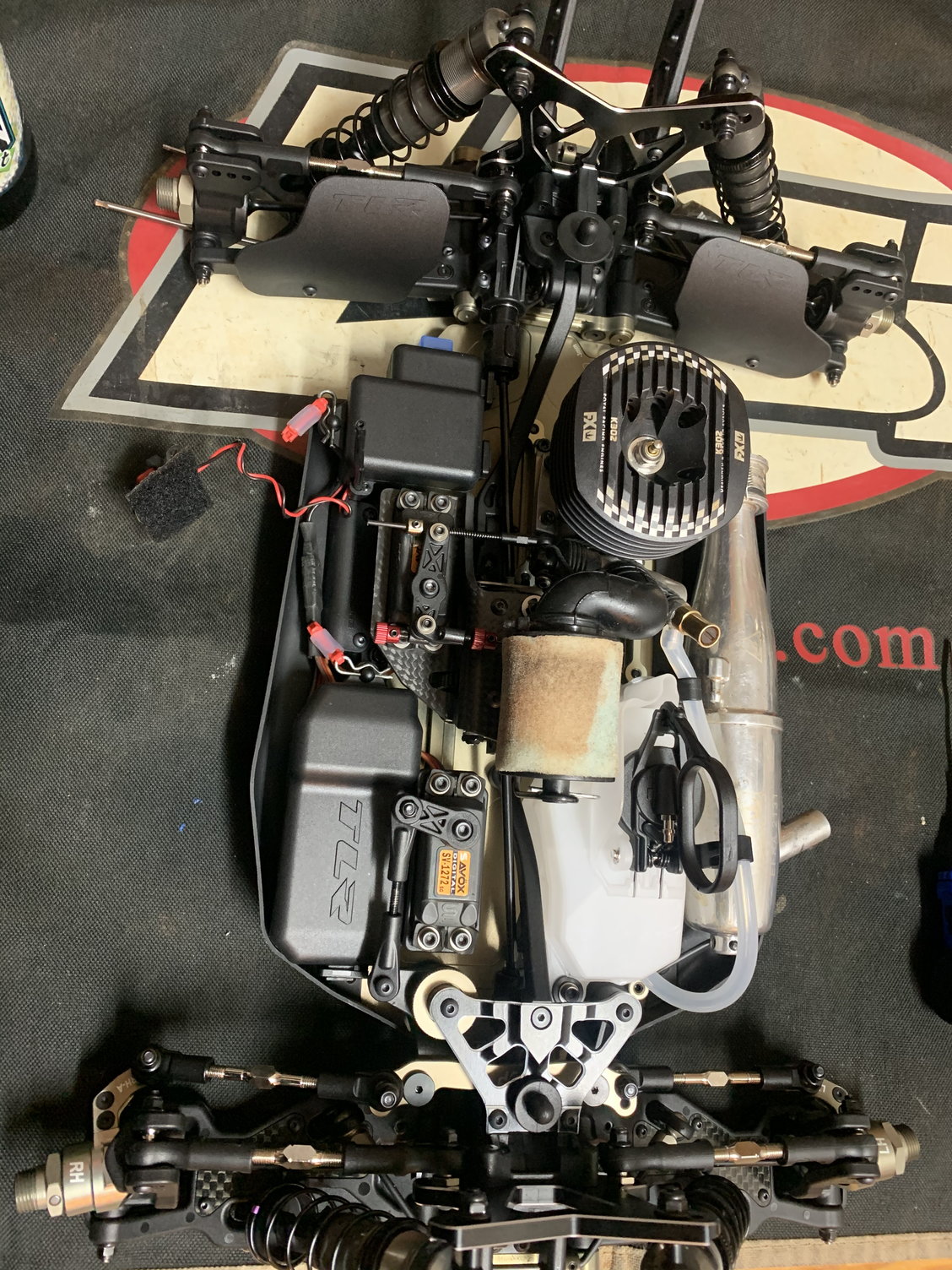

TLR 8ightX

|

|||

#946

#947

Hey, thanks a lot, TurnNBurn! Iím super excited. I canít wait to see how it feels on the track with all the changes and option parts! Still two more weeks until the next race though! Lol so far away, counting down the minutes. 🥺

#948

Gents, anyone know, or can find the part number for the clear lexan wing that comes with the elite kit? I canít find it in the manual, google search, nothing! Just looking to get a couple extra, because Iím sure they break often, but canít find a part number anywhere! Help?

