Project: Low Maintenance Savage Flux

#1

I like many others wanted a badass monster truck and was torn between a brushless Emaxx, revo and savage flux and I decided to go with the flux due to the claims of durability. So far the reliability has been so-so, I have had two fairly decent wrecks and suffered a mechanical failure each time. The first time I was hauling butt down a road and a dog ran in front of the flux and forced me to head on a cement culvert resulting in the failure of the 18/23 drive gear in the transmission(Next time I will hit the dog)lol.

Heres the original cast gear. Not sure what its made out of, but it's the only gear in the trans thats not steel I guess to act as a fuse.

Replaced it with this steel gear, so tranny is all steel now.

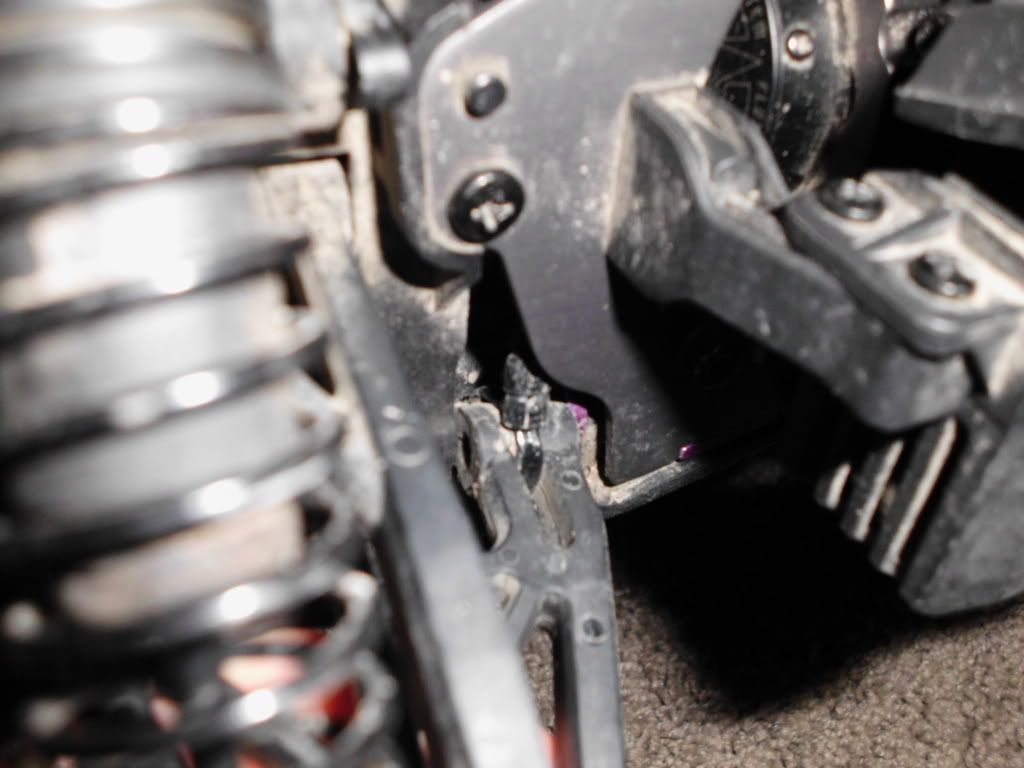

The second issue I have had is the a arms snapping around the hinge pins. Like so.

