Tamiya XV-01

#1201

Tech Addict

Hey,

I've always wondered what the holes located directly behind (inline) with the ball studs are meant for? It looks to be a mounting of some sort which can also take a grub screw from the top. Does anyone have an idea of what this is designed to do?

As far as I know this piece is only on the xv-01. I was thinking some sort of wire would fit inside, and the grub screw would hold it.

I've always wondered what the holes located directly behind (inline) with the ball studs are meant for? It looks to be a mounting of some sort which can also take a grub screw from the top. Does anyone have an idea of what this is designed to do?

As far as I know this piece is only on the xv-01. I was thinking some sort of wire would fit inside, and the grub screw would hold it.

Last edited by 4roller; 11-09-2016 at 07:34 AM.

#1202

Tech Addict

Fair. I got the xv-01 as my first RC car in 15 years. It has turned out to be a great car to "get academic" on, with a lot of real world tuneability. I only wanted 1 road car. And if I can maintain composure, I will continue to only have one, though the lure of a lot of the carbon TAs and TBs and heaven forbid, TRFs are always clawing at my will.

I am pretty happy to geek out with this car because it's so awesome with its ability to handle realish (not just track) driving applications.

Did your parts come in yet?

I am pretty happy to geek out with this car because it's so awesome with its ability to handle realish (not just track) driving applications.

Did your parts come in yet?

#1204

Tech Adept

How well the wheels fit the chassis with all the additional width? Would I be able to use 190mm bodies, or do I need to get 200mm ones?

#1205

Tech Addict

I did run into one issue which may be of importance to you with the need for crazy steering angle. The hub carriers of the TC are much closer to the rims' spokes. If you run Tamiya, HPI rims, or deep spokes rims, you will have to shave down the arms around the pins, maybe 1-2mm.

I don't actually have all the parts numbers because, I won an auction for the bulk of the bits from a Tamiya Touring Car (TA, TB, or TRF) that was stripped of its suspension.

There is, however, a kit you can purchase that has 70% of the parts you need. Tamiya light weight short reversible suspension kit #53899. It lacks the CVDs shafts, since different cars use different length shafts, the xv-01TC Pro (manual) said to use 44mm and they indeed work. If you get the kit, then you will also need 46mm (#51093) and 22mm/25mm (#53825) suspension shafts, also front and rear suspension blocks from any ta05/06, tb04, or trf417/418. These could either be aluminum or the stock plastic ones. 1XA(x4) 1A 1E are the blocks I have.

I ended up looking at the xv01TC manual for sizes of the hinge pins and CVD shafts. Check the link I included above in case you are unsure of what you need.

On the side, if you can mount sway bars, the Trf418 stablizer set work (with some minor modifications)

Also as I noted above wider (6mm+) wheel hexes and a slight trim of the arms will help with deep spoked rims.

Last edited by 4roller; 11-10-2016 at 12:53 AM.

#1206

Tech Addict

What kind of ride height is everyone running? And on what surface?

I'd be interested to know what other users have found to be ideal.

I saw an interesting term on RedRc (RC news site) in Singapore, they have an "Urban Touring Series", what does that mean exactly? I don't know, but I took it to mean touring cars, or street cars with maybe some decent handling suspension for various driving surfaces other than your typical manicured track.

Kind of like rally, but road stages rally. Driving on smooth tarmac, or brick, cobbles, curbs, broken parking lots. You know what our cars are made for.

I went ahead and lifted my car again, from the 8mm tarmac setup, to 13mm of "Urban Touring". Love it. Yellows up front and reds in the back. 400cst and 3 hole pistons in all four corners. Ready to race to a fast food drive through near you.

I've found at this ~12-13mm height it makes for some spectacular on power turning traction because of the softish rear end squat. And the inner rear wheel lifts ever so slightly. Just enough traction to hold it through a turn with turbo on, if you let off the power you get some very controlled oversteer.

A couple of millimeters higher and the car just spins out.

This is with the TC arms setup and the front and rear end have almost vertical dampers, bottom links closest to the chassis. This should be achievable on the xv-01 too, maybe with long damper ends.

I'd be interested to know what other users have found to be ideal.

I saw an interesting term on RedRc (RC news site) in Singapore, they have an "Urban Touring Series", what does that mean exactly? I don't know, but I took it to mean touring cars, or street cars with maybe some decent handling suspension for various driving surfaces other than your typical manicured track.

Kind of like rally, but road stages rally. Driving on smooth tarmac, or brick, cobbles, curbs, broken parking lots. You know what our cars are made for.

I went ahead and lifted my car again, from the 8mm tarmac setup, to 13mm of "Urban Touring". Love it. Yellows up front and reds in the back. 400cst and 3 hole pistons in all four corners. Ready to race to a fast food drive through near you.

