What are acceptable/maximum temps for motors? How do you manage temperatures?

#1

Like the title says, what is the max you should be running temp wise?

What drives temps up more? RPM or load?

I'm interested in knowing for 8th scale buggy.

What drives temps up more? RPM or load?

I'm interested in knowing for 8th scale buggy.

#2

Tech Master

iTrader: (19)

how hot should a brushless motor get?

It is important to add that the windings need current for the heat per-say to leave the windings/core, move heat outward not inward. A brushless motor requires to be at least loaded periodically to its redline but most will be happier riding 80% with that same load. The higher the amount of voltage the lower the amount of current to do the same amount of power, this can be both good and have cons if of course of you want to carry the same load.

Brakes can influence motor temps both ways so to that a cheap temp gun and you can observe your esc and motor during different types of runs.

Overall chassis weight has some effect on the motor temp, rotational mass has the most effect on a brushless motor. It is odd that current limiting certain rig setups may actually raise motor temp but the motor is happy when operating at around 120-160F.

It is important to add that the windings need current for the heat per-say to leave the windings/core, move heat outward not inward. A brushless motor requires to be at least loaded periodically to its redline but most will be happier riding 80% with that same load. The higher the amount of voltage the lower the amount of current to do the same amount of power, this can be both good and have cons if of course of you want to carry the same load.

Brakes can influence motor temps both ways so to that a cheap temp gun and you can observe your esc and motor during different types of runs.

Overall chassis weight has some effect on the motor temp, rotational mass has the most effect on a brushless motor. It is odd that current limiting certain rig setups may actually raise motor temp but the motor is happy when operating at around 120-160F.

Last edited by Juglenaut; 06-04-2021 at 10:03 PM.

