Kyosho Mini-Z Series

#6871

--oops wrong thread--

deleted.

deleted.

#6872

After months of waiting,I finally got my hands on the PN Racing MM Motor Mount (90-94) this for MY MR-03 Evo. So the motor mount has screws for front end bell. The Kyosho Brushless motor has no holes on end bell?

PN Racing Mini-Z MR02/03 90-94mm MM Motor Mount (Silver)

PN Racing Mini-Z MR02/03 90-94mm MM Motor Mount (Silver)

#6873

Tech Prophet

iTrader: (9)

Join Date: Nov 2014

Location: Far south suburbs of Chicago area

Posts: 17,629

Trader Rating: 9 (100%+)

After months of waiting,I finally got my hands on the PN Racing MM Motor Mount (90-94) this for MY MR-03 Evo. So the motor mount has screws for front end bell. The Kyosho Brushless motor has no holes on end bell?

PN Racing Mini-Z MR02/03 90-94mm MM Motor Mount (Silver)

PN Racing Mini-Z MR02/03 90-94mm MM Motor Mount (Silver)

#6874

Tech Apprentice

After months of waiting,I finally got my hands on the PN Racing MM Motor Mount (90-94) this for MY MR-03 Evo. So the motor mount has screws for front end bell. The Kyosho Brushless motor has no holes on end bell?

PN Racing Mini-Z MR02/03 90-94mm MM Motor Mount (Silver)

PN Racing Mini-Z MR02/03 90-94mm MM Motor Mount (Silver)

The new NEXX rear ends are compatible with the kyosho motors. Unfortunately they do not have a short wheel base mount yet, but that would be an option for using your kyosho motor in a 98mm or 102mm car.

#6875

Tech Addict

iTrader: (10)

My mini z RWD M03 turns right but turning left it snaps left uncontrollable. Any help would be greatly appreciated. Thank You.

Checked binding on everything. Nothing bent or broken. Even installed the ball differential but it was $40 thrown away. Good radial tires. Taped the wheels. Even put weight on different places. Front wheels turn the same. Tighten the diff as tight as I dare. No more than 360 degrees. My surface is #15 roof felt paper. It turned for about a week then the issue showed up.

Checked binding on everything. Nothing bent or broken. Even installed the ball differential but it was $40 thrown away. Good radial tires. Taped the wheels. Even put weight on different places. Front wheels turn the same. Tighten the diff as tight as I dare. No more than 360 degrees. My surface is #15 roof felt paper. It turned for about a week then the issue showed up.

Last edited by major3d; 09-14-2020 at 08:28 AM.

#6876

Tech Prophet

iTrader: (9)

Join Date: Nov 2014

Location: Far south suburbs of Chicago area

Posts: 17,629

Trader Rating: 9 (100%+)