I've found at this ~12-13mm height it makes for some spectacular on power turning traction because of the softish rear end squat. And the inner rear wheel lifts ever so slightly. Just enough traction to hold it through a turn with turbo on, if you let off the power you get some very controlled oversteer.

A couple of millimeters higher and the car just spins out.

This is with the TC arms setup and the front and rear end have almost vertical dampers, bottom links closest to the chassis. This should be achievable on the xv-01 too, maybe with long damper ends.

#1207

Tech Adept

Bodies fits nicely for both of my 190mm lids.

I did run into one issue which may be of importance to you with the need for crazy steering angle. The hub carriers of the TC are much closer to the rims' spokes. If you run Tamiya, HPI rims, or deep spokes rims, you will have to shave down the arms around the pins, maybe 1-2mm.

I don't actually have all the parts numbers because, I won an auction for the bulk of the bits from a Tamiya Touring Car (TA, TB, or TRF) that was stripped of its suspension.

There is, however, a kit you can purchase that has 70% of the parts you need. Tamiya light weight short reversible suspension kit #53899. It lacks the CVDs shafts, since different cars use different length shafts, the xv-01TC Pro (manual) said to use 44mm and they indeed work. If you get the kit, then you will also need 46mm (#51093) and 22mm/25mm (#53825) suspension shafts, also front and rear suspension blocks from any ta05/06, tb04, or trf417/418. These could either be aluminum or the stock plastic ones. 1XA(x4) 1A 1E are the blocks I have.

I ended up looking at the xv01TC manual for sizes of the hinge pins and CVD shafts. Check the link I included above in case you are unsure of what you need.

On the side, if you can mount sway bars, the Trf418 stablizer set work (with some minor modifications)

Also as I noted above wider (6mm+) wheel hexes and a slight trim of the arms will help with deep spoked rims.

I did run into one issue which may be of importance to you with the need for crazy steering angle. The hub carriers of the TC are much closer to the rims' spokes. If you run Tamiya, HPI rims, or deep spokes rims, you will have to shave down the arms around the pins, maybe 1-2mm.

I don't actually have all the parts numbers because, I won an auction for the bulk of the bits from a Tamiya Touring Car (TA, TB, or TRF) that was stripped of its suspension.

There is, however, a kit you can purchase that has 70% of the parts you need. Tamiya light weight short reversible suspension kit #53899. It lacks the CVDs shafts, since different cars use different length shafts, the xv-01TC Pro (manual) said to use 44mm and they indeed work. If you get the kit, then you will also need 46mm (#51093) and 22mm/25mm (#53825) suspension shafts, also front and rear suspension blocks from any ta05/06, tb04, or trf417/418. These could either be aluminum or the stock plastic ones. 1XA(x4) 1A 1E are the blocks I have.

I ended up looking at the xv01TC manual for sizes of the hinge pins and CVD shafts. Check the link I included above in case you are unsure of what you need.

On the side, if you can mount sway bars, the Trf418 stablizer set work (with some minor modifications)

Also as I noted above wider (6mm+) wheel hexes and a slight trim of the arms will help with deep spoked rims.

#1208

Tech Adept

The result is impressive. I have 28mm rear and 26mm front. However, this required not only milling lower plate under the a-arms and where steering mount extension hits the plate, but also top plate (to unbind steering links when shocks are compressed), and finally front a-arms and c-hub. Basically everything, as at this height, there was binding simply pretty much everywhere.

However, it works, and now I can take measurements to incorporate this into my new design.

I've tried to drive the car, and it works very well. It even rides over my sons's books we've had all around the apartment today without any problems ;-). To test it, I have mounted new TA BB v2 shocks. I really love the selection of springs, because I can finally start properly tune the suspension.

BTW - if you don't know it, read this thread (well, at least a part of it, it has 100 pages): http://www.rctech.net/forum/electric...ber-links.html. Start with post #4. Really really helpful.

#1210

Tech Adept

No, I was just modifying the plates I have with something similar to Dremel today. The mess it does milling carbon is horrible, but for once... (I've been using some cloth over my mouth and nose, and vacuum cleaner to suck it away all the time).

My wife is drawing the new plates I was talking about in ArchiCAD, and those will be of course cut on a proper CNC lathe - which is fortunately not in my apartment :-).

My wife is drawing the new plates I was talking about in ArchiCAD, and those will be of course cut on a proper CNC lathe - which is fortunately not in my apartment :-).

#1211

Tech Addict

It sounds like you are making a crawler to handle going over obstacles. Almost 3cm of ground clearance for a touring car is pretty impressive.

I think with the stock chassis, you can put some shims below the suspension blocks to get a couple of mm out of the car. It allows the arms to swing downward more and not be restricted by the bottom plate of the chassis. It sounds like you are either making chassis or modifying the carbon one you have already.

I wonder how your car will handle turns with all that height.

I'd be interested to see what it looks like with all that sky high travel.