#949

Tech Master

iTrader: (241)

Gents, anyone know, or can find the part number for the clear lexan wing that comes with the elite kit? I canít find it in the manual, google search, nothing! Just looking to get a couple extra, because Iím sure they break often, but canít find a part number anywhere! Help?

TLR340004

#950

#951

This is a weird question, but only due to a weird fact with Losi. Why is it that they put a reverse thread (silver) screw on the right A-arm for the shock? Literally just a curiosity question. Never really understood why they do this, with only this ONE screw on the entire kit. lol

#952

Tech Master

iTrader: (241)

This is a weird question, but only due to a weird fact with Losi. Why is it that they put a reverse thread (silver) screw on the right A-arm for the shock? Literally just a curiosity question. Never really understood why they do this, with only this ONE screw on the entire kit. lol

#953

oh yeah, duh, I knew that, 2 screws. That was my hunch, that it had something to do with the screw backing out with the movement of the a-arm during racing. But still to this day, have never seen that happen, so it made me wonder. Haha curious if itís even necessary at this point. Lol

#954

Tech Master

iTrader: (25)

oh yeah, duh, I knew that, 2 screws. That was my hunch, that it had something to do with the screw backing out with the movement of the a-arm during racing. But still to this day, have never seen that happen, so it made me wonder. Haha curious if itís even necessary at this point. Lol

Back in the 3-4.0 days I had a couple sets of arms get loose enough to back out the shock screws front right back left every run. But they had a place for a set screw at one time that helped. Now it's just better to use reverse thread. Funny it was opposite back then, the black screws were the reverse thread and silver were normal so to anyone new make sure to remember the silver screw is now the reverse threaded.

#955

There are people who will run the arms so long bashing or even racing that over time you will have them backing out. Tho I must admit this buggy has suck tight screw holes it literally stripped a few screws building the kit. Mainly the center diff. Thankfully I have some titanium replacements. Tho I might have to get some mip tools for those certain areas cause my perfectly tight in the head tools I have now start camming out in my drill gun.

Back in the 3-4.0 days I had a couple sets of arms get loose enough to back out the shock screws front right back left every run. But they had a place for a set screw at one time that helped. Now it's just better to use reverse thread. Funny it was opposite back then, the black screws were the reverse thread and silver were normal so to anyone new make sure to remember the silver screw is now the reverse threaded.

Back in the 3-4.0 days I had a couple sets of arms get loose enough to back out the shock screws front right back left every run. But they had a place for a set screw at one time that helped. Now it's just better to use reverse thread. Funny it was opposite back then, the black screws were the reverse thread and silver were normal so to anyone new make sure to remember the silver screw is now the reverse threaded.

Last edited by xlrsd; 03-04-2020 at 06:35 AM.

