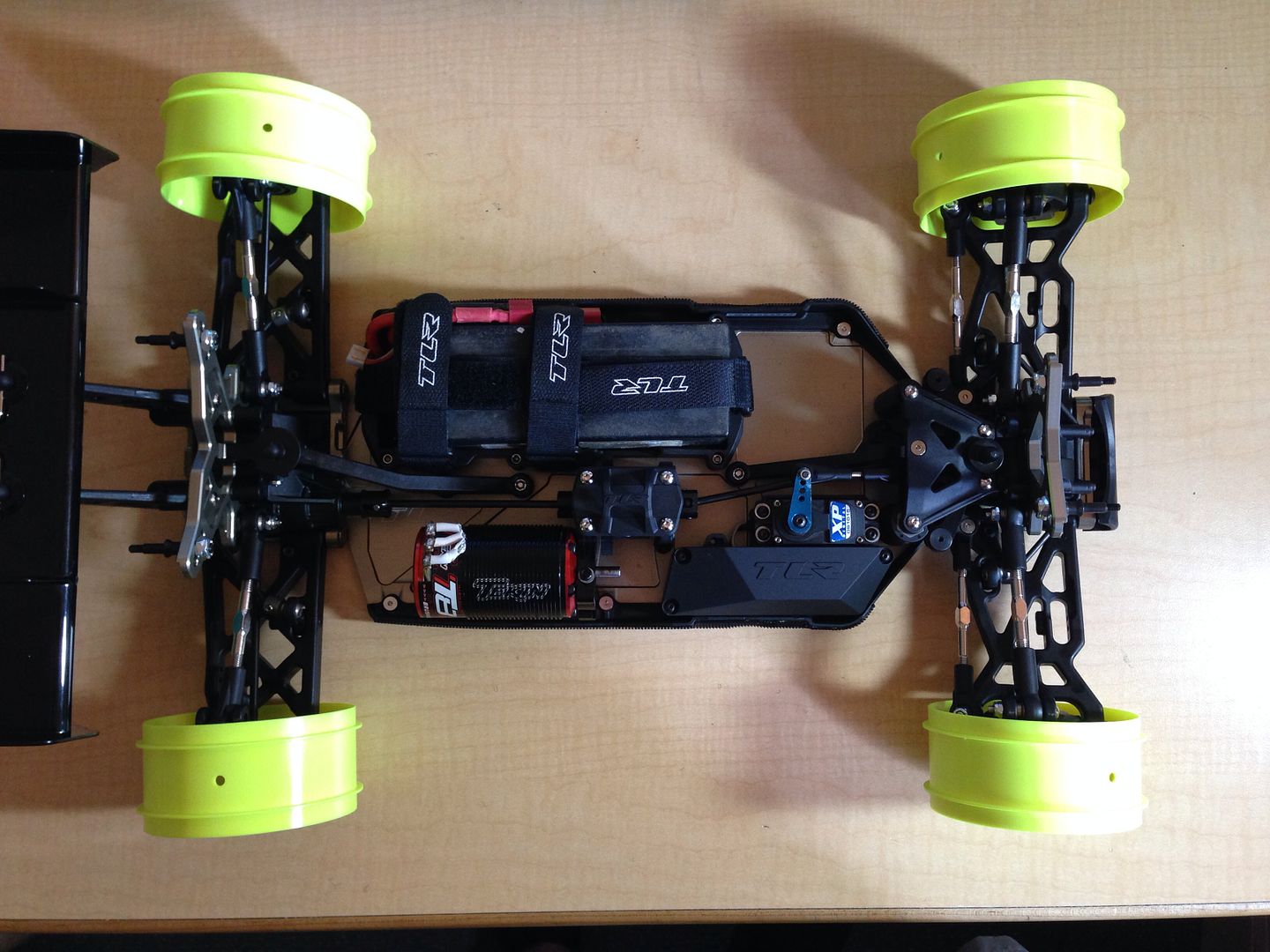

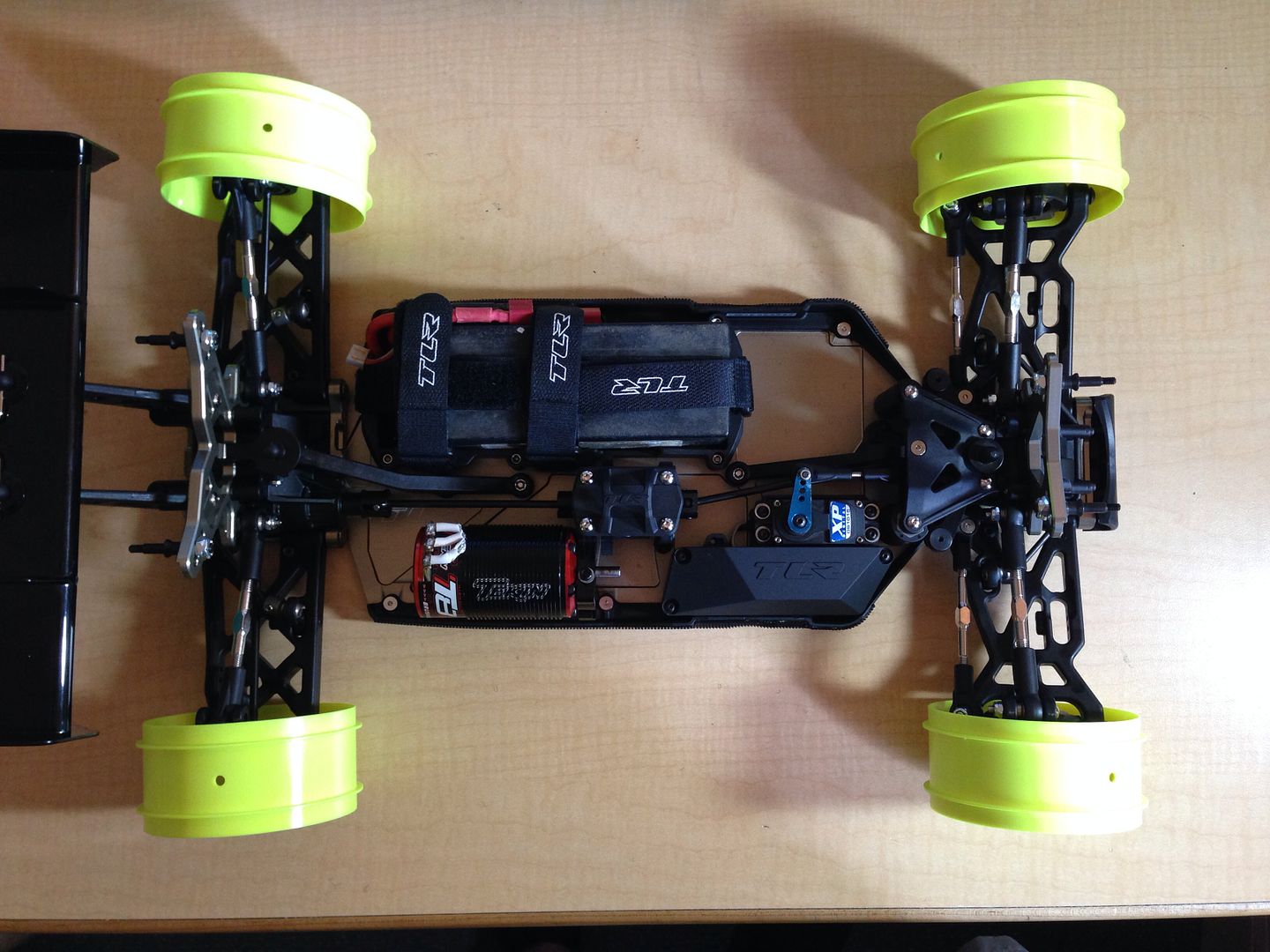

Almost done with my build. Just gotta do the shocks and wire everythig up. This was a great build! The way the the side gaurds mount to the chassis as well as the battery tray was a great touch. No more stripping plastic  The rod ends are pretty tight like everyone says but it will break in.

The rod ends are pretty tight like everyone says but it will break in.

The only thing I had to adjust were the rear diff shims. Doing it per the manual made the aluminum inserts almost impossible for me to install into the gear box. I went with one .25 shim on the left and one .10 on the right. Went together good after that and felt smooth.