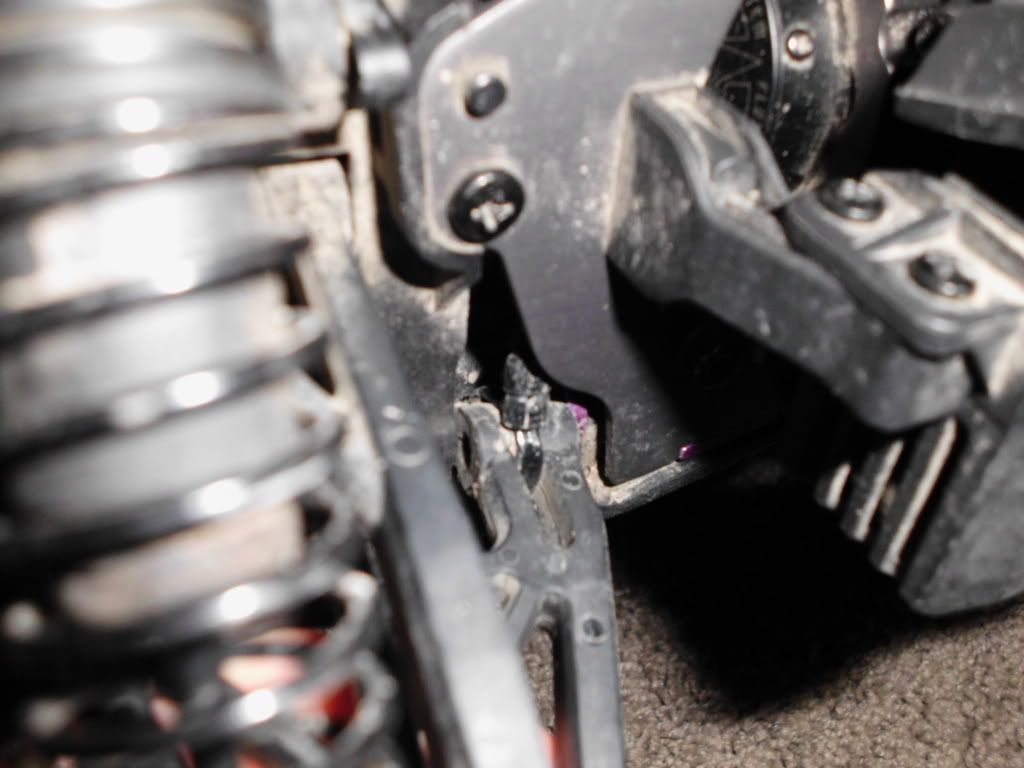

I didn't feel like shelling out the $ for full rpm arms at the moment so I threw some zip ties around the hinge pin area around the a arm. The zip ties will try to slip under stress so i cut the keeper heads off some spare zip ties and added the extra keeper as back ups behind the original keeper and haven't had an issue with the again.

I also added the zip ties around the upper bumper supports to keep the upper hinge pins where they belong.

Another issue I was dealing with was spinning the hexes half way and the wheel nuts constantly loosening up. I jb welded the hexes in and they have been holding up well and put lock tite on the wheel nuts. I know the jb weld will eventually give and I will have to convert to a different style wheel mounts, but i am still pretty clueless when it comes to that area right now so hopefully they will hold up for a good while, meanwhile I can study up on what I will convert to. I was checking over the flux the other day and seen a few tiny scratches on the trans so I decided to rig up some kind of skid plate to cover my drive train. I found that the skid plate of a axial crawler fit the bill after I narrowed it 1/8" on each side and drilled and tapped the tvp for the skid mounting holes. It doesn't look like much, but it will take a hit and is easy to remove and weighs next to nothing.

Heres the original cast gear. Not sure what its made out of, but it's the only gear in the trans thats not steel I guess to act as a fuse.

Replaced it with this steel gear, so tranny is all steel now.

The second issue I have had is the a arms snapping around the hinge pins. Like so.

I didn't feel like shelling out the $ for full rpm arms at the moment so I threw some zip ties around the hinge pin area around the a arm. The zip ties will try to slip under stress so i cut the keeper heads off some spare zip ties and added the extra keeper as back ups behind the original keeper and haven't had an issue with the again.

I also added the zip ties around the upper bumper supports to keep the upper hinge pins where they belong.

Another issue I was dealing with was spinning the hexes half way and the wheel nuts constantly loosening up. I jb welded the hexes in and they have been holding up well and put lock tite on the wheel nuts. I know the jb weld will eventually give and I will have to convert to a different style wheel mounts, but i am still pretty clueless when it comes to that area right now so hopefully they will hold up for a good while, meanwhile I can study up on what I will convert to. I was checking over the flux the other day and seen a few tiny scratches on the trans so I decided to rig up some kind of skid plate to cover my drive train. I found that the skid plate of a axial crawler fit the bill after I narrowed it 1/8" on each side and drilled and tapped the tvp for the skid mounting holes. It doesn't look like much, but it will take a hit and is easy to remove and weighs next to nothing.