I think with the stock chassis, you can put some shims below the suspension blocks to get a couple of mm out of the car. It allows the arms to swing downward more and not be restricted by the bottom plate of the chassis. It sounds like you are either making chassis or modifying the carbon one you have already.

I wonder how your car will handle turns with all that height.

I'd be interested to see what it looks like with all that sky high travel.

#1212

Tech Addict

Today I moved my battery pack to the front of the chassis, meaning I shifted it forward. Why? Because I think it will help balance the rear end of the car.

I originally had it pulled all the way to the rear, hoping to offset the front weight bias, but instead it just weights the one left rear wheel.

Now it seems to have helped equalize rear end traction in both directions.

I originally had it pulled all the way to the rear, hoping to offset the front weight bias, but instead it just weights the one left rear wheel.

Now it seems to have helped equalize rear end traction in both directions.

#1213

The XV-01T had that much ground clearance, thanks to its taller tires. The problem was it traction-rolled constantly; it had no cornering ability anymore, because it was still only 200mm wide like a normal touring car.

Last edited by fyrstormer; 03-29-2018 at 04:29 PM.

#1214

Tech Addict

What tires do you have on that xv-01T? They look like a Tamiya tire that I used to have but could never use. Sand-something. The pattern looked like little squares. I bought them with my own money for my first RC car, a Tamiya quick run Avante, when I was 11 years old. They didn't fit. So I had stared at them dreamingly for years without being able to use them. Memories...

#1215

Tech Adept

It sounds like you are making a crawler to handle going over obstacles. Almost 3cm of ground clearance for a touring car is pretty impressive.

I think with the stock chassis, you can put some shims below the suspension blocks to get a couple of mm out of the car. It allows the arms to swing downward more and not be restricted by the bottom plate of the chassis. It sounds like you are either making chassis or modifying the carbon one you have already.

I wonder how your car will handle turns with all that height.

I'd be interested to see what it looks like with all that sky high travel.

I think with the stock chassis, you can put some shims below the suspension blocks to get a couple of mm out of the car. It allows the arms to swing downward more and not be restricted by the bottom plate of the chassis. It sounds like you are either making chassis or modifying the carbon one you have already.

I wonder how your car will handle turns with all that height.

I'd be interested to see what it looks like with all that sky high travel.

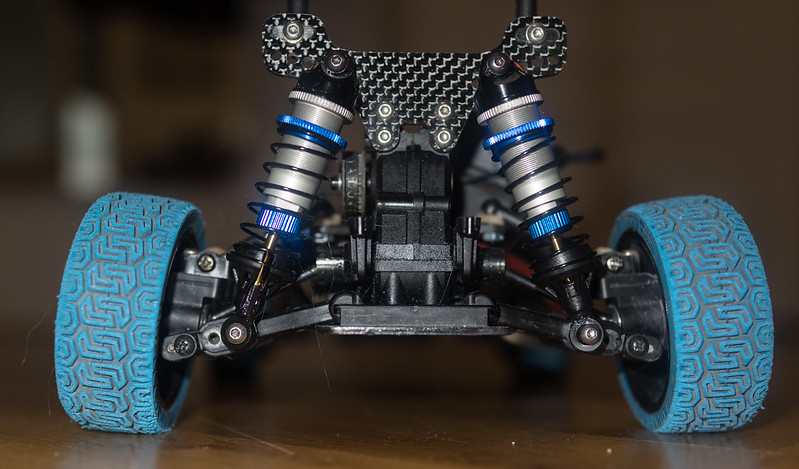

This is 28mm rear, 26mm front:

And the rear:

Interesting is, that with this ride height, you need longer shocks than 75mm on the rear for most of the mounting positions. So I have shortened the 85mm TA shocks (27.5B/27.5S) that I was planning to use in the front to ±80mm, and used them in the rear. I think I no longer need these longer shocks in the front, because the 75mm (23B/21S) TA shocks have little longer travel than 75mm Gmade, so now I have all the movement that I need there.

With this setup, there's obviously a lot of weight transfer, but the car is not rolling in the speed I can achieve on our tracks (I guess, I can only test it at home, as it is freezing outside).

I did suspension tuning using the method I have referenced yesterday, and I have to say that it makes a lot of sense. First thing I have realized when I have dumped the oil from the shocks was, how different natural frequencies I've had front/rear. After some spring changes, I now have a combination of springs and mounting points that give me the same frequencies front/rear, plus the desired ride height. What is surprising is, that it rides better than before even without any oil :-).

BTW - I've been complaining about spring selection for Gmade shocks. To my surprise, I've just found out that the 45mm long springs for 12mm BB shocks (TA, TD, etc.) fit Gmade 75mm shocks without any problem! I'm really surprised that nobody mentioned this anywhere. So it seems that I have plenty of shocks and springs now :-).

Last edited by haplm; 11-13-2016 at 09:24 AM.

167Likes

167Likes