How to solder correctly (a not so brief lesson)

#586

Tech Regular

iTrader: (26)

While wick and desoldering guns can work, they are inefficient and donít remove he as much as dropping the component.

Magen you drop something you face the section down so that when it impacts, the solder slides down and away from the contacts. You can also hold the part and slam your arm down to better control the direction the solder slide off in.

As for wire... when it comes to RC or high end applications, flexibility is paramount so once solder makes its way too far inside the wire, it will NEVER flex properly again and will forever have increased resistance so therefore it is pointless to try and remove solder. Itís best to just cut a new piece and strip a minimal amount of insulation

and tin MINIMALLY as per my instructions in previous pages.

Magen you drop something you face the section down so that when it impacts, the solder slides down and away from the contacts. You can also hold the part and slam your arm down to better control the direction the solder slide off in.

As for wire... when it comes to RC or high end applications, flexibility is paramount so once solder makes its way too far inside the wire, it will NEVER flex properly again and will forever have increased resistance so therefore it is pointless to try and remove solder. Itís best to just cut a new piece and strip a minimal amount of insulation

and tin MINIMALLY as per my instructions in previous pages.

I'll just agree to disagree with you and leave it at that. What you say is true about the wire, but I wasn't speaking to the flexibility. That said, if your removing solder from the wire, there is less of a chance that solder will wick further inside the insulation, at least not enough to make a measurable impact on flexibility. Again it depends on quality of tools and the skill level of those operating said tools.

#588

Tech Regular

iTrader: (26)

No lie though, not once, not ever.

No lie though, not once, not ever.

#589

I will admit to using a method like the drop method mentioned. Usually when not at a bench and not having wick with me.

Such a method does remove most of the solder very quickly though.

Solder wick works very well when the amount of solder is fairly small. Large amounts saturate the wick, and you have to move to a fresh section of the wick.

Wick also needs fresh liquid flux applied before use. The small amount of flux already in the wick is usually old and dry by the time you go to use it. Fresh solder makes wick work very very well.

Desolder guns... They work ok. They can remove larger amounts than wick, and more quickly.

But a heated desolder tool is best, and better still when equiped with a button controlled vacuum pump.

So long as you haven't globbed on a ton of solder, wick with fresh flux is a good method.

Such a method does remove most of the solder very quickly though.

Solder wick works very well when the amount of solder is fairly small. Large amounts saturate the wick, and you have to move to a fresh section of the wick.

Wick also needs fresh liquid flux applied before use. The small amount of flux already in the wick is usually old and dry by the time you go to use it. Fresh solder makes wick work very very well.

Desolder guns... They work ok. They can remove larger amounts than wick, and more quickly.

But a heated desolder tool is best, and better still when equiped with a button controlled vacuum pump.

So long as you haven't globbed on a ton of solder, wick with fresh flux is a good method.

#591

A simple flick does work usually. Dropping onto a surface isn't necessary most of the time.

#596

The method shown in the video for solder cups works. It is plenty fine for most solder needs.

I don't use that method for aerospace though, not considered reliable enough for critical connections.

I don't use that method for aerospace though, not considered reliable enough for critical connections.

#597

Tech Regular

I just bought the 5mm chisel tip for my hako clone...

WHAT A DIFFERENCE!!!!

going from the 4mm chisel tip to the 5mm tip made such a massive difference doing motor and battery wires.... best mod ever

WHAT A DIFFERENCE!!!!

going from the 4mm chisel tip to the 5mm tip made such a massive difference doing motor and battery wires.... best mod ever

#598

Tech Regular

I bought a roll of 63/37 solder off eBay as I read it's a better quality than the 60/40 should change from solid to liquid qicker. However, when I'm using it the 63/37 seems to turn in to a paste before melting and comes out a dull grey colour whereas the 60/40 I have melts quickly and has a shiny finish when set.

Am I doing something wrong with the 63/37 solder?

Am I doing something wrong with the 63/37 solder?

#599

Tech Regular

Curios if there's a trick to removing factory installed wires? When buying let's say a LRP Flow, it comes with the wires installed. I like my wire black so I usually have to remove the wires. I noticed that even on my XR10 stock that it's really hard to remove them. I have my Hakko set at 800 degrees and it takes for ever to heat up the area to remove from the post on the ESC board. I'm assuming there's maybe a different solder used at the factory and that maybe it has a higher silver content or something. Is this what makes it difficult to remove? I removed the wires but the heat sink on the ESC was awfully warm but it still works. Just wondering what the secret is?