I also didn't realize the esc mounted straight to the chassis. I will mount it on a thin piece of foam for some cushion. I usually just use shoe goo to mount my speedos.

The rod ends are pretty tight like everyone says but it will break in.

The rod ends are pretty tight like everyone says but it will break in. The only thing I had to adjust were the rear diff shims. Doing it per the manual made the aluminum inserts almost impossible for me to install into the gear box. I went with one .25 shim on the left and one .10 on the right. Went together good after that and felt smooth.

I also didn't realize the esc mounted straight to the chassis. I will mount it on a thin piece of foam for some cushion. I usually just use shoe goo to mount my speedos.

#692

what's the right way to loosen up the ball ends on this buggy when it's new?

#695

What exactly needs to break in?

#697

Thanks. Worked like a charm.

So reaming the arm holes for the hinge pins to open and free them up and squeezing the ball end on the links to get everything super smooth and free isnt enough to get this car the handle well without breaking in? Just went thru the car last night and loosened everything up and the suspension and steering and everything is super free and smooth now. I plan on breaking in the diffs on the bench once I finish wiring. Really hope it doesn't take 45 minutes of track time for the car to start driving well. Thats almost 2 race days of track time for me.

So reaming the arm holes for the hinge pins to open and free them up and squeezing the ball end on the links to get everything super smooth and free isnt enough to get this car the handle well without breaking in? Just went thru the car last night and loosened everything up and the suspension and steering and everything is super free and smooth now. I plan on breaking in the diffs on the bench once I finish wiring. Really hope it doesn't take 45 minutes of track time for the car to start driving well. Thats almost 2 race days of track time for me.

#698

Thanks. Worked like a charm.

So reaming the arm holes for the hinge pins to open and free them up and squeezing the ball end on the links to get everything super smooth and free isnt enough to get this car the handle well without breaking in? Just went thru the car last night and loosened everything up and the suspension and steering and everything is super free and smooth now. I plan on breaking in the diffs on the bench once I finish wiring. Really hope it doesn't take 45 minutes of track time for the car to start driving well. Thats almost 2 race days of track time for me.

So reaming the arm holes for the hinge pins to open and free them up and squeezing the ball end on the links to get everything super smooth and free isnt enough to get this car the handle well without breaking in? Just went thru the car last night and loosened everything up and the suspension and steering and everything is super free and smooth now. I plan on breaking in the diffs on the bench once I finish wiring. Really hope it doesn't take 45 minutes of track time for the car to start driving well. Thats almost 2 race days of track time for me.

#699

Thanks Ryan. After going through the car last night I actually found the rear suspension was less free than the front. Before loosening everything up the rear arms wouldn't even move under their own weight. (shocks off) I reamed the arms and squeezed the link ends and it freed up quite a bit, but was still binding a little. What I found was the outer hing pins through the hub uprights were binding. By just loosening the nuts 1/4 turn that totally freed it up and everything was silky smooth. Maybe the bearing surface on the outer hinge pin could be a half mm longer so if you bottom out the nut on the shoulder of the pin it doesn't squeeze the arm and make it bind. No issue with turning the nut out a little. It works and shouldn't come loose.

#700

Thanks Ryan. After going through the car last night I actually found the rear suspension was less free than the front. Before loosening everything up the rear arms wouldn't even move under their own weight. (shocks off) I reamed the arms and squeezed the link ends and it freed up quite a bit, but was still binding a little. What I found was the outer hing pins through the hub uprights were binding. By just loosening the nuts 1/4 turn that totally freed it up and everything was silky smooth. Maybe the bearing surface on the outer hinge pin could be a half mm longer so if you bottom out the nut on the shoulder of the pin it doesn't squeeze the arm and make it bind. No issue with turning the nut out a little. It works and shouldn't come loose.

#702

#704

Make sure you shoe goo the front nose area and around the body pin area in the back and it should last long with the Velcro on the sides like its made to be.

#705

i to had a hell of time getting the receminded shems in the rear diff. but finally got it very smooth. ryan any other combo thats easier to install.thanks

1Likes

1Likes