RWD, 4 Wheel Independent Susp. Onroad Cards - Why Not?, Why?, How?

#137

Tech Adept

I had one. It was a huge step forward. Although it didn't take long for the RS4 Pro to be released, which was the same car with dual belts instead of the Stealth in the back.

I had one. It was a huge step forward. Although it didn't take long for the RS4 Pro to be released, which was the same car with dual belts instead of the Stealth in the back.

#138

Tech Apprentice

iTrader: (4)

Man, first thing, I'm happy I still remember my rctech password, haven't been here since NorCal Hobbies moved to San Jose.

I landed in this thread searching for a RWD drift car after finding myself in a deep Google rabbit hole about how the best Japanese rc drifters still use a 4WD counter steer (rear wheels overdrive the front wheels) in conjunction WITH a one-way diff/pulley. I thought, "Isn't this this just RWD at its core?" There is no way power is ever getting to the front wheels if the rear ratio is lower than the front--the one-way is always freewheeling.

I'm old enough to have raced 10th scale pan cars, and the reason we made those work was with rear tire widths almost 40% wider than the fronts, and liberal application of Paragon at the rears and just a pencil line of that same stuff in the fronts.

F1 was actually bearable with foams, even though I had a good few years racing rubber outdoor F1 with the RCFIA group, I never really enjoyed it as much as the foam tire days.

I landed in this thread searching for a RWD drift car after finding myself in a deep Google rabbit hole about how the best Japanese rc drifters still use a 4WD counter steer (rear wheels overdrive the front wheels) in conjunction WITH a one-way diff/pulley. I thought, "Isn't this this just RWD at its core?" There is no way power is ever getting to the front wheels if the rear ratio is lower than the front--the one-way is always freewheeling.

I'm old enough to have raced 10th scale pan cars, and the reason we made those work was with rear tire widths almost 40% wider than the fronts, and liberal application of Paragon at the rears and just a pencil line of that same stuff in the fronts.

F1 was actually bearable with foams, even though I had a good few years racing rubber outdoor F1 with the RCFIA group, I never really enjoyed it as much as the foam tire days.

#139

Tech Apprentice

iTrader: (4)

But back to the topic of RWD touring, after a few failed attempts at converting a few platforms, the main issue I've had, and as other folks have brought up, is off-power/braking oversteer, unless there is a way to have front wheel braking (several ideas I've seen in this thread have got me thinking at another RWD conversion attempt.

Historically speaking, we obviously can make RWD platforms work without front brakes, but the similarities in all the classes that have stuck around for a while have always been rear tires wider than the front and the ability to bias a lot of weight to the rear--buggies, pan cars.

The only thing I can think of that would come close, is the M-06, but with the ability to place the battery across the chassis instead of lengthwise.

That Yokomo YD-2 would be perfect if it had the option to put the motor behind the rear axle.

Historically speaking, we obviously can make RWD platforms work without front brakes, but the similarities in all the classes that have stuck around for a while have always been rear tires wider than the front and the ability to bias a lot of weight to the rear--buggies, pan cars.

The only thing I can think of that would come close, is the M-06, but with the ability to place the battery across the chassis instead of lengthwise.

That Yokomo YD-2 would be perfect if it had the option to put the motor behind the rear axle.

#140

Unless you're running mod, front brakes is only for emergency stops....

#141

Tech Adept

But back to the topic of RWD touring, after a few failed attempts at converting a few platforms, the main issue I've had, and as other folks have brought up, is off-power/braking oversteer, unless there is a way to have front wheel braking (several ideas I've seen in this thread have got me thinking at another RWD conversion attempt.

Why Bother? A RWD pan car is better in every possible way. The only downside to a pan car is you need a smooth track. Nowadays they are usually only run with 1S, however in the days of NiCd and NiMh batteries they were run with 6 cells like most other 1/10 scale cars. The current 1/10 scale pan cars can all be run with 2S and with that much power and foam tires they will be faster than 4WD touring cars.

You can even get rubber tires if you want. Although I would stay with foam.

#142

The only downside to a pan car is you need a smooth track. Nowadays they are usually only run with 1S

I do HATE 1c PAN CARS (waste of time IMHO) the 1c itself...hate it.

But TIRES (foam) get old (caps) are now hard to get, and (rubber) is gaining popularity because they last, don't have to be trued down to 2.05 from 2.4-2.5" work on multiple surfaces...kinda, but are kinda pricey.

Where as you can get SPEC TC tires for less than 1/2 the price, so long as the 2wd RWD TC uses standard TC hexes.

My fear is a RWD TC would handle like CRAP, but I for 1 would like to try one at a few places...and one of those places would be on an OVAL track.

#143

Tech Regular

Well, NiMH packs heated too  That's why you need 100W+ resistor and proper cooling. It would heat less than mechanical controler. I'm more afraid of voltage drop.

That's why you need 100W+ resistor and proper cooling. It would heat less than mechanical controler. I'm more afraid of voltage drop.

Anyway, what sort of motor are you using? In M06 thread people drive 15,5t succesfully. And I didn't have problems with traction on 15,5 with 10:1 gearing on gravel. Actually, I had problems to make it turn in low speed, that's why I abadoned rear motor concept.

That's why you need 100W+ resistor and proper cooling. It would heat less than mechanical controler. I'm more afraid of voltage drop.

