Team Associated RC10 B5m Mid-Motor Thread

|

|||

http://www.schelleracing.com/Associa...ng-Set-SCH1087

http://www.redrc.net/2015/08/t-works...gpin-bushings/

T-Works have introduced brass kingpin bushing sets for Team Associatedís fifth generation 1/10th off-road vehicles such as the B5 and T5. The parts help to alter the roll centre settings and also add unsprung weight which can be beneficial at certain track conditions. Available are a 4-piece standard, a 4-piece offset and an 8-piece ďcompleteĒ set for the B5, T5 and SC5.

http://www.redrc.net/2015/08/rdrp-b5...bellcrank-set/

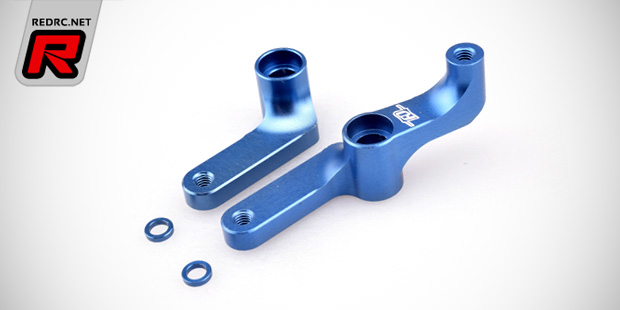

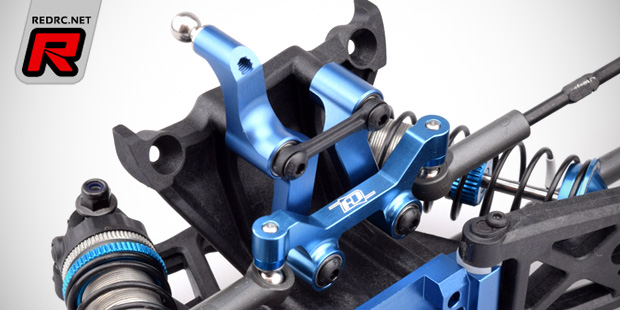

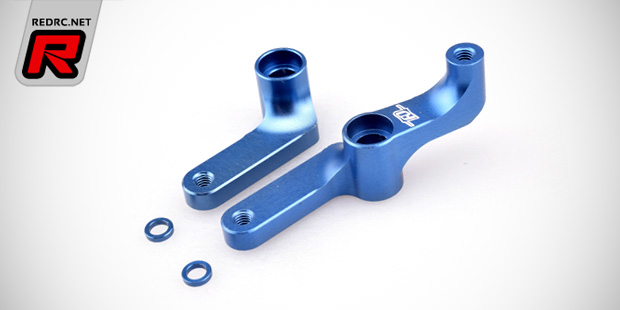

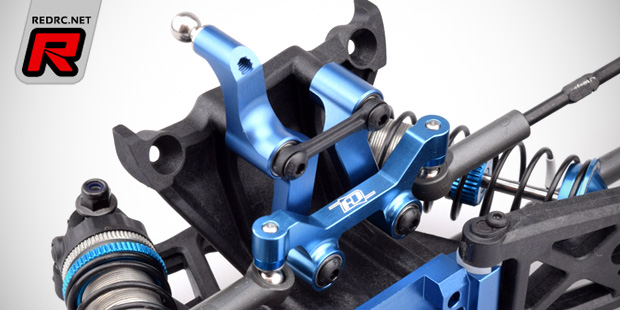

Made to replace the standard plastic steering bellcranks of Team Associatedís B5 series vehicles is the RDRP B5RM/MM aluminium bellcrank set. The parts do away with the kitís plastic steering bellcranks in favour of stronger levers for added rigidity and better looks. The CNC-machined 7075-T6 aluminium construction considerably strengthens the steering assembly for less slop, a more precise steering reaction and less flex, resulting in a rock solid steering feeling and more durability in the event of a crash. The RDRP B5RM/MM bellcrank aluminium set is made for the use with fifth generation kits and it comes blue anodised and laser-etched to match the remainder of RDRPís Team Associated option parts.

T-Works have introduced brass kingpin bushing sets for Team Associatedís fifth generation 1/10th off-road vehicles such as the B5 and T5. The parts help to alter the roll centre settings and also add unsprung weight which can be beneficial at certain track conditions. Available are a 4-piece standard, a 4-piece offset and an 8-piece ďcompleteĒ set for the B5, T5 and SC5.

http://www.redrc.net/2015/08/rdrp-b5...bellcrank-set/

Made to replace the standard plastic steering bellcranks of Team Associatedís B5 series vehicles is the RDRP B5RM/MM aluminium bellcrank set. The parts do away with the kitís plastic steering bellcranks in favour of stronger levers for added rigidity and better looks. The CNC-machined 7075-T6 aluminium construction considerably strengthens the steering assembly for less slop, a more precise steering reaction and less flex, resulting in a rock solid steering feeling and more durability in the event of a crash. The RDRP B5RM/MM bellcrank aluminium set is made for the use with fifth generation kits and it comes blue anodised and laser-etched to match the remainder of RDRPís Team Associated option parts.

To help things get back on topic, I remember a while back people asking about the quality of the AC RC gear lowrider off of shapeways compared to the reds workshop. So, I have been running the AC RC one, with a slipper eliminator, and have yet to strip any gears. Gear mesh seems a little tight internally, and the reds has less internal resistance. But for the difference in price... I can live with that. Also note that the AC RC uses the old style top shaft and bearings. And if you want to save some extra coin on your low rider conversion, its pretty easy to replace the waterfall and battery strap with a carbon B5R strap and a turnbuckle to the gearbox, using shock eyelets on the turnbuckle. But the main question was, is it reliable? Yes

do you have the updated version of the gearbox? They released an improved version in july, if I remember correctly... I installed this one and I think in terms of resistance it's pretty much the same as the original AE 4 gear gearbox.

Another question:

Did you drill the two additional (optional) holes in the chassis to mount the gearbox with six screws instead of four?

Thomas,

do you have the updated version of the gearbox? They released an improved version in july, if I remember correctly... I installed this one and I think in terms of resistance it's pretty much the same as the original AE 4 gear gearbox.

Another question:

Did you drill the two additional (optional) holes in the chassis to mount the gearbox with six screws instead of four?

do you have the updated version of the gearbox? They released an improved version in july, if I remember correctly... I installed this one and I think in terms of resistance it's pretty much the same as the original AE 4 gear gearbox.

Another question:

Did you drill the two additional (optional) holes in the chassis to mount the gearbox with six screws instead of four?

Word up to the noobs: Think long and hard about getting an aluminum steering rack. That's one of the best ways to start going through servos you will ever find. The stock plastic rack provides some damping from impacts and will likely break before your servo will, especially if you have a reasonably tough servo. When I see people stripping gears in their servo, they almost always have an aluminum rack.

The stock b5 steering is already one of the tightest and nicest steering racks you will find on a car, and it breaks away during a hard impact.

My $0.02,

Wayne

The stock b5 steering is already one of the tightest and nicest steering racks you will find on a car, and it breaks away during a hard impact.

My $0.02,

Wayne

Tech Regular

Word up to the noobs: Think long and hard about getting an aluminum steering rack. That's one of the best ways to start going through servos you will ever find. The stock plastic rack provides some damping from impacts and will likely break before your servo will, especially if you have a reasonably tough servo. When I see people stripping gears in their servo, they almost always have an aluminum rack.

The stock b5 steering is already one of the tightest and nicest steering racks you will find on a car, and it breaks away during a hard impact.

My $0.02,

Wayne

The stock b5 steering is already one of the tightest and nicest steering racks you will find on a car, and it breaks away during a hard impact.

My $0.02,

Wayne

I would definitely agree this is not one of the vehicles that benefits from an aluminum steering rack. In a bad enough hit to ruin your servo you are most likely going to also ruin that nifty aluminum rack and add to the cost of repairs, it adds nothing but bling. There is some slop in my front suspension but it all seems to come from the loose castor blocks on my car, I need some 1-2mm x 3mm nylon shims to tighten it up. The steering rack is one of the better ones I have seen and having the plastic adds some safety in hard hits.

After having made it through this entire thread, that took some time, I would like to get a waterfall fan mount and it seems the printed ones are not worth the effort as they fail pretty quickly. Is there any mfg that actually makes a molded waterfall fan mount?

Word up to the noobs: Think long and hard about getting an aluminum steering rack. That's one of the best ways to start going through servos you will ever find. The stock plastic rack provides some damping from impacts and will likely break before your servo will, especially if you have a reasonably tough servo. When I see people stripping gears in their servo, they almost always have an aluminum rack.

The stock b5 steering is already one of the tightest and nicest steering racks you will find on a car, and it breaks away during a hard impact.

My $0.02,

Wayne

The stock b5 steering is already one of the tightest and nicest steering racks you will find on a car, and it breaks away during a hard impact.

My $0.02,

Wayne

I would definitely agree this is not one of the vehicles that benefits from an aluminum steering rack. In a bad enough hit to ruin your servo you are most likely going to also ruin that nifty aluminum rack and add to the cost of repairs, it adds nothing but bling. There is some slop in my front suspension but it all seems to come from the loose castor blocks on my car, I need some 1-2mm x 3mm nylon shims to tighten it up. The steering rack is one of the better ones I have seen and having the plastic adds some safety in hard hits.

After having made it through this entire thread, that took some time, I would like to get a waterfall fan mount and it seems the printed ones are not worth the effort as they fail pretty quickly. Is there any mfg that actually makes a molded waterfall fan mount?

After having made it through this entire thread, that took some time, I would like to get a waterfall fan mount and it seems the printed ones are not worth the effort as they fail pretty quickly. Is there any mfg that actually makes a molded waterfall fan mount?

This one is pretty stout. The fans seem to fail more than the waterfall

http://www.shapeways.com/product/SJN...ionId=55945004

I just picked up a B5M and reading up on the thread here. I was considering picking up an aluminum rack and bell cranks but after reading the last few posts I am thinking otherwise. Is it better to keep both the cranks and rack plastic?

Spencer Rivkin stead on his FB page when I asked him about the plastic steering and why he and Cav use them on buggy. He saidits more forgiving. Less twitchy I would believe. High bite track maybe use plastic and metal on med to low bite.

New Parts I noticed on the website for keeping the dogbone in for full droop and FT Alum +4 arm mounts:

http://www.teamassociated.com/news/l...CVA_Axle_Shims

http://www.teamassociated.com/news/l...CVA_Axle_Shims

Tech Regular

Have my buggy tore down, doing a total cleanup, checking settings and original build and adding a few upgrades along the way. One item I picked up, not usre it's usefulness but grabbed anyway since I was tearing down to transmission, the Schelle offset motor mount. Cleaned out transmission, checked gears and bearings and added this item, no instructions and it seemed straight forward but the transmission bearing below output shaft is making a strange rattling noise and wondering if the shim is required in my B5M Lite as in the old rear motor setup? Thanks for help.

EDIT: Had I looked at it a bit longer it would of been clear. The aluminum shim sits outside the diff casing to shift the contact with the slipper hub. Meh, maybe some one else questions this one..

EDIT: Had I looked at it a bit longer it would of been clear. The aluminum shim sits outside the diff casing to shift the contact with the slipper hub. Meh, maybe some one else questions this one..

If you are racing and practicing only (trying your best not to go full throttle head on into a wall), you will be fine. Like i said, just use a plastic servo horn and that will be your weak point.

Tech Addict

iTrader: (18)

I was surprised to see cav's car set up the way it was for nationals. It seems nobody (pros) on high bite uses anything but 4mm trail but cav went to the 2mm trail.

Razathorn,

any thoughts or explanation on why you think he set up his car the way he did on a track with that much traction? Green spring in the rear threw me off too.

Razathorn,

any thoughts or explanation on why you think he set up his car the way he did on a track with that much traction? Green spring in the rear threw me off too.

54Likes

54Likes