Optimum Crankshaft Opening and Closing Points

#1

This is probably a taboo subject but it's an interesting one. Of course the opening and closing points are application specific. For instance, if it's an all-out drag race engine the opening and closing points can be pushed, where in a road race engine those points wouldn't be as aggressive.

Are there any professional and personal (such a myself) engine modifiers out there willing to engage in a discussion regarding what you consider Optimum Crankshaft Opening and Closing Points are?

Of course there is more involved when getting these little engines to scream and charge the finish line but, I would like to discuss those points above.

Are there any professional and personal (such a myself) engine modifiers out there willing to engage in a discussion regarding what you consider Optimum Crankshaft Opening and Closing Points are?

Of course there is more involved when getting these little engines to scream and charge the finish line but, I would like to discuss those points above.

#2

Okay, obvious a Taboo Subject. Let me downsize; what have you Professional and Personal Engine Modifiers thing is the single best thing/modification you can do to increase power the most in these little engines?

I have read where increasing compression will do more for power than any other mod. That's not my believe. It helps as long as you tune for it with cooler plugs. Some believe changing the timings, such as myself, is the best mod. However, if you don't make other changes/mods in other areas, you will not see the benefits of changing the timings.

Moreover, if you don't know EXACTLY what you're doing when changing the timings you will NOT maximize power, and may make less power or destroy the engine. I have a pile of engines, cranks and sleeves in the lab to attest to that fact.

So, what have you guys found to be the single best modification you can do to these little engines to see the most power gain?

I have read where increasing compression will do more for power than any other mod. That's not my believe. It helps as long as you tune for it with cooler plugs. Some believe changing the timings, such as myself, is the best mod. However, if you don't make other changes/mods in other areas, you will not see the benefits of changing the timings.

Moreover, if you don't know EXACTLY what you're doing when changing the timings you will NOT maximize power, and may make less power or destroy the engine. I have a pile of engines, cranks and sleeves in the lab to attest to that fact.

So, what have you guys found to be the single best modification you can do to these little engines to see the most power gain?

#3

There is no optimum, it can be with every engine different and beside that different timing can give a same performance but a different feeling of the engine.

#4

Thanks for commenting Roelof. I have noticed that there are certain points (2-3 degrees on both sides of the crank) seems to make the best power in Drag Race engines as long as the Exhaust Port duration/timing is altered as well.

#5

Giving on both sides more timing will always give moroe performance. There is a kind of limit on the total opening, beyound about 220 degrees the engine can go critical on the tuning. (yes, there are some enginews with more....)

#6

Yeah, I have never gone as high as 220 degrees but, that's interesting. I have one (vir-tus .21) that I'm going to open at 31 and close at 71 and see how it responds.

#7

31/71 sounds like an Ielasi. I have used it on an 35+ (also a 14.5mm crankshaft) and it works.

#8

#9

Tech Apprentice

Hi Roelof, forgive me for asking an old thread question. How to mod 31/71 on a crankshaft. To be honest I don't have any idea what it is all about.

Last edited by shambmk; 07-28-2019 at 08:29 AM. Reason: Message too long.

#10

If you have no idea then it is wise to be carefull when you try to do it....

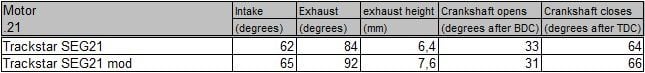

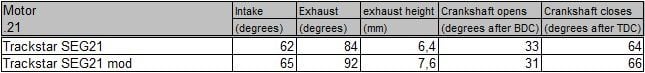

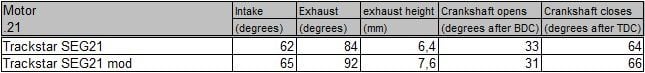

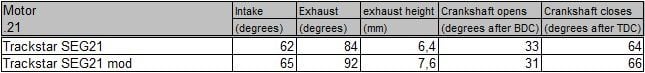

Her numbers of a SEG21 onroad with a mild modification because the rod and piston are not made to withstand loads of power:

As with any engine you have to use a deegree wheel or any other kind of angle meassure tool set to zero at BDC or TDC to meassure timings. Use light in the rear of the engine and look through the carburator hole to see the opening and closing of the crankshaft. With enough light you can do the same on the transfer ports and with a small light in the exhaust port you can meassure up the exhaust timing.