That's why you need 100W+ resistor and proper cooling. It would heat less than mechanical controler. I'm more afraid of voltage drop.Anyway, what sort of motor are you using? In M06 thread people drive 15,5t succesfully. And I didn't have problems with traction on 15,5 with 10:1 gearing on gravel. Actually, I had problems to make it turn in low speed, that's why I abadoned rear motor concept.

#144

Tech Master

iTrader: (1)

I will make one statement about WGT-R rubber vs USGT rubber or TC rubber. Yes they cost twice as much but they are competitive almost 4 times longer. This is based on road course racing. I run F1, WGT-R (same tire) and USGT. We have a healthy core of TC racers and based on observation they go through tires the fastest. A USGT tire slows down a bunch due to stretch, not surface wear.

Maybe I will pull the shaft on my TC and see how it works.

Maybe I will pull the shaft on my TC and see how it works.

#145

Well, NiMH packs heated too  That's why you need 100W+ resistor and proper cooling. It would heat less than mechanical controler. I'm more afraid of voltage drop.

That's why you need 100W+ resistor and proper cooling. It would heat less than mechanical controler. I'm more afraid of voltage drop.

Anyway, what sort of motor are you using? In M06 thread people drive 15,5t succesfully. And I didn't have problems with traction on 15,5 with 10:1 gearing on gravel. Actually, I had problems to make it turn in low speed, that's why I abadoned rear motor concept.

That's why you need 100W+ resistor and proper cooling. It would heat less than mechanical controler. I'm more afraid of voltage drop.

That's why you need 100W+ resistor and proper cooling. It would heat less than mechanical controler. I'm more afraid of voltage drop.Anyway, what sort of motor are you using? In M06 thread people drive 15,5t succesfully. And I didn't have problems with traction on 15,5 with 10:1 gearing on gravel. Actually, I had problems to make it turn in low speed, that's why I abadoned rear motor concept.

#146

Tech Adept

I would be all for a 1/10 scale electric version of a 1/8 scale nitro car like this. It would be awesome in either 4WD or RWD versions.

#147

Tech Apprentice

iTrader: (4)

I guess my main question would about RWD touring would be...

Why Bother? A RWD pan car is better in every possible way. The only downside to a pan car is you need a smooth track. Nowadays they are usually only run with 1S, however in the days of NiCd and NiMh batteries they were run with 6 cells like most other 1/10 scale cars. The current 1/10 scale pan cars can all be run with 2S and with that much power and foam tires they will be faster than 4WD touring cars.

You can even get rubber tires if you want. Although I would stay with foam.

Why Bother? A RWD pan car is better in every possible way. The only downside to a pan car is you need a smooth track. Nowadays they are usually only run with 1S, however in the days of NiCd and NiMh batteries they were run with 6 cells like most other 1/10 scale cars. The current 1/10 scale pan cars can all be run with 2S and with that much power and foam tires they will be faster than 4WD touring cars.

You can even get rubber tires if you want. Although I would stay with foam.

One thing that is quite obvious to me is that the ratio in width between front and rear wheels is becoming closer and closer to 1:1, with the new Yokomo RWD touring and Tamiya M-06 platforms exactly at 1:1.

Now, when we were running foams, the rears were definitely more than a marginal width wider than the fronts. With the current trend of rubber tires WGT, F1, etc, that has changed. What also has changed is that the rear pod setup and the "suspension" that goes along with it has become softer and softer, with arguably more adjustment besides splashing some oil on a friction plate to control damping in all directions.

I personally feel that the margin in chassis setup to get foam tires to work was wider. With rubber tires, chassis tuning and weight balance was much more key, and the window for a good setup is much narrower. But I don't want to derail the discussion into a foam vs. rubber argument.

#148

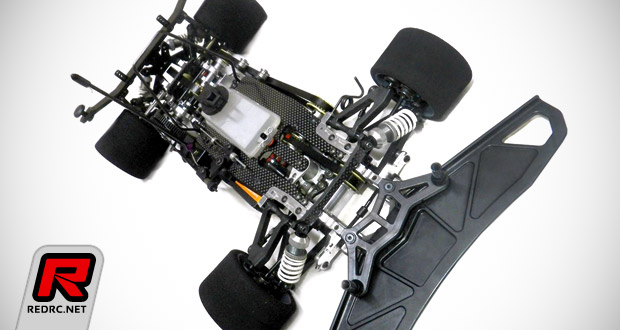

My work in progress, a Tamiya TA06, took out 2 oz (62 grams) of weight by removing the front diff, dogbones, belts, pulleys. I know it only has a silver can motor in it, but I figured I'd start small before investing in more powerful and expensive power.

The rear tires are HPI vintage 31mm wide. They don't feel real soft, but I will try them.

I need to finish an experimental body for this experimental chassis, so stay tuned.

It obviously will not keep up with racing touring cars with the silver can, but it will (hopefully) make a fun test bed for me.

The rear tires are HPI vintage 31mm wide. They don't feel real soft, but I will try them.

I need to finish an experimental body for this experimental chassis, so stay tuned.

It obviously will not keep up with racing touring cars with the silver can, but it will (hopefully) make a fun test bed for me.

#150

I suppose lightweight electronics would help a bit, but not 30%. A 1 cell battery pack would help a bunch. Then weight distribution stuff like putting the motor behind the rear axle, etc. but that is beyond my capabilities.

85Likes

85Likes