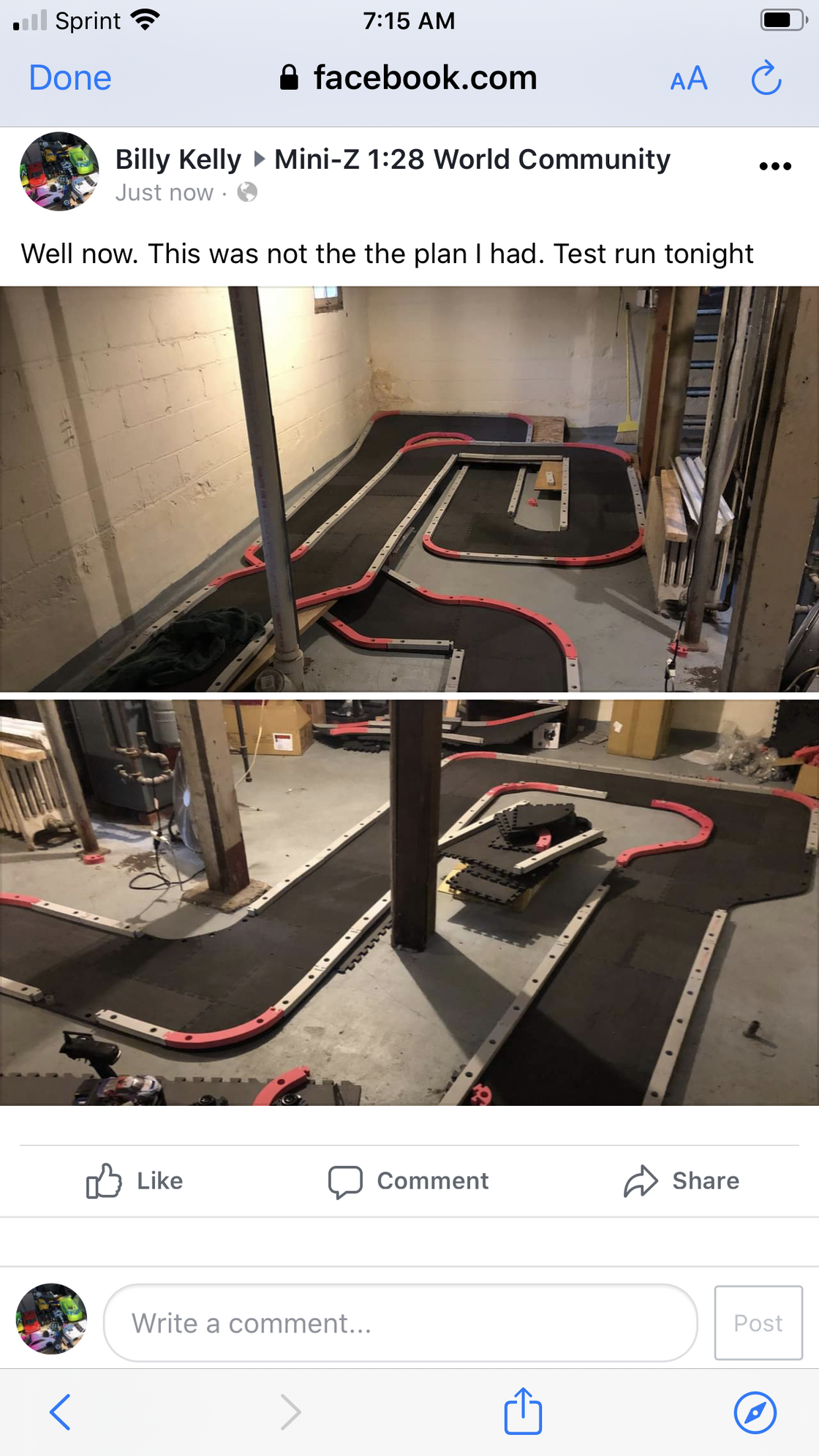

After getting a chance to run 1/10 this summer. Small scale got put on hold. No idea if this layout is driveable, find out tonight

#6877

Very cool. Been itching to get a new MA030 EVO and MR030 EVO along with their prop this winter. In my case I want to run my m-chassis too so I'm going with EVA foam and make a parking lot track in my basement and use Kyosho's curbs and sand barriers to lay down the course. I'm not racing anyone nor doing any serious driving so I don't want the track barriers which can scratch the body.

I have an exercise room with this stuff so I will test one of my older Mini-Z's on it to see how well it runs. My m-chassis ran fairly well on it and will use high grip tape (for stair cases) on the critical corners if needed.

I have an exercise room with this stuff so I will test one of my older Mini-Z's on it to see how well it runs. My m-chassis ran fairly well on it and will use high grip tape (for stair cases) on the critical corners if needed.

#6878

Tech Addict

iTrader: (22)

My mini z RWD M03 turns right but turning left it snaps left uncontrollable. Any help would be greatly appreciated. Thank You.

Checked binding on everything. Nothing bent or broken. Even installed the ball differential but it was $40 thrown away. Good radial tires. Taped the wheels. Even put weight on different places. Front wheels turn the same. Tighten the diff as tight as I dare. No more than 360 degrees. My surface is #15 roof felt paper. It turned for about a week then the issue showed up.

Checked binding on everything. Nothing bent or broken. Even installed the ball differential but it was $40 thrown away. Good radial tires. Taped the wheels. Even put weight on different places. Front wheels turn the same. Tighten the diff as tight as I dare. No more than 360 degrees. My surface is #15 roof felt paper. It turned for about a week then the issue showed up.

#6880

Tech Addict

iTrader: (10)

In my experience its usually the wheel nut on the left (opposite gear side) that is too tight. Don't over tighten that wheel nut with any diff, especially the stock gear diff. I usually snug it down and then back it off about 1/4 turn. Don't over tighten the gear side nut either. You want your ball diff loose as possible without slipping. Other things that can cause this are bad bearings in the rear, broken t-plate (sometimes hard to tell on carbon ones), front wheel locked up (too tight) or hitting the body inside, or maybe a tweaked chassis.

#6882

Tech Addict

iTrader: (22)

Well really neither should be very tight but its usually with the ready set kits with no mods that the left or drivers side of the chassis wheel nut is over tightened. That pulls the axle through and can bind up the whole thing. Best to just back both sides off a little after snugging them.

Have you tried it without the body to eliminate that? I usually wouldnt suggest running it without the body but since you have no barriers to contact it should be ok. Have you checked that you have the correct bearings/bushings in place on the axle? The larger inside diameter one goes on the gear side. Maybe you could take a few close up pics of the rear end. Perhaps a video of the car running.

#6884

Tech Addict

iTrader: (10)

I raced two wheel drive 1/10 scale buggy and currently race a Tekno 2.0 Ebuggy. I also race a Hotbodies Etruggy. This little mini z has me puzzled.

#6885

Tech Prophet

iTrader: (9)

Join Date: Nov 2014

Location: Far south suburbs of Chicago area

Posts: 17,629

Trader Rating: 9 (100%+)

It does it both with body on or off. Today I took out the drive shaft and ran it with and without the washers. Also took off the nucklers and inspected for cracks or bent. Kingpins have also been inverted. Running out of options. It's getting traction or the tires would not wear out in 5 days. Does the same thing on a smooth carpet. I am stumped. Do the AWD drive any better? It's fast enough for me right now. Maybe a brushed AWD.

I raced two wheel drive 1/10 scale buggy and currently race a Tekno 2.0 Ebuggy. I also race a Hotbodies Etruggy. This little mini z has me puzzled.

I raced two wheel drive 1/10 scale buggy and currently race a Tekno 2.0 Ebuggy. I also race a Hotbodies Etruggy. This little mini z has me puzzled.

Iím not sure Iím understanding what the car is doing. Iím guessing the snap steering means spinning out? Like was mentioned body contact with tire would definitely do that. Iíve had that before.

Kingpin inverted. Still never done this. But any chance itís catching on the track?

5 days for tires to wear is very quick.

In my opinion, the RWD are better cars. Iíve had 7. I do have a brushed AWD. I never liked how it drove. Just felt odd.It developed a steering issue, sometimes it just does not turn right. Or sticks when it does. I do like FWD.

Thereís almost always a tiny mechanical cause for drive problem with these.

7770Likes

7770Likes