I have made a small manual on my site:

Untitled Document

Do not be fooled with light shining through, you have to find the spot that both edges are in line.

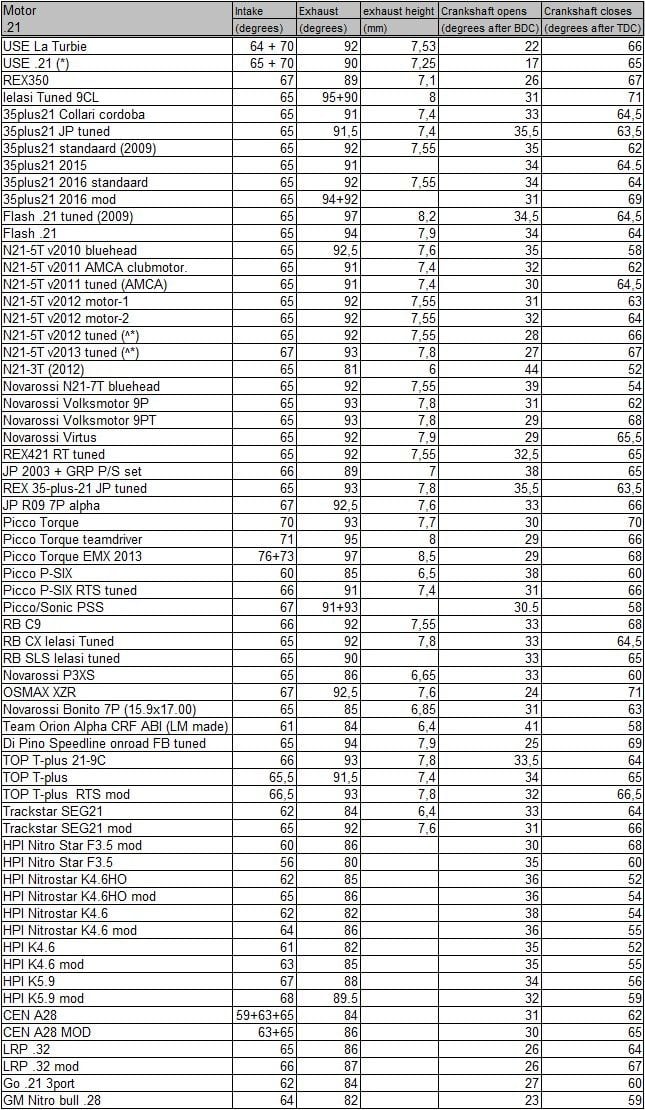

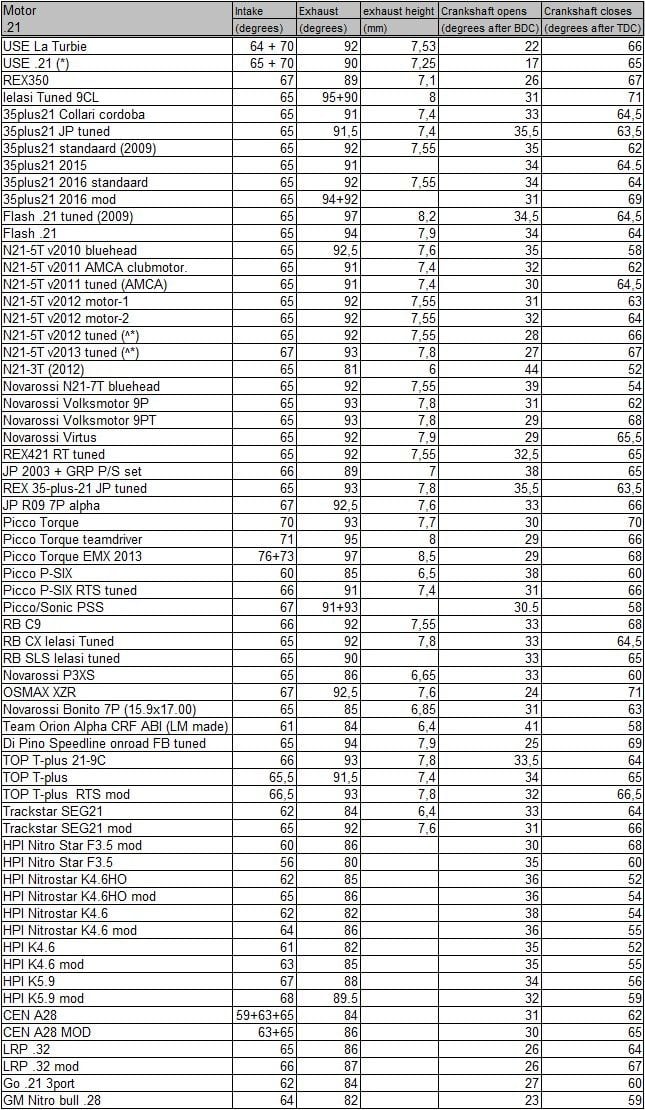

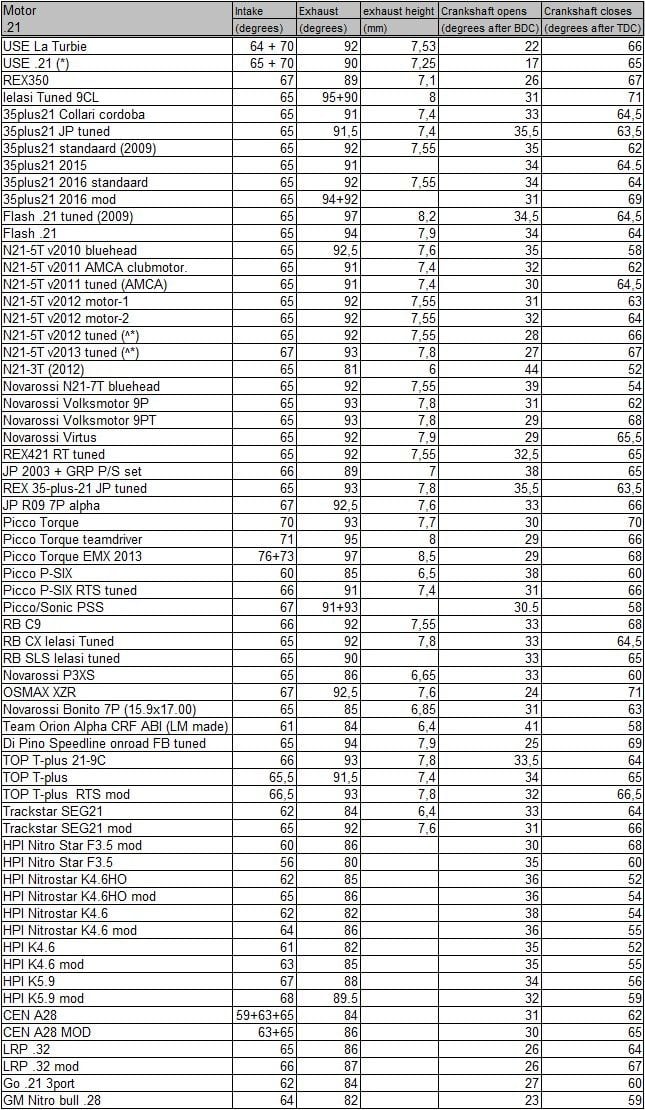

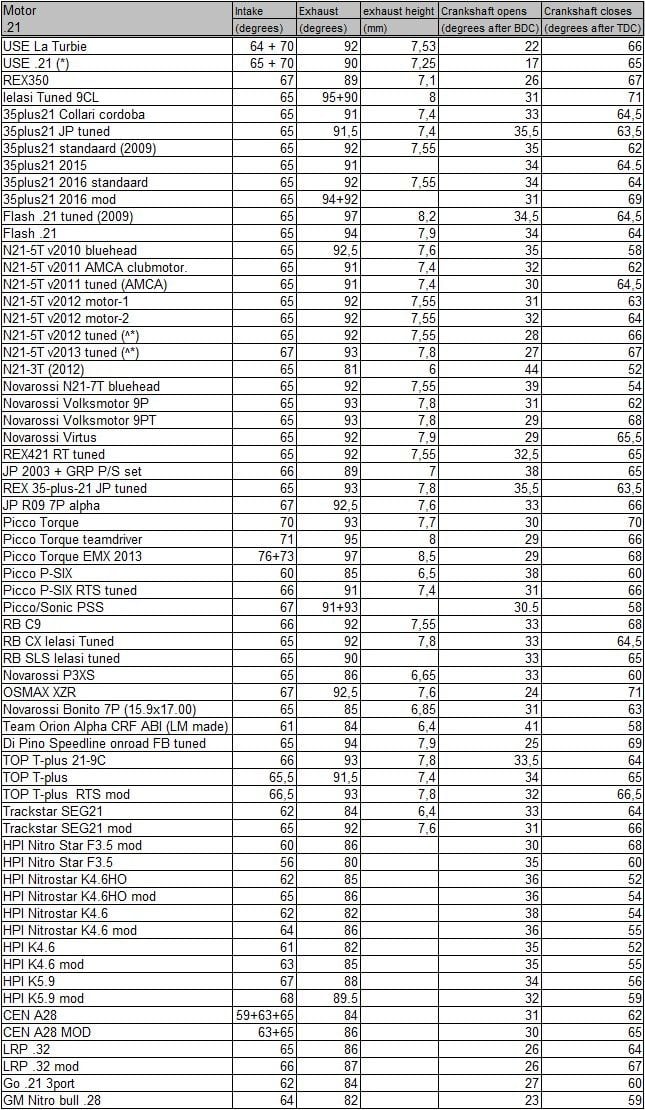

Many engines I have seen and done:

Just be aware that thinks among brands can not always be copied, it has to do with differenses on dimensions and volumes on the inside.

Her numbers of a SEG21 onroad with a mild modification because the rod and piston are not made to withstand loads of power:

As with any engine you have to use a deegree wheel or any other kind of angle meassure tool set to zero at BDC or TDC to meassure timings. Use light in the rear of the engine and look through the carburator hole to see the opening and closing of the crankshaft. With enough light you can do the same on the transfer ports and with a small light in the exhaust port you can meassure up the exhaust timing.

I have made a small manual on my site:

Untitled Document

Do not be fooled with light shining through, you have to find the spot that both edges are in line.

Many engines I have seen and done:

Just be aware that thinks among brands can not always be copied, it has to do with differenses on dimensions and volumes on the inside.

#11

Tech Apprentice

If you have no idea then it is wise to be carefull when you try to do it....

Her numbers of a SEG21 onroad with a mild modification because the rod and piston are not made to withstand loads of power:

As with any engine you have to use a deegree wheel or any other kind of angle meassure tool set to zero at BDC or TDC to meassure timings. Use light in the rear of the engine and look through the carburator hole to see the opening and closing of the crankshaft. With enough light you can do the same on the transfer ports and with a small light in the exhaust port you can meassure up the exhaust timing.

I have made a small manual on my site:

Untitled Document

Do not be fooled with light shining through, you have to find the spot that both edges are in line.

Many engines I have seen and done:

Just be aware that thinks among brands can not always be copied, it has to do with differenses on dimensions and volumes on the inside.

Her numbers of a SEG21 onroad with a mild modification because the rod and piston are not made to withstand loads of power:

As with any engine you have to use a deegree wheel or any other kind of angle meassure tool set to zero at BDC or TDC to meassure timings. Use light in the rear of the engine and look through the carburator hole to see the opening and closing of the crankshaft. With enough light you can do the same on the transfer ports and with a small light in the exhaust port you can meassure up the exhaust timing.

I have made a small manual on my site:

Untitled Document

Do not be fooled with light shining through, you have to find the spot that both edges are in line.

Many engines I have seen and done:

Just be aware that thinks among brands can not always be copied, it has to do with differenses on dimensions and volumes on the inside.

2Likes

2Likes