#3

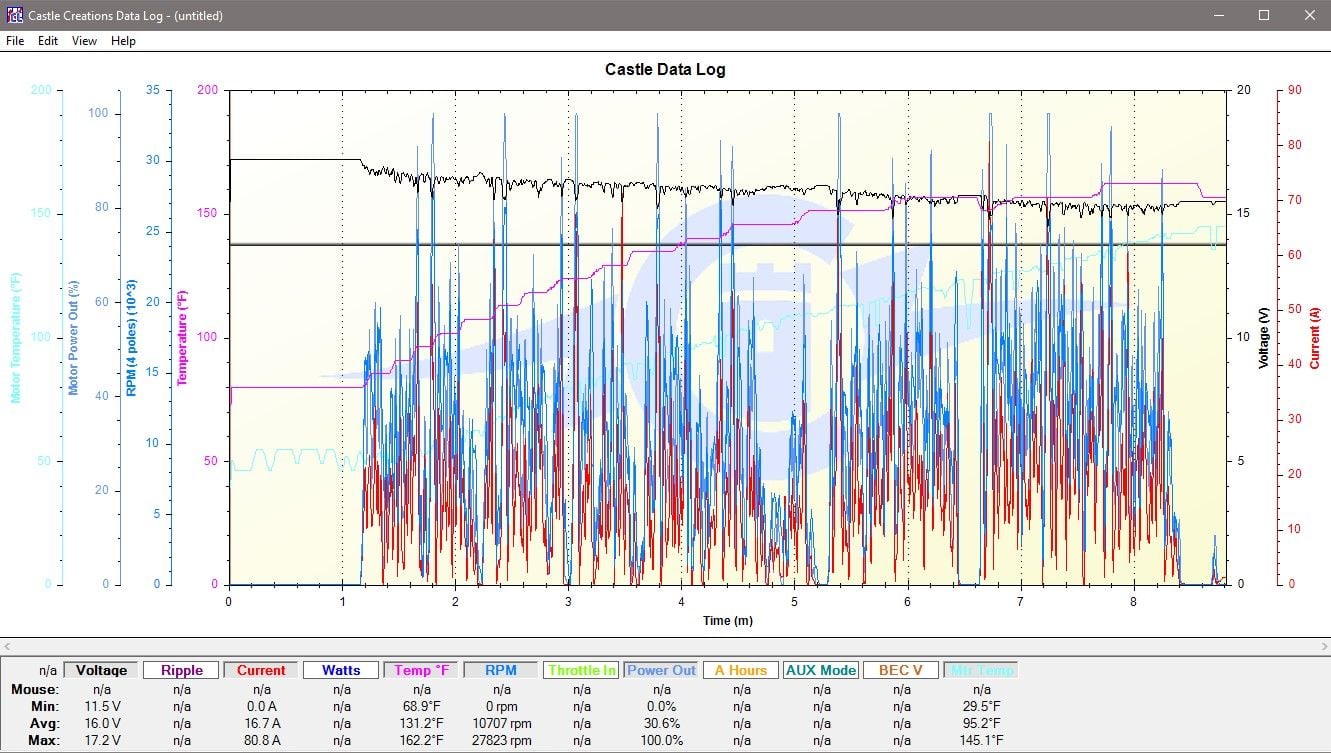

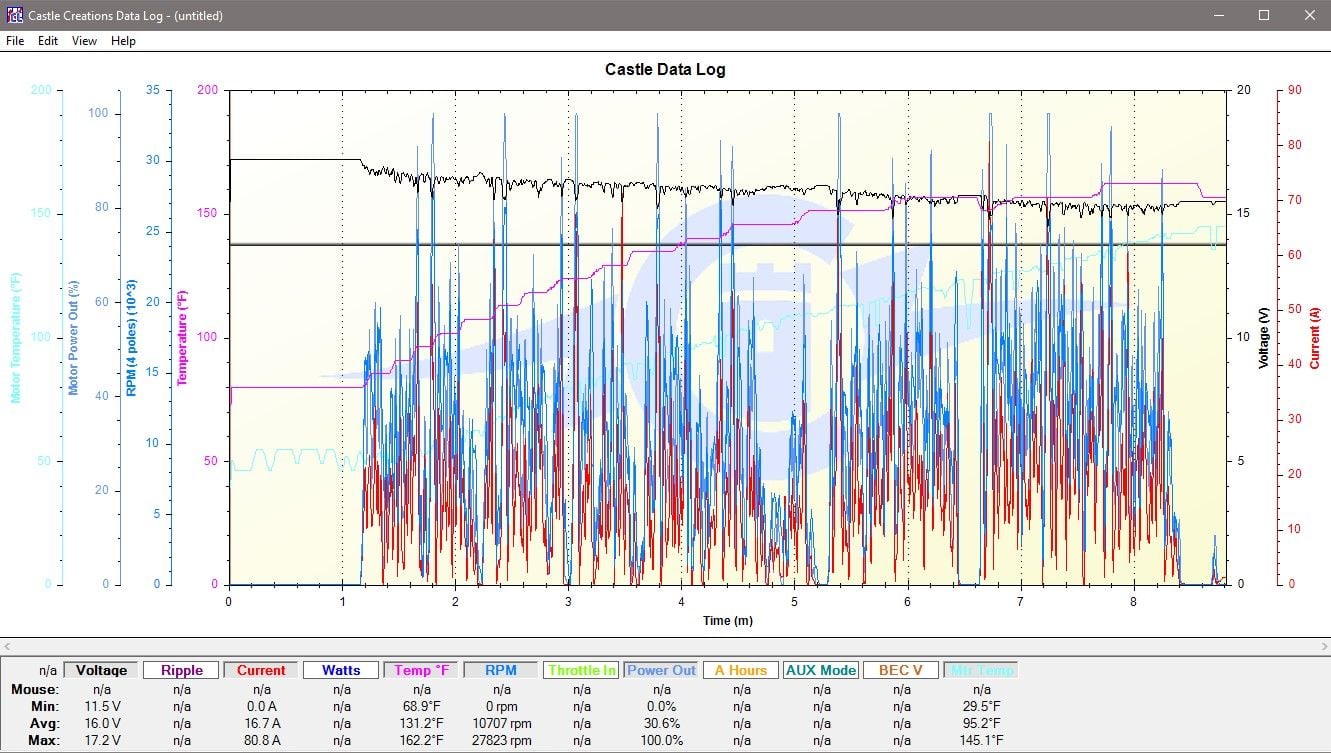

I use the the data logging from my Mamba X escs to set gearing and temps. For ebuggy on a 70F day I want temps to be around 140 - 160F.

#5

When measured with an IR gun, I try to keep motor temp below 60C, but it'll occasionally get up to 80C on a really hot day. Over 80C and the rotor strength starts to degrade.

Note that temps measured with an IR gun will usually be different to temps reported by the internal motor sensor.

Note that temps measured with an IR gun will usually be different to temps reported by the internal motor sensor.

#6

I've only run indoors but if you stay at or below 150deg measured on the can or hottest part, max of 155-160 it should basically last forever.

I bought a 17.5 from Troy owner of Fantom at one race, and saw him at another about 8 months later. I was asking about possibly replacing the rotor and he was 50/50 on if it'd benefit me so we measured it and it was almost new. I probably had gotten it to 175f once or twice but the rotor and everything else was still in great shape. Troy was surprised it was all perfect and we didn't replace the rotor since it was fine. So I stick to the 150's and if something happens I don't have to be too worried.

Others will tell you 170-180 is ok, but if you hit that regularly you will degrade the rotor over time and have no margin of error if a fan or something fails.

I bought a 17.5 from Troy owner of Fantom at one race, and saw him at another about 8 months later. I was asking about possibly replacing the rotor and he was 50/50 on if it'd benefit me so we measured it and it was almost new. I probably had gotten it to 175f once or twice but the rotor and everything else was still in great shape. Troy was surprised it was all perfect and we didn't replace the rotor since it was fine. So I stick to the 150's and if something happens I don't have to be too worried.

Others will tell you 170-180 is ok, but if you hit that regularly you will degrade the rotor over time and have no margin of error if a fan or something fails.

#7

I've only run indoors but if you stay at or below 150deg measured on the can or hottest part, max of 155-160 it should basically last forever.