#956

Matt, you arenít kidding on those center diff screws! Holy cow!! Same happened to me, I basically stripped 3 of the 4 screws on the initial build of my X Elite! They were so tight, I was concerned with removing them again at all, in fear that I would strip them on the way out, and not be able to remove them at all! But of course, being the center diff and the maintenance require to that critical component, obviously never removing them again is out of the question. Lol so hereís what I did. I ordered replacement screws for the center diff, because they were pretty much toast just from screwing them in during the build. Once I had the replacements, I added a little bit of heat to the center diff with a heat gun, used the tightest mesh driver for the screw head I had in my tool box, and applied a lot of downward pressure when backing them out. I was actually surprised at how much easier they came out than I was expecting. So I think adding the heat to soften the plastic a little worked great. I then replaced all 4 screws that had been basically stripped. When i reassembled with the new screws, I was relieved to see how easily they went in. Wonít be an issue anymore, it was just that initial installation of the screws, where you are basically creating the threads in the diff mount. I suggest anyone building the X Elite, either buy a 3m tap, and pretap the bottom diff mount (which was exactly the piece that was causing the tightness), or expect to just purchase a separate set of diff mount screws and exercise the process I just outlined above. It would be a nightmare to strip those to the point you canít remove them, and essentially have to destroy your center diff clip, just to salvage what you can, order all the parts you destroyed to get it disassembled with 4 un-removable screws, and completely rebuild. Could have been a nightmare! Lol. I thought that severe tightness was just MY kit, but apparently this is more common that I thought.

Pre-tapping might be even better.

#958

Tech Master

iTrader: (25)

I wanted to use grease but my luck on the first hole I put grease it was a hole that didn't go all the way threw, it had s cavity and the grease pressure cracked the hole mount from the pressure so the rest I just did normal and realized most of those went all the way threw and wouldn't have cracked but I was over it at that point and just wanted to get the car together. I just now got done fixing all the little spots I didn't get perfect, ie. the stiff turnbuckles I squeezed and they freed up, my hinge pins in the arm were decent but I drilled some materiel from the arms and got them better. And then the shocks, I noticed they don't move at all with those shock cap inserts, very stiff. So I checked my 4.0 that have the old titanium standoffs and old old style insert for the cap and noticed how they move ALOT and this X buggy the shocks don't move at all, so I took the front inserts out and used 2.0 inserts and my front shocks move just like my old cars. I kept the rear inserts the same X inserts since you don't really turn in the back end but I imagine I will text them but the fronts atleast need to move and not bind, I mean there kinda like the turnbuckles and I hate stiff binding up turnbuckles. I don't want it in my shocks even more so that's something I was not liking.

The front and rear hubs I'm not sure what holes to go to, front aluminum hubs I'm in the outside top hole and the plastic rear hubs I'm 3 out, almost fully out, and I noticed most picture show it in the most outer hole but with 30k front diff oil this thing might feel lazy and dead all the way out. I also went with stiffer yellow rear springs as red again will make the rear end lazy with so much oil in front. I have 0 experience with the car tho so I may be in for a treat, I just don't understand the front 30k oil. I want to put 10 in it if I need to go up a lot upfront, not 30, that's not very normal.

ive also seen guys using the associated rear hubs and axles, anyone care to chime in over using these compared to Losi parts?

The front and rear hubs I'm not sure what holes to go to, front aluminum hubs I'm in the outside top hole and the plastic rear hubs I'm 3 out, almost fully out, and I noticed most picture show it in the most outer hole but with 30k front diff oil this thing might feel lazy and dead all the way out. I also went with stiffer yellow rear springs as red again will make the rear end lazy with so much oil in front. I have 0 experience with the car tho so I may be in for a treat, I just don't understand the front 30k oil. I want to put 10 in it if I need to go up a lot upfront, not 30, that's not very normal.

ive also seen guys using the associated rear hubs and axles, anyone care to chime in over using these compared to Losi parts?

#959

Never put grease in the holes. It will hydro lock and strip the threads or split the plastic.

You put a very small amount of grease on the threads on the screw. The excess will stay outside the screw hole if you do it like that.

You put a very small amount of grease on the threads on the screw. The excess will stay outside the screw hole if you do it like that.