( youll need to pull the wire wiith needle nose pliers or youll have burnt fingers)

#600

Tech Regular

raved007,

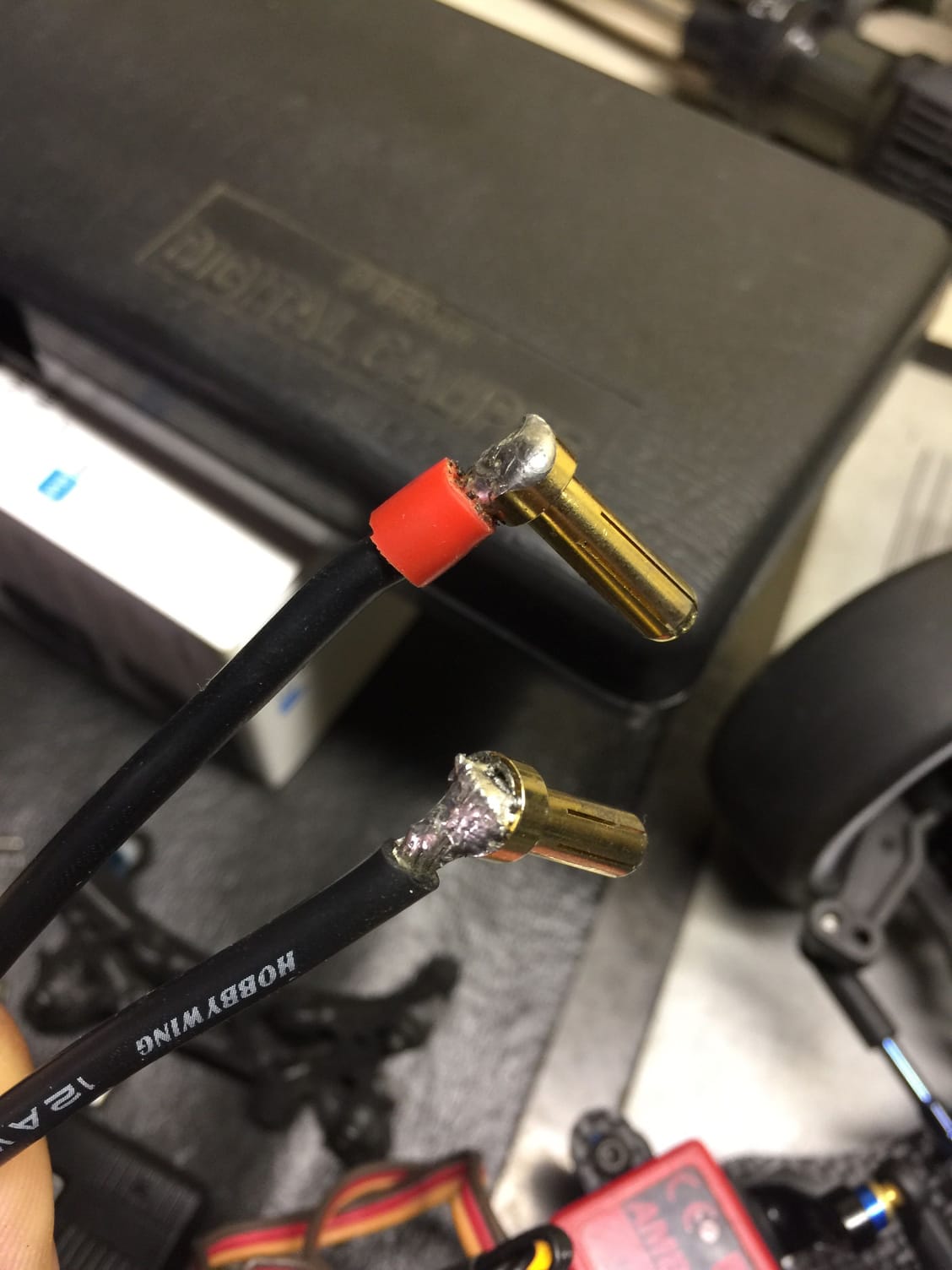

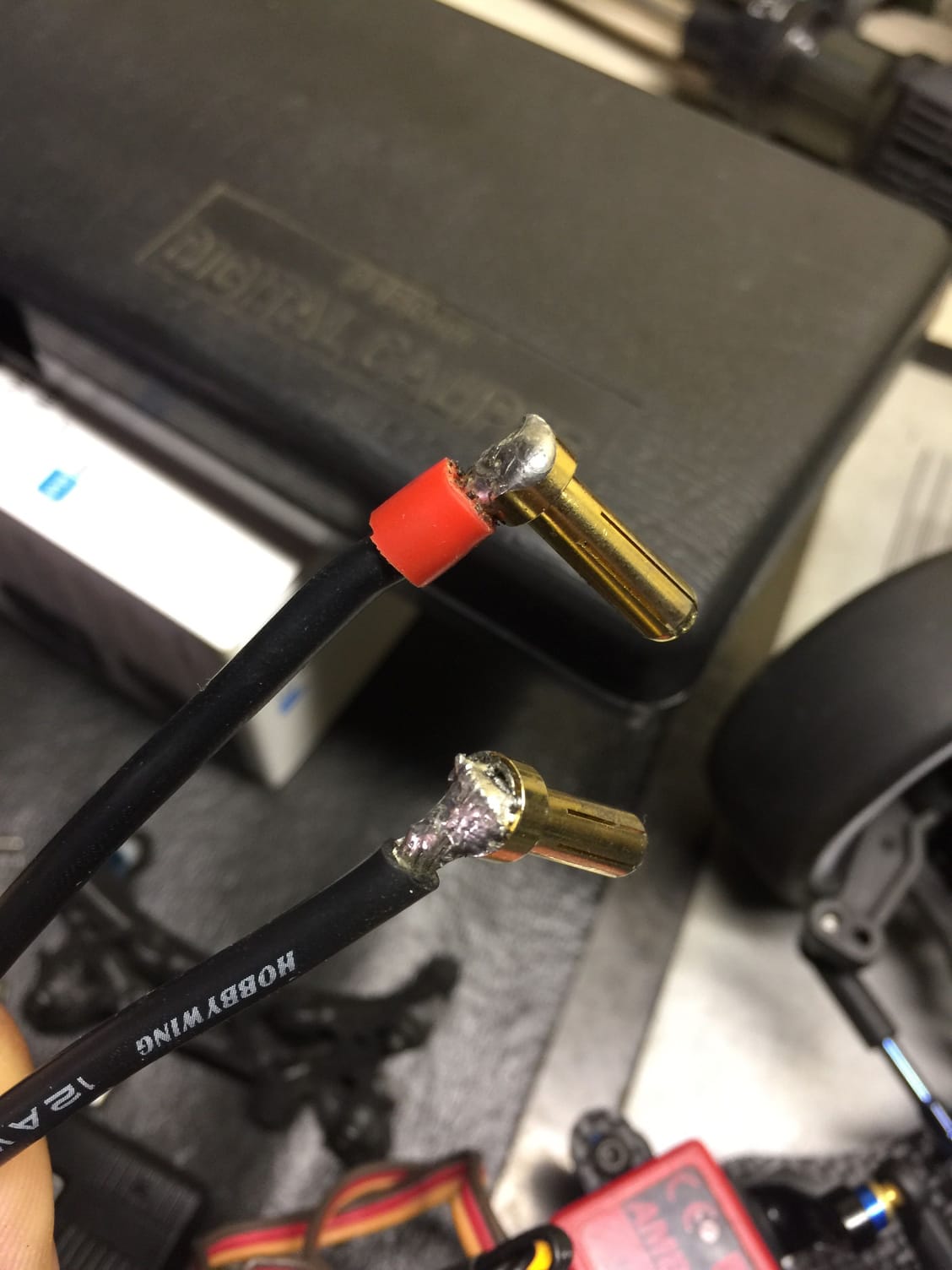

So far Iím very satisfied with the Hakko. I use a 3.5mm chisel tip and keeping it clean and shiny made a world of difference. I tried some Kester 63/37(.031) rosin core solder and rosin paste flux from SRA soldering products. This was the first time I was able to solder my electronics with ease. I need to continue to fine tune my technique but, Iím very satisfied for now. Here are some pictures. Any feedback is welcome. Thanks.

So far Iím very satisfied with the Hakko. I use a 3.5mm chisel tip and keeping it clean and shiny made a world of difference. I tried some Kester 63/37(.031) rosin core solder and rosin paste flux from SRA soldering products. This was the first time I was able to solder my electronics with ease. I need to continue to fine tune my technique but, Iím very satisfied for now. Here are some pictures. Any feedback is welcome. Thanks.

also stop pushing down so hard on the wire. that is causing the wire to splay out. the wires should still be cylindrical. i suspect that your tip isnt big enough which is causing you to push down hard to try and get it to melt.

31Likes

31Likes