I bought a 17.5 from Troy owner of Fantom at one race, and saw him at another about 8 months later. I was asking about possibly replacing the rotor and he was 50/50 on if it'd benefit me so we measured it and it was almost new. I probably had gotten it to 175f once or twice but the rotor and everything else was still in great shape. Troy was surprised it was all perfect and we didn't replace the rotor since it was fine. So I stick to the 150's and if something happens I don't have to be too worried.

Others will tell you 170-180 is ok, but if you hit that regularly you will degrade the rotor over time and have no margin of error if a fan or something fails.

I bought a 17.5 from Troy owner of Fantom at one race, and saw him at another about 8 months later. I was asking about possibly replacing the rotor and he was 50/50 on if it'd benefit me so we measured it and it was almost new. I probably had gotten it to 175f once or twice but the rotor and everything else was still in great shape. Troy was surprised it was all perfect and we didn't replace the rotor since it was fine. So I stick to the 150's and if something happens I don't have to be too worried.

Others will tell you 170-180 is ok, but if you hit that regularly you will degrade the rotor over time and have no margin of error if a fan or something fails.

On a hot day say 90 degrees + I would only consider 180F as warm. It's no real big deal for my castle motors to see over 200F in the summer after a 10 minute run.

#8

The biggest issue is the magnets, not the copper or epoxy. I had a motor die recently that would run great at the start of the pack but fade to the point of having no power when it got hot. Measured it to be 210F on the can.

#9

What you are describing is a rotor in a brushed motor. In a brushless motor the windings are in the stator and the rotor is a permanent magnet which WILL degrade at easily obtainable temperatures. When heated above 176° Fahrenheit (80° Celsius), magnets will quickly lose their magnetic properties. The magnet will become permanently demagnetized if exposed to these temperatures for a certain length of time or heated at a significantly higher temperature.

#10

Well I guess castle motors have some special sauce cause mine have definitely not lost any performance after years of exceeding 180F every run.

#11

Tech Master

iTrader: (19)

I think people tend to overestimate the effect of heat on a motor. You say rotor which is really just a bunch of laminations and copper windings. You can't really degrade those materials. You can melt the enamel that holds the windings together but that takes some pretty intense heat.

On a hot day say 90 degrees + I would only consider 180F as warm. It's no real big deal for my castle motors to see over 200F in the summer after a 10 minute run.

On a hot day say 90 degrees + I would only consider 180F as warm. It's no real big deal for my castle motors to see over 200F in the summer after a 10 minute run.

Clearly it depends on what kind of material is used to coat the wires. Most electronics are design based to withstand short durations around 300-350F 148c-175c.. nominal ambient operating temperature of -40 to 85C industrial rating, most industrial windings temp class usually falls in the 200c range or higher

https://www.google.com/amp/s/www.ele...nic-parts/amp/

#12

Tech Master

iTrader: (19)

What you are describing is a rotor in a brushed motor. In a brushless motor the windings are in the stator and the rotor is a permanent magnet which WILL degrade at easily obtainable temperatures. When heated above 176° Fahrenheit (80° Celsius), magnets will quickly lose their magnetic properties. The magnet will become permanently demagnetized if exposed to these temperatures for a certain length of time or heated at a significantly higher temperature.

Again it depends what the magnet is made of and technology used with it.

https://www.first4magnets.com/tech-c...um-magnets-i91

#13

The weaker the rotor starts out, the less likely you're going to notice it losing performance from heat. Some versions of magnet material will probably withstand heat than others, but other stronger magnets may not hold up to heat as well. That's a guess based on what I know about materials, who knows what motor uses what material. Just think of it as a guideline.

Yes not much in the motor gets damaged at high temps. But the few things that do, are quite important. 1st thing noticeable is magnet strength, but as you pointed out the enamel coating the windings is very important too. Either wires get loose and eventually break or they short out on each other after rubbing off insulation and the whole motor also smokes. Heat degrades everything including bearings just to a smaller degree.

This is why I included my fantom story. I kept it to 150degf as much as possible and the owner (1 of 2) of the company was impressed with its condition 8 months later. Its a known limit to show you what is fine for a long term motor. Argue whatever you want, I'll continue to run my stuff conservatively and not only have long life, but less power fade in a given qualifier or main. Thats for 1/10 stock motors, where power is critical. Mod and 1/8 is SLIGHTLY more forgiving and I keep those 170-175 or under but I did have a 1.5-2 year old mod motor die from wire failure last week. So take that however you want to.

Yes not much in the motor gets damaged at high temps. But the few things that do, are quite important. 1st thing noticeable is magnet strength, but as you pointed out the enamel coating the windings is very important too. Either wires get loose and eventually break or they short out on each other after rubbing off insulation and the whole motor also smokes. Heat degrades everything including bearings just to a smaller degree.

This is why I included my fantom story. I kept it to 150degf as much as possible and the owner (1 of 2) of the company was impressed with its condition 8 months later. Its a known limit to show you what is fine for a long term motor. Argue whatever you want, I'll continue to run my stuff conservatively and not only have long life, but less power fade in a given qualifier or main. Thats for 1/10 stock motors, where power is critical. Mod and 1/8 is SLIGHTLY more forgiving and I keep those 170-175 or under but I did have a 1.5-2 year old mod motor die from wire failure last week. So take that however you want to.

16Likes

16Likes