#960

I wanted to use grease but my luck on the first hole I put grease it was a hole that didn't go all the way threw, it had s cavity and the grease pressure cracked the hole mount from the pressure so the rest I just did normal and realized most of those went all the way threw and wouldn't have cracked but I was over it at that point and just wanted to get the car together. I just now got done fixing all the little spots I didn't get perfect, ie. the stiff turnbuckles I squeezed and they freed up, my hinge pins in the arm were decent but I drilled some materiel from the arms and got them better. And then the shocks, I noticed they don't move at all with those shock cap inserts, very stiff. So I checked my 4.0 that have the old titanium standoffs and old old style insert for the cap and noticed how they move ALOT and this X buggy the shocks don't move at all, so I took the front inserts out and used 2.0 inserts and my front shocks move just like my old cars. I kept the rear inserts the same X inserts since you don't really turn in the back end but I imagine I will text them but the fronts atleast need to move and not bind, I mean there kinda like the turnbuckles and I hate stiff binding up turnbuckles. I don't want it in my shocks even more so that's something I was not liking.

The front and rear hubs I'm not sure what holes to go to, front aluminum hubs I'm in the outside top hole and the plastic rear hubs I'm 3 out, almost fully out, and I noticed most picture show it in the most outer hole but with 30k front diff oil this thing might feel lazy and dead all the way out. I also went with stiffer yellow rear springs as red again will make the rear end lazy with so much oil in front. I have 0 experience with the car tho so I may be in for a treat, I just don't understand the front 30k oil. I want to put 10 in it if I need to go up a lot upfront, not 30, that's not very normal.

ive also seen guys using the associated rear hubs and axles, anyone care to chime in over using these compared to Losi parts?

The front and rear hubs I'm not sure what holes to go to, front aluminum hubs I'm in the outside top hole and the plastic rear hubs I'm 3 out, almost fully out, and I noticed most picture show it in the most outer hole but with 30k front diff oil this thing might feel lazy and dead all the way out. I also went with stiffer yellow rear springs as red again will make the rear end lazy with so much oil in front. I have 0 experience with the car tho so I may be in for a treat, I just don't understand the front 30k oil. I want to put 10 in it if I need to go up a lot upfront, not 30, that's not very normal.

ive also seen guys using the associated rear hubs and axles, anyone care to chime in over using these compared to Losi parts?

I am very curious about a couple things you said in this post, and want to make sure you have things right with your Eight X Elite build. This isn't one of them, but I NEVER put grease in the holes during new car builds. Even as many times as Losi suggests it in the build manual, never. To me, this just means more elbow "grease"! Causes more problems than it cures, I've found.

First thing you mentioned that i'm a little curious about is when you were discussing your shock cap insert, and how it was causing your shock to not move? To me that sounds more like the shock could have possibly been built incorrectly. The shock cap insert shouldn't mechanically cause the shock to not move unless it is installed improperly or the shock was built with SO much shock oil, the pressure within the shock body prevents the shaft from moving. Were you using the bladder or emulsion shock cap insert?

Second thing is, you talking about your rear hub position and your front diff fluid weight. First, the outer position on your rear hub, I always start with the base setup settings in the back of the manual when I'm doing a new build. The reason for this, is because these base setups were decided by hours and hours of testing to come up with a best overall set up by the manufacturers, and then of course make changes to this base setup after you have ran it at your local tracks, and make the tweaks to fit your driving style and track conditions as you go. These base setups are also based on geometric changes and other drastic changes that are made to the car compared to the previous model. And so much has been improved and changed from the Eight-X, to the Eight-X Elite. So, I always suggest running it on the track with the base setup first, because it will feel different for sure with all the drastic changes made from one model to the next, and then tweak from there to get the setup characteristics you are looking for. The base setup for Eight X Elite has the rear hub in the full out position, position 4 (or D) from the inside.

Lastly is the 30k diff fluid in the front diff. Where are you getting that from? Is that just the weight you typically run, or did you see that somewhere else? Because yes, that is extremely high. On the base set up sheet, it calls for 7k front-7k middle-and 4k rear. So I was just wondering where you got that 30k front diff from. Anyway, let me know what you think about some of these questions and comments. Something just seems a little off with the things you are experiencing.

521Likes

521Likes