8Likes

8Likes

Best brand of springs?

#1

Looking at getting some short (20mm) TC springs, which brand is the most accurate and well matched?

#2

Tech Regular

SMJ springs are very well matched, I'm using em since a while and I'm pretty happy

https://smj-rc.com/products/springs/smj1200

https://smj-rc.com/products/springs/smj1200

#3

+1 on the SMJ springs

#4

Xray, Axon, and SMJ are all great options.

#6

Can anybody tell me what's up with the spring ratings on some of these things? Some are rated at 30lbs. and 40lbs. And others rated in the single digits. (I'm referring to A.E.) My understanding was that springs were rated at lbs. of pressure to compress the spring 1".

This tool comes in handy .: Spring Rate Conversion Calculator :. | NorWest Suspension LLC

#8

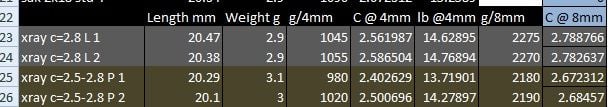

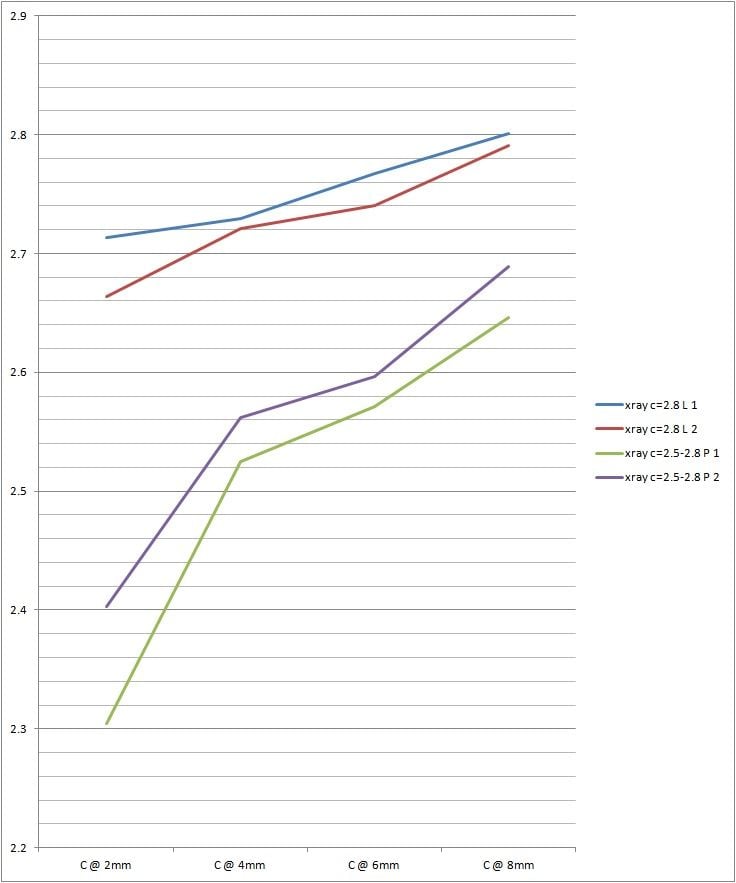

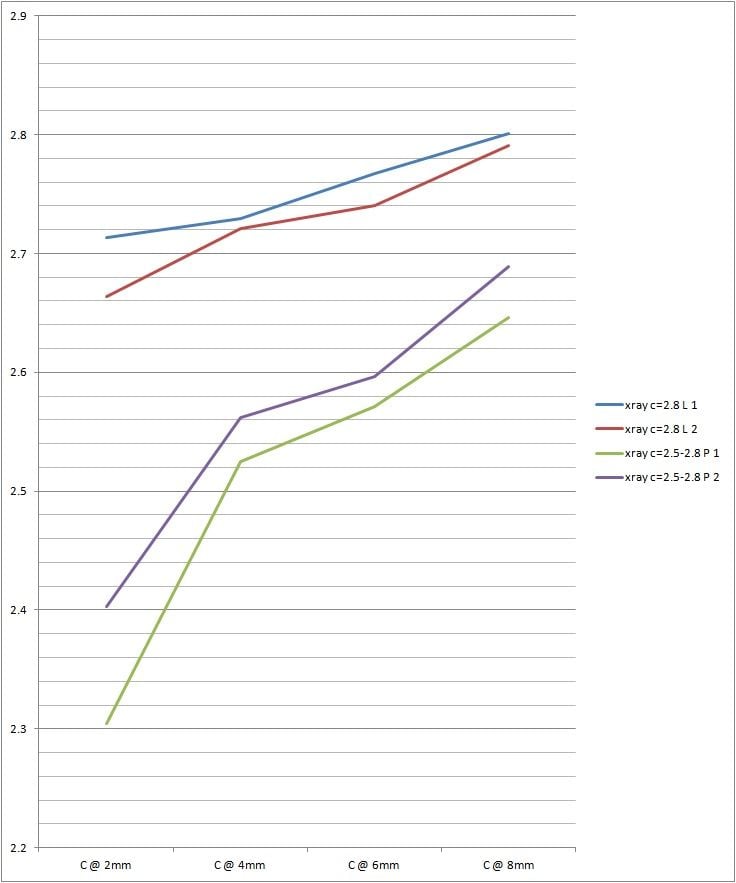

Just got some xray springs, initial measurements suggest they're not 100% perfectly matched. Also the 'linear' springs are still fairly progressive.

#9

More detailed measurement of the xray springs... there's an obvious mismatch between the springs in each pair  also the progressive springs are softer over the whole useful range, they may get up to C=2.8 at the very end of travel but that's never practically going to happen.

also the progressive springs are softer over the whole useful range, they may get up to C=2.8 at the very end of travel but that's never practically going to happen.

also the progressive springs are softer over the whole useful range, they may get up to C=2.8 at the very end of travel but that's never practically going to happen.

also the progressive springs are softer over the whole useful range, they may get up to C=2.8 at the very end of travel but that's never practically going to happen.

#10

What level of accuracy is reasonable to expect? The the worst case scenario in this graph looks to be about a 96% match?

#11

Closest to 100% perfect match left/right would be ideal, especially when you think of the lengths we go to to de-tweak our cars, it makes sense to have perfect springs.

Does anyone have a set of SMJ springs they'd be willing to measure?

#12

Tech Master

I think that if you find springs that have a similar slope and are within .1 to .2 you can make up for the difference in collar preload fairly easy. Looking above it looks like .5mm of preload will bring the slopes together.

you can also condition the springs by working them for awhile. They stop changing as you condition them fairly quickly. There are some weak bonds that break fairly quickly.

you can also condition the springs by working them for awhile. They stop changing as you condition them fairly quickly. There are some weak bonds that break fairly quickly.

#13

My worry about correcting using the preload collars is that on full droop, one spring may be loose whilst the other is still slightly compressed. Could this lead to some strange handling at max roll?

#14

Tech Master

You will never get your springs perfect and probably wont notice a difference in them being a little off but you can shim a spring or bend a portion to increase length. Conditioning doesnt just have to be about compressing. You can stretch them to get length and compress them to get comparable yield. If you condition a long spring with repeated compressions you can condition a short spring to be longer. The stretching and compression will break the bonds in both directions so if the measurement is 2lbsfor 10 mm and you have one that is short you can drop the resistance by stretching and compressing. The bonds break in both direction they dont grow back in a stretch.

you will find that the bonds break in a very narrow window. For example 5mm stretch or compression may not break very many or any bonds but 6 will break allot.

think of a bolt being screwed into a and aluminum joint. It might take 180 degrees to damage the threads from over tightening. Now think of a bolt screwed into a cast iron joint. Torque rises very quickly and you can damage the threads in 90 degrees. Its the same bonds being broken in a spring. The harder the metal the smaller the window is before the metal loses elasticity